Professional Documents

Culture Documents

Passive Fire Protection: Fire Design of Concrete Structures

Uploaded by

Ada Darmon0 ratings0% found this document useful (0 votes)

25 views20 pagesOriginal Title

ConcreteExercises_Lesson6

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views20 pagesPassive Fire Protection: Fire Design of Concrete Structures

Uploaded by

Ada DarmonCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 20

Passive Fire Protection

Fire design of concrete structures - Exercises

Prof. dr. ir.-arch. Emmanuel Annerel

Exercise 1

Derive the equation for continuous slabs and beams, as given

in EN 1992-1-2

2

Exercise 1 - solution

3

Exercise 2

Consider a continuous concrete slab with equal span lengths of 5 m and a slab

thickness of 200 mm (a=25mm). The slab is load carrying in 1 direction over

multiple intermediate supports. The slab is heated at the center span from

the bottom.

Materials:

Concrete C25/30

Longitudinal reinforcement (field: 250mm/m; support: 471mm/m), strength class

BE 500 S

Loads:

40 mm of floor finishing (screed + tiles) - g

k,floor finishing

: 1 kN/m

Dead weight of the slab - g

k,concrete slab

: 25 kN/m

Variable load - g

k,variable load

: 4.1 kN/m ;

2

=0.3

4

What is the fire resistance according to the table method?

Can the same value be derived with the 500C isotherm method?

Exercise 2 solution: table method

5

h

s

= h

slab

+ h

floor finishing

=200 + 40 mm = 240 mm

REI120

; a = 25 mm

Exercise 2 solution: 500C isoth. meth. (1)

LOADS

What is needed for the design?

M

Ed,fi

= ?

M

Ed,support

= ?

M

Ed,field

= ?

p

k,fi

=

2

. q

k,variable load

+ g

k,floor finishing

+ (g

k,concrete slab

. h)

= 0.3 . 4.1 + 1 + (25 . 0.2) = 7.23 kN/m

M

Ed,fi

= p

k,fi

. l

eff

/ 8 = 7.23 . 5 / 8 = 22.6 kNm/m

p

d

= 1.35 . (25 . 0.2 + 1) + 1.5 . 4.1 = 14.25 kN/m

M

Ed,support

= pl/12 = 14.25 . 5/12 = 29.7 kNm/m

M

Ed,field

= pl/24 = 14.25 . 5/24 = 14.84 kNm/m

6

Time ISO 834 [min] Temperature [C] * k

s

() ** M

Rd

,

fi,field

[kNm/m]

30 300 1 20.8

60 450 0.89 18.53

90 550 0.625 13.01

120 650 0.35 7.29

180 750 0.17 3.54

240 800 0.11 2.29

(*) Temperature read from Figure A.2, EN1992-1-2, p.64 with a = 25 mm

(**) From EN1992-1-2 p.33: Figure 4.2a (hot rolled)

Exercise 2 solution: 500C isoth. meth. (2)

FIELD MOMENT

M

Rd,fi,field

= (

s

/

s,fi

) . k

s

() . M

Ed,field

. (A

s,prov

/ A

s,req

)

= (1.15 / 1) . k

s

() . 14.84 . (250 / 204.9) = 20.8 . k

s

()

7

M

Ed,field

= 14.84 kNm/m EN1992-1-1 A

s,field, req

= 204.9 mm/m

Exercise 2 solution: 500C isoth. meth. (2)

FIELD MOMENT

M

Rd,fi,field

= (

s

/

s,fi

) . k

s

() . M

Ed,field

. (A

s,prov

/ A

s,req

)

= (1.15 / 1) . k

s

() . 14.84 . (250 / 204.9) = 20.8 . k

s

()

8

M

Ed,field

= 14.84 kNm/m EN1992-1-1 A

s,field, req

= 204.9 mm/m

Time ISO 834 [min] Temperature [C] * k

s

() ** M

Rd

,

fi,field

[kNm/m]

30 300 1 20.8

60 450 0.89 18.53

90 550 0.625 13.01

120 650 0.35 7.29

180 750 0.17 3.54

240 800 0.11 2.29

(*) Temperature read from Figure A.2, EN1992-1-2, p.64 with a = 25 mm

(**) From EN1992-1-2 p.33: Figure 4.2a (hot rolled)

