Professional Documents

Culture Documents

Hydro Test Procedures

Uploaded by

azimr157Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydro Test Procedures

Uploaded by

azimr157Copyright:

Available Formats

HYDROSTATIC TEST API 598 PROCEDURE MANUAL

Issued By : Approved By : Date Version

Kumaran Bernard Wong 18th Oct 2011 02

QA Managing Director 18th Oct 2011

PANAFLO CONTROLS PTE LTD

HYDROSTATIC TEST API 598 1. Purpose

DOC. NO REVISION

PFC-QA-TP-01 02

Page 2 of 10

To define the retesting requirements for the metal seated Gate / Globe & Check valves and Resilience seat Butterfly valve. Standard testing comprises hydrostatic testing of the pressure envelope (body), backseat and seat tightness testing (hydrostatic and/or pneumatic) as applicable.

2. RELEVANT STANDARD

The requirements set out in this standard are in accordance with the following International Standards API 598,BS6755Pt.1, pr EN12266 Pt.1.The hydrostatic test pressures expressed in this standard comply with ASME B16.34 for valves and API Std. 602 for Class 800 valves.

3. SCOPE

This specification applies to metal seated Gate / Globe & Check valves including bellows sealed valves, tested according to API 598 Table 1 & 2 as described below. Valves specified for double block & bleed are not covered by this procedure.

Test Description

NPS 4 & ASME Class 1500 NPS > 4 & ASME Class 600 Gate Globe Check Required Required Required

NPS 4 & ASME Class > 1500 NPS > 4 & ASME Class > 600 Gate Required Globe Required Check Required

Shell (Hydrostatic Body Test) Backseat (1) (Hydrostatic Seat Test) High Pressure Closure (Hydrostatic Seat Test) Low-pressure Closure (Pneumatic Seat Test)

Required(4)

Required(4)

N/A

Required(4)

Required(4)

N/A

Optional (2) Required

Required (3) Optional (2)

Required Optional (2)

Required Optional (2)

Required (3) Optional (2)

Required Optional (2)

(1) The backseat test is required for all valves, except bellows seal valves, that have the backseat feature. (2) When an optional test is specified by the purchaser, the test shall be performed in addition to the required tests.

PANAFLO CONTROLS PTE LTD

HYDROSTATIC TEST API 598

DOC. NO REVISION

PFC-QA-TP-01 02

Page 3 of 10

(3) For power-operated and manually operated gear actuated globe valves, including non-return type globe valves, the high-pressure closure test shall be performed at 110% of the design differential pressure used for sizing of the operator. (4) Unless stipulated otherwise by the purchaser, back seat test shall be the High-pressure (hydrostatic) closure test.

4. TEST REQUIREMENTS

4.1. General Surface treatments of pressure containing valve components to prevent corrosion during storage prior to and during manufacture with a single primer coat (maximum 25 microns thickness) or phosphate treatment is acceptable provided these preservations do not hide any porosity.

4.2. Test Apparatus Valves which have a split body design must not be tested on equipment which subjects the valve to externally applied loads which may affect the body joint sealing performance. Single piece bodied valves may be clamped.

4.3. Shell Test (Hydrostatic Body Test) Every valve shall be subjected to a hydrostatic test of the body shell at 1.5 times the maximum permissible working pressure at 100F (38C), see Table 1. The body should remain tight for the test duration given in Table 1. The test shall show no leakage, no wetting of the external surfaces, and no Permanent distortion under the full test pressure. No device shall be used in testing the valve that will reduce the stress in the body.

The valve shall be set in the partially open position for this test, and completely filled with test fluid. Any entrapped air should be vented from both ends and the body cavity via either

1) The upper test flange with the valve axis vertical. 2) The body vents connection with the valve axis horizontal. After venting the body, vent plugs should be replaced. The gland or bellows and anybody jointing shall be deemed as part of the pressure envelope. Where a bellows is fitted, the stuffing box packing & gland shall not be fitted.

The valve shall then be brought to the required test pressure.

PANAFLO CONTROLS PTE LTD

HYDROSTATIC TEST API 598

DOC. NO REVISION

PFC-QA-TP-01 02

Page 4 of 10

All external surfaces should be dried and the pressure held for at least the minimum test duration. There shall be no visible leakage during the test duration specified in Table 2.

