Professional Documents

Culture Documents

Installation Guide: 1) Foundation Preparation

Uploaded by

darkchechoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Guide: 1) Foundation Preparation

Uploaded by

darkchechoCopyright:

Available Formats

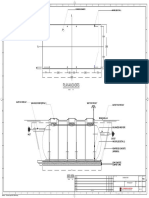

INSTALLATION GUIDE

1) FOUNDATION PREPARATION

The foundation on which the gabions are to be placed shall be cut or filled and graded to the lines and grades shown on the drawings. Surface irregularities, loose material, vegetation, and all foreign matter shall be removed from foundation surface area. When fill is required, it shall consist of materials conforming to the specified requirements. Gabions and bedding or specified geotextiles shall not be placed until the foundation preparation is completed, and the subgrade surfaces have been inspected and approved by the engineer or the engineers representative. Compaction of bedding or filter material will be required per plans and specifications. The surface of the finished material shall be to grade and free of mounds, dips or windrows. Extra care should be taken with foundation preparations in order to ensure a level and smooth surface. Geotextile shall be installed in accordance with the requirements of the plans and specifications.

2) ASSEMBLY AND PLACEMENT

The assembly and placement of gabions shall be in accordance with the following procedures: Assembly. Rotate the gabion panels into position and join the vertical edges with fasteners for gabion assembly. Where lacing wire is used, wrap the wire with alternating single and double half hitches at intervals between 100) to 130 mm. Where spiral fasteners are used, crimp the ends to secure the spirals in place. Where ring type alternate fasteners are used for basket assembly, install the fasteners at a maximum spacing of 150 mm. Use the same fastening procedures to install interior diaphragms where they are required. Interior diaphragms will be required where any inside dimension exceeds 91 cm for gabion baskets thicker than 300mm. Diaphragms will be installed to assure that no open intervals are present that exceeds 91 cm. For baskets 300 mmor less rectangular cells are allowed with dimensions 91 cm in one direction and not to exceed 183 cm in the perpendicular direction. Placement. Place the empty gabions on the foundation and interconnect the adjacent gabions along the top, bottom, and vertical edges using lacing wire or spirals. Wrap the wire with alternating single and double half hitches at intervals between 100 mm and 150 mm. Spiral fasteners are commonly used for the assembly and interconnection of welded mesh gabions. Spirals are screwed down at the connecting edges then each end of the spiral is crimped to secure it in place. Lacing may be used as needed to supplement the interconnection of welded mesh gabions, and the closing of lids. Interconnect each layer of gabions to the underlying layer of gabions along the front, back, and sides. Stagger the vertical joints between the gabions of adjacent rows and layers by at least one-half of a cell length.

3) FILLING OPERATION

After adjacent empty wire gabion units are set to line and grade and common sides properly connected, they shall be placed in straight-line tension to gain a uniform alignment. Staking of the gabions may be done to maintain the established proper alignment prior to the placement of rock. No temporary stakes shall be placed through geotextile material. Connecting lacing wire and other fasteners (as allowed) shall be attached during the filling operation to preserve the strength and shape of the structure. Internal connecting cross-tile wires shall be placed in each unrestrained gabion cell greater than 500 mm in height, including gabion cells left temporarily unrestrained. Two internal connecting wires shall be placed concurrently with rock placement, at each 300 mm interval of depth. In welded mesh gabions these crossties or stiffeners will be placed across the corners of the gabions (at 300 mm from the corners) providing diagonal bracing. Lacing wire or preformed wire stiffeners may be used. The gabions shall be carefully filled with rock, either by machine or hand methods, ensuring alignment, avoiding bulges, and providing a compact mass that minimizes voids. At no point in the filling process may rock be mechanically placed from a height of over 91 cm from machine to fill area. Machine placement will require supplementing with handwork to ensure the desired results. The cells in any row shall be filled in stages so that the depth of rock placed in any one cell does not exceed the depth of rock in any adjoining cell by more than 300 mm. Along the exposed faces, the outer layer of stone shall be carefully placed and arranged by hand to ensure a neat, compact placement with a uniform appearance.

