Professional Documents

Culture Documents

Decking Smartdek

Uploaded by

rahulgehlot2008Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Decking Smartdek

Uploaded by

rahulgehlot2008Copyright:

Available Formats

SMARTDEK 51 Structural Decking System

LYSAGHT SMARTDEK 51 Structural Decking System is

an innovative high strength zinc-coated steel decking system

designed for use in the construction of composite foor slabs. It is

specifcally developed for the Indian Construction Industry and is

one of the most economical structural steel decking in the country.

SMARTDEK 51 system complements the LYSAGHT

profles,

which is a premium range of roofng and wall cladding solutions.

The high quality LYSAGHT SMARTDEK 51 Structural Decking

System reinforces the principles of trust and reliability that Tata

BlueScope Steel represents.

Overview

SMARTDEK 51 is suitable for typical applications as it

provides widest cover per weight of steel and also minimises

the requirement for reinforcement. It acts as a permanent

formwork for a composite concrete slab, which in its assembled

state can be used as a working platform as well as a formwork to

support wet concrete, construction materials and trades. When

the concrete hardens, it acts as the bottom tensile reinforcement.

SMARTDEK 51 system is a complete structural steel decking

system for concrete, masonry and steel frame construction and

has an exceptional composite performance.

History of LYSAGHT

Decking Profle

TROFDEK

1964

CELDEK

1968

BONDEK

II

1989

W-DEK

1992

POWERDEK

1998

SMARTDEK

TM

51

2006

Menara Imperium, Jakarta, Indonesia

2

Designed to Perfection

LYSAGHT SMARTDEK 51 Structural Decking System is an

innovative W profle structural steel decking system. It brings

greater economy and design freedom as it is precision engineered

and provides ease of use as well as safety. SMARTDEK 51

system has excellent spanning capacities that ensure greater

strength and less defection.

SMARTDEK 51 panel has a rib depth of 51 mm and provides

an effective cover width of 960 mm as shown in the fgure 1.1.

Embossments on top of the fange provide excellent mechanical

interlocking between steel and concrete. In the assembled state,

the profle compromises of intermediate male and female ribs for

every interlocking side-lap joint.

b

51 mm

Cover width 960mm

Embossments

Reinforcement

Mesh Reinforcement

Stiffener

Concrete

SMARTDEK 51

Figure 1.1

LYSAGHT SMARTDEK 51

SMARTDEK 51 Section Properties

SMARTDEK 51 Self Weight Full Zinc Steel Inertia Section

Thickness (kg/m

2

) Cross-Sectional Coating Grade Moment Modulus

(BMT) (mm) Area (mm

2

/m) (g/m

2

)* (MPa)** lx

1

(mm

4

/m)

Zx

1

(mm

3

/m)

0.70 7.35 888.9 275 550 409687.50 15156.25

1.00 10.34 1269.7 275 550 526562.50 19479.17

1.20 12.33 1523.9 275 500 701979.17 25958.33

Jin Mao Tower, Shanghai, China

Embossment

Stiffener

Note:

* Nominal coating thickness

** Minimum yield strength of steel

Please contact nearest Tata BlueScope Steel offce for other thickness and coating options

3

Level 1

Level 2

Level 1

Props at

Regular

Interval

Props at

Regular

Interval

Top Reinforcement

Bottom Reinforcement

Top

Reinforcement

Bottom

Reinforcement

Lost Formwork

(Extra Steel)

a

Concrete as Required

b

Extra Concrete

Temporary

Shuttering

No

Bonding

Benefts of LYSAGHT SMARTDEK 51 system

Comparison Chart

4

Conventional RCC Slab Lost Formwork Decking Slab SMARTDEK

TM

51 Structural Decking Slab

Temporary Shuttering removed after slab sets

Concrete volume as per required slab depth

Reinforcement steel as required

Requires complex prop arrangement

Normal speed of construction

No bonding between steel sheet & concrete

Extra concrete required at the profle valleys

Decking acts as extra steel to the slab

Reduction in props

Decking application enhances construction speed

Temporary

Shuttering

Lost

Formwork

Temporary Shuttering removed after concrete curing

Decking acts as a lost formwork material

S

t

r

u

c

t

u

r

a

l

E

l

e

m

e

n

t

C

o

m

p

o

s

i

t

e

A

c

t

i

o

n

C

o

n

c

r

e

t

e

S

a

v

i

n

g

S

t

e

e

l

S

a

v

i

n

g

P

r

o

p

A

r

r

a

n

g

e

m

e

n

t

C

o

n

s

t

r

u

c

t

i

o

n

T

i

m

e

Level 2

Level 3

Level 1

Few or

No Props

Top

Reinforcement

Smartdek 51

(As Bottom

Reinforcement)

