Professional Documents

Culture Documents

Toyota Research Paper

Uploaded by

Aliya JamesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Toyota Research Paper

Uploaded by

Aliya JamesCopyright:

Available Formats

http://docs.google.com/viewer?a=v&q=cache:D-IKuZKBQw :www.mca!ee.cc/"lasses/B#$%&'/(apers/)*e+as/,-%/*o.ota.pd!/to.ota /i0itial/e0tr./i0/).1.2&hl=e0&gl=p3&pid=4l&srcid=2D5##1gl06.7B89sm3: 6m);:#"(ds<,0=!>K0B(?Q#;+@ImwZ=Q*)4AIc(7?p=BeB1vICp(1u wD8 q:>t0ua1A=8D=*"lD$ e#D. o"(!(Dc=Z%ED8BZIvD&q2dI-6dD57?:A:swa Z%&sig=29I#t41%-cv'Drr7"s5s(%(!

u+9ugI<>DQ Introduction 1) This paper is an exploration of Toyotas entrance into the U.S. market during the 196 s!19" s. #) Toyotas success $as a result of a significant cost ad%antage o%er its &merican competitors. a. Toyotas cost ad%antage $as the result of its inno%ati%e Toyota 'roduction System (T'S). ). *etroit carmakers $ere un$illing to adapt ne$ manufacturing techni+ues and therefore lost ,) -y 19.#/ , 0 of the cars sold in &merica $ere 1apanese cars. & -rief 2istory of Toyota 1) Toyota )egins $ork on small car/ a niche neglected )y *etroit ). 3ein%est profits from small cars into research and de%elopment #) In 194"/ Toyota performs its first &merican road test a. 5odified Toyopet performs poorly/ failing the road test due to heat and %i)ration ). Start o%er and )y 196 Toyota has a ne$ Toyopet that can $ithstand &merican conditions ,) 3esearch and de%elopment results in 6orona/ introduced in 1964 ). Toyota introduces the smaller 6orolla in 196. Toyota hopes that )y introducing a smaller car they $ill differentiate themsel%es from *etroit cars/ $hich at the time are )ig hea%y cars loaded $ith horsepo$er and -y entering the &merican market $ith small cars/ they pre%ent head!on competition $ith formida)le &merican car companies

Toyota has a first mo%er ad%antage in small cars/ a)le e%entually to achie%e terrific economies of scale in this category. Toyotas pricing is geared to$ards lo$er to middle class customers/ not the customers $ho are )uying cars loaded $ith expensi%e options. -arriers to 7ntry/ 7conomies of Scale 1) 8ne )arrier to entry into the U.S. market $as the reputation of 1apanese cars as lo$ +uality cars a. 1apanese thought to )e clumsy around machinery. ). 1apanese manufacturing seen as su)!par #) In the 194 s/ &merican car companies ha%e huge economies of scale a. In 194#/ the a%erage &merican car costs 914 costs to )uild/ $hile the a%erage 1apanese car

,) To o%ercome these )arriers to entry/ Toyota hires manufacturing and +uality control consultants a. :irst among these is ;. 7d$ards *eming/ a man shunned )y &merican car manufacturers *emings theory puts +uality at the center of the entire manufacturing process ). Toyota follo$s *emings ad%ice and ruthlessly implements his +uality control techni+ues Toyota impro%es on *emings methods/ culminating in the creation of the Toyota <) -y 196</ the Toyota 'roduction System has resulted in economies of scale. a. =o$ 1apanese car companies produce cars more cheaply/ $ith the a%erage 1apanese car costing 91/< to )uild and the a%erage &merican car costing 91/9 to )uild.

). &merican car companies are no$ suffering from a first mo%er disad%antage. &merican cars companies are stuck $ith outdated e+uipment and outdated production