Updated September 2008 | www.permathene.com

The last layer of rock shall be uniformly leveled to the top edges of the gabions. Lids shall be placed over the rock filling using only approved lid closing tools as necessary. The use of crowbars or other single point leverage bars for lid closing is prohibited due to the potential for damage to the baskets. The gabion lid shall then be secured to the sides, ends, and diaphragms with spiral binders, approved alternate fasteners, or lacing wire wrapped with alternating single and double halfhitches in the mesh openings. Any damage to the wire or coatings during assembly, placement and filling shall be repaired promptly in accordance with the manufacturers recommendations or replaced with undamaged gabion baskets.

Updated September 2008 | www.permathene.com

Updated September 2008 | www.permathene.com

GAB/ON SYSTEMS

MODULAR GAB/ON SYSTEMS

(C) partially assembled gabions or mattresses.

Modular Gabions Systems (B) pre-cut panels or may be supplied in (A) roll form,

When using roll stock, begin the assembly process at Step 1.

When using preassembled gabions, When using pre-cut panels, proceed to Step 2 proceed to Step 3. Ends, diaphragms, front and back panels are placed upright on the bottom section of wire mesh.

Panels may be cut to appropriate sizes in the field. When using roll stock, bottoms, lids, fronts and backs may be rolled out in lengths up to 300'.

~ E a r t h Solutions

PERMATHENE

Secure panels by screwing spiral binders through the mesh openings in adjacent panels.

18 Stiffeners should be placed inside at 12 intervals (4 per cell)and crimped over the line and cross wires on the front and side faces. None are needed in interior cells.

Gabions may be filled with graded stone After filling, close the lid and secure by hand or with a backhoe or loader. with spiral binders at the diaphragms, ends, front and back.

All illustrations depict a 3' x 3' x 6' gabion. Gabions constructed from roll stock may utilize continuous sections of welded wire mesh up to 300' long. Please review the instructions on page 3 for options to eliminate redundant panels.

Redundant panels may be eliminated between gabions as illustrated. An end panel has been removed from the gabion on the right. This gabion will butt up against the gabion on the left so that the end panel of the left gabion becomes a diaphragm between the cells of the two gabions. Spiral connectors will secure all the adjoining panels.

Spirals will connect the gabions here End panel removed

When stacking tiers of gabions (or gabions on mattresses), the lid of the lower tier may serve as the base of the upper tier. Secure with spiral binders and add pre-formed stiffeners to exterior cells before filling with graded stones.

The lid of the lower tier of gabions now forms the base for the upper gabion.

This gabion has been assembled without a base.

All illustrations depict a 3' x 3' x 6' gabion. Gabions constructed from roll stock may utilize continuous sections of welded wire mesh up to 300' long. Please review basic assembly instructions on pages 1 & 2.

Disclaimer

The information presented herein, while not guaranteed, is to the best of our knowledge true and accurate. While every effort has been made to provide accurate and reliable information, it is up to the user of this brochure to verify all information, including designs it might be based upon, with an independent source. Application of this data must be made on the basis of responsible professional judgement. Except when agreed to in working conditions of use, no warranty expressed or implied is made regarding the performance of any product, since the manner of use and handling is beyond our control.

Legal | www.permathene.com

You might also like

- Gabions Install GuideDocument2 pagesGabions Install GuideTele2 Phone2100% (1)

- Management Systems For Gabion Construction and InstallationsDocument4 pagesManagement Systems For Gabion Construction and InstallationsSebastián LagosNo ratings yet

- Gabion Wall SpecificationDocument4 pagesGabion Wall SpecificationRAY ENGINEERING SYNGAS100% (1)

- Woodwork Joints: How They Are Set Out, How Made and Where UsedFrom EverandWoodwork Joints: How They Are Set Out, How Made and Where UsedNo ratings yet

- 150 Cordwood CabinDocument4 pages150 Cordwood CabinEmmanuel BarbiniNo ratings yet

- Deck Construction GuideDocument13 pagesDeck Construction Guidefaxtackley100% (2)

- Installing A Pre-Hung DoorDocument3 pagesInstalling A Pre-Hung DoorEng_20140% (1)

- 10 Stuff You Have To Realize Solar RooftopsDocument17 pages10 Stuff You Have To Realize Solar RooftopsSanelite SolarNo ratings yet

- A Practical Handbook For The Trainer of Trainers of Biogas Construction EnterprisesDocument44 pagesA Practical Handbook For The Trainer of Trainers of Biogas Construction EnterprisesTaimur AkhtarNo ratings yet

- Ferrocement Biogas DigesterDocument38 pagesFerrocement Biogas DigesterBotár CsabaNo ratings yet