Exercise 2 solution: 500C isoth. meth. (3)

INTERMEDIATE SUPPORT MOMENT

M

Rd,fi,support

= (

s

/

s,fi

) . k

s

() . M

Ed,support

. (A

s,prov

/ A

s,req

) . (d a) / d

= (1.15 / 1) . k

s

() . 29.7 . (471 / 409.5) . (175 25) / 175

with k

s

() = 1, because temperature at top is < 350C

= 33.67 kNm/m

9

M

Ed,support

= 29.7 kNm/m EN1992-1-1 A

s,support, req

= 409.5 mm/m

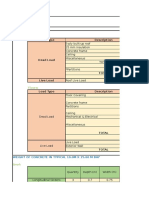

Time ISO834

[min]

( M

Rd,fi,support,1

+ M

Rd,fi,support,2

) / 2

[kNm/m]

M

Rd,fi,field

[kNm/m]

Sum

[kNm/m]

M

Ed,fi

[kNm/m]

30 33.67 20.8 54.47 >22.6 OK

60 33.67 18.53 52.20 >22.6 OK

90 33.67 13.01 46.68 >22.6 OK

120 33.67 7.29 40.96 >22.6 OK

180 33.67 3.54 37.21 >22.6 OK

240 33.67 2.29 35.96 >22.6 OK

Exercise 2 solution: 500C isoth. meth. (4)

CONTROL OF FIRE RESISTANCE

( M

Rd

,

fi,support,1

+ M

Rd

,

fi,support,2

) / 2 + M

Rd

,

fi,field

M

Ed,fi

10

Time ISO834

[min]

( M

Rd,fi,support,1

+ M

Rd,fi,support,2

) / 2

[kNm/m]

M

Rd,fi,field

[kNm/m]

Sum

[kNm/m]

M

Ed,fi

[kNm/m]

30 33.67 20.8 54.47 >22.6 OK

60 33.67 18.53 52.20 >22.6 OK

90 33.67 13.01 46.68 >22.6 OK

120 33.67 7.29 40.96 >22.6 OK

180 33.67 3.54 37.21 >22.6 OK

240 33.67 2.29 35.96 >22.6 OK

Exercise 2 solution: 500C isoth. meth. (4)

CONTROL OF FIRE RESISTANCE

( M

Rd

,

fi,support,1

+ M

Rd

,

fi,support,2

) / 2 + M

Rd

,

fi,field

M

Ed,fi

11

CONCLUSION: The slab designed has a fire resistance of REI 120, and even REI 240!

(CAUTION! The slab can still fail due to shear! This should now be controlled Also, spalling is not considered!)

Exercise 3

Consider a concrete slab with dimensions 3 m x 5 m and simply supported at

its 4 edges, which is heated only from the bottom.

Materials :

Concrete C 25/30

Reinforcement grid 5 x 8mm/m, BE 500 S

Loads:

M

vx

= 8.8 kNm/m

M

vy

= 2.9 kNm/m

Concrete cover = 46 mm

Slab thickness = 180 mm

REI 240?

12

Exercise 3 - Solution

Loads ( = 0.7)

M

vx,fire

= M

vx

. = 8.8 x 0.7 = 6.2 kNm/m

M

vy,fire

= M

vy

. = 2.9 x 0.7 = 2.0 kNm/m

R 240?

a

x

= c + /2 = 46 + 8/2 = 50 mm

a

y

= c + + /2 = 46 + 8+ 8/2 = 58 mm

T(a

x

) = 570C ; T(a

y

) = 500C

k

s

(T

ax

) = 0.55 ; k

s

(T

ay

) = 0.8

A

s

= 5 . . (/2) = 251 mm/m

d

x

= h - a

x

= 180 - 50 mm = 130 mm

d

y

= h - a

y

= 180 - 58 = 122 mm

M

Rvx,fi

= A

s

. f

yk

. k

s

(T) . 0.9 . d

x

= 251 . 500 . 0.55 . 0.9 . 130

= 8.07 kNm/m

M

Rvy,fi

= A

s

. f

yk

. k

s

(T) . 0.9 . d

y

= 251 . 500 . 0.8 . 0.9 . 122

= 11.02 kNm/m

EI 240?

T 140C ?? Probably need for a floor finishing!