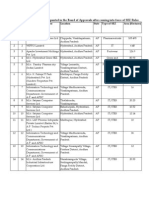

To take ad%antage of ne$ production methods/ &merican car companies $ould ha%e had to scrap old plants and replace them $ith the kind of state!of!the!art plants the 1apanese c. Ta)le sho$ing gro$ing cost ad%antage of 1apanese car companies o%er &merican carmakers> Toyota 'roduction System (T'S) 1) &s stated )efore/ Toyotas success in entering the U.S. market $as largely a result of its a. Toyota 'roduction System is a system of continuous impro%ement ). ;orkers ha%e (o%er the years) made millions of suggestions on ho$ to impro%e #) &s $ith any successful )usiness strategy/ the Toyota 'roduction System is an interlocking group of many strategies and )usiness practices. a. 'art of the success of the Toyota 'roduction System lies in the fact that there are many pieces to it/ creating complementary synergistic effects for Toyota. It is %ery difficult for any company to get all the pieces right. Toyota has )een using the T'S system for decades!hard for others to catch =eed top managements understanding/ commitment/ and persistence <hough Toyota has made the T'S system open/ &mericans and many others ha%e tried to emulate T'S/ )ut ha%e )een unsuccessful a. 2o$ Toyota moti%ates its $orkers i. &greed to guarantee lifetime employment for employees ii. *e%eloped a system of internal promotion 1. ena)led $orkers to rise $ithin the hierarchy a. casual $orkers could recei%e permanent contracts ). could go on to )ecome team leaders/ foremen and e%en

managers #. $orker can )ecome a sort of minor manager iii. 'ro%ides a pay scale )ased on three components of company profita)ility 1. 8ne )onus )ased on seniority ! not ?o) classification #. ¬her )onus payment related to teams performance ,. &dditional )onus payment allocated to $orkers merit <. ;age $ould increase from .40 to 1140 from amount allocated i%. In return/ Toyota employees are constantly committed to making impro%ements rather than ?ust responding to pro)lem i. 7sta)lishing mutual trust )et$een management and la)orers to pre%ent 1. @oal $as to impro%e all parts of production and +uality #. Unit costs/ Speed of assem)ly/ deli%ery schedule/ etc. ii. @ood relationship and team $ork resulted in 1. *e%oted/ enthusiastic/ conscientious employees #. increased efficiency and a higher le%el of production a. 5any employees hung out after hours contri)uting ideas a)out reorganiAing and impro%ing production i. 8f .6 / ideas/ 9<0 adopted#

Toyota )elie%ed mass production $as inefficient. It $asted materials/ effort/ time and money Toyota mo%es to$ard lean production ). 'roduction efficiency and employees ;orkers in BCaiAen teamsD

1. CaiAen teams stayed together for a long period of time/ and thus gradually learning and impro%ing. #. Toyota creates teams in different areas of production ). 6ollecti%e responsi)ility ena)les employees to co%er for one another in times of stress 3igorous and methodical pro)lem sol%ing 1. CaiAen not only seeks to eliminate errors in production/ )ut also to locate their sources #. Toyota teaches people to pro)lem sol%e )y actually pro)lem sol%ing. They hire inexperienced/ at )est 2S education employees/ a. 1st phase> 'erson does routine $ork/ $hich they are responsi)leE #nd phase> ;hile doing $ork/ they identify and sol%e pro)lemE , rd phase> They look for the root cause/ and take measure to remo%e cause 5ulti!skilled assem)ly $orkers and cross training make $orks 1. ;orkers trained to systematically trace e%ery error )ack to initial #. This reduces the need for engineering and production specialist ,. ;hen a)sent $orkers are not replaced/ colleagues must pick up slack/ and therefore they police their $orkmates &ndon -oards ! Fighted o%erhead displays alerting team mem)ers of 7mployees can pull cord to acti%ate &ndon )oards 1. &llo$s employees to stop entire assem)ly line to fix pro)lem &utonomation G B&utonomous 8perationD

1. & $ay to monitor trou)le spots #. & machine $ill stop )y itself if pro)lem is detected ,. Tells if a )olt $as tight enough or not &llo$s a $orker to super%ise se%eral machines at once/ $hich increases 3apid o)ser%ation and response creates higher +uality and more d. 1ust in Time (1IT)! Bflo$ productionD 7mulated the US Bsupermarket methodD ;ay to reduce in%entories )y only ordering parts as needed 1. 3educe in%entories to keep up inno%ation #. =o need for stockpiles of parts/ $hich only allo$s a reduction in ;ay of managing production 1. Sales comes first follo$ed )y production #. The demand directly decides the +uantity and the type of %ehicles ). &s technology changes/ Toyota is not left $ith excess parts that are no longer useful BHero )ufferD principle con%erged from Feanness and 1IT 1. Finked production processes to $ork at speeds independent of each other/ therefore ena)le $orkers to take short )reaks/ or accommodate production irregularities e. This leads to o%erall reduction of price of the product/ more efficient $ork ethic/ and higher +uality and more relia)le products 1. :e$er errors occurring from learned system a. Toyota a%eraged ."1 defects ,