c < a & b

c

Concrete Saving

Embossments

(Strong Mechanical Interlock)

Smart Software

Excel based SMARTDEK 51 software and MEGAFLOOR

structural decking software for the design of composite slabs with

SMARTDEK 51 profle will be available to assist engineers and

consultants in deriving an optimal solution. SMARTDEK 51

software should be used in conjunction with the SMARTDEK

51 design manual.

Smart Construction

SMARTDEK 51 system provides a safe working platform that

is fast and easy to set up and therefore minimises multi-storey

construction time. Faster construction time allows optimisation on

construction schedule delivering faster value to the developers.

Smart Application

Besides its application in composite foors in multi-storey

buildings and commercial establishments, it is extensively used

for Mezzanine applications. Corrosion resistant coating makes

it the best solution for typical applications like parking sheds,

where SMARTDEK 51 system provides better appearance to

exposed ceilings.

ICBC Headquarter Building,Beijing

5

Lost Formwork Decking Slab SMARTDEK

TM

51 Structural Decking Slab

Embossments provide mechanical interlock between steel & concrete

Concrete saving makes construction economical

SMARTDEK 51 acts as bottom tensile reinforcement Steel Saving

High tensile steel (G550) provides large unpropped spans

SMARTDEK 51 application delivers faster value to developers

Structural

Decking

SMARTDEK 51 acts as an integral structural element

Specifcations

SMARTDEK Span Table Formwork Stage*

0.7 1 1.2 0.7 1 1.2 0.7 1 1.2

100 2360 2600 2600 2610 3200 3200 2610 3200 3200

110 2280 2620 2800 2520 3290 3580 2520 3130 3340

120 2200 2540 2710 2430 3200 3490 2430 3030 3240

130 2140 2460 2630 2360 3110 3400 2360 2950 3150

140 2080 2400 2560 2290 3040 3320 2290 2840 3070

150 2030 2340 2500 2230 2950 3240 2230 2740 2990

160 1980 2290 2450 2180 2870 3170 2160 2650 2930

170 1930 2240 2390 2120 2800 3100 2090 2570 2840

180 1890 2190 2350 2080 2740 3040 2030 2490 2750

200 1810 2110 2260 1990 2620 2900 1920 2360 2610

220 1740 2040 2190 1910 2510 2790 1820 2240 2480

S

l

a

b

T

h

i

c

k

n

e

s

s

(

m

m

)

BMT

Span

Type

Single Continuous End

Continuous interior

Material Specifcations

SMARTDEK 51 panel is manufactured from hot dipped zinc

coated high strength steel with minimum 550 MPa yield strength

and coating mass of Z275 (min 275g/m

2

total of zinc coating on

both sides). The available thickness ranges from 0.70 mm to

1.2 mm BMT (Base Metal Thickness). The steel conforms to

AS1397 and BS EN 10147:2000.

Tested to Extreme Conditions

SMARTDEK 51 panels have been subjected to rigorous tests

such as slip block test, formwork tests including shear and

bearing, full scale slab test, composite slab cycle test, fre rating

test, formwork-air pressure test, formwork-four point load test

and concentrated load test. These tests are carried out in the

labs of LYSAGHT

technology centre in Chester Hill, Sydney,

Australia, to ensure maximum performance and quality of our

decking profles. (Ref. fgure 2.1 to 2.4)

Quality Assurance

The LYSAGHT

brand name is synonymous with quality

and performance. As with all other LYSAGHT

products,

SMARTDEK 51 steel sheets comply with major Indian standards

and design standards adopted across Asia. Manufactured using

high tensile steel, it is optimally confgured and uses advanced

design and construction method.