Or insulation (EN13381-3), or additional concrete 13

a

x

a

y

k

s

(T

ax

)

k

s

(T

ay

)

T

ax

T

ay

OK! > M

vx,fire

OK! > M

vy,fire

Exercise 4

Simply supported concrete beam with a rectangular shaped cross section. The span

length is 4 m, the total height of the beam is 500 mm and its width is 200 mm. The

beam is heated according to ISO 834 curve from 3 sides.

Materials :

- Concrete C 30/37

- Longitudinal reinforcement 10 mm, strength class BE 500 S

- Stirrups 8 mm, strength class BE 500 S

Loads:

- Variable load: 22.4 kN/m

14

What is the maximum fire resistance

according to the table method?

Illustrate this with the 500C isotherm

method.

40 mm

70 mm

100 mm

200 mm

500 mm

38 mm

Exercise 4 Solution (1)

15

Element

Axis

distance

to side

face

(mm)

Axis

distance to

bottom

face (mm)

Fig. A4-b:

Beam

300 mm

x 160 mm

R 60

Fig. A7-a:

Beam

600 mm

x 300 mm

R 60

2 corner bars 40 38 520 C 500 C

2 intermediate

bars

70 38 430 C 390 C

1 central bar 100 38 420 C 350 C

Width

compression zone

with temperatures

500C

200 mm 2 . 22.5

mm = 155 mm

200 mm 2 .

21.43 mm =

157.14 mm

b

min

= 200 mm

R 60 is possible

Exercise 4 Solution (2)

16

Element

Axis

distance

to side

face

(mm)

Axis

distance to

bottom

face (mm)

Fig. A4-b:

Beam

300 mm

x 160 mm

R 60

Fig. A7-a:

Beam

600 mm

x 300 mm

R 60

2 corner bars 40 38 520 C 500 C

2 intermediate

bars

70 38 430 C 390 C

Central bar 100 38 420 C 350 C

Width

compression zone

with temperatures

500C

- -

200 mm 2 . 22.5

mm = 155 mm

200 mm 2 .

21.43 mm =

157.14 mm

Exercise 4 Solution (2)

17

Element

Axis

distance

to side

face

(mm)

Axis

distance to

bottom

face (mm)

Fig. A4-b:

Beam

300 mm

x 160 mm

R 60

Fig. A7-a:

Beam

600 mm

x 300 mm

R 60

2 corner bars 40 38 520 C 500 C

2 intermediate

bars

70 38 430 C 390 C

Central bar 100 38 420 C 350 C

Width

compression zone

with temperatures

500C

- -

200 mm 2 . 22.5

mm = 155 mm

200 mm 2 .

21.43 mm =

157.14 mm

Exercise 4 Solution (3)

The total tensile force in the longitudinal reinforcing steel is given by:

F

s

(T) = 2 . A

bar

. f

y,corner

(T) + 2 . A

bar

. f

y,intermediate

(T) + A

bar

. f

y,central

(T)

= 2 . 78.53 mm . 365 N/mm + 2 . 78.53 mm . 475 N/mm + 78.53 mm . 475 N/mm

= 169.232 kN

The total compressive force in the concrete is given by:

F

c

(T) = b(T) . 0.8 . x . f

ck

= 155 mm . 0.8 . 30 N/mm . x

= 3720 N/mm . x

18

Reinforcement k

s

(T) f

y

(T)

Central bar at 420 C 0.95 475 N/mm

Intermediate bars at 430 C 0.95 475 N/mm

Corner bars at 520 C 0.73 365 N/mm

Exercise 4 Solution (4)

Balance of the forces results in the position x of the neutral axis.

F

s

(T) = F

c

(T) or 169232 N = 3720 N/mm . x

From which: x = 169232 N / 3720 N/mm = 45.49 mm

The level arm z between the compressive and tensile force is:

z = d (0.8 . x) / 2 = 462 mm 0.8 . 45.49 mm /2 = 443.8 mm

From this, the resisting bending moment can be calculated

M

Rd

(T) = F

s

(T) . z = 169.232 kN . 0.4438 m = 75.1 kNm

The applied moment (with y

2

= 0.3) is given by:

M

Ed

(T) = (2.5 kN/m + 0.3 . 22.4 kN/m) . (4 m) / 8 = 18.44 kNm.