Note: For valves with adjustable stem seals, leakage through the stem seals during the shall test shall not be cause for rejection, provided the stem seals are capable of retaining pressure at least equal to the 100F (38C) valve rating without visible leakage. If leakage is found, corrective action may be taken to eliminate the leakage and the test repeated.

4.4. Backseat Test (Hydrostatic Seat Test)

When applicable (with exception of bellows seal valves), every valve shall be subjected to a hydrostatic test of the backseat at 1.1 times the maximum permissible working pressure at 100 F (38C), see Table 1. The seat sealing surface / closure Interface shall be free from oil, grease and sealant. The backseat should remain tight for the test duration given in Table 1. The test shall show no leakage, no wetting of the external surfaces, and no permanent distortion under the full test pressure. The valve shall be set in the fully open position with the packing gland loose or packing not installed. If the backseat test is performed after the shell test, the packing shall be installed and/or packing gland re-tightened after the backseat test. The valve shall be completely filled with test fluid. Any entrapped air should be vented from both ends and the body cavity via either a) The upper test flange with the valve axis vertical or via the stem with the packing removed. b) The body vents connection with the valve axis horizontal. After venting the body, vent plugs should be replaced. The valve shall then be brought to the required test pressure. All external surfaces should be dried and the pressure held for at least the minimum test duration. There shall be no visible leakage during the test duration specified in Table 2. If unacceptable leakage is found, corrective action may be taken to eliminate the leakage and the test repeated. If the valve is disassembled to eliminate the leakage, all previous testing must be repeated upon re-assembly.

PANAFLO CONTROLS PTE LTD

HYDROSTATIC TEST API 598

4.5. High-pressure Closure Test (Hydrostatic Seat Test)

DOC. NO REVISION

PFC-QA-TP-01 02

Page 5 of 10

When applicable or specified by purchaser, every valve shall be subjected to a hydrostatic seat test to 1.1 times the maximum permissible working pressure at 100 F (38C), see Table 1 for the test duration specified in Table 1. The seat sealing surface / closure interface shall be free from oil, grease and sealant. Depending on the valve design and size a varying settling in period is allowed. The allowable leakage of test fluid from the seat seal interface shall be according to those listed in Table 2. The test shall show no leakage through the disc, behind the seat rings or past the shaft seals. With the valve in the partially open position, the cavity shall be completely filled with test fluid and any entrapped air should be vented from both ends and the body cavity via either a) The upper test flange with the valve axis vertical. b) The body vents connection with the valve axis horizontal. The valve should be closed and the body cavity vent (where fitted) shall remain open. Gate Valve & Screw Down Non-return Globe Valve: The pressure shall be applied successively to each side of the closed valve with the other side open to the atmosphere to check for leakage at the atmospheric side of the closure. Globe Valve: The pressure shall be applied in one direction with the pressure applied under the disc (upstream side) of the closed valve with the other side open to the atmosphere to check for leakage at the atmospheric side of the closure. Check valve: The pressure shall be applied in one direction with the pressure applied behind the disc (downstream side) of the closed valve with the other side open to the atmosphere to check for leakage at the atmospheric side of the closure. If unacceptable leakage is found, corrective action may be taken to eliminate the leakage and the seat test repeated. If the valve is disassembled to eliminate the leakage, all previous testing must be repeated upon re-assembly.