- Recommended Standards For The Installation of Woodburning StovesDocument13 pagesRecommended Standards For The Installation of Woodburning StovesJohnny LibitzNo ratings yet

- Super Insulated Slab FoundationsDocument8 pagesSuper Insulated Slab Foundationsevazeta100% (1)

- Boral Installation MasonryGuideDocument25 pagesBoral Installation MasonryGuidem0172No ratings yet

- Small Farm 2017 DicDocument80 pagesSmall Farm 2017 Dicmalpaso4242No ratings yet

- Figure 1: A Ventilated Improved Pit - LatrineDocument7 pagesFigure 1: A Ventilated Improved Pit - LatrineKiran Basu100% (1)

- Greenhouse Heating Using Geothermal EnergyDocument9 pagesGreenhouse Heating Using Geothermal EnergyHenokh PrasetyoNo ratings yet

- Full Oven InstructionsDocument46 pagesFull Oven InstructionsJoshua RosenkrantzNo ratings yet

- How To Tie Rebar - 15 Steps (With Pictures) - Wikihow PDFDocument4 pagesHow To Tie Rebar - 15 Steps (With Pictures) - Wikihow PDFa769No ratings yet

- Straw Bale Is Future House Building MaterialDocument14 pagesStraw Bale Is Future House Building MaterialJcdenaesNo ratings yet

- THC ShellKit CASULADocument1 pageTHC ShellKit CASULAAdolf John Montero EceNo ratings yet

- Gable Shed Plan: Free Streamlined VersionDocument9 pagesGable Shed Plan: Free Streamlined VersionUdu OgahNo ratings yet

- Annex6 RMHeaterDocument5 pagesAnnex6 RMHeaterDobri StefNo ratings yet

- MinimumStandards - (Ext Wall Framing)Document14 pagesMinimumStandards - (Ext Wall Framing)Samia H. BhuiyanNo ratings yet

- Canadian Wood Frame House Construction PDFDocument378 pagesCanadian Wood Frame House Construction PDFmsenerNo ratings yet

- Wolfcraft Wooden Deck BuildingDocument16 pagesWolfcraft Wooden Deck Buildingvergopi100% (3)

- Brick Veneer WallDocument16 pagesBrick Veneer Wallpilapil_jNo ratings yet

- Greenhouse Structural Design ManualDocument68 pagesGreenhouse Structural Design Manualdeepteck000No ratings yet

- Instructions for Setting Up a Sioux TipiDocument31 pagesInstructions for Setting Up a Sioux TipivictorNo ratings yet

- DO Lookout 1 Cabin PlansDocument29 pagesDO Lookout 1 Cabin PlansJerry FoltzNo ratings yet

- Pergolas and TrellisDocument11 pagesPergolas and TrellisPARVATHY R S 170564No ratings yet

- Connection and Fastening Guide: Recommendations For The Construction of Code-Compliant DecksDocument40 pagesConnection and Fastening Guide: Recommendations For The Construction of Code-Compliant DecksbassigwNo ratings yet

- Straw Bale PrimerDocument8 pagesStraw Bale PrimerVmeupNo ratings yet

- Timber-Frame Garden Shed: Index Furnishings Outdoor Wood FurnishingsDocument7 pagesTimber-Frame Garden Shed: Index Furnishings Outdoor Wood Furnishingscarra80100% (1)

- Wide Module Pan Skip Joist Spandrel Torsion Concrete Floor Design Detailing PDFDocument92 pagesWide Module Pan Skip Joist Spandrel Torsion Concrete Floor Design Detailing PDFGonzalo Gomez CastilloNo ratings yet

- Masterrib: Installation ManualDocument32 pagesMasterrib: Installation ManualIgor Lainovic100% (1)

- Hydronic Radiant-Floor HeatingDocument8 pagesHydronic Radiant-Floor Heatingkasandra01No ratings yet

- Passive Cooled Wine CellarDocument11 pagesPassive Cooled Wine Cellarrazzuk100% (1)

- How To Keep Your Produce Fresh For Weeks - WirecuDocument14 pagesHow To Keep Your Produce Fresh For Weeks - Wirecujunaa Albayati100% (1)

- Timber Frame Construction Project PresentationDocument18 pagesTimber Frame Construction Project PresentationscegtsNo ratings yet