Or for the alternative method:

M

Ed

(T) = 0.7 . M

Ed

= 0.7 . 73.95 kNm= 51.765 kNm

This value is smaller than the resisting moment and the beam will not fail.

19

Exercise 4 Solution (5)

This result is only valid if the strain of the reinforcement is larger than 2% bedraagt,

because curve 1 of figure 4.2-a of EN 1992-1-2 is used.

Assuming a compression of 3.5 at the top fiber and the known position x of the

neutral axis, a steel strain of 32.04 or 3.204 % is found. Thus, the calculated

resisting moment is valid.

20

c

= 3.5

s

= ?

d -x

x

3.5

s

x

(d x)

=

s

=

3.5

x

(d x)

=

3.5

45.49

(462 45.49)

= 32.04

You might also like

- Distillation HandbookDocument94 pagesDistillation HandbookEr Bali Pandhare100% (2)

- Distillation HandbookDocument94 pagesDistillation HandbookEr Bali Pandhare100% (2)

- Structural design and analysis of a low-rise buildingDocument42 pagesStructural design and analysis of a low-rise buildingMohammed SumerNo ratings yet

- How To Build An Alcohol Distillation DeviceDocument45 pagesHow To Build An Alcohol Distillation Devicelokikg100% (2)

- How To Build An Alcohol Distillation DeviceDocument45 pagesHow To Build An Alcohol Distillation Devicelokikg100% (2)

- T Beam Roof SlabDocument22 pagesT Beam Roof SlabRohit Khandelwal100% (1)

- Structural AnalysisDocument5 pagesStructural AnalysishampshireiiiNo ratings yet

- Design of Compound WallDocument4 pagesDesign of Compound WallMaku Rajkumar100% (2)

- Span Deflection (Double Integration Method)Document14 pagesSpan Deflection (Double Integration Method)Ikhwan Z.88% (8)

- Pad Footing DesignDocument6 pagesPad Footing DesignmonNo ratings yet

- Post TensioningDocument13 pagesPost TensioningAbdullah AhamedNo ratings yet

- Design of Box CulvertDocument21 pagesDesign of Box CulvertAnirbanBhattacharjeeNo ratings yet

- Design of Counterfort Retaining WallDocument14 pagesDesign of Counterfort Retaining WallMonjit Gogoi100% (5)

- RC2009 University of HongKong Reinforced Concrete DesignDocument29 pagesRC2009 University of HongKong Reinforced Concrete DesignApril IngramNo ratings yet

- Design ExamplesDocument12 pagesDesign ExamplesBrajesh Suman100% (1)

- Water TankDocument22 pagesWater TankSamik SenNo ratings yet

- Calculation Procedure, Low-Finned Tubes: Exxon EngineeringDocument56 pagesCalculation Procedure, Low-Finned Tubes: Exxon Engineeringvin ssNo ratings yet

- Three Dimensional Analysis and Design of Al-Arab Hospital ProjectDocument52 pagesThree Dimensional Analysis and Design of Al-Arab Hospital ProjectkusumchitikaNo ratings yet

- Civil Auditorium Building DesignDocument23 pagesCivil Auditorium Building DesignRamachantran RamachantranNo ratings yet

- Design of Cantilever BeamDocument23 pagesDesign of Cantilever Beamjs kalyana rama83% (12)

- Floor ManualDocument35 pagesFloor ManualGihan ChathurangaNo ratings yet

- Design SectionDocument19 pagesDesign SectionKrishna KumarNo ratings yet

- Design and Detailing of Counterfort Retaining WallDocument48 pagesDesign and Detailing of Counterfort Retaining WallSWADES RANJAN PAIRANo ratings yet

- Design and detailing of a combined footing with central beam supporting two columnsDocument34 pagesDesign and detailing of a combined footing with central beam supporting two columnsgundulpNo ratings yet

- C3 Pr0bl3msDocument41 pagesC3 Pr0bl3msLimuel Milo Lebios100% (3)

- Example - Slab Bridge PDFDocument7 pagesExample - Slab Bridge PDFRefisa Jiru100% (3)

- Design of Combined FootingDocument12 pagesDesign of Combined FootingAhmmed Muhsee100% (2)

- Preliminary Design: Area of Steel Required Area of Steel ProvidedDocument10 pagesPreliminary Design: Area of Steel Required Area of Steel ProvidedArchana Poudel100% (1)