PANAFLO CONTROLS PTE LTD

HYDROSTATIC TEST API 598

4.6. Low-pressure Closure Test (Pneumatic Seat Test)

DOC. NO REVISION

PFC-QA-TP-01 02

Page 6 of 10

When applicable or specified by purchaser, every valve shall be subjected to an air seat test at a minimum gauge pressure differential of 4 to 7 bar (60-100 psig) for the test duration specified in Table 1. The seat sealing surface / closure interface shall be free from oil, grease and sealant. Depending on the valve design and size a varying settling in period is allowed. The allowable leakage of test fluid from the seat seal interface shall be according to those listed in Table 2. The test shall show no leakage through the disc, behind the seat rings or past the shaft seals. The valve should be moved to the half open position and any test fluid drained via either: a) The lower test flange with the valve axis vertical. b) The body drains connection with the valve axis horizontal. Gate Valve & Screw Down Non-return Globe Valve: The pressure shall be applied successively to each side of the closed valve with the other side open to the atmosphere to check for leakage at the atmospheric side of the closure. Globe Valve: The pressure shall be applied in one direction with the pressure applied under the disc (upstream side) of the closed valve with the other side open to the atmosphere to check for leakage at the atmospheric side of the closure. Check valve: The pressure shall be applied in one direction with the pressure applied behind the disc (downstream side) of the closed valve with the other side open to the atmosphere to check for leakage at the atmospheric side of the closure.

5. TEST LIQUID

5.1. Test Liquid

Hydrostatic tests shall be carried out with water at ambient temperatures, within the range of 41F (5C) and 122F (50C), unless the use of another liquid is agreed between the purchaser and the manufacturer. If water is used, it will contain water-soluble oil or rust Inhibitor. Potable water used for pressure test of austenitic stainless steel valves shall have chloride content less than 30ppm and for carbon steel valves shall be less than 200ppm.

PANAFLO CONTROLS PTE LTD

HYDROSTATIC TEST API 598

5.2. Cleaning

DOC. NO REVISION

PFC-QA-TP-01 02

Page 7 of 10

Austenitic and duplex stainless steel valves and valves made of 9% nickel alloy shall be flushed with demineralized water (chloride content of 1ppm maximum) immediately after the hydrostatic test. 5.3. Drying

After Hydrostatic testing, the valves should be blown through using dry compressed air, followed by a visual inspection for dryness. If moisture is still found, the above process shall be repeated until visually dry.

6. TEST GAUGES

Test bay gauges shall be calibrated at once a year.

7. TEST CERTIFICATION

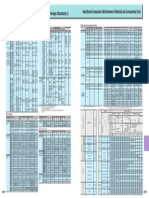

According to attached model test certificate confirming that the valves have been tested in accordance with the requirements of this specification. Table 1 Test Pressure & Time duration Class Description Material A105, A350-LF2, A216WCB, A352 LCC A182-F5,F9,F11,F22 A182-F304,F316 A182-F304L, F316L Class Description Material A105, A350-LF2 A216WCB, A352 LCC A182-F5,F9,F11,F22 A182-F304,F316 A182-F304L, F316L CWP psig 1480 1500 1440 1200 CWP psig 285 290 275 230 150# Shell Kg/cm2 32 32 30 25 600# Shell Kg/cm2 157 159 153 127 Seat Kg/cm2 117 117 113 94 CWP psig 1975 2000 1920 1600 Seat Kg/cm2 23 23 23 20 CWP psig 740 750 720 600 300# Shell Kg/cm2 80 80 78 64 800# Shell Kg/cm2 210 211 204 169 Seat Kg/cm2 153 155 150 125 Seat Kg/cm2 59 59 57 48

PANAFLO CONTROLS PTE LTD

HYDROSTATIC TEST API 598

DOC. NO REVISION

PFC-QA-TP-01 02

Page 8 of 10

1500#

Class Description Material A105, A350-LF2 A216WCB, A352 LCC A182-F5,F9,F11,F22 A182-F304,F316 A182-F304L, F316L Class Description Material A105, A350-LF2 A216WCB, A352 LCC A182-F5,F9,F11,F22 A182-F304,F316 A182-F304L, F316L CWP psig 6170 6250 6000 5000 CWP psig 2225 2250 2160 1800

900# Shell Kg/cm2 235 233 224 187 2500# Shell Kg/cm2 653 660 633 528 Seat Kg/cm2 478 484 465 387 CWP psig Seat Kg/cm2 173 172 164 137 CWP psig 3705 3750 3600 3000

Shell Kg/cm2 392 396 380 317 Shell Kg/cm2 -

Seat Kg/cm2 289 291 280 233

Seat Kg/cm2 -

CWP: The maximum allowable pressure at 20 OF to 100 OF 38C). TABLE 2 TEST DURATION NOMINAL SIZE (NPS) 2 2 1/2 6 8 12 14 MINIMUM TEST DURATIONS (Seconds) Hydro Shell Test 15 60 120 300 Backseat Test 15 60 60 60 Hydro Seat Test 15 60 120 120 Air Seat Test 15 60 120 120