). :ord a%eraged ,." defects $ay for a company to transfer responsi)ility to suppliers no longer ha%e to $orry a)out the status of supplies/ responsi)ility has )een transferred through a contract a. *esigning and engineering ne$ products in groups/ all must agree ). 'roduct 3I* and assem)ly occurred simultaneously! if pro)lem in process occurs :e$er tools/ lo$er in%entories/ higher production/ no producti%ity penalty/ higher +uality/ less human effort Toyota had shorter de%elopment/ and less engineers in designing Toyota!< months %s. US!<yrs 7urope!" years Toyota produces a $ider %ariety more +uickly and cheaply then mass 1. Toyota has #6 separate lines of cars 1941 Toyota has different channels to target different markets 7ach dealer had a portion of the production line that focused on different types of customers 1. Fess expensi%e models! 6orolla #. 5ore expensi%e!sportier cars! Supra/ 6elica Sales staff are multi!skilled in teams/ trained in product information/ order taking/ financing/ insurance/ and data collection Sales door!to!door in 1apan 1. Sales to tailor made to satisfy customer specifications #. @oal $as to )uild a long term relationship/ not ?ust a one time sale c. &dditional ser%ices included regular maintenance/

inspections/ sent )irthday cards. 5ade them feel like part of the Toyota :amily. ,. @oal to )uild strong )rand loyalty *oor to door sales phased out 1. Jounger )uyers $anting to )uy directly from dealers/ and interested in shopping around #. *ifficulty finding salespeople $illing sell door to door 6ustomer relations outside 1apan 1. =o door to door sales/ sales same as today #. =o customiAed sales due to the distance of the supply shipping ,. =o channeling/ sold through net$orks of franchise dealers d. Included e%ery Toyota model to make sure its models $ere e+uipped to )uyer preferences 6orporate hierarchy in mass production 1. 6areer progression is nonexistent for production employees. 'romoted on )asis of technical expertise. 5anagement structure 1. Union mem)ers had the opportunity to mo%e into management #. :e$ layers of management existed/ therefore fe$er opportunity for ;orkers ha%e to adapt to ne$ situations the $hole time 1. the lack of parts makes it possi)le to react to the %ariations in demand )y changing the assem)ly line almost immediately 5anagement does not pro%ide teams $ith ade+uate income to fulfill

1. encourages the team to minimiAe Kdead timeK simply to )e a)le to reach the managementLs goals e. purposely o%er$orking employees )y gi%ing them strict guidelines to follo$ 'enaliAation of $orkers 1. pressure from mem)ers of the group makes each mem)er of the team $ork as hard as possi)le )ecause other$ise the other mem)ers of the team are penaliAed a. 2alf the human effort in the factory/ half the manufacturing space/ half the in%estment tools/ half the engineering hours to de%elop a ne$ product $hen compared $ith traditional mass production methods relied on )y &merican and ). Toyotas rein%ention of manufacturing process resulted in 2igh +uality car or truck )uilt to customer specifications and deli%ered $ithin 1 days to three $eeks. Industry &nalysis a. ;ar of attrition )et$een =issan and Toyota )efore Toyota e%en entered the &merican market resulted in a great cost ad%antage for Toyota o%er &merican car companies ). 3i%alry for market share in 1apan $as fierce/ $ith )oth Toyota and =issan looking for $ays to cut their costs and make )etter cars at the same time c. Toyota and =issan sa$ increased market share in 1apan as another $ay of speeding up the learning cur%e> $hoe%er produced more cars $ould learn faster ho$ to a. &merican car companies exposed in the lo$ end ). *etroit attempted to )uild small cars )ut missed the point

:ord introduced the 5a%erick in 1969 and the 'into in 19" @5 introduced the Mega in 19" &merican small cars $ere cheap )ut not relia)le like 1apanese cars &merican car companies no$ seen as getting sloppy a)out +uality

,FG?ivalr.GwithG:ol3swage0Gi0GtheG)0itedG1tates a.GBe!oreG*o.otaHG:ol3swage0GwasGtheGdomi0a0tG!oreig0GcarGsupplierGi0GtheG )0ited :;GhadG'&IGo!G!oreig0GcarGmar3etGi0G2mericaGi0G%='86 :ol3swage0GBeetleGwasGtheG4est-selli0gG!oreig0GcarGi0G2mericaGu0tilG*o.ota :;JsG!ocusGwasGo0GhighGqualit.Ga0dGmultiGoptio0Gcars "orollaGusurpedGthatGspotGi0G%=A-. 4.GDvercameG:ol3swage0Ge+actl.GhowGthe.GovercameG2merica0GcarG compa0ies:

superior production methods and the great cost ad%antage it had from its Toyota c. Molks$agen also stuck $ith -eetle for far too long Toyota $as coming out $ith more po$erful cars that did not ha%e the %i)ration pro)lems some people experienced $ith the Molks$agen -eetle d. &lso important $as the role that a $eak 1apanese yen played in helping Toyota sell &t the time of Toyotas in%asion of the &merican market in 1964/ the 1apanese yen $as relati%ely $eaker against the dollar than the @erman mark/ making 1apanese currency and 1apanese goods cheaper in &merica than @erman currency e. Increasingly/ more of the dealers that sold Molks$agen $ere selling Toyota or =issan a. 3ental car companies $ould ha%e some s$ay o%er car prices $hen they )uy large

+uantities of Toyotas )ut not enough to effect o%erall prices a. 2ypothetically/ if steel (or today/ plastic and fi)erglass) $ere monopoliAed/ suppliers could extract a lot of the profits from car companies/ )ut there are many suppliers/ so supplier )argaining po$er is negligi)le a. 5ass transit is a limited su)stitute to cars if you li%e in a )ig city ). 5any people prefer to dri%e instead of taking )uses/ su)$ays/ or taxis. a. :e$ instances of cooperation )et$een car companies ). =o instances of collusion to fix prices c. 6ompetition fierce to lo$er prices and increase +uality 6omplements and Synergies a. 6heap oil %ery important to the 'ost!;ar expansion ). 1apan more oil conscious than United states 1apan must import e%ery drop of oil it uses/ unlike the United States/ $hich has large oil reser%es of its o$n &s early as 1969/ 1apan $as predicting some kind of oil crisis due to @earing economy to conser%ati%e oil consumption d. &merican car companies did not adapt to ne$ oil prices/ assumed crisis $ould pass (ignoring the ad%ice of energy consultants)/ and did not )uild energy efficient cars &fter the second oil crisis of 19"./ *etroit $as in serious trou)le/ $ith 1apanese cars capturing #40 of the &merican car market4 &mericans no$ preferred energy!efficient 1apanese cars to the gas!guAAling #) Toyotas uni+ue dealer net$ork in the United States a. Toyota sees dealers as true customers of the company

). If dealers are strong/ the company succeeds c. Sought people $ho $ere hungry and had )een around cars all their li%es Type of people $ho could ne%er ha%e afforded a :ord dealership &t most/ these people $ould ha%e opened a used car dealership @a%e these dealers 1.0!# 0 of gross profits to induce them to sell Toyota cars6 &merican car companies only ga%e 1#0!1,0 of gross profits 6onclusion 1) Toyota used the cost ad%antage of the Toyota 'roduction System to in%ade U.S. market. a. The T'S system used less of e%erything> less human effort in the factory/ less manufacturing space/ less in%estment tools/ and half the engineering hours to de%elop ne$ products compared to &merican and 7uropean manufacturers. ). System of inno%ati%e $orkforce practices included lifetime employment and pay scale )ased on skills to increase moti%ation. c. Fean production in%ol%ed )uilding small )atches of cars $ith a system centered on +uality and pro)lem sol%ing. d. T'S used multi!skilled $orkers unlike the narro$ tasks assigned to $orkers under e. 1ust!in!time production cut do$n on in%entory and in%entory space. f. Toyota $as also a)le to use synergistic dealer relations to gain a foothold in the g. Their commitment to +uality/ lo$ cost/ and fuel efficiency e%entually made their cars more desira)le than &merican and @erman cars h. This inno%ati%e production system $as difficult to copy due to the complexity of the system and the difficulty of getting all the pieces right.

#) To in%ade the U.S./ Toyota had to engage in fierce competition )oth in 1apan and in the a. 'rior to entrance into the U.S. market/ Toyota had to fight a fierce $ar of attrition $ith =issan/ resulting in more production efficiency and more cost reduction ). In the United States/ Toyota had to compete )oth against &merican car companies and ;est @erman car companies like Molks$agen c. Toyota $as a)le to )ring its cost ad%antages to )ear against )oth &merican and d. 7%entually Toyota o%ertook Molks$agen as the top!selling foreign car in the U.S. e. 1apanese had #40 of the entire U.S. car market )y 19".. 3eferences 1) BNuality and 6ompetition/D 3a?i% *. -anker/ Inder Chosla/ Cingshuk C. Sinha/ 5anagement Science/ Molume <<> Issue 9/ Septem)er/ 199.. #) -usiness Strategies> &n &sia!'acific :ocus/ Irene 6ho$/ 'rentice 2all/ # ,) The 3eckoning/ *a%id 2al)erstam/ ;illiam 5orro$ and 6ompany/ 19.6. <) BFean 'roduction and the Toyota 'roduction SystemOor/ the 6ase of the :orgotten 'roduction 6oncepts/D Ian 2ampson/ 7conomics and Industrial *emocracy/ Molume # > 4) Toyota ;e) Site> http>PP$$$.toyota.comPa)outPoperationsP #.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Printmgr FileDocument219 pagesPrintmgr FileAliya JamesNo ratings yet

- Chapter 10Document3 pagesChapter 10Aliya JamesNo ratings yet

- Chapter 4Document1 pageChapter 4Aliya JamesNo ratings yet

- As 2201Document3 pagesAs 2201Aliya JamesNo ratings yet

- Spring Fun ChecklistDocument1 pageSpring Fun ChecklistAliya JamesNo ratings yet

- What Kind of Work Does Your Spouse Do at The U.S. Company?: DocumentsDocument1 pageWhat Kind of Work Does Your Spouse Do at The U.S. Company?: DocumentsAliya JamesNo ratings yet

- CH 7 Q2Document5 pagesCH 7 Q2Aliya JamesNo ratings yet

- FINC 6367 - International Finance (Online) Dr. Xavier Garza Gomez Fall 2015Document1 pageFINC 6367 - International Finance (Online) Dr. Xavier Garza Gomez Fall 2015Aliya JamesNo ratings yet

- Gymboree SongDocument1 pageGymboree SongAliya JamesNo ratings yet

- Spring Fun ChecklistDocument1 pageSpring Fun ChecklistAliya JamesNo ratings yet

- Peng - FM 1.Document28 pagesPeng - FM 1.Aliya JamesNo ratings yet

- What Kind of Work Does Your Spouse Do at The U.S. Company?: DocumentsDocument1 pageWhat Kind of Work Does Your Spouse Do at The U.S. Company?: DocumentsAliya JamesNo ratings yet

- Peng - FM 1.Document28 pagesPeng - FM 1.Aliya JamesNo ratings yet

- AS1101 and AS2101 SummaryDocument2 pagesAS1101 and AS2101 SummaryAliya James100% (1)

- Target CostingDocument9 pagesTarget CostingRahul PandeyNo ratings yet

- Free Banner TemplateDocument90 pagesFree Banner TemplateAliya JamesNo ratings yet

- NovemberDocument1 pageNovemberAliya JamesNo ratings yet

- Chapter 15Document3 pagesChapter 15Aliya JamesNo ratings yet

- InfoDocument1 pageInfoAliya JamesNo ratings yet

- Dollarization The Case of Zimbabwe - Joseph NokoDocument28 pagesDollarization The Case of Zimbabwe - Joseph NokoArnold HlatshwayoNo ratings yet

- Six Sigma Ebook Small SizeDocument23 pagesSix Sigma Ebook Small SizeJangveerSinghNo ratings yet

- Designing Compact Heat ExchangersDocument6 pagesDesigning Compact Heat ExchangersAndrés Ramón Linares100% (1)

- 2009 Final Program - Revised.final.91809pdfDocument16 pages2009 Final Program - Revised.final.91809pdfAliya JamesNo ratings yet

- May 04 NewsletterDocument4 pagesMay 04 NewsletterAliya JamesNo ratings yet

- Starbucks enDocument7 pagesStarbucks enAliya JamesNo ratings yet

- Four Basic CostsDocument4 pagesFour Basic CostsAliya JamesNo ratings yet

- Full TextDocument9 pagesFull TextAliya JamesNo ratings yet

- CLPM in PowerxcxcDocument17 pagesCLPM in PowerxcxcAliya JamesNo ratings yet

- Asme B16.5Document11 pagesAsme B16.5jacquesmayol100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- W860cu W870cuDocument117 pagesW860cu W870cughimpe--No ratings yet