- Slab Design As Per IS 456Document7 pagesSlab Design As Per IS 456RitaBiswas100% (1)

- Structural Report On 400 KLD STPDocument16 pagesStructural Report On 400 KLD STPVipin SinghalNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFRegan Tandukar44% (9)

- STRAP FOOTING DESIGN FOR MULTI-STOREY BUILDINGDocument5 pagesSTRAP FOOTING DESIGN FOR MULTI-STOREY BUILDINGNabin Acharya100% (1)

- Seismic Analysis of Structures - Concrete Ductile Moment Resisting Space FrameDocument34 pagesSeismic Analysis of Structures - Concrete Ductile Moment Resisting Space FrameEmmanuel LazoNo ratings yet

- MANUFACTURING II: BULK DEFORMATION PROCESS TUTORIALDocument38 pagesMANUFACTURING II: BULK DEFORMATION PROCESS TUTORIALberhane100% (1)

- Design of Rectangular Water Tank with L/B Ratio Greater than 2Document5 pagesDesign of Rectangular Water Tank with L/B Ratio Greater than 2Hareesh RameshNo ratings yet

- Farm STR ProjectDocument17 pagesFarm STR ProjectShinyi GanNo ratings yet

- Din en 1561 - en - 1997-08Document21 pagesDin en 1561 - en - 1997-08AlissonFernandes17No ratings yet

- Beamsaet 1Document3 pagesBeamsaet 1omar_sool2No ratings yet

- Answer The Stresses Are 69.92 Mpa and - 38.67 Mpa and The Neutral Axis Is 38.6 MM From The Tensile EdgeDocument3 pagesAnswer The Stresses Are 69.92 Mpa and - 38.67 Mpa and The Neutral Axis Is 38.6 MM From The Tensile Edgelayiro2No ratings yet

- TutorialDocument27 pagesTutorial朱星宇No ratings yet

- 4b-Flexural Analysis of Reinforced Concrete T-Section BeamsDocument14 pages4b-Flexural Analysis of Reinforced Concrete T-Section Beamsßlack ßoodyNo ratings yet

- Strength of MatrialDocument36 pagesStrength of MatrialahmedanyNo ratings yet

- Tension Members: Version 2 CE IIT, KharagpurDocument24 pagesTension Members: Version 2 CE IIT, KharagpurolomizanaNo ratings yet

- Class 4 BeamDocument1 pageClass 4 Beamsori1386No ratings yet

- Unit 3 32,33,34,35Document3 pagesUnit 3 32,33,34,35Deepanshu VermaNo ratings yet

- Engineering Mechanic For Conditioning &refrigeration Dept. First Class Part (1) Strength of MaterialsDocument21 pagesEngineering Mechanic For Conditioning &refrigeration Dept. First Class Part (1) Strength of MaterialsN AbdullahNo ratings yet

- Strength of Materials-II 2-2 Set-2 (A)Document13 pagesStrength of Materials-II 2-2 Set-2 (A)Sri DNo ratings yet

- Week 11 Lecture Material - WatermarkDocument57 pagesWeek 11 Lecture Material - WatermarkVaibhav SharmaNo ratings yet

- Structure Design Basis: Page - 1Document7 pagesStructure Design Basis: Page - 1MdShahbazAhmedNo ratings yet

- Footing Subjected To Eccentric LoadingDocument5 pagesFooting Subjected To Eccentric LoadingPratik DhariwalNo ratings yet

- Problem Statment DARSHANDocument10 pagesProblem Statment DARSHANMayuresh NalawadeNo ratings yet

- Tension Members: Version 2 CE IIT, KharagpurDocument24 pagesTension Members: Version 2 CE IIT, KharagpurAvishek DeyNo ratings yet

- Moment Resistance Calculation of a Class 4 W150x22 BeamDocument1 pageMoment Resistance Calculation of a Class 4 W150x22 BeamstructuresNo ratings yet

- Strength of Materials-II 2-2 Set-4 (A)Document10 pagesStrength of Materials-II 2-2 Set-4 (A)Sri DNo ratings yet

- Analysis of The SectionsDocument25 pagesAnalysis of The SectionsSara ZavariNo ratings yet