- Science: Hoop House Construction For New MexicoDocument10 pagesScience: Hoop House Construction For New MexicoWen RollandNo ratings yet

- LP® Shed Assembly Instructions Hawthorne Place 10'X12' Gable Roof ShedDocument10 pagesLP® Shed Assembly Instructions Hawthorne Place 10'X12' Gable Roof ShedMinuteman ModelworksNo ratings yet

- Build a Post-and-Plank Retaining WallDocument13 pagesBuild a Post-and-Plank Retaining WallAnonymous 1TTYYaNo ratings yet

- Gable Shed Building GuideDocument61 pagesGable Shed Building GuideBach Xuan NguyenNo ratings yet

- Chainsaw Mill Build Use Tips N TricksDocument34 pagesChainsaw Mill Build Use Tips N TricksRosangela Rafaele Dos SantosNo ratings yet

- Majestic Outdoor Fireplace ManualDocument20 pagesMajestic Outdoor Fireplace Manualdenizen27No ratings yet

- Log Cabin TechnologyDocument1 pageLog Cabin TechnologyRoger BryantNo ratings yet

- Pole Barn Metal DetailsDocument52 pagesPole Barn Metal DetailsKurt Stailey100% (1)

- Ceiling TechnologyDocument6 pagesCeiling Technologypdf2004No ratings yet

- Earthbag Building Step-by-Step GuideDocument15 pagesEarthbag Building Step-by-Step GuideVander De Almeida Candido0% (1)

- Straw Bale Green HomeDocument13 pagesStraw Bale Green Homedanut_docNo ratings yet

- C 2007Document204 pagesC 2007saurabhbhardwajNo ratings yet

- Setting up a yurt in 2-4 hoursDocument22 pagesSetting up a yurt in 2-4 hoursMichel ManginNo ratings yet

- Arcadia Glasshouse Planning Guide PDFDocument12 pagesArcadia Glasshouse Planning Guide PDFArya ParamelNo ratings yet

- All American TreehouseDocument50 pagesAll American Treehousecompulsorylogin50% (2)

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersFrom EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersNo ratings yet

- Patios (UK Only): Designing, building, improving and maintaining patios, paths and stepsFrom EverandPatios (UK Only): Designing, building, improving and maintaining patios, paths and stepsNo ratings yet

- Practical hints to builders and those contemplating buildingFrom EverandPractical hints to builders and those contemplating buildingNo ratings yet

- An Introduction to the Seasoning of Timber: Pergamon Series of Monographs on Furniture and TimberFrom EverandAn Introduction to the Seasoning of Timber: Pergamon Series of Monographs on Furniture and TimberW. J. KapeNo ratings yet

- 05 Corr RepairDocument43 pages05 Corr RepairdarkchechoNo ratings yet

- 21 Cleaning and Maintenance 7.2Document10 pages21 Cleaning and Maintenance 7.2darkchechoNo ratings yet

- GOLD Guidelines2009Document47 pagesGOLD Guidelines2009darkchechoNo ratings yet

- EnglishDocument21 pagesEnglishjhony_sucasacaNo ratings yet

- Official Redsn0w LicenseDocument1 pageOfficial Redsn0w LicensespencerschromebookNo ratings yet

- Patching Instructions.Document1 pagePatching Instructions.ridemypony22No ratings yet

- Eula 1036Document4 pagesEula 1036Erik Yoel T RNo ratings yet

- LicenseDocument1 pageLicensehyperparanoidNo ratings yet

- Read Me!Document2 pagesRead Me!Faisal AhmedNo ratings yet

- DS Rebar Splicing HBDocument64 pagesDS Rebar Splicing HBdarkchechoNo ratings yet

- Volume Changes in Brick MasonryDocument9 pagesVolume Changes in Brick MasonryNgoc Ba NguyenNo ratings yet

- Rocket Division Software License Agreement ImportantDocument2 pagesRocket Division Software License Agreement ImportantdadbabaNo ratings yet

- Modelling Load Flow and Short Circuit ScenariosDocument4 pagesModelling Load Flow and Short Circuit ScenariosCRISTIAN CAMILO MORALES SOLISNo ratings yet

- Detail Biofile 1Document1 pageDetail Biofile 1Rully SaputraNo ratings yet

- Calculating torque, stresses, and bearing pressure for a C-clamp designDocument4 pagesCalculating torque, stresses, and bearing pressure for a C-clamp designSayed Mesallamy100% (3)

