Professional Documents

Culture Documents

Concrete Mix Design - M 20 Grade of Concrete

Uploaded by

akash nairOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Mix Design - M 20 Grade of Concrete

Uploaded by

akash nairCopyright:

Available Formats

Road & Pavement Profiler Concrete Mix Design M 20 Grade Of

www.dipstick.com The Face Dipstick - Most Accurate and Most Specified in 63 Countries

Concrete

Posted in Mix Design |

Like 16

Email This Post |

1. REQUIREMENTS a) Specified minimum strength = 20 N/Sq mm b) Durability requirements i) Exposure Moderate ii) Minimum Cement Content = 300 Kgs/cum c) Cement (Refer Table No. 5 of IS:456-2000) i) Make Chetak (Birla) ii) Type OPC iii) Grade 43 d) Workability i) compacting factor = 0.7 e) Degree of quality control Good 2. TEST DATA FOR MATERIALS SUPPLIED a) CEMENT i) Specific gravity = 3.05 ii) Avg. comp. strength 7 days = 46.5 more than 33.0 OK 28 days = 55.0 more than 43.0 OK b) COARSE AGGREGATE i) 20mm Graded Type Crushed stone aggregate Specific gravity = 2.68 Water absorption = 1.46 Free (surface) moisture = 0

c) FINE AGGREGATE (Coarse sand) i) Type Natural (Ghaggar) Specific gravity = 2.6 Water absorption = 0.5 Free (surface) moisture = 1.4

3. TARGET MEAN STRENGTH (TMS) a) Statistical constant K = 1.65 b) Standard deviation S = 4.6 Thus, TMS = 27.59 N/Sqmm 4. SELECTION OF W/C RATIO a) As required for TMS = 0.5 b) As required for Moderate Exposure = 0.55 Assume W/c ratio of 0.5 5. DETERMINATION OF WATER & SAND CONTENT For W/C = 0.6 C.F. = 0.8 Max. Agg. Size of 20 mm a) Water content = 186 Kg/cum b) Sand as percentage of total aggregate by absolute volume = 35 % Thus, Net water content = 180.42 Kg/cum Net sand percentage = 33 %

6. DETERMINATION OF CEMENT CONTENT W/c ratio = 0.5 Water content = 180.42 Kg/cum Thus, Cement content = 360.84 Kg/cum Adequate for moderate exposure Say 360 Kg/cum 7. DETERMINATION OF COARSE AND FINE AGGREGATE CONTENT Assume entrapped air as 2 % Thus, 0.98 cum = [180.42+360/3.05 + {1/0.33}*{fa/2.6}]/1000 & 0.98 cum = [180.42+360/3.05 + {1/0.67}*{Ca/2.68}]/1000 Hence, fa = 584 Kg/cum Ca = 1223.8 Kg/cum The final mix proportions of M-20 grade of concrete become:-

Note: 1 The above recommended mix design must be verified, by actual cube tests. 2 The mix design is based on the quality and grading of the materials actually supplied, by the client. Any variation in quality and gradation will result in changes in the mix design. This mix design was submitted by a regular contributor to this site. We are thankful to him for his excellent service. More Entries : Mix Design For M35 Grade Of Concrete M 15 Mix Designs as per IS-10262-2009 Concrete Mix Design M60 Grade Of Concrete (OPC 53 Grade) M-20 Mix Designs as per IS-10262-2009 M-25 Mix Designs as per IS-10262-2009 M-30 Mix Designs as per IS-10262-2009 M-35 Mix Designs as per IS-10262-2009 Concrete Mix Design M70 Grade of Concrete (OPC 53 Grade) Comments Jayagandan October 1, 2013 at 8:24 am Friends i am doing 3rd yr in chennai, i need a guide to guide me. Reply Link Quote KAZEEM January 13, 2014 at 3:58 am PLEASE, EXPLAIN HOW TO PLACE REINFORCEMENT ON SITE Reply Link Quote Narayanan January 18, 2014 at 5:29 am i need these mix design details, please sent to my mail id Reply Link Quote suji February 10, 2014 at 9:35 am can you please tell me.. how to derive mix design for M20 and M25 concrete.. if fine aggregate and cement is partially replaced by waste materials like glass, slag and etc Reply Link Quote Post a comment Name Email Website

Post your comment

1 13 14 15

Share Information

Submit Content Ask An Expert

What is Civil Engineering

Civil Engineering Home Civil Engineering Disciplines Civil Engineering History

Journals Books And Softwares

Free Civil Engineering Magazines and White Papers Civil Engineering Books Civil Engineering Journals Civil Engineering Softwares

Branches Of Civil Engineering

Building Bridge Engineering Concrete Engineering Highway Engineering Hydraulics Marine Engineering Piles Engineering Prestress Engineering Soil Engineering Steelworks Surveying Timber Engineering

Civil Engineering Jobs

Civil Engineering Jobs

Follow Us On FB

Find us on Facebook

EngineeringCivil.com

Like

419 people like EngineeringCivil.com.