Fig. 2.1 - Formwork - Point Load Fig. 2.2 - Formwork - Air Pressure Test Fig. 2.3 - Composite - Slip Block Test Fig. 2.4 - Fire Test - Victoria University

Roll Forming Machine

6

* Please refer to SMARTDEK

TM

51 Design and Construction Manual for detail design of composite slab.

Optional: SMARTDEK 51 system is available in pre-painted galvanised steel.

Connection Details

SMARTDEK 51 fxing detail: The accessories are added as per design requirement

Shear Studs

Steel Bracket

Shear Stud

Edge

Form

Universal Beam

Universal Beam SMARTDEK 51 profle

SMARTDEK 51 profle

End details-Flush Type: Standard end closure detail adopted for steel frame structure

Above connection details for guidance purpose only.

7

Steel Connection Details

End details - Option 1: Detail adopted for cantilever end projections

End details-Option 2: Alternate details for structures where projections are necessary

Above connection details for guidance purpose only.

Connection Details

8

As Required

As Required

Cantilever

Length

Stud on Beam

Centerline

Edge

Form

Edge

Form

Cantilever Length

Steel Bracket

Steel Bracket

Shear Stud

Universal Beam

Universal Beam

SMARTDEK 51 profle

SMARTDEK 51 profle

Butt joint details: Standard joint detail for continuous casting of slab

Temporary support details (If required): SMARTDEK 51 profle spans longer than conventional system where possibility of

temporary support is less. Please refer to SMARTDEK 51 Design & Construction Manual for details

Above connection details for guidance purpose only.

Connection Details

9

Shear Stud

Universal Beam

SMARTDEK 51 profle

SMARTDEK 51 profle

Wooden Support

Temporary Prop

Universal Beam

Concrete Connection Details

Corner details: The ends are closed to make sure the concrete slurry takes the required shape quickly

Concrete fxing details: The casting of beam & slab is done simultaneously. This saves time and brings economy.

Above connection details for guidance purpose only.

Connection Details

10

Edge Form

Formwork

Reinforcement Bar

Stirrups

Shear Stud

Steel Bracket

Reinforcement Bar

Edge

Form

SMARTDEK 51 profle

SMARTDEK 51 profle

Connections Details

Open SMARTDEK

TM

51 sheet bundles Place temporary support if required Place on steel or concrete beam Clinch male and female lip

Fix steel edge form wherever required Fix SMARTDEK

TM

51 profles to steel

or concrete beam

Place reinforcement Place concrete

Sequence of Construction

Fire Details

Option 1

Option 2 Above details for guidance purpose only.

Please refer SMARTDEK

TM

51 design and

construction manual

1

5

2

6

3

7

4

8

11

Negative Reinforcement (Ast

-

)

Negative Reinforcement (Ast

-

)

0.3Ln

Ln

SMARTDEK 51 profle

SMARTDEK 51 profle

Additional Fire

Reinforcement

(Ast

f

)

-

Mesh

Universal Beam

Universal Beam

0.3Ln

Ln

Additional Fire

Reinforcement

(Ast

f

)

+

Mesh

The Metropolitan, Final Plot No. 27,

Survey No. 21, Wakdewadi,

Shivaji Nagar, Pune - 411005. India.

Tel: + 91 20 6674 2000 Fax: +91 20 6674 2001

Website: www.tatabluescopesteel.com

Email: smartdek@tatabluescopesteel.com

For more information, please contact:

North Region Gurgaon: Tel: +91 124 4263051

East Region Kolkata: Tel: +91 33 65502335

West Region Pune: Tel: +91 20 66218000

South Region Chennai: Tel: +91 44 42693319

Note:

No part of this brochure may be reproduced, stored in retrieval system or transmitted in any form or by any means,

electronic, mechanical, recording or otherwise, without written permission from Tata BlueScope Steel Limited.

TROFDEK

, CELDEK

, BONDEK

II, W-DEK

, POWERDEK

, SMARTDEK

TM

51 and LYSAGHT

are registered

trademarks of BlueScope Steel Limited. BONDEK

II, W-DEK

, POWERDEK

, SMARTDEK

TM

51 and LYSAGHT

are

under license to Tata BlueScope Steel Limited.