- Moment Resistance Calculation of a Class 4 BeamDocument1 pageMoment Resistance Calculation of a Class 4 Beamsom_bs79No ratings yet

- STEEL ROOF TRUSS DESIGN FOR PETROL STATIONDocument22 pagesSTEEL ROOF TRUSS DESIGN FOR PETROL STATIONemuan vanessaNo ratings yet

- Eurocode 2 Concrete Design GuideDocument50 pagesEurocode 2 Concrete Design GuideanhkhoacgNo ratings yet

- Strength of Materials-II 2-2 Set-3 (A)Document18 pagesStrength of Materials-II 2-2 Set-3 (A)Sri DNo ratings yet

- Strap FootingDocument6 pagesStrap Footingrukesh104No ratings yet

- Design Shear Reinforcement 06-07-2023Document14 pagesDesign Shear Reinforcement 06-07-2023Diploma - CE Dept.No ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- PROMFG INTER ENG 2019 DarmonDocument6 pagesPROMFG INTER ENG 2019 DarmonAda DarmonNo ratings yet

- Guideline No 17 2008 PDFDocument14 pagesGuideline No 17 2008 PDFAda DarmonNo ratings yet

- BancDocument1 pageBancAda DarmonNo ratings yet

- Dârmon 2022 IOP Conf. Ser. Mater. Sci. Eng. 1242 012012Document7 pagesDârmon 2022 IOP Conf. Ser. Mater. Sci. Eng. 1242 012012Ada DarmonNo ratings yet

- Ben Hume and Kevin Weller DraftToSubmitDocument34 pagesBen Hume and Kevin Weller DraftToSubmitAda DarmonNo ratings yet

- A323 FinalDocument312 pagesA323 FinalFlorin BabotaNo ratings yet

- Probabilistic Methods To Assess The Fire Risk of An Industrial BuildingDocument10 pagesProbabilistic Methods To Assess The Fire Risk of An Industrial BuildingAda DarmonNo ratings yet

- The Assessment of Fire Safety Measures in Service Risers - DARMON - 2018Document6 pagesThe Assessment of Fire Safety Measures in Service Risers - DARMON - 2018Ada DarmonNo ratings yet

- Elsevier B.V. INTER ENG 2017 DarmonDocument8 pagesElsevier B.V. INTER ENG 2017 DarmonAda DarmonNo ratings yet

- RF Fire Flow Water ConsumptionDocument238 pagesRF Fire Flow Water ConsumptionKrish DoodnauthNo ratings yet

- Elsevier B.V. INTER-EnG 2011 Darmon, SuciuDocument7 pagesElsevier B.V. INTER-EnG 2011 Darmon, SuciuAda DarmonNo ratings yet

- Smoke Control Design in Large Spaces - Darmon, SuciuDocument6 pagesSmoke Control Design in Large Spaces - Darmon, SuciuAda DarmonNo ratings yet

- Elsevier B.V. INTER ENG 2017 DarmonDocument8 pagesElsevier B.V. INTER ENG 2017 DarmonAda DarmonNo ratings yet

- Ruxandra Dârmon: External Fire Spread Analysis, Mircea SuciuDocument4 pagesRuxandra Dârmon: External Fire Spread Analysis, Mircea SuciuAda DarmonNo ratings yet

- 98 Tips For Designing Structural Steel PDFDocument5 pages98 Tips For Designing Structural Steel PDFAda DarmonNo ratings yet

- Jaes2 15 1 2012 DarmonDocument6 pagesJaes2 15 1 2012 DarmonAda DarmonNo ratings yet

- Creation of Wire Mesh Charts With Plan and Elevation ViewsDocument1 pageCreation of Wire Mesh Charts With Plan and Elevation ViewsAda DarmonNo ratings yet

- The Assessment of Fire Safety Measures in Service Risers - DARMON - 2018Document6 pagesThe Assessment of Fire Safety Measures in Service Risers - DARMON - 2018Ada DarmonNo ratings yet

- Strength of Material by R K Bansal PDFDocument611 pagesStrength of Material by R K Bansal PDFAda DarmonNo ratings yet

- Wind and Eq Design PDFDocument48 pagesWind and Eq Design PDFAda DarmonNo ratings yet

