Professional Documents

Culture Documents

Circle Systems, Inc.: Mi-Glow® 850

Uploaded by

carlosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Circle Systems, Inc.: Mi-Glow® 850

Uploaded by

carlosCopyright:

Available Formats

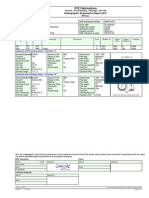

CIRCLE SYSTEMS, INC.

479 West Lincoln P.O. Box 1228 Hinckley, IL 60520 Ph.: 815-286-3271 Fax: 815-286-3352 customerservice@circlesafe.com

Technical Bulletin #273

Mi-Glow 850

Mi-Glow 600 red particles premixed with powdered Wetting Agent 100 for use in water media. It is designed to be used with visible light for detecting discontinuities found in structural fabrications and weldments. Higher particle concentration provides heavier indication buildup for easy detection. Mi-Glow 850 can be further enhanced when used with a black light or blue light. Properties Particle Color: Red Specific Gravity: 0.6 g/ml Particle Size: Not less than 98% passage through US Standard No. 325 (45 m). The typical range of particle sizes is from 5 to 20 m, with an average particle size of 7 m. Particle Certification: Particles meet or exceed all relevant industry specifications, including but not limited to MIL-STD-1949, AMS 3042, MIL-STD-271, NAVSEA 250-1500-1, NTR-1E, ASTM E 1444. Certification is included with each shipment. Temperature Limits: 32-120F (0-49C) Shelf Life: Four (4) years, when closed containers are stored in a clean, dry environment away from excessive heat and cold. A Certificate of Shelf Life is available upon request. Directions for Use Preparation: Mi-Glow 850 should be mixed at the recommended concentration of 3.2oz per one gallon (24.0 grams/liter) of water. For best results, add a small amount of water to the powder and form a slurry prior to adding to the bath. Pour the slurry near the pump inlet. Settling Test: The settling test, to check particle concentration and contamination, shall be performed upon startup, at each shift thereafter and whenever the bath is changed or adjusted. Checking Bath Concentration - The settling test is essential to check the bath concentration and is accomplished by gravity settling in a graduated pear-shaped centrifuge tube as specified in Guide E709. 1. Run the pump for 30-60 minutes, to agitate the suspension thoroughly and to assure particle distribution. 2. Fill 100 ml sample from the delivery hose into the centrifuge tube. 3. Demagnetize the sample and stand, together. 4. Allow particles to settle for a minimum of 30 minutes or until completely settled.

Revised 12/9/2010

Technical Bulletin #273, Mi-Glow 850

Page 2

5. The recommended volume is 2.2 ml. 6. Adjust bath, either by adding particles or vehicle, if necessary. Checking Bath Contamination - To determine bath contamination, use the same sample that was used for the concentration settling test, and examine the liquid above the settled particles with a black light. The liquid should be clear. If the bath is noticeably fluorescent, the bath must be changed. Next, examine the graduated portion of the tube where the particles have settled, with a black light and visible light for striations or bands of contamination that will be different in color and appearance than the settled particles. These striations or bands represent solid contamination, and if they exceed 30% of the settled particles, the bath should be changed.

DISCLAIMER: OUR TECHNICAL ADVICE, INFORMATION AND STATEMENTS GIVEN VERBALLY, IN WRITING OR IN THE FORM OF TEST RESULTS, ARE OFFERED FOR YOUR GUIDANCE WITHOUT WARRANTY. NO WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE IS MADE. IT IS THE USERS RESPONSIBILITY TO TEST THE SUITABILITY OF EACH PRODUCT FOR HIS INTENDED PROCESS AND APPLICATIONS. OUR GUARANTEE IS LIMITED TO THE CONSISTENT QUALITY OF OUR PRODUCTS.

Revised 12/9/2010

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Pogil - Periodic Trends RHSDDocument7 pagesPogil - Periodic Trends RHSDErin DodsonNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- As 2278.1-2008 Aerosol Containers Metal Aerosol Dispensers of Capacity 50 ML To 1000 ML InclusiveDocument7 pagesAs 2278.1-2008 Aerosol Containers Metal Aerosol Dispensers of Capacity 50 ML To 1000 ML InclusiveSAI Global - APAC50% (2)

- Zetec Ultravision EC DatasheetDocument2 pagesZetec Ultravision EC Datasheetcarlos0% (1)

- Cygnus 1 Manual V617ADocument42 pagesCygnus 1 Manual V617AMichael JordanNo ratings yet

- Weld ProcedureDocument2 pagesWeld ProcedurecarlosNo ratings yet

- Winter 2018 Registration FormDocument1 pageWinter 2018 Registration FormcarlosNo ratings yet

- HDV Accessories: Videoscope Camera Probes & AccessoriesDocument1 pageHDV Accessories: Videoscope Camera Probes & AccessoriescarlosNo ratings yet

- Setup Guide No 4 Weld Inspection WeldcheckDocument7 pagesSetup Guide No 4 Weld Inspection WeldcheckcarlosNo ratings yet