B

P

/

P

M

/

7

.

3

/

0

2

1

0

Petronas Tower, Kuala Lumpur, Malaysia

Fusionpolis, Singapore

Key Benefts

Excellent spanning capacities for greater strength

and less defection

Embossments provide mechanical interlock

ensuring adequate composite action

Precision Engineered; brings greater economy

and design freedom

Ease of installation combined with safety

Saves on concrete and reinforcement cost

Greater corrosion resistance provides long life

Emirates Towers, Dubai

Key Benefts

Excellent spanning capacities for greater strength

and less defection

Embossments provide mechanical interlock

ensuring adequate composite action

Precision Engineered; brings greater economy

and design freedom

Ease of installation combined with safety

Saves on concrete and reinforcement cost

Greater corrosion resistance provides long life

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Advance Engine Timing with STCDocument28 pagesAdvance Engine Timing with STCLuisPupiales100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Role of DSS in RefineryDocument24 pagesRole of DSS in Refineryramadoss_alwar7307100% (1)

- CHEMISTRY LAB VIVA QuestionsDocument3 pagesCHEMISTRY LAB VIVA QuestionsUjjWal MahAjan55% (20)

- Special Process Audit Check Sheet - PlatingDocument8 pagesSpecial Process Audit Check Sheet - PlatingHariprasanth ChandranNo ratings yet

- Big Batch Soap MakingDocument24 pagesBig Batch Soap MakingAnonymous Vu1R35s4WZ100% (2)

- The Changing World of OleochemicalsDocument9 pagesThe Changing World of OleochemicalsMarta Szymańska100% (1)

- How Does A Refrigerator WorkDocument5 pagesHow Does A Refrigerator WorkAlfis0% (1)

- Astm D1785-15Document11 pagesAstm D1785-15david franco0% (1)

- Against Water Hummer PDFDocument36 pagesAgainst Water Hummer PDFDenstar Ricardo SilalahiNo ratings yet

- Practical Design to Eurocode 2: FoundationsDocument76 pagesPractical Design to Eurocode 2: FoundationsTarek Ed E100% (1)

- UK SP MB Kingspan Multibeam Brochure PDFDocument144 pagesUK SP MB Kingspan Multibeam Brochure PDFhemendraengNo ratings yet

- NetKey Guide PDFDocument10 pagesNetKey Guide PDFMohamed Abo-ZaidNo ratings yet

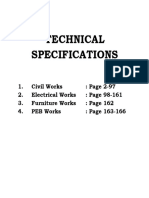

- NIT - 2.1.technical SpecificationDocument166 pagesNIT - 2.1.technical SpecificationpaldesigndeepNo ratings yet

- PopoDocument1 pagePoporahulgehlot2008No ratings yet

- ICE Professional Review GuidanceDocument23 pagesICE Professional Review Guidancerahulgehlot2008No ratings yet

- Heho He HoDocument1 pageHeho He Horahulgehlot2008No ratings yet

- LeloliftDocument1 pageLeloliftrahulgehlot2008No ratings yet

- OpennnDocument1 pageOpennnrahulgehlot2008No ratings yet

- Eft % XL.: F.iql-Ci-I W1rT FCTMDocument2 pagesEft % XL.: F.iql-Ci-I W1rT FCTMrahulgehlot2008No ratings yet

- SdfdsDocument3 pagesSdfdsrahulgehlot2008No ratings yet

- 2010 Bridges EN1990 SDentonDocument83 pages2010 Bridges EN1990 SDentonNita BogdanNo ratings yet

- E-Public - Fire Proofing of Structural Steel Suuports..Document40 pagesE-Public - Fire Proofing of Structural Steel Suuports..rahulgehlot2008No ratings yet

- BeamhgvDocument10 pagesBeamhgvrahulgehlot2008No ratings yet

- Holiday List 2017 GurgaonDocument1 pageHoliday List 2017 Gurgaonrahulgehlot2008No ratings yet

- Tata RoofDek D135 - 1.25 0.0Document16 pagesTata RoofDek D135 - 1.25 0.0rahulgehlot2008No ratings yet