PANAFLO CONTROLS PTE LTD

HYDROSTATIC TEST API 598

DOC. NO REVISION

PFC-QA-TP-01 02

Page 9 of 10

Table 2 Maximum Allowable Leakage for Seat Test Valve Size Metal Seated Valves Except Check Liquid Test (drops/minute) 0 5 6 8 10 12 16 20 24 28 32 36 40 48 52 56 60 64 72 80 84 96 Gas Test (bubbles/minut e) 0 10 12 16 20 24 32 40 48 56 64 72 80 96 104 112 120 128 114 160 168 192 Metal Seated Check valves Liquid Test (cc/min) 6 7.5 9 12 15 18 24 30 36 42 48 54 60 72 78 84 90 96 108 120 126 144

DN (mm) < 50 65 80 100 125 150 200 250 300 350 400 450 500 600 650 700 750 800 900 1000 1050 1200

NPS (in.) <2 2 1/2 3 4 5 6 8 10 12 14 16 18 20 24 26 28 30 32 36 40 42 48

All Resilient Seated Valves 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Gas Test (m3/h) 0.08 0.11 0.13 0.17 0.21 0.25 0.34 0.42 0.50 0.59 0.67 0.76 0.84 1.01 1.09 1.18 1.26 1.34 1.51 1.68 1.76 2.02

Gas Test (ft3/h) 3 3.75 4.5 6 7.5 9 12 15 18 21 24 27 30 36 39 42 45 48 54 60 63 72

PANAFLO CONTROLS PTE LTD

HYDROSTATIC TEST API 598

a b For the Liquid test, 1 ml is considered equivalent to 16 drops.

DOC. NO REVISION

PFC-QA-TP-01 02

Page 10 of 10

There shall be no leakage for minimum specified test duration (see table 2). For Liquid test, 0 drops means no visible leakage per minimum specified test duration. For gas test, 0 bubbles means less than 1 bubble per minimum specified test duration.

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Hydrostatic Shell TestDocument5 pagesHydrostatic Shell TestsojeckNo ratings yet

- ROCEDURE - INSPECTION & TEST ValvesDocument10 pagesROCEDURE - INSPECTION & TEST Valvessabes26No ratings yet

- Ball Valve Testing ProcedureDocument7 pagesBall Valve Testing ProcedureVipul Panchal100% (2)

- API 598 Testing Procedure-20130720-032647Document2 pagesAPI 598 Testing Procedure-20130720-032647JOMAGUES100% (1)

- Control Valve Test ProcedureDocument5 pagesControl Valve Test ProcedureMark Haizlip100% (2)

- Pressure Testing of Well Control EquipmentDocument7 pagesPressure Testing of Well Control EquipmentAmit Kumar SinghNo ratings yet

- Butterfly Valve Cycle TestDocument4 pagesButterfly Valve Cycle TestParthiban MechanicalNo ratings yet

- Testing Procedure of Ball ValveDocument2 pagesTesting Procedure of Ball Valverajesh100% (2)

- Valve Testing ProcedureDocument10 pagesValve Testing Proceduremoytabura96100% (5)

- To Commissioning Manual: Appendix No. 1Document7 pagesTo Commissioning Manual: Appendix No. 1Bassem BalghouthiNo ratings yet

- Butterfly Valve Info PDFDocument14 pagesButterfly Valve Info PDFCS100% (1)

- Pages From NSH-SAOMPP-QCP-PI-021 Hydratight Procedure For Flange Hydraulic Torque TighteningDocument2 pagesPages From NSH-SAOMPP-QCP-PI-021 Hydratight Procedure For Flange Hydraulic Torque TighteningRajis Rahim100% (1)

- Testing Procedure of Dual Plate Check ValveDocument2 pagesTesting Procedure of Dual Plate Check Valverajesh100% (2)

- Hydrotest & Pneumatic TestDocument3 pagesHydrotest & Pneumatic TestjokishNo ratings yet

- Neles Seat Leakage SpecDocument9 pagesNeles Seat Leakage SpecIkhsan Ly100% (1)