Facebook social plugin

Knowledge Center

Construction Equipments Civil Engineering Disasters Civil Engineering Events Civil Engineering Facts Civil Engineering Information Civil Engineering Notes From Universities Civil Engineering Presentations Civil Engineering Quotes Civil Engineering Videos Civil Engineering Wonders Construction Terms Famous Civil Engineers

Interviews Material and Site Testing Measurement Units Mix Design Project Reports Research Papers Student Corner Help Others

Civil Engineering Universities/Events

Civil Engineering Universities Shanghai International Green Wooden Residential Exhibition 2013 TTUS 2014 Advertise Your Event Here

Gallery - Civil Engineering Pictures

Bridges Civil Engineers And Workers Construction Equipments Construction Site Roads And Highways Skyscrapers

Search

Search

Top Contributors

You can list yourself here by submitting civil engineering related topics to us.

Er. Harpal Aujla Er. Raj M. Khan Er. Vikrant Ramasesh Iyer Er. Kaushal Kishore Vincent T. H. CHU

Yahoo Group - Civil Engineering Portal

Subscribe to EngineeringCivil.com Enter email address

Powered by groups.yahoo.com

Recently Added

Water Proofing By Ferrocement

Indias Lodha World One To Be Worlds Tallest Residential Tower Concrete Mix Design with Fly Ash and Superplasticizer Alkali-Silica Reaction In Concrete Concrete Curing Compound Green Architecture and Construction Materials Expo M-80 Grade Pumpable Concrete Laying of Bituminous Concrete Feasibility study of Sky Bus Metro Linking Cities in Himalaya Region From Sediment Dredging to Island Making

Civil Engineering Links

Gemini Geek The Bigger Civil Engr. Software Database Impressive Buildings Civil Engineering Links

Follow Us On FB

Find us on Facebook

EngineeringCivil.com

Like

419 people like EngineeringCivil.com.

Facebook social plugin

About Us | Contact Us | Disclaimer | Copyright Policy | Privacy Policy | Media | Testimonials All Rights Reserved:2007-2014 |

You might also like

- Trial Trench Measurement SheetDocument7 pagesTrial Trench Measurement Sheetakash nairNo ratings yet

- Trial Pit Under RoadDocument3 pagesTrial Pit Under Roadakash nairNo ratings yet

- Total Pipe QtyDocument1 pageTotal Pipe Qtyakash nairNo ratings yet

- Credit Shield Insurance SummaryDocument19 pagesCredit Shield Insurance Summaryakash nairNo ratings yet

- Germany (Germany (German: Bundesrepublik DeutschlandDocument1 pageGermany (Germany (German: Bundesrepublik Deutschlandakash nairNo ratings yet

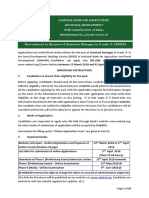

- "Indo-Tibetan Border Police Force": (Ministry of Home Affairs) Govt. of IndiaDocument20 pages"Indo-Tibetan Border Police Force": (Ministry of Home Affairs) Govt. of Indiaakash nairNo ratings yet

- Kerala Public Service Commission: 1. Department 2. Name of Post 3. Scale of Pay 4. Number of VacancyDocument3 pagesKerala Public Service Commission: 1. Department 2. Name of Post 3. Scale of Pay 4. Number of Vacancyakash nairNo ratings yet

- First Part Completed CompletedDocument2 pagesFirst Part Completed Completedakash nairNo ratings yet

- Customer Guide Lines TSC Ver 4 0Document53 pagesCustomer Guide Lines TSC Ver 4 0akash nairNo ratings yet

- KPSC Ranked List for Assistant Engineer (Soil ConservationDocument5 pagesKPSC Ranked List for Assistant Engineer (Soil Conservationakash nairNo ratings yet

- AmericaDocument1 pageAmericaakash nairNo ratings yet

- India-Republic of South AsiaDocument4 pagesIndia-Republic of South Asiaakash nairNo ratings yet

- Mastercard: Purchase Protection Per Occurrence: 2,000 Annual Aggregate: 5,000Document3 pagesMastercard: Purchase Protection Per Occurrence: 2,000 Annual Aggregate: 5,000akash nairNo ratings yet

- Pipe Bedding and Backfill: Geotechnical Training Manual No. 7Document88 pagesPipe Bedding and Backfill: Geotechnical Training Manual No. 7AKASH FERAG100% (1)

- Junior Instructor Draftsman Civil RecruitmentDocument5 pagesJunior Instructor Draftsman Civil Recruitmentakash nairNo ratings yet

- Report ErrorDocument1 pageReport Errorakash nairNo ratings yet

- Twin Chamber Twin Chamber: No Spindle RequiredDocument1 pageTwin Chamber Twin Chamber: No Spindle Requiredakash nairNo ratings yet

- Sewerage: Gravity Collection ParametersDocument2 pagesSewerage: Gravity Collection Parametersakash nairNo ratings yet

- Twin Chamber Twin Chamber: No Spindle RequiredDocument1 pageTwin Chamber Twin Chamber: No Spindle Requiredakash nairNo ratings yet

- Notification NABARD Asst Manager PostsDocument28 pagesNotification NABARD Asst Manager Postsrakesh_200003No ratings yet