- Isolation and Purification of Peroxidase From Shoots of OF TOMATODocument9 pagesIsolation and Purification of Peroxidase From Shoots of OF TOMATOPooja WalkeNo ratings yet

- Hall Buttons Car Operating Panel: Standard Hall Call Button & Position IndicatorDocument1 pageHall Buttons Car Operating Panel: Standard Hall Call Button & Position Indicatorsameer hassanNo ratings yet

- Kelayakan Investasi Instalasi Sea Water Reverse Osmosis (Swro) Di Kawasan Wisata Pantai Kenjeran SurabayaDocument9 pagesKelayakan Investasi Instalasi Sea Water Reverse Osmosis (Swro) Di Kawasan Wisata Pantai Kenjeran SurabayaKang SudikNo ratings yet

- Prosedur uji bantalan betonDocument2 pagesProsedur uji bantalan betonArie SaiyukiNo ratings yet

- Welding Guide PDFDocument24 pagesWelding Guide PDFJán KožičkaNo ratings yet

- Amortiguador Pala 7495Document2 pagesAmortiguador Pala 7495milenko Cortes100% (1)

- Section R6 Selected Granular Material-Sub-Base CourseDocument21 pagesSection R6 Selected Granular Material-Sub-Base CourseBALEN KAKLNo ratings yet

- RES-p Personal Profile:: Name Date of Birth Marital Status Address: Mail IDDocument4 pagesRES-p Personal Profile:: Name Date of Birth Marital Status Address: Mail IDkspNo ratings yet

- Using A System Cost Analysis ToDocument11 pagesUsing A System Cost Analysis Tosaa6383No ratings yet

- Measuring wavelength of light using diffraction gratingDocument5 pagesMeasuring wavelength of light using diffraction gratingSaksham BargujarNo ratings yet

- Katalog Pipa HDPE Wavin BlackDocument2 pagesKatalog Pipa HDPE Wavin BlackChristian MakigaweNo ratings yet

- Gels in Polyethylene Films - enDocument5 pagesGels in Polyethylene Films - enNanh TrắngNo ratings yet

- Global Positioning System Steering (GPSS) Converter Pilot's Operating HandbookDocument32 pagesGlobal Positioning System Steering (GPSS) Converter Pilot's Operating HandbookDanielLobatoBernardesNo ratings yet

- JAR 66 Module 1 Propeller Exam PracticeDocument43 pagesJAR 66 Module 1 Propeller Exam Practicerobija1No ratings yet

- Computer History Timeline2Document31 pagesComputer History Timeline2Janina CalimlimNo ratings yet

- Titan Mare Explorer (TiME) : The First Exploration of An Extra-Terrestrial SeaDocument15 pagesTitan Mare Explorer (TiME) : The First Exploration of An Extra-Terrestrial SeaIan M MairNo ratings yet

- Nuclear Instruments and Methods in Physics Research BDocument4 pagesNuclear Instruments and Methods in Physics Research BguiburNo ratings yet

- Actuation Product Catalogue - OneSteelDocument65 pagesActuation Product Catalogue - OneSteelJOHN100% (1)

- Redbox: Model Rbl4000 LithiumDocument1 pageRedbox: Model Rbl4000 LithiumAbdullah SindhuNo ratings yet

- G8 BOW Commercial Cooking First QuarterDocument4 pagesG8 BOW Commercial Cooking First QuarterAllen Dimapilis100% (1)

- NI PXI-4110 Specifications: Triple-Output Programmable DC Power SupplyDocument8 pagesNI PXI-4110 Specifications: Triple-Output Programmable DC Power SupplyDonnaNo ratings yet

- Glovebox FabricationDocument44 pagesGlovebox FabricationRezaNo ratings yet

- Uml Super Market Case StudyDocument16 pagesUml Super Market Case StudynikoNo ratings yet

- Isotope TutorialDocument6 pagesIsotope Tutorialask4imadeosas9393No ratings yet

- Ecn 30210 PDocument22 pagesEcn 30210 PMajid MollaieNo ratings yet

- SPM Overview PDFDocument39 pagesSPM Overview PDFnaldhita100% (1)

- Cat Sos 793&793b TrucksDocument7 pagesCat Sos 793&793b TrucksmkNo ratings yet