- Piping Pneumatic Test ProcedureDocument2 pagesPiping Pneumatic Test Procedureruzla67% (3)

- Testing StandardDocument7 pagesTesting StandardDiego Fernando Pedroza UribeNo ratings yet

- Testing Procedure For Ball Valve MAPDocument16 pagesTesting Procedure For Ball Valve MAPbasuki100% (3)

- Valve Testing ProcedureDocument9 pagesValve Testing ProcedureFaiz Zainudin83% (6)

- Factory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: DDocument6 pagesFactory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: Dbayu dewantoNo ratings yet

- Inspection of ValvesDocument85 pagesInspection of ValvesAnand Kesarkar86% (7)

- Overhaul Procedure ValveDocument4 pagesOverhaul Procedure ValveRansley Tong100% (1)

- Double Piston and Single Piston Effect in Ball ValvesDocument5 pagesDouble Piston and Single Piston Effect in Ball ValvesPipeline Engineer100% (6)

- Sample - Template - Itp For Piping Fabrication and InstallationDocument2 pagesSample - Template - Itp For Piping Fabrication and Installationmohd as shahiddin jafriNo ratings yet

- Mechanical PlugsDocument6 pagesMechanical Plugskategord0% (1)

- Pneumatic Test ProcedureDocument2 pagesPneumatic Test Proceduredyke_engg67% (3)

- Diesel Pipeline Flushing and PurgingDocument3 pagesDiesel Pipeline Flushing and PurgingVaradaraj CkNo ratings yet

- KVC Ball ValvesDocument1 pageKVC Ball ValvesAlex VarHerNo ratings yet

- Mov ItpDocument1 pageMov ItpMussab Salih100% (1)

- Hydro Test ProcedureDocument9 pagesHydro Test ProcedureAdeel QaiserNo ratings yet

- Plug ValvesDocument14 pagesPlug Valvesashish.mathur1100% (1)

- Hydrotest ProcedureDocument3 pagesHydrotest Procedureaman131100% (2)

- Procedure Welding Part 2Document14 pagesProcedure Welding Part 2mohammadNo ratings yet

- GRE-RTR QC Responsibilities.Document1 pageGRE-RTR QC Responsibilities.ansar100% (1)

- Inspection and Test Plan For Pressure Safety Valve PDFDocument3 pagesInspection and Test Plan For Pressure Safety Valve PDFsherviny100% (3)

- Gate Valve MaintenanceDocument8 pagesGate Valve Maintenancechar_lynNo ratings yet

- Hydro Test Work ProcedureDocument9 pagesHydro Test Work ProcedureshahidbolarNo ratings yet

- API 570 - Asme B31.3 Q&ADocument29 pagesAPI 570 - Asme B31.3 Q&AShaalan Ali100% (1)

- Ansi Fci 70-2Document5 pagesAnsi Fci 70-2Rafael100% (1)

- Asme Code XIII enDocument2 pagesAsme Code XIII enjacquesstrappe06100% (1)

- Visual Inspection Method of Storage TankDocument2 pagesVisual Inspection Method of Storage TankAnonymous NDkWQpp100% (1)

- 5.3 CES 1002 F Seat Leakage TestingDocument22 pages5.3 CES 1002 F Seat Leakage TestingBowo Edhi Wibowo100% (1)

- PSV TestingDocument26 pagesPSV Testingmanoj thakkar100% (1)

- Inspection and Test Plan For Pressure VesselDocument2 pagesInspection and Test Plan For Pressure Vesselalokbdas50% (2)

- Sa (Valves and Fittings Exam)Document6 pagesSa (Valves and Fittings Exam)rajaksekar100% (2)

- Safety Relief Valve Set Pressure and Seat Leakage TestDocument30 pagesSafety Relief Valve Set Pressure and Seat Leakage TestAnonymous ffje1rpa100% (1)

- API 6D Overview - Pipeline & Piping ValvesDocument3 pagesAPI 6D Overview - Pipeline & Piping ValvesNilesh MistryNo ratings yet

- Itp For Ball ValveDocument9 pagesItp For Ball ValveHamid Taghipour ArmakiNo ratings yet

- Procedure Manual: Ball Valve Hydro TestDocument5 pagesProcedure Manual: Ball Valve Hydro Testnima_h10No ratings yet

- Notes - API 598 Valve Inspection & TestingDocument5 pagesNotes - API 598 Valve Inspection & TestingM Saad KhanNo ratings yet

- Panaflo Controls Pte LTD: 4. Test RequirementsDocument1 pagePanaflo Controls Pte LTD: 4. Test RequirementsSheik Abdullah BakrudeenNo ratings yet

- Valve TestingDocument6 pagesValve TestingjobertNo ratings yet

- Tests For Surface Wellheads and BOP Equipment Used in Operations On Land and Above Water LevelDocument6 pagesTests For Surface Wellheads and BOP Equipment Used in Operations On Land and Above Water Levelahmed121No ratings yet

- Proposed Hydro Test Procedures For ValvesDocument8 pagesProposed Hydro Test Procedures For ValvesNilesh GhodekarNo ratings yet

- Bench Testing of Relief ValvesDocument1 pageBench Testing of Relief ValvesSARATH KRISHNAKUMARNo ratings yet

- Fugitive Emission Test ReportDocument15 pagesFugitive Emission Test ReportNitin AggarwalNo ratings yet

- Assignment 5Document7 pagesAssignment 5Sharizada KanapiyevaNo ratings yet

- Hydro TestDocument9 pagesHydro TestPrathap JohnNo ratings yet

- Pneumatic Test - Write UpDocument7 pagesPneumatic Test - Write UpDilip0% (1)

- General Assembly DrawingDocument2 pagesGeneral Assembly Drawingazimr157No ratings yet

- Malaysias Meltdown Moment - The INSIDE STORY Sarawak ReportDocument8 pagesMalaysias Meltdown Moment - The INSIDE STORY Sarawak Reportazimr157No ratings yet

- Material ComparisonDocument1 pageMaterial ComparisonNoir HamannNo ratings yet

- Master of Petroleum EngineeringDocument2 pagesMaster of Petroleum Engineeringazimr157No ratings yet

- Nada Alam Seri Pajam TestimonyDocument1 pageNada Alam Seri Pajam Testimonyazimr157No ratings yet

- ISO - 15848-1 First Edition 2006Document56 pagesISO - 15848-1 First Edition 2006azimr15750% (2)

- Cryogenic Valve Test Procedure PDFDocument9 pagesCryogenic Valve Test Procedure PDFazimr157100% (1)

- CADWorx Training ScheduleDocument1 pageCADWorx Training Scheduleazimr157No ratings yet

- 6696 Msia Maju Integrated EngDocument1 page6696 Msia Maju Integrated Engazimr157No ratings yet

- Inspectation Test PlanDocument1 pageInspectation Test Planazimr157No ratings yet

- Papa Jew SkiDocument33 pagesPapa Jew Skiazimr157No ratings yet

- PMI Test ProcedureDocument5 pagesPMI Test Procedureazimr157100% (2)

- An Introduction To Production and Specifications of Steel PipesDocument5 pagesAn Introduction To Production and Specifications of Steel PipesAnthony WongNo ratings yet

- Chapter-3 Corrugated Hdpe ProductsDocument10 pagesChapter-3 Corrugated Hdpe ProductsWan Yoon HinNo ratings yet

- Documentation and Change Control: 10-1. GeneralDocument4 pagesDocumentation and Change Control: 10-1. Generalazimr157No ratings yet

- Process, Electrical & Instrumentation Drawings and DocumentationDocument2 pagesProcess, Electrical & Instrumentation Drawings and DocumentationmasakpNo ratings yet

- DHFmanualDocument43 pagesDHFmanualEsteban Valencia RamírezNo ratings yet

- Zacklift Owner and Installation ManualDocument64 pagesZacklift Owner and Installation ManualCarlos ValdezNo ratings yet

- Technical Manual: Vacuklav 41-B Vacuklav 43-BDocument45 pagesTechnical Manual: Vacuklav 41-B Vacuklav 43-Bmohamed hegazyNo ratings yet

- Abbreviations LEAP - 1ADocument5 pagesAbbreviations LEAP - 1AwenjukwaxNo ratings yet