- Cham ChamDocument1 pageCham Chamrahulgehlot2008No ratings yet

- Holiday List 2017 GurgaonDocument1 pageHoliday List 2017 Gurgaonrahulgehlot2008No ratings yet

- Civil SpecsDocument1 pageCivil Specsrahulgehlot2008No ratings yet

- JHDocument1 pageJHrahulgehlot2008No ratings yet

- Plot - NotepadDocument1 pagePlot - Notepadrahulgehlot2008No ratings yet

- BT Practices For: Microsoft Office Outlook 2007Document2 pagesBT Practices For: Microsoft Office Outlook 2007rahulgehlot2008No ratings yet

- Short Doc TitleDocument1 pageShort Doc Titlerahulgehlot2008No ratings yet

- Appendix 4Document2 pagesAppendix 4rahulgehlot2008No ratings yet

- Doc about random letters and symbolsDocument1 pageDoc about random letters and symbolsrahulgehlot2008No ratings yet

- MY UNIVERSE Terms - ConditionDocument17 pagesMY UNIVERSE Terms - ConditionparveencareNo ratings yet

- BT Prs For: Microsoft Office Outlook 2007Document2 pagesBT Prs For: Microsoft Office Outlook 2007rahulgehlot2008No ratings yet

- Best Practices For Microsoft Office Outlook 2007Document40 pagesBest Practices For Microsoft Office Outlook 2007hmaurinNo ratings yet

- GFHFHDocument1 pageGFHFHrahulgehlot2008No ratings yet

- Lennox Kca090s4bn2yDocument36 pagesLennox Kca090s4bn2yGerardo ZamoranoNo ratings yet

- Omeprazole: by Jennica Mae V. CuicoDocument7 pagesOmeprazole: by Jennica Mae V. Cuicoジェンニカ メイNo ratings yet

- Cniai 34686 0003Document45 pagesCniai 34686 0003Nirosha Dilrangi PereraNo ratings yet

- SeminarDocument15 pagesSeminarAditi ChandraNo ratings yet

- 2014 Ifa Phosphate Method PDFDocument21 pages2014 Ifa Phosphate Method PDFsanford siegelNo ratings yet

- Integrated Ferroelectrics: An International JournalDocument10 pagesIntegrated Ferroelectrics: An International JournalBhabani Sankar SwainNo ratings yet

- Spontaneous Combustion ConversionDocument68 pagesSpontaneous Combustion ConversionRizwan Ullah BaigNo ratings yet

- 309-King Agar-110991 PDFDocument1 page309-King Agar-110991 PDFSneyder MurciaNo ratings yet

- Chemical Properties of Food-1Document47 pagesChemical Properties of Food-1Mbabazi Jackson CalmaxNo ratings yet

- 2 Basic Clinical Genetic - ppt-1Document24 pages2 Basic Clinical Genetic - ppt-1Najib M. NauvalNo ratings yet

- FuelsDocument22 pagesFuelsADITYA GAURNo ratings yet

- Limites condenatorios aceite en MeritorDocument4 pagesLimites condenatorios aceite en MeritorJavier H Durán ValeroNo ratings yet

- ASTM G5-94 Standard Practice PDFDocument12 pagesASTM G5-94 Standard Practice PDFMarcela BaronaNo ratings yet

- Assignment 2Document1 pageAssignment 2Varun PahujaNo ratings yet

- Chem 2 Course OutlineDocument15 pagesChem 2 Course Outlineapi-607966786No ratings yet

- MScSYChem18 19Document40 pagesMScSYChem18 19kumarNo ratings yet

- Oil Debate Chromatography PPT 2Document17 pagesOil Debate Chromatography PPT 2Eridha TriwardhaniNo ratings yet

- FINALSDocument8 pagesFINALSSeenpai23No ratings yet

- Chemistry SBA7 ReportDocument6 pagesChemistry SBA7 ReportSam ChanNo ratings yet

- Index TO XV: ArsphenamineDocument7 pagesIndex TO XV: ArsphenamineAlex12No ratings yet

- Application of Industrial and Agricultural Waste For Sustainable Construction PDFDocument9 pagesApplication of Industrial and Agricultural Waste For Sustainable Construction PDFJayesh MagarNo ratings yet