- Ndtspec Radiographic Nde ReportDocument1 pageNdtspec Radiographic Nde ReportcarlosNo ratings yet

- 1463520118Document2 pages1463520118carlosNo ratings yet

- RotoUTscan v8Document2 pagesRotoUTscan v8carlosNo ratings yet

- NDT MarketplaceDocument1 pageNDT MarketplacecarlosNo ratings yet

- Eddyliner PX User ManualDocument146 pagesEddyliner PX User ManualcarlosNo ratings yet

- 30mm CalibrationDocument10 pages30mm CalibrationcarlosNo ratings yet

- Aerofab NDT Rotary Probes CatalogDocument23 pagesAerofab NDT Rotary Probes CatalogcarlosNo ratings yet

- Safety Data Sheet: SIR Chem® Dry Powder 63 RedDocument6 pagesSafety Data Sheet: SIR Chem® Dry Powder 63 RedcarlosNo ratings yet

- 811 2800 - PFINDER 280 - Flyer - GB - v2Document1 page811 2800 - PFINDER 280 - Flyer - GB - v2carlosNo ratings yet

- VM Products Gain Test Box2Document16 pagesVM Products Gain Test Box2carlos100% (1)

- Tofd PCNDocument22 pagesTofd PCNmarforall5205No ratings yet

- M-107/M-208 Wheel SpecificationDocument40 pagesM-107/M-208 Wheel SpecificationKristian Marchena100% (3)

- OmniScan SX \ MX2 Training - Phased Array Wedge OverviewDocument37 pagesOmniScan SX \ MX2 Training - Phased Array Wedge OverviewcarlosNo ratings yet

- OmniSX MX2 Training 5A Weld and Part Wizard UseDocument15 pagesOmniSX MX2 Training 5A Weld and Part Wizard Usecarlos100% (1)

- 2.a.omniscan Setup - Calibration For Sectorial ScanDocument34 pages2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- Omniscan Setup - Basic SetupDocument29 pagesOmniscan Setup - Basic SetupcarlosNo ratings yet

- 3dii BrochureDocument6 pages3dii BrochurecarlosNo ratings yet

- OmniSX MX2 Training 4B Phased Array ProbesDocument49 pagesOmniSX MX2 Training 4B Phased Array Probescarlos100% (2)

- 4.omniscan Setup - Min-Wheel Encoder SetupDocument13 pages4.omniscan Setup - Min-Wheel Encoder SetupcarlosNo ratings yet

- OmniSX MX2 Training 4A PA Calculator OverviewDocument10 pagesOmniSX MX2 Training 4A PA Calculator OverviewcarlosNo ratings yet

- 3 OmniSX GettingStarted PA Weld AnalysisDocument16 pages3 OmniSX GettingStarted PA Weld AnalysiscarlosNo ratings yet

- 1 OmniSX GettingStarted Touchscreen UseDocument25 pages1 OmniSX GettingStarted Touchscreen UsecarlosNo ratings yet

- 2.a.omniscan Setup - Calibration For Sectorial ScanDocument34 pages2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- Omniscan Setup - Basic SetupDocument29 pagesOmniscan Setup - Basic SetupcarlosNo ratings yet

- Calculation Dilute Phase Pressure Drop Rhodes MethodDocument3 pagesCalculation Dilute Phase Pressure Drop Rhodes MethodBTENo ratings yet

- 309-King Agar-110991 PDFDocument1 page309-King Agar-110991 PDFSneyder MurciaNo ratings yet

- Big Batch Soap MakingDocument24 pagesBig Batch Soap MakingAnonymous Vu1R35s4WZ100% (2)

- Cracking of Inconel 800H - SMRDocument8 pagesCracking of Inconel 800H - SMRkoyasrujanaNo ratings yet

- Essco Product CatalogueDocument23 pagesEssco Product CatalogueMohammedAasimUmairNo ratings yet

- Spontaneous Combustion ConversionDocument68 pagesSpontaneous Combustion ConversionRizwan Ullah BaigNo ratings yet

- Determination of % Available Chlorine in Bleaching PowderDocument10 pagesDetermination of % Available Chlorine in Bleaching PowderABHILASHA MISHRA0% (1)

- Flashing CalculationsDocument8 pagesFlashing CalculationsjcmarabouNo ratings yet

- The Effect of Size Thickness and Type of The Bonding Interlayer On Bullet Proof Glass As Per EN 1063Document4 pagesThe Effect of Size Thickness and Type of The Bonding Interlayer On Bullet Proof Glass As Per EN 1063Anonymous hk1fhAkwyNo ratings yet

- How buffers maintain pH levelsDocument4 pagesHow buffers maintain pH levelsManP13No ratings yet

- 810-701 CRSeals Handbook PRESSURE Apr-2018Document4 pages810-701 CRSeals Handbook PRESSURE Apr-2018Anonymous VNu3ODGavNo ratings yet

- Presentation1. AEC GeoTech LANDFILLDocument22