- Dynamic Analysis of Hydraulic DrivesDocument50 pagesDynamic Analysis of Hydraulic DrivesAnonymous Hy5Ir9QXNo ratings yet

- Tightening Torques Lubricants Tools: AB 0100 EN Servicing SAMSON ProductsDocument174 pagesTightening Torques Lubricants Tools: AB 0100 EN Servicing SAMSON ProductsGordinhorsNo ratings yet

- Seawater Service Pressure Relief Valve: ModelDocument2 pagesSeawater Service Pressure Relief Valve: ModelHemant RasamNo ratings yet

- Unit IV Pelton TurbineDocument12 pagesUnit IV Pelton TurbinePavanNo ratings yet

- Sirri Island Gas Gathering & NGL Recovery Project: Active Fire Fighting Safety Equipment SpecificationDocument12 pagesSirri Island Gas Gathering & NGL Recovery Project: Active Fire Fighting Safety Equipment SpecificationRIMEL ASMANo ratings yet

- v2500 Fam NewDocument113 pagesv2500 Fam NewTango Sierra100% (2)

- Steam Source Book PDFDocument108 pagesSteam Source Book PDFJose Levican A100% (1)

- MaK Main Engine Starting Up Procedure Rev3Document2 pagesMaK Main Engine Starting Up Procedure Rev3Arun DasNo ratings yet

- Training Manual Consepts of Steam Turbine MaintenanceDocument102 pagesTraining Manual Consepts of Steam Turbine Maintenancemen100% (2)

- DIA 3 y 4 - SISTEMA HIDROSTATICODocument29 pagesDIA 3 y 4 - SISTEMA HIDROSTATICOLcc Lenin CaballeroNo ratings yet

- Mechrun Test ProcedureDocument5 pagesMechrun Test ProcedureDerry PraditaNo ratings yet

- Control Valves & Actuators: Course OnDocument4 pagesControl Valves & Actuators: Course OnHarish GundaNo ratings yet

- Valves - Kirloskar BrothersDocument4 pagesValves - Kirloskar BrothersJaydev ChakrabortyNo ratings yet

- XATS 156 DD Ed 03.04parts List For Portable Compressor Atlas CopcoDocument114 pagesXATS 156 DD Ed 03.04parts List For Portable Compressor Atlas Copcosebastian88% (8)

- PO Box 4038, Doha, Qatar Telephone (+974) 4407 6000 / 4460 0099 /4407 6444 Fax: (+974) 4407 6498Document12 pagesPO Box 4038, Doha, Qatar Telephone (+974) 4407 6000 / 4460 0099 /4407 6444 Fax: (+974) 4407 6498ClarkFedele27No ratings yet

- 20 RT-flex MechanicalDocument60 pages20 RT-flex MechanicalKesavan Vimal KumarNo ratings yet

- Lexus - GS300 - GS430 - Service - Manual 7Document158 pagesLexus - GS300 - GS430 - Service - Manual 7seregap8475% (4)

- TR 113859Document517 pagesTR 113859Ulises Valencia PorcayoNo ratings yet

- Varioklav 75s and 135sDocument6 pagesVarioklav 75s and 135spribadi socojatiNo ratings yet

- Cylinder Head Pressure Test D12DDocument7 pagesCylinder Head Pressure Test D12DHamilton MirandaNo ratings yet

- A MA - Aviation Maintenance Technician AirframeDocument19 pagesA MA - Aviation Maintenance Technician AirframeSajadNo ratings yet

- SteeringDocument20 pagesSteeringFernandoNo ratings yet

- Control Valves For Ahu Chilled WaterDocument4 pagesControl Valves For Ahu Chilled WaterHussein Akil100% (1)

- Instruction Manual: WL 230 Condensation ProcessDocument48 pagesInstruction Manual: WL 230 Condensation ProcessSaba ArifNo ratings yet

- 1 汽机运维规程 Steam Turbine Operation and Maintenance ManualDocument212 pages1 汽机运维规程 Steam Turbine Operation and Maintenance ManualMd Suzon MahmudNo ratings yet

- Valco Group France: Dedication To DeliveryDocument2 pagesValco Group France: Dedication To Deliverysinou.25No ratings yet