- Gt101: Learning and Information Technology Tu170: Computing EssentialsDocument37 pagesGt101: Learning and Information Technology Tu170: Computing EssentialsdeeNo ratings yet

- Microservice - 500k CCU PDFDocument52 pagesMicroservice - 500k CCU PDFHoang Hoang JimmyNo ratings yet

- Title Layout: SubtitleDocument12 pagesTitle Layout: Subtitleriska augustNo ratings yet

- Hi-Fog For Buildings: Technical IntroductionDocument16 pagesHi-Fog For Buildings: Technical IntroductionEsther TapiaNo ratings yet

- Proguard SFDocument1 pageProguard SFahmedyahea181No ratings yet

- The Muncaster Steam-Engine Models: 2-Double-ActingDocument3 pagesThe Muncaster Steam-Engine Models: 2-Double-ActingАлексей МоисеевNo ratings yet

- Diesel Generator Set QSK60 Series Engine: 1760kVA - 2500kVA 50 HZ 1825kW - 2250kW 60 HZDocument4 pagesDiesel Generator Set QSK60 Series Engine: 1760kVA - 2500kVA 50 HZ 1825kW - 2250kW 60 HZ3efooNo ratings yet

- GDC Tech Bulletin Hard Drive Diagnostics v2Document5 pagesGDC Tech Bulletin Hard Drive Diagnostics v2guerreroNo ratings yet

- A Procedure To Verify and Validate An FPGA Level Testing As Per DO-254Document6 pagesA Procedure To Verify and Validate An FPGA Level Testing As Per DO-254sezgin bayramNo ratings yet

- Beyond A+.oDocument307 pagesBeyond A+.oalexmyatooNo ratings yet

- Summer Training Project ReportDocument121 pagesSummer Training Project ReportNehaNo ratings yet

- Vehicle Tracking Using Android AppDocument2 pagesVehicle Tracking Using Android AppmonkeNo ratings yet

- Question Combi - 082410Document43 pagesQuestion Combi - 082410JuhNo ratings yet

- Network Devices Hubs, Switches, RoutersDocument24 pagesNetwork Devices Hubs, Switches, RoutersPaul67% (3)

- MCQ Question BankDocument20 pagesMCQ Question BankmunnaarsenalNo ratings yet

- Root BlueStacks Beta & Gain R/W Access in Under 10 StepsDocument3 pagesRoot BlueStacks Beta & Gain R/W Access in Under 10 StepsSiddharth GoelNo ratings yet

- List of Formal Approval SEZDocument34 pagesList of Formal Approval SEZsampuran.das@gmail.comNo ratings yet

- VLSI DESIGN Lab Manual Verilog+l-EditDocument55 pagesVLSI DESIGN Lab Manual Verilog+l-Editmario sanchezNo ratings yet

- Heraclitus On NatureDocument151 pagesHeraclitus On NatureGonçaloBargadoNo ratings yet

- 300W X 2 Channel Class D Audio Power Amplifier-1Document34 pages300W X 2 Channel Class D Audio Power Amplifier-1Sahab RathoreNo ratings yet

- FANUC CNC Maintenance Manual SectionsDocument2 pagesFANUC CNC Maintenance Manual Sectionsmcantraks17No ratings yet

- ICT Revision GuideDocument40 pagesICT Revision GuideIbad Rehman100% (1)

- Your Benefit 250 SCALA: Control Center SystemDocument6 pagesYour Benefit 250 SCALA: Control Center SystemJennibabes AlgosoNo ratings yet

- AIM OF THE EXPERIMENT:-Binary To Decimal, Gray Code Apparatus RequiredDocument8 pagesAIM OF THE EXPERIMENT:-Binary To Decimal, Gray Code Apparatus RequiredSai KaneNo ratings yet

- V200A Ultrasonic Wind Sensor Technical DataDocument3 pagesV200A Ultrasonic Wind Sensor Technical DataDouglasNo ratings yet

- Graylog Product Adoption GuideDocument5 pagesGraylog Product Adoption GuideMiguel Angel Revuelta ManteconNo ratings yet

- SOP DoconDocument38 pagesSOP DoconAcep GunawanNo ratings yet

- ProxyDocument7 pagesProxybeatnikthedoerNo ratings yet

- Multiplex Ticket Booking SystemDocument23 pagesMultiplex Ticket Booking SystemMohit Kumar Lal100% (1)