- Deepika Calendar2018Document8 pagesDeepika Calendar2018akash nairNo ratings yet

- 03.12.17 AnadhanDocument2 pages03.12.17 Anadhanakash nairNo ratings yet

- (Direct Recruitment) : 1 Department/Name of InstitutionDocument3 pages(Direct Recruitment) : 1 Department/Name of Institutionakash nairNo ratings yet

- 03.12.17 AnadhanDocument2 pages03.12.17 Anadhanakash nairNo ratings yet

- Live Chilled Water Line CautionDocument1 pageLive Chilled Water Line Cautionakash nairNo ratings yet

- Fire Fighting LineDocument1 pageFire Fighting Lineakash nairNo ratings yet

- EHV Handbook ENG LowResDocument91 pagesEHV Handbook ENG LowResSharique T. Baig100% (1)

- Follow The Below Font For Both English and ArabicDocument1 pageFollow The Below Font For Both English and Arabicakash nairNo ratings yet

- AC 198 Insp Request KamDocument588 pagesAC 198 Insp Request Kamakash nairNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- RPS 2020 Infrastruktur BerkelanjutanDocument12 pagesRPS 2020 Infrastruktur BerkelanjutanDevi AgustinaNo ratings yet

- Feasibility Analysis: Heritage Walk & Adventure Trail, Warangal, TelanganaDocument32 pagesFeasibility Analysis: Heritage Walk & Adventure Trail, Warangal, Telanganakarthik1216No ratings yet

- Ashok LeylandDocument78 pagesAshok LeylandKajal Kaundal33% (3)

- 2009 Audi ExclusiveDocument33 pages2009 Audi ExclusiveXozanNo ratings yet

- Executive Summary of Bangalore-Chennai Expressway Feasibility ReportDocument54 pagesExecutive Summary of Bangalore-Chennai Expressway Feasibility ReportAsom Mala Group5No ratings yet

- EhamDocument119 pagesEhamNeethNo ratings yet

- Concrete - Draft - Manual DrawingDocument3 pagesConcrete - Draft - Manual DrawingSiska LieNo ratings yet

- Gantt Chart ModifiedDocument1 pageGantt Chart ModifiedVishnu priya0% (1)

- Pre-Feasibilty Report For Indore MetroDocument82 pagesPre-Feasibilty Report For Indore MetroA4onlyNo ratings yet

- Inspect Concrete Box CulvertsDocument14 pagesInspect Concrete Box CulvertsDeepak Kr GuptaNo ratings yet

- Best Bosch Nozzles for Toyota Diesel EnginesDocument2 pagesBest Bosch Nozzles for Toyota Diesel EnginesTamer Moustafa100% (1)

- Cover Letter For Driving Job With No Experience PDFDocument5 pagesCover Letter For Driving Job With No Experience PDFe7dqxazz100% (1)

- WMKP-Penang International AirportDocument10 pagesWMKP-Penang International AirportAmjad RanaNo ratings yet

- Model Railroad Hobbyist July, 2013Document119 pagesModel Railroad Hobbyist July, 2013olgumby50% (2)

- Ere Ijesa ReportDocument52 pagesEre Ijesa ReportolaNo ratings yet

- Haruki Murakami - Norwegian WoodDocument2 pagesHaruki Murakami - Norwegian WoodsengottaiyanNo ratings yet

- Transition Track PDFDocument1 pageTransition Track PDFMohamad SaquibNo ratings yet

- Geometric DesignDocument25 pagesGeometric Designkrakesh1999No ratings yet

- Model Minor Bridge EstimateDocument32 pagesModel Minor Bridge EstimateRavi KumarNo ratings yet

- EMPL Recovery Vehicle Operating ManualDocument160 pagesEMPL Recovery Vehicle Operating ManualSayel MokhaimerNo ratings yet

- Railway Engineering MCQ PDF (Erexams - Com)Document55 pagesRailway Engineering MCQ PDF (Erexams - Com)krishna chaithanyaNo ratings yet

- The Development of The London Underground RailwayDocument9 pagesThe Development of The London Underground RailwayNhung Lê Thị HồngNo ratings yet

- Springs Shock Absorbers BizHouse - UkDocument3 pagesSprings Shock Absorbers BizHouse - UkAlex BekeNo ratings yet

- On TweelDocument21 pagesOn TweelRaju UpparapellyNo ratings yet

- Dir PGDocument15 pagesDir PGHumTum InLoveeNo ratings yet

- qps4 Full Speed in GallivareDocument13 pagesqps4 Full Speed in Gallivarejayjay37No ratings yet

- Navara Brochure All Pages 2019 MAY17 PDFDocument8 pagesNavara Brochure All Pages 2019 MAY17 PDFKattie ValerioNo ratings yet

- Traffic Incident Photographs of The Crime SceneDocument5 pagesTraffic Incident Photographs of The Crime SceneNoel CasilNo ratings yet

- Corus RailsDocument27 pagesCorus RailsnarasimhanrajuNo ratings yet

- mpc08 206Document99 pagesmpc08 206albertoxinaNo ratings yet