- Nist SP-1021Document489 pagesNist SP-1021Ada DarmonNo ratings yet

- Simens Etal JCP09Document14 pagesSimens Etal JCP09Ada DarmonNo ratings yet

- Ten Questions Concerning The Large-Eddy Simulation of Turbulent OwsDocument24 pagesTen Questions Concerning The Large-Eddy Simulation of Turbulent OwsAda DarmonNo ratings yet

- Heat and Mass Transfer in Fires Scaling Laws, Ignition of Solid Fuels andDocument11 pagesHeat and Mass Transfer in Fires Scaling Laws, Ignition of Solid Fuels andAda DarmonNo ratings yet

- Ten Questions Concerning The Large-Eddy Simulation of Turbulent OwsDocument24 pagesTen Questions Concerning The Large-Eddy Simulation of Turbulent OwsAda DarmonNo ratings yet

- 1135 RosbergDocument17 pages1135 RosbergAda DarmonNo ratings yet

- Petr Zamostny Tablet CompressionDocument57 pagesPetr Zamostny Tablet CompressionIka AniNo ratings yet

- New Components Help Prevent Air Leaks in Improved Fuel Ratio Control Groups (1278)Document3 pagesNew Components Help Prevent Air Leaks in Improved Fuel Ratio Control Groups (1278)TASHKEELNo ratings yet

- Awardees List - 11th VKA 2019 (Final)Document14 pagesAwardees List - 11th VKA 2019 (Final)ANKIT DWIVEDINo ratings yet

- Insulation ProductsDocument1 pageInsulation ProductsDygoPalNo ratings yet

- F. M. 1Document3 pagesF. M. 1Aashish PardeshiNo ratings yet

- Solar Powered Automatic Toilet LightDocument10 pagesSolar Powered Automatic Toilet LightarwinNo ratings yet

- ASTM 210cDocument1 pageASTM 210cDodi SuhendraNo ratings yet

- Behaviour of Cold Formed Steel Single and Compound Plain Angles in CompressionDocument13 pagesBehaviour of Cold Formed Steel Single and Compound Plain Angles in Compressionthiya123No ratings yet

- Declarative KnowledgeDocument2 pagesDeclarative KnowledgeEliiAfrNo ratings yet

- Culata JD 6466Document4 pagesCulata JD 6466TECNOTRAC AldanaNo ratings yet

- Process Management: Operating SystemsDocument48 pagesProcess Management: Operating SystemsvidishsaNo ratings yet

- Hitachi SetFree MiniVRF 0120LRDocument52 pagesHitachi SetFree MiniVRF 0120LRAhmed AzadNo ratings yet

- SCC Development, Applications and InvestigationsDocument5 pagesSCC Development, Applications and InvestigationslauravoineagNo ratings yet

- Specialized Epic EVO 2021Document3 pagesSpecialized Epic EVO 2021MTB-VCONo ratings yet

- Mini-Split Service GuideDocument49 pagesMini-Split Service Guideady_gligor7987No ratings yet

- Certification Authorities Software Team (CAST) Cast 10Document8 pagesCertification Authorities Software Team (CAST) Cast 10Anastasia SuckallahNo ratings yet

- Acha Teff ThresherDocument62 pagesAcha Teff ThresherTANKO BAKO100% (2)

- Numeric To Numeric Encryption of Databases Using 3kDES AlgorithmDocument5 pagesNumeric To Numeric Encryption of Databases Using 3kDES AlgorithmSwathi VasudevanNo ratings yet

- 0806 02 Los5 - UgDocument124 pages0806 02 Los5 - Ugbmds kocakNo ratings yet

- B2B ApiDocument350 pagesB2B ApiratnavelpNo ratings yet

- DT Progression Pathways ks3 Textiles Y9Document1 pageDT Progression Pathways ks3 Textiles Y9api-240012980No ratings yet

- Mapping UCLA Network DrivesDocument2 pagesMapping UCLA Network DriveswebscaleNo ratings yet

- TM4320 PDFDocument85 pagesTM4320 PDFandres cortezNo ratings yet

- Blackberry Enterprise Server For Microsoft Exchange: Troubleshooting GuideDocument48 pagesBlackberry Enterprise Server For Microsoft Exchange: Troubleshooting GuideKhaled AjouzNo ratings yet

- BNI Vision April 2023 Roster BookDocument16 pagesBNI Vision April 2023 Roster BookTushar MohiteNo ratings yet

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet