Professional Documents

Culture Documents

Chapter 7 Forecasting

Uploaded by

Raghuram SeshabhattarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 7 Forecasting

Uploaded by

Raghuram SeshabhattarCopyright:

Available Formats

Chapter 7 - Forecasting

Chapter 7 Forecasting

Expired surplus swine flu vaccines to be incinerated. Another estimated 30 million doses will expire soon.1 The above headline is an example of a forecasting faux pas. The need for Swine Flu vaccine was obviously forecast wrong. The above referenced article states, About a quarter of the swine flu vaccine produced for the .S. public has expired ! meaning that a whopping "# million doses worth about $%&# million is being written off as trash.' This is a very serious forecasting error. This is not the only forecasting error in business. (ut it does show the need to have a good forecast ) especially important in forecasting the need or demand for perishable items such as the Swine Flu vaccine. According to reports on the %##*+%#,# Swine flu vaccine approximately "-. of the vaccines will be destroyed. The story of the swine flu vaccine was the sub/ect of business case studies for the ability to react, forecast and produce the vaccines. The Food and 0rug Administration, the 1enter for 0isease 1ontrol, and the manufacturers will now become the sub/ect of case studies for the inability to forecast properly and get the product to the mar2et in time to be used by the consumers. Forecasting has impacts on multiple areas of the operations management chain. Ta2e a loo2 at some of the 2ey areas of the chain impacted by forecasting3 4The impacts on each of these areas will be clear by the end of the chapter.5

Srobbe, Mike, Associated Press, http://www.news-sentinel.co /apps/pbcs.dll/article! A"#$/S%/&'1''7'1/(%)S/7'1'*+&, accessed ,-l. 1/, &'1'

Chapter 7 - Forecasting

6 6

Sales a forecast of what the company will sale. Production a forecast of what should be made to meet the sales forecast.

Inventory a forecast of how much the company should have in finished goods to meet normal demands and to cover fluctuations in demand.

Facilities a forecast of how large the facility should be and where should the facility be.

Raw

aterials a forecast of how much should the

company have in raw materials to meet the production forecast 6 People a forecast of how many people are re!uired to support the customer and to ma"e the products necessary to support the production forecast. 6 Profits a forecast of how much profits the company will ma"e based on the other forecasts. 6 Products a forecast of what products the company should ma"e now and in the future# as well as a forecast of what

&

Chapter 7 - Forecasting

products should be retired or eliminated as they reach their planned end of life. Forecasting may be accomplished using a number of different models and techniques. 7e could spend the entire semester on forecasting models and techniques. The goal of this chapter is to provide the operations manager tools necessary to ma2e educated forecasts in order to support decision ma2ing and the requirements placed on the managers by their bosses. Forecasts can be presented in graphs, tables, spreadsheets and can even be used in what if' analyses to improve operations for the company. 8egardless of how the forecast is used and presented9 regardless of what technique or formula is used, the 2ey is to use a presentation technique that the boss understands and that you understand and can explain in plain language to the boss and his+her advisors. 8egardless of the value of the forecast, if you cannot explain how the forecast was derived, it will be of no value to you, the boss or the company. $%amples of using the wrong forecasting model 6 Ira! Rebuilding. The original forecast for the rebuilding of :raq was based on the intelligence provided at the time. This proves that a forecast with flawed information will be a flawed forecast. The forecast was for a very short occupation and a very quic2 rebuild of the infrastructure. ;bviously the infrastructure was in worse shape than the intelligence reported and the strength of the insurgency was stronger than the intelligence reported. 6 &verstoc".com'(ig )ots. These two corporations have made a business out of other people<s forecasting errors based on flawed forecasting models.

Chapter 7 - Forecasting

$nd of Season Sales. These sales are obviously a result of flawed forecasts either by the store or the corporation coupled with a push strategy.

*oing out of (usiness sales. A good forecasting model should prevent this type of sale. ;f course sometimes this type of sale comes from the owners /ust getting tired of the business or the owner passes away and the children are not interested in 2eeping the family business. =owever, most going out of business sales are the result of bad forecasting on what should be stoc2ed, how much should be stoc2ed and when the stoc2s should turnover.%

+hat is Forecasting, Forecasting is simply a prediction of a future event. >ost common forecasts involve what will happen with the weather tomorrow or for the wee2end. :n operations management we are still concerned with forecasts. 0epending on the where we are in the operations management chain, the weather forecast may be important. =owever, we are really concerned with how much we need to have, ma2e, stoc2, ship or return. :n the operations management chain the true benefits of forecasting will be the amount of inventory remaining at the end of the season or the ability to meet the need of the customer. Forecasting based on historical data ma2es the assumption that the events of history will repeat themselves. Principles of Forecasting 6 The first and most important principle of forecasting is that forecasts are usually wrong. :n fact, forecasts are always wrong. There are lots of models and techniques for forecasting, but there is no way to accurately forecast the future.

&

)e will disc-ss the concept o0 in1entor. t-rno1er d-ring the disc-ssions o0 in1entor.

anage ent.

Chapter 7 - Forecasting

?very forecast should include an estimate of error. Actually, every good forecast should and usually does have an estimate of error. The estimates that are made every election year based on the polls have a margin of error. This margin of error tells the user of the forecast how accurate the forecaster believes the forecast to be.

Forecasts are more accurate for families or groups. This is the rule of aggregation. The forecast for the product family should always be more accurate than the forecast for the individual models or colors. Automobile manufacturers can more accurately forecast the number of a particular car model that will be sold than they can forecast the number of red ones, blue ones or yellow ones that will be demanded by the customer. A printer of college T@shirts should be able to better forecast how many of a particular slogan shirt will sell than they will be able to forecast the colors and siAes that will be demanded by the customers.

Forecasts are more accurate for nearer periods. The closer the event is the more accurate the forecast should be. ?ven in the weather forecasting business it is easier to forecast tomorrow<s weather than to forecast next wee2<s weather. :t is easier to forecast the sales for this wee2 than the sales for next year. ;ne company that : recently wor2ed with had a series of forecasts. They forecasted sales eleven wee2s out with an accuracy of &*. 4there was no reason for a forecast that far out except, 7e<ve always done it that wayB' : am guessing somewhere in the past this corresponded to their replenishment times5. They also forecasted four wee2s out with an accuracy of about *#. 4this actually was tied to their current replenishment cycle time5. And, they had a forecast for next wee2<s sales that was about *C. accurate. This company<s forecasts help to prove the theory that the closer to the event the more accurate the forecast. The most amaAing thing about this

Chapter 7 - Forecasting

company was that the only forecast that they reported to their corporate management was the eleven wee2 forecast 4because they had always reported that forecast5. -he Importance of Forecasting The ability to forecast as accurately as possible may very well impact the profitability of the company and the stoc2 of the company. :n addition, the ability to improve demand forecasting for customer demands and then sharing that information downstream will allow more efficient scheduling and inventory management throughout the entire operations management chain. :n ,**D (oeing wrote off $%.& billion as a result of forecasting errors by themselves and their suppliers. They deemed these shortages as not only raw material shortfalls 4read that to be a forecasting error5 but also internal shortfalls and supplier shortages as well. ?ach of these shortfalls, internal and external, were the result of forecasting errors, very expensive forecasting errors. A few years earlier in ,**-, S Surgical suffered from forecasting errors that resulted in excess supplies that ended up costing the company approximately $%% million, representing a %C. decrease in sales. This forecasting mista2e came from not 2nowing what their customers had in stoc2 at the hospitals. Enowing the customer and the customers< requirements is essential to accurate forecasts. :n ,**", the Aetna computer was unveiled by :(>. This was supposed to be the greatest' new personal computer on the mar2et. The problem was that :(> under@ forecasted the demand for the computer resulting in a potential cost in millions in lost sales' according to the 7all Street Fournal. As we will see, forecasting for new products is much

Chapter 7 - Forecasting

more difficult than forecasting for the demand for an existing product. :(> learned this lesson the hard way. :n %#,# a leading sporting goods retailer sent out a flyer for a sale on a Saturday morning. This particular flyer contained an ad for a fly fishing rod and reel combination. This company had this fly rod for sale for a four hour period and thought that they had forecasted enough rods to last the entire four hour period of the special sale. nfortunately for this retailer, the forecast was only off by about two hours. The result was having to place another more expensive rod on sale to meet the demands of customers that came from several states to shop the specials. Forecasting is essential for smooth operations of business organiAations. Forecasting provides the company with estimates of the occurrence, timing, or magnitude of uncertain future events. Forecasting is not free ) there are costs associated with forecasting future demand or future events for the company. These costs to provide a smooth operation include the costs of lost revenues from forecasting wrong as we saw with :(> when forecasting on the short side. ;n the other side of the forecast are the costs of having too many people or too few employees on the /ob or in the factory+store9 excess materials or material shortages9 or having to expedite shipments and paying for expedited freight to meet customer due dates. :f forecasting is so important to the company and the operations management chains how do you ensure that you get the right data in order to improve the forecastsG The first tip is to capture the data in the same way that you will be using the data. :f the forecast is for a monthly period, the data capture has to be in monthly time buc2ets. :f your forecast is for daily demand or daily production, monthly data will not wor2. ;ne company wanted to ta2e daily data and extrapolate hourly production from the daily data. 7hat the company wanted

Chapter 7 - Forecasting

to do was ta2e eight hours of demand data and average it over the day. The problem with this technique is that in actuality none of the hours had the average demand. :f there are certain circumstances that may s2ew the data if not ta2en into consideration, these should be recorded. An example of this is the impact on building materials after =urricane Eatrina. (uilding material demand actually increased the cost of materials by almost ,#. as far away as Eansas. Another area that may impact the ability to more accurately forecast demand or production may be to separate customers into different demand groupings. This is basically what Heneral >otors used to do with the 1hevrolet 4the wor2ing man<s car5, Iontiac, ;ldsmobile, (uic2 and 1adillac. :f customers are segmented for mar2eting purposes, their demands and resultant forecasts should also be segmented. Forecasting inaccuracies 4forecasting errors ) more on this later in the chapter5 can increase the total cost of ownership for the company for products being produced or stored. These increased costs come in the form of3 :ncreased inventory carrying costs as a result of forecasting the production of more product than the customer is buying. ;bsolete inventory 4although this may be considered part of carrying costs5 as a result of grossly over forecasting to the point that there is so much stuff on the shelf that it becomes obsolete before it can be sold. This is common in the electronics industry where items become obsolete about ninety days after produced and in the fresh foods industry. Jot forecasting for sufficient quantities of raw materials to meet production levels and having to expedite more materials in or worse accept less than quality

Chapter 7 - Forecasting

materials to ma2e up for the shortfall in the forecast. This particular problem results in the potential of producing substandard quality because of the substandard materials substituted for the forecasting shortfalls. The cost of expediting finished products to the customer to meet customer due dates or required delivery dates as a result of the forecasting shortfalls. (ecause the product is not ready in time to meet normal delivery methods, the company may be forced to ship via expedited delivery in order to 2eep customers satisfied. -he Role of Forecasting in &perations anagement

:n supply chain management forecasting, as we saw in 1hapter C, is critical to the overall success of the supply chain. :n the short term, the forecast is critical to the production of products. This includes the forecasting of the raw materials, components, assemblies and sub@ assemblies, the forecasting of the personnel necessary to ma2e the supply chain operate effectively, and the forecasting of where the finished goods should be stored based on demand forecasts. :n the long term, forecasts are necessary to predict the requirements and demand for new products and how many of the new products should be stoc2ed and where they should be stoc2ed. The processes and facilities necessary for the production and storage of new products is part of the long term supply chain forecast. Since the goal of the operations management chain is to satisfy customer demand, a forecast is necessary to meet the production, distribution and quality to meet the customers< demands. The forecast has to be robust enough to ensure an uninterrupted flow of products and+or services for the customers. The strategic plan of the company has to include some form of

Chapter 7 - Forecasting

forecasting in order to plan where the company needs to be in the future and what capacity the company will have to have in order to meet these forecasts. This strategic plan and the ability to meet the forecasts in the strategic plan for publicly held companies are very closely watched by 7all Street. Sometimes companies play games with their forecasts and production to meet the forecasts. Erispy Ereme 0oughnuts tried to do this. Several years ago as Erispy Ereme tried to pump up their production and shipment numbers and the resulting forecasts for future production. Seems Erispy Ereme was not actually selling and shipping the numbers of doughnuts that they were reporting. The company was actually shipping the doughnuts to their retail customers 4grocery stores and convenience stores5 at the end of reporting periods with the understanding that the retailers would not be charged for the extra amount of doughnuts shipped. After the reporting period was closed out, Erispy Ereme would have the retailers ship the excess doughnuts bac2. The quantity shipped and the not actual sales quantity was reported thus s2ewing the forecasts for future sales and drove the stoc2 price through the roof. 7hen this deceptive practice was discovered the price went from approximately $"# per share to $" per share almost overnight. The darling of 7all Street crashed and seven years later the stoc2 price is still depressed. Forecasting -echni!ues There are basically two commonly used techniques 4not methods5 for forecasting or predicting future events+demand+production. ?xtrinsic Forecasting Technique. 7ith ?xtrinsic Forecasting, the forecast for the future is based on external indicators that are related to the product being

1'

Chapter 7 - Forecasting

forecasted. For example, a distributor of refrigerators may use the extrinsic technique to forecast sales of refrigerators based on the historical correlation between the sales of new homes and the sales of refrigerators. Another example3 ?very summer approximately K## mid@grade S Army ;fficers move to Fort Leavenworth, Eansas for a year@long :ntermediate Level ?ducation program. These officers and their families transfer in to Fort Leavenworth from all over the world and include foreign officers attending the education program. ?xtrinsic forecasting techniques would allow local merchants to base their stoc2s of household products on the number of families moving into the area and the historical correlation between families moving into the area and the number of household products such as blinds, cleaning supplies, rugs, etc., are sold. :ntrinsic uses straight historical data to forecast future demand or production. These techniques are more common and will be discussed in greater detail by loo2ing at the different methods of forecasting used under the :ntrinsic Forecasting umbrella. Intrinsic Forecasting :ntrinsic forecasting basically falls into two categories of methodologies. These methodologies are qualitative and quantitative methods. Mualitative forecasting is based on sub/ective methods when quantitative data is not available. 1onversely, quantitative forecasting is based on mathematical models and formulas.

11

Chapter 7 - Forecasting

.ualitative Forecasting Mualitative forecasting is sub/ective in nature. :t is based on best guesses, opinions and /udgment. A Mualitative forecast may be used for mar2eting, production or purchasing decisions. The problem with opinion based forecasts or expertise based forecasts is that it is critical to have a well experienced person ma2ing the forecast. Anyone can ma2e a forecast based on an opinion but if the opinion is not based on experience in that particular area, the forecast may not be of any value. Another qualitative technique used in academia frequently is the 0elphi method of forecasting. The 0elphi method uses a panel of experts' to come to a consensus to ma2e forecasts or predictions for the future. The 0elphi methodology ta2es its name from the ;racles of 0elphi in Hree2 >ythology. This technique<s validity is obviously dependent on pic2ing the right experts' for the panel. Several years ago, : had the opportunity to participate in a 0elphi panel loo2ing at the future trends that would affect supply chains into the future. The panel submitted a list of potential trends. These lists were consolidated and redistributed to the panel members for ran2 ordering of the trends. The top %C trends were sent out again to the panel with the goal to get the top ,# trends that would impact supply chain management in the future. 7e were fairly accurate9 however, the panel of experts' did not forecast the increase in fuel+crude oil prices that hit supply chains in %##K or the recession that followed closely in late %##K+early %##*. =ad we possessed the expertise' to foresee these issues, we would all probably be retired now from shorting the stoc2 mar2et and placing the timely puts and calls on oil futures.

1&

Chapter 7 - Forecasting

.uantitative

ethods

Muantitative methods for forecasting employ the use of mathematical formulas and calculations to predict the future. These models and calculations ma2e the assumption that what happened in the past will happen in some form in the future. Mualitative methods may ta2e the form of a linear trend line, a regression analysis, an average, a moving average, a weighted average or another more complicated method. ?ach of these methods loo2s at the trends, cycles, seasons, random events that may impact the forecast and indices from business that may also impact the forecast. :n %##C the Fortune (usiness 1ouncil conducted a survey on what indices companies used to shape their forecasts. Some of these indices are still used very frequently today and some of them have greater importance now than they did in %##C. The 1onsumer Irice :ndex is still frequently used, the price of a barrel of oil is much more prominent in shaping forecasts today than it was in %##C after the $,"# a barrel price in %##K. As a result of the recession of %##K@%#,#, everyone is aware of the unemployment rates and considers these rates as part of the forecasting process. A -rend is a gradual up or down movement in the demand of the product. A trend can be used to predict what will happen in the future. :t is important for a firm to 2now where they are in the trend in order to accurately forecast the future. The ability to spot a trend, up or down, is critical to the forecaster and his+her company. Figure D., and Figure D.% show trend lines.

1*

Chapter 7 - Forecasting

Figure 7./ 0pward -rend )ine

Figure 7.1 2ownward -rend

A Cycle is usually tied to a business cycle. A cycle is a repetitive upward and downward movement of the production or demand for a product. Fust li2e the trend, it is important for the forecaster to 2now where in the cycle his or her product or company is at

1+

Chapter 7 - Forecasting

the time of the forecasted period. Jot 2nowing where they were in the cycle is what helped to deepen and lengthen the 8ecession of %##K@%#,#. 1ompanies that did not identify where they were in the business cycle continued to produce products based on the previous trend and not the new business cycle that was spiraling downward. Figure D.- shows a cycle for the sales of a product.

Figure 7.3 $%ample of a Cycle A Seasonal pattern could possibly be trend line with spi2es during certain seasons. ;r, the seasonal pattern may be more obvious as shown in Figure D." below. Seasonal items show a propensity to be sold in certain periods of the year. :n Eansas, the sale of snow shovels is, than2fully, a seasonal item. Swimsuits in most parts of the country are seasonal items. 7inter coats are also seasonal items. The sale of tur2eys is seasonal in nature. The ma/ority of tur2eys sold in the nited States are sold in the fourth quarter ) the largest demand for tur2eys come around Than2sgiving and the 1hristmas holidays. After the holidays, the demand for tur2eys falls off dramatically.

12

Chapter 7 - Forecasting

Figure 7.4 $%ample of a Seasonal Pattern -ime Series .uantitative ethods

Time series methods are statistical methods that use historical data with the assumption that the historical patterns will repeat themselves in the future. For the application of these techniques to operations management and supply chain management forecasting, we will focus on moving averages, weighted moving averages, exponential smoothing and seasonal forecasting. =owever, a discussion of forecasting would not be complete without a discussion of the simplest technique of all ) the 5a6ve Forecast. The JaNve Forecast is very easy to use. :t simply assumes that whatever happened last period will repeat itself exactly in the next period. :n Figure D.C the use of the JaNve Forecast can be seen. 7hatever was demanded in the previous month is forecasted for the next month.

13

Chapter 7 - Forecasting

A"tual %emand January $ebruary Mar"# April May June July August 75 !0 125 1 0 150 175 185 125

$ore"asted %emand

75 !0 125 1 0 150 175 185

Figure 7.78 5a6ve Forecasting The Simple oving 9verage Forecast is also a simple methodology to use to forecast

future demand, production or shipments. Stoc2 mar2et analysis usually starts with a moving average to show the trend line for the mar2ets. 7ith this technique all the forecaster to doing is averaging the demand+sales+production for previous periods. Formula 7./ is the formula for calculating the moving average3 Sum of periods data Number of periods

Moving Average =

Formula 7./ Simple

oving 9verage

sing the same data as in Figure D.C, Figure D.& shows the forecast using a - month and C month moving average. 7hich one is betterG That depends on some historical analysis of the forecasts.

17

Chapter 7 - Forecasting

7e will discuss forecast error and comparing the techniques in another section. For example purposes to understand the calculations, Figure D.& shows the decimal places in the forecast, as we move from the academic calculation to the concrete forecast for the business, we need to round to the next whole number. The rationale for this is that we cannot ma2e a #.&&&&&D of a product, therefore in the example below9 the forecast for April using the - month moving average should be rounded to *D. The moving average is a good technique when forecasting for products that are in a trend and have relatively stable demand patterns.

onth oving 9verage 9ctual Forecasted 2emand 2emand Calculation :anuary 77 February ;< arch /17 9pril /3< ;=.=====7 >77?;<?/17@'3 ay /7< //7 >;<?/17?/3<@'3 :une /77 /37 >/17?/3<?/7<@'3 :uly /A7 /7/.====7 >/3<?/7<?/77@'3 9ugust /17 /7< >/7<?/77?/A7@'3 Figure 7.= Simple

7 onth oving 9verage Forecasted 2emand

//4 /34 /73

oving 9verage Forecast

-he +eighted

oving 9verage oving 9verage method sometimes creates confusion with students the

The +eighted

first time they encounter forecasting. The 7eighted >oving Average method does not involve any division as in the Simple >oving Average method. This method is called 7eighted >oving Average because weights are assigned to the data. The weighs are usually provided by the

1/

Chapter 7 - Forecasting

forecasting team, mar2eting department based on the validity of the data or the manufacturing department based on their assessment of the data. The weights may be sub/ectively assigned which may reduce the value of the forecast. The weights can be used to place more emphasis on the most recent data by placing a higher weight on the most recent data or can be used to place more importance and value on the older data by weighting that data more heavily. All of the weights must add up to ,. The weights are multiplied by the corresponding data and all of the products of the multiplication are added together to get the forecast. The goal of this method is to ta2e into account data fluctuation. The formula for the 7eighted >oving Average method is shown in Formula 7.1 while Figure D.D shows the forecast using our previous data3 >weight / % data /@ ? >weight 1 % data 1@ ? >weight 3 % data 3@ Formula 7.1 +eighted oving 9verage

9ctual 3 onth +eighted oving 2emand 9verage Forecast +eight :anuary 77 February ;< arch /17 9pril /3< ay /7< <./7 :une /77 <.3 :uly /A7 <.77 9ugust /17 /7=.77 >./7B/7<@?>.3B/77@?>.77B/A7@

11.7 71.7 /</.77 /7=.77

Figure 7.7 +eighted

oving 9verage $%ample

14

Chapter 7 - Forecasting

So far we have forecasted August<s demand to be ,D# using a - >onth Simple >oving Average, ,C- using a C >onth Simple >oving Average, and ,DD 4,D&.C5 using a - >onth 7eighted >oving Average. $%ponential Smoothing Forecasting The $%ponential Smoothing method is widely used in business to help shape a more accurate forecast. Li2e the +eighted oving 9verage method, this method also uses weights to

smooth the forecast. And li2e the 7eighted >oving Average, the weights have to add up to ,. This method uses a smoothing factor 4C5. The smoothing factor has to be between # and ,3 >< D C E /@ The closer the smoothing factor is to ,, the emphasis is being placed on the most recent data9 consequently, the closer the smoothing factor is to #, the more emphasis that is being placed on the older data. There are three basic steps to applying the ?xponential Smoothing method to create a forecast3 ,. The first period that will be forecasted using this method will be the JaNve Forecast ) the actual demand+production+sales from the previous period. %. The next period forecasted will use Formula 7.3, ?xponential Smoothing Forecast by ta2ing the A1T AL 0?>AJ0 from the I8?O:; S I?8:;0 multiplied by the smoothing factor. Forecast F >9ctual 2emand Previous Period % C@ ? >Previous 2emand % >/GC@@ Formula 7.3 $%ponential Smoothing Forecast

&'

Chapter 7 - Forecasting

-.

sing Formula 7.3 multiply the F;8?1AST from the I8?O:; S I?8:;0 by 4,@ the smoothing factor5 and A00 that to the calculation in Step %.

Figure D.K shows an example of ?xponential Smoothing Forecasting using the same data that we have used for the other forecasting methods.

A"tual %emand January $ebruary Mar"# April May June July August 75 !0 125 1 0 150 175 185 125

$ore"ast

1

75'00 8,'00 108'(0 121',, 1 8'58 1(0', 175'17

-al"ulations. Mar"# April May June July August &'()!0* + &',)75* &'()125* &'()1 0* + + &',)8,* &',)108'(* &'()150* + &',)121',,* &'()175* + &',)1 8'58* &'()185* + &',)1(0', *

Figure 7.Aa8 $%ponential Smoothing Forecasting with .= Smoothing Factor

&1

Chapter 7 - Forecasting

A"tual %emand January $ebruary Mar"# April May June July August Smoot#ing $a"tor = '7 -al"ulations. Mar"# April May June July August &'7)!0* + &' )75* &'7)125* + &' )8,* &'7)1 0* + &'7)150* + &' )108'(* &' )121',,* &'7)175* + &' )1 8'58* &'7)185* + &' )1(0', * 75 !0 125 1 0 150 175

$ore"ast

1

75'00 85'50 11 '15 12,'!5 1,2',8 1(5'25 17!'07

185 125

Figure 7.Aa8 $%ponential Smoothing Forecasting with .7 Smoothing Factor Seasonal 9dHustments to the Forecast :n some cases a Seasonal 9dHustment may be necessary to provide a more accurate forecast for a period. The Seasonal Ad/ustment is designed to do /ust that. A Seasonal Forecast and forecast factor is necessary when there is a repetitive increase or decrease in the demand tied to a particular set of periods. The sale of winter sports apparel is seasonal by design but becomes even more seasonal in nature every four years after the 7inter ;lympics. As discussed earlier, the sale of tur2eys is seasonal. 7hen a seasonal spi2e is noticed then the seasonal factor can be

&&

Chapter 7 - Forecasting

computed and a Seasonal Ad/ustment made to the forecast. 1omputing the seasonal factor is done using Formula D.". %emand during period /otal %emand Formula 7.48 Seasonal Factor Computation Let<s loo2 at an example to ma2e this concept clearer. SA01S 213 45A3/13 61A3 1 Annual 2007 Sales 2008 200! 172 1!1 21 2( 2 5( 5 1 2 3 125 102 22( 4 2( 720 7 5

Seasonal $a"tor =

Sales for /. F /71?/;/?1/3 F 77=

/otal 57( ! ,5F /<7 1781 Sales for 105 1. F 1=?13?7= Sales for 3. F 3?7?/ F ; Sales for 4. F /17?/<1?11= F 473 -otal Sales for all 3 years F //43 Factor for /. F 77='//43 F .7<3 this tells us the I 7<.3J of all the sales for this product over the past 3 years came in the first !uarter of the year. -he ne%t step is to compute the Simple oving 9verage to forecast 1</< sales F //43'3 F 3A/ as the forecast for total sales in 1</< -o get the Seasonal 9dHusted Forecast8 multiply 3A/ >total annual forecast@ by .7<3 >seasonal factor@ F /;/.=4 F /;1 as the forecast for sales in the first !uarter of 1</<

&*

Chapter 7 - Forecasting

Forecasting 9ccuracy So far we have loo2ed at methods and variations of methods to produce a forecast of future demand, production, sales, or shipments. The purpose of loo2ing at various methods is to allow some what if' analysis to find the most accurate method for our company and our products. Fust because one method wor2ed at your last company does not mean that it will wor2 at your new company. Forecast ?rror is a very simple calculation as shown in Formula 7.7. Forecasting accuracy is simply the actual sales+demand+production minus the forecast. Figure D.* shows the Forecast ?rror using our original example with the - month and C month Simple >oving Averages. Forecast $rror F 9ctual 2emand Forecasted 2emand Formula 7.78 Forecast 9ccuracy

onth oving 9verage 9ctual Forecasted Forecast 2emand 2emand $rror :anuary 77 February ;< arch /17 9pril /3< ;7 ay /7< //7 37 :une /77 /37 4< :uly /A7 /71 33 9ugust /17 /7< G47

onth oving 9verage Forecasted 2emand

Forecast $rror

//4 /34 /73

=/ 7/ G1A

Figure 7.;8 Forecasting $rror

&+

Chapter 7 - Forecasting

Jote that in some months the forecast was over and in some months the forecast was under. Simply adding up the forecasting errors will give a distorted picture of the impact of the forecasting error. Therefore in order to get a more accurate picture of the magnitude of the forecasting error over time, the >ean Absolute 0eviation is used to measure the accuracy of the forecast. Figure D.,# shows the original forecasting example for the - month Simple >oving Average and the calculation of the >ean Absolute 0eviation. This will tell us on average how much our forecast deviated from the actual sales of our product. :t is important to remember that this is an average and you will note that at no point did our forecast actually deviate by -K. This calculation does give us a mar2 on the wall as to how well we are forecasting. /. -he first step is to convert all of the forecast errors to their absolute values. -his simply removing the negative signs in front of the forecast errors when the forecast was short. 1. Sum up all of the absolute values. 3. 2ivide the sum from step 1 by the number of periods that were forecast and you have the ean 9bsolute 2eviation.

&2

Chapter 7 - Forecasting

onth oving 9verage 9ctual Forecasted Forecast 2emand 2emand $rror 9bsolute $rror :anuary 77 February ;< arch /17 9pril /3< ;7 ay /7< //7 37 37 :une /77 /37 4< 4< :uly /A7 /71 33 33 9ugust /17 /7< G47 47 Sum of 9bsolute $rrors ean 9bsolute 2eviation

/73

3A.17

Figure 7./<8

ean 9bsolute 2eviation $%ample

Another method of measuring or gauging the forecast accuracy is called a -rac"ing Signal. A Trac2ing Signal is used to alert the forecaster of when a forecast is out of tolerance. 8emember all forecasts are wrong and a good forecast has a margin of error. The Trac2ing Signal provides an indicator of when the forecast is not within acceptable limits. ;ne rule of thumb states that band of P - >ean Absolute 0eviations 4>A05 is an acceptable Trac2ing Signal. This is also tied to the law of large numbers ) the larger the numbers the more accurate the forecast. :n our example above, if the P - >A0s is the standard then the forecast is not out of tolerance. =owever, if you are running a small company with forecasts for smaller numbers, P >A0s may not be an acceptable Trac2ing Signal. :n that case, a tolerance level based on a certain number of units may be used as the Trac2ing Signal. 7hatever the technique used to

&3

Chapter 7 - Forecasting

establish a Trac2ing Signal, it is important to note that the larger the number the more the forecast is out of tolerance. Forecast Control Some events are out of the control of the forecaster or the company but still may impact the accuracy of the forecast. 8esearch is necessary to determine why a forecast is out of tolerance or out of whac2. Any number of things can impact the demand for your product and therefore impact the accuracy of the forecast. The following is a short list of potential impacts to the forecast accuracy3 Iolitics and political change. :n %##K the nited States made history with the election of the first =awaiian born Iresident and the first surfing Iresident. This caused ripples across the hunting and gun owning world as there was a fear 4based on transition and campaign rhetoric5 that the sale of weapons and ammunition would be severely controlled or banned. This created a run' on the sale of hand guns, rifles, shot guns and ammunition. Such a run that 1abela<s had a record quarter based on the six wee2s of sales after the Jovember election. This had a serious impact on their forecasting for that quarter as well as the forecasts for future quarters to show progress. The appearance of an unexpected business cycle. This is exactly what happened world@ wide in %##K. A new and unexpected business cycle appeared. This cycle is now called the Hreat 8ecession. Forecasts drove manufacturing and retail stoc2s based on a continued growth trend. This drove the recession farther down as a result of increased inventories coupled with severely decreased sales. And, when no one is buying basically

&7

Chapter 7 - Forecasting

no one is selling and the forecasts, based on historical data, become s2ewed and out of tolerance. 1hanges in the weather. After a hurricane the demand for building and rebuilding supplies goes through the roof, no pun intended. The same phenomenon is seen after a ma/or flood. These weather changes impact the accuracy of forecasts that did not include these events and could very well impact future forecasts for demand if the abnormal demand from the weather change is not bac2ed out of the forecast. The appearance of a new competitor. 7hen Lowe<s and (est (uy went into the ma/or appliance business it impacted, or should have impacted, the forecasts of 1ircuit 1ity. Apparently since 1ircuit 1ity is no longer in business and Lowe<s and (est (uy are in the top three sellers of ma/or appliances, 1ircuit 1ity should have altered their forecasts to ta2e into account the new competition. Jot seeing trends. :n the ,*D#s and ,*K#s there was a clothier named >erry@go@8ound. This chain of stores carried the latest in fashions for the high school, college age and young professionals. :t was the darling of 7all Street and consistently out performed the competition. Then in the early ,**#s, >erry@go@8ound did not see a new trend in clothing coming and forecasted the wrong merchandise ) a critical and fatal mista2e in the fashion industry. As a result of not seeing a trend coming, this company, li2e 1ircuit 1ity, is no longer in business.

&/

Chapter 7 - Forecasting

Summary Forecasting has the capability to impact positively or negatively the success or failure of a company. Although forecasts are almost always wrong and a good forecast should have a margin of error, forecasting remains critical to smoothing production, getting the right product on the shelf in the right quantities to meet the customers< needs. (ecause everyone admits that forecasts are almost always wrong, we discussed multiple ways to create a forecast. The different methods of forecasting allow companies to conduct what@if' analyses to twea2 the forecast and get the best method to minimiAe forecasting error.

&4

Chapter 7 - Forecasting

2iscussion .uestions'-hought )eaders'Problems to 9ssist in *rasping the Concepts ,. A 777777777777777777 is an -p-and-down repetiti1e

ti e. o1e ent o1er a long period o0

%. 77777777777777777

ethods o0 0orecasting are based on best g-esses, past e5perience, and other s-b6ecti1e ethods. -. )hat i pacts does 0orecasting ha1e on the operations anage ent chain!

". 7ook at the newspaper or an online article or an Ann-al 8eport 0or a co pan. and see i0

0orecasting is a proble 0or that partic-lar co pan..

C. 1alculate the - and C month Simple >oving Average for the following data3 onth oving 9verage 9ctual Forecasted 2emand 2emand 177 /;7 17< 177 317 4<< 117 177 3 7 onth oving 9verage Forecasted Forecast 2emand $rror

1<<1 1<<3 1<<4 1<<7 1<<= 1<<7 1<<A 1<<; &.

sing the data above calculate the >ean Absolute 0eviation for the forecast error for both the - and C month calculations.

*'

Chapter 7 - Forecasting

D.

sing the table below and the following weights, calculate the 7eighted >oving Average starting in %##C. >ost recent data Q ."C9 next previous data @ .-C9 next previous data Q .%

1<<1 1<<3 1<<4 1<<7 1<<= 1<<7 1<<A 1<<; K.

+eighted 9ctual oving 2emand 9verage 177 /;7 17< 177 317 4<< 117 177 sing a smoothing factor of R Q .DC, calculate the forecast for the following sales data3 9ctual 2emand Forecast //<< //17 //17 /3<< ;7< 1<<< 1/<< 17<<

:anuary February arch 9pril ay :une :uly 9ugust September Smoothing Factor F .77 *.

sing the data above, calculate the forecast through September using a smoothing factor of ."C.

,#. 7hich of these forecasting calculations provides the company with the most accurate forecastG

*1

Chapter 7 - Forecasting

,,. Thin2 of a situation, politically or otherwise, where the actions may have impacted the forecast.

*&

You might also like

- Decision TreesDocument10 pagesDecision TreesMarketing ExpertNo ratings yet

- Decoding DuPont AnalysisDocument3 pagesDecoding DuPont AnalysisShalu PurswaniNo ratings yet

- Premier Bank HR Case StudyDocument31 pagesPremier Bank HR Case StudyacidreignNo ratings yet

- Presentation Week 1 - BSBHRM513Document10 pagesPresentation Week 1 - BSBHRM513Xavar XanNo ratings yet

- Demand Forecasting Pharma Supply Chains Case StudyDocument25 pagesDemand Forecasting Pharma Supply Chains Case StudyAviral AroraNo ratings yet

- AFP History TimelineDocument22 pagesAFP History TimelineBrendan Lewis DelgadoNo ratings yet

- Strategic HR Call Center Case StudyDocument16 pagesStrategic HR Call Center Case StudyRaza Y MoghalNo ratings yet

- Human Resource Notes Planning RecruitmentDocument3 pagesHuman Resource Notes Planning RecruitmentfirdhauzpopoNo ratings yet

- Operations Management Chap-1Document32 pagesOperations Management Chap-1khantiger100100% (1)

- Common Elements, Uses & DescriptionsDocument3 pagesCommon Elements, Uses & DescriptionsTaibah Nurwahidah Mohamad0% (1)

- Chapter 14 - : Materials PlanningDocument42 pagesChapter 14 - : Materials Planningoryz agnuNo ratings yet

- Introduction To Operations ManagementDocument23 pagesIntroduction To Operations ManagementAzeem MirzaNo ratings yet

- The Strategic Position: Johnson, Whittington and Scholes, Exploring Strategy, 9 Edition, © Pearson Education Limited 2011Document43 pagesThe Strategic Position: Johnson, Whittington and Scholes, Exploring Strategy, 9 Edition, © Pearson Education Limited 2011Radu Elena MadalinaNo ratings yet

- Operations ManagementDocument3 pagesOperations ManagementKim Cristian MaañoNo ratings yet

- Chapter 4 - : E-Commerce and Supply Chain ManagementDocument31 pagesChapter 4 - : E-Commerce and Supply Chain Managementkl25No ratings yet

- OPM101Chapter12 000Document51 pagesOPM101Chapter12 000N Satish MohanNo ratings yet

- Opm101chapter8 000Document43 pagesOpm101chapter8 000Manprita BasumataryNo ratings yet

- Types of DemandDocument31 pagesTypes of DemandVeera MuthuNo ratings yet

- Chapter 1Document11 pagesChapter 1Areef Mahmood IqbalNo ratings yet

- Walmart's HRM - HR Planning, Job Analysis & Design - Panmore InstituteDocument6 pagesWalmart's HRM - HR Planning, Job Analysis & Design - Panmore InstituteNamita Dey0% (1)

- Case 03 02 Frito LayDocument16 pagesCase 03 02 Frito LayGunjan ShethNo ratings yet

- Membership Status Verification Slip MembDocument1 pageMembership Status Verification Slip MembDaye anne marie tolibasNo ratings yet

- Brooks 3e PPT 09Document73 pagesBrooks 3e PPT 09Israa RamadanNo ratings yet

- Inventory Management: Mcgraw-Hill/IrwinDocument24 pagesInventory Management: Mcgraw-Hill/Irwinsankalp pandey0% (1)

- The Impact of Effective Work Design in Achieving Profitability in Organization (A Case Study of Selected Companies in Nigeria)Document9 pagesThe Impact of Effective Work Design in Achieving Profitability in Organization (A Case Study of Selected Companies in Nigeria)Yus EfendiNo ratings yet

- SUMMARY Linking The Balanced Scorecard To Strategy SummaryDocument4 pagesSUMMARY Linking The Balanced Scorecard To Strategy SummaryCamilleNo ratings yet

- Template For Breakout Activity 2Document6 pagesTemplate For Breakout Activity 2M Rahman0% (3)

- HQP-HLF-063 Membership StatusDocument1 pageHQP-HLF-063 Membership StatusMaria Roschel Salvador100% (1)

- Operational Research NotesDocument18 pagesOperational Research Notesdypdbm75% (4)

- Forecasting Models Under 40 CharactersDocument8 pagesForecasting Models Under 40 Characterslovely abinalNo ratings yet

- Organizational Structure and DesignDocument31 pagesOrganizational Structure and DesignPata NheNo ratings yet

- Process Analysis - Little's LawDocument16 pagesProcess Analysis - Little's LawSarah Zazella100% (1)

- Capacity Planning - Pdfcapacity PlanningDocument3 pagesCapacity Planning - Pdfcapacity PlanningPranjeet ChakravartyNo ratings yet

- Capacity PlanningDocument47 pagesCapacity Planningcharles makasabiNo ratings yet

- Lesson 8 - Supply Network DesignDocument39 pagesLesson 8 - Supply Network DesignDerrick Maatla Moadi100% (1)

- Lay Inc. (A) CaseDocument22 pagesLay Inc. (A) Casesatendra121No ratings yet

- Army Capstone Concept V 2 7.2 (DRAFT)Document55 pagesArmy Capstone Concept V 2 7.2 (DRAFT)pkryanNo ratings yet

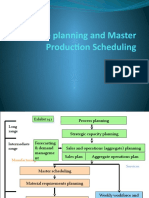

- Aggregate Planning and Master Production SchedulingDocument17 pagesAggregate Planning and Master Production SchedulingAshwani Singh100% (1)

- Finantial Statement AnalysisDocument19 pagesFinantial Statement AnalysisShaekh AzmiNo ratings yet

- Business Model Innovation The Strategy of Business Breakthroughs, by Langdon MorrisDocument3 pagesBusiness Model Innovation The Strategy of Business Breakthroughs, by Langdon MorrisInternational Journal of Innovation ScienceNo ratings yet

- Stevenson 13e Chapter 9Document39 pagesStevenson 13e Chapter 9Harold WasinNo ratings yet

- Operations Management: Sustainability and Supply Chain ManagementDocument64 pagesOperations Management: Sustainability and Supply Chain ManagementAbdullah S.No ratings yet

- Mba 5101: Advanced Quanitative Business AnalysisDocument1 pageMba 5101: Advanced Quanitative Business AnalysisAtiqul IslamNo ratings yet

- DuPont AnalysisDocument15 pagesDuPont Analysisgarconfrancais06No ratings yet

- Clarifying the Link Between Entrepreneurial Orientation and PerformanceDocument24 pagesClarifying the Link Between Entrepreneurial Orientation and PerformanceMaricielo Q. LlerenaNo ratings yet

- The Mechanics of Double-Entry Accounting: Slide 4.1Document23 pagesThe Mechanics of Double-Entry Accounting: Slide 4.1muhammadtaimoorkhan100% (3)

- Aggregate Planning Strategies and Cost AnalysisDocument17 pagesAggregate Planning Strategies and Cost AnalysisTina HumphreyNo ratings yet

- Group 7 Homework Chap 6 Introduction To POMDocument7 pagesGroup 7 Homework Chap 6 Introduction To POMLâm NguyễnNo ratings yet

- Maximizing profit for newspaper salesDocument12 pagesMaximizing profit for newspaper salesBhargav D.S.No ratings yet

- Chapter 9 Layout StrategyDocument51 pagesChapter 9 Layout StrategyHimanshu TipreNo ratings yet

- Professor Blake OPM 101 Name - Spring 2009 EXAMINATION 2, Version ADocument6 pagesProfessor Blake OPM 101 Name - Spring 2009 EXAMINATION 2, Version ASivaMarojuNo ratings yet

- Exploring Corporate Strategy: Gerry Johnson, Kevan Scholes, Richard WhittingtonDocument26 pagesExploring Corporate Strategy: Gerry Johnson, Kevan Scholes, Richard Whittingtonnazish143No ratings yet

- Case ChaseDocument6 pagesCase ChaseVinay GatagatNo ratings yet

- Heizer Om12 Ch06 FinalDocument73 pagesHeizer Om12 Ch06 FinalBahri Karam KhanNo ratings yet

- Lecture 1 On Feasibility Nature of BusinessDocument4 pagesLecture 1 On Feasibility Nature of BusinessJanet T. CometaNo ratings yet

- Technology Management AssignmentDocument11 pagesTechnology Management AssignmentVarinder AnandNo ratings yet

- Chapter 2 The Management EnvironmentDocument24 pagesChapter 2 The Management EnvironmentHaris FadillahNo ratings yet

- Lecture 5 - Product StrategyDocument30 pagesLecture 5 - Product StrategyWeeHong Ngeo100% (1)

- Forecasting NotesDocument14 pagesForecasting NotesDaniel MueniNo ratings yet

- Stock Pitch 2002Document4 pagesStock Pitch 2002jibranqqNo ratings yet

- Improving Airport Capacity Asset Utilisation Oi ConsultingDocument3 pagesImproving Airport Capacity Asset Utilisation Oi ConsultingRaghuram SeshabhattarNo ratings yet

- Employee Absenteeism StudyDocument64 pagesEmployee Absenteeism StudyRaghuram SeshabhattarNo ratings yet

- Indiainfoline Stock Prices As On 2007Document57 pagesIndiainfoline Stock Prices As On 2007Raghuram SeshabhattarNo ratings yet

- Cell Biology PDFDocument35 pagesCell Biology PDFLega Wann0% (1)

- VTJCC02Document13 pagesVTJCC02Raghuram SeshabhattarNo ratings yet

- A Study On Need Analysis For Training in An OrganizationDocument56 pagesA Study On Need Analysis For Training in An OrganizationRaghuram SeshabhattarNo ratings yet

- A Comparative Study of NpaDocument55 pagesA Comparative Study of NpaRaghuram SeshabhattarNo ratings yet

- Capital BudgetingDocument12 pagesCapital Budgetingjunhe898No ratings yet

- Courses Offered by GyanfinderDocument1 pageCourses Offered by GyanfinderRaghuram SeshabhattarNo ratings yet

- Article On Venture Capital Funding ProcessDocument12 pagesArticle On Venture Capital Funding ProcessRaghuram SeshabhattarNo ratings yet

- Sebi ReportDocument140 pagesSebi ReportRaghuram SeshabhattarNo ratings yet

- Ray Optics ModifyDocument178 pagesRay Optics ModifyRaghuram SeshabhattarNo ratings yet

- Consumer Durables Industry in IndiaDocument22 pagesConsumer Durables Industry in IndiaRaghuram SeshabhattarNo ratings yet

- 05 F10 Consumer BehaviorDocument37 pages05 F10 Consumer BehaviorHemanta Kumar DashNo ratings yet

- Article On HR and Multi Variate AnalysisDocument10 pagesArticle On HR and Multi Variate AnalysisRaghuram SeshabhattarNo ratings yet

- Ashish Kumar Vidyarthi Long Term Performance of Indian IPOs Finance ThesisDocument13 pagesAshish Kumar Vidyarthi Long Term Performance of Indian IPOs Finance ThesisRaghuram SeshabhattarNo ratings yet

- Article by Mr.s.raghuramDocument21 pagesArticle by Mr.s.raghuramRaghuram SeshabhattarNo ratings yet

- P4223Document68 pagesP4223Raghuram SeshabhattarNo ratings yet

- Critical Success Factors in M&A ProjectsDocument101 pagesCritical Success Factors in M&A ProjectsjerinleNo ratings yet

- P4223Document68 pagesP4223Raghuram SeshabhattarNo ratings yet

- A Study on Promotional Strategies of Big Bazaar & D-MartDocument82 pagesA Study on Promotional Strategies of Big Bazaar & D-MartAarti Tomar70% (10)

- Document ClusteringDocument12 pagesDocument ClusteringSravan Kumar KondaparthyNo ratings yet

- Global Economic Slowdown-ITDocument42 pagesGlobal Economic Slowdown-ITRaghuram SeshabhattarNo ratings yet

- HR Report-Rajashri CementDocument75 pagesHR Report-Rajashri CementKumar RajadhyakshNo ratings yet

- Emerging Concepts and Technological Tools for Effective Customer Relationship ManagementDocument3 pagesEmerging Concepts and Technological Tools for Effective Customer Relationship ManagementRaghuram SeshabhattarNo ratings yet

- Dissertation Sept2011Document56 pagesDissertation Sept2011Raghuram SeshabhattarNo ratings yet

- Global Recession and Its Impact On Indian Economy Paper in JournalDocument8 pagesGlobal Recession and Its Impact On Indian Economy Paper in Journalkrahulsharma11No ratings yet

- Online System For Grid Resource MonitoringDocument12 pagesOnline System For Grid Resource MonitoringSelva KumarNo ratings yet

- COM, Collisions MasterDocument72 pagesCOM, Collisions MasterRaghuram Seshabhattar67% (3)

- GST Simplifies India's Complex Indirect Tax SystemDocument6 pagesGST Simplifies India's Complex Indirect Tax SystemVishal Ashok ChandNo ratings yet

- 2019 Customer Expo Event GuideDocument49 pages2019 Customer Expo Event GuideLoyalty360No ratings yet

- Introduction To Operations Management Operations Is The4547 - 2Document75 pagesIntroduction To Operations Management Operations Is The4547 - 2Prateek VyasNo ratings yet

- PPTDocument6 pagesPPTpreetkr_kaur480No ratings yet

- University of NottinghamDocument119 pagesUniversity of NottinghamRini DasNo ratings yet

- 73 - Watches Over $ 1million - Most Expensive & Exquisite Watches EverDocument219 pages73 - Watches Over $ 1million - Most Expensive & Exquisite Watches EverCapri LeoNo ratings yet

- Cost of Reverse VendingDocument14 pagesCost of Reverse VendingbenibenoNo ratings yet

- A Fiasco Playset by Jason MorningstarDocument11 pagesA Fiasco Playset by Jason MorningstarArmin Sebastian Cano FuicaNo ratings yet

- Earn Over 100k Joe Verde PDFDocument186 pagesEarn Over 100k Joe Verde PDFdomini809No ratings yet

- One Dusun Draft Resi e Brochure FullDocument32 pagesOne Dusun Draft Resi e Brochure Fullapi-124172301No ratings yet

- Fortune 500 Spreadsheet List 2015Document120 pagesFortune 500 Spreadsheet List 2015David BowmanNo ratings yet

- Adm Bussiness PlanDocument27 pagesAdm Bussiness Planmohdarif22No ratings yet

- ResumeDocument1 pageResumeapi-361726508No ratings yet

- The Secrets of The Mystery ShopperDocument5 pagesThe Secrets of The Mystery ShopperMiguiel del ÁngelNo ratings yet

- Understanding the Importance of Supply Chain ManagementDocument27 pagesUnderstanding the Importance of Supply Chain ManagementParth Kapoor100% (1)

- Buying Behaviour of Indian Semi-Urban Women For Personal Care ProductsDocument10 pagesBuying Behaviour of Indian Semi-Urban Women For Personal Care ProductsTJPRC PublicationsNo ratings yet

- Retailer Supplier PartnershipsDocument18 pagesRetailer Supplier Partnershipscharurastogi83% (18)

- SNCDocument10 pagesSNCdev_90100% (2)

- Mcdonalds Power PointDocument23 pagesMcdonalds Power PointbainunrafiNo ratings yet

- RockFord Plaza For SaleDocument7 pagesRockFord Plaza For SaleabrealtyNo ratings yet

- Statewood Properties Jan. 18Document11 pagesStatewood Properties Jan. 18Miranda GathercoleNo ratings yet

- Fybcom Second Open Merit List 2022 23Document5 pagesFybcom Second Open Merit List 2022 23Gamer nestNo ratings yet

- Making TrousersDocument145 pagesMaking TrousersTelas Sim100% (26)

- Marketing Channels, Retailing, Wholesaling (9-11E)Document25 pagesMarketing Channels, Retailing, Wholesaling (9-11E)Ayaz KhanNo ratings yet

- Mathematics Third Periodical ReviewerDocument2 pagesMathematics Third Periodical ReviewerAna Liza MendozaNo ratings yet

- LabelDocument2 pagesLabelmdms03No ratings yet

- MBA-PROJECT Guidelines 4th SemesterDocument13 pagesMBA-PROJECT Guidelines 4th SemesterJigar RangoonwalaNo ratings yet

- Gross Domestic Product: GDP $5.6 Billion, Marginally Up 0.7% in 2013Document15 pagesGross Domestic Product: GDP $5.6 Billion, Marginally Up 0.7% in 2013BernewsAdminNo ratings yet

- PosterDocument1 pagePosterNgô Ngọc Mai ThyNo ratings yet

- Tax Invoice TemplateDocument1 pageTax Invoice Templatebigboss2276623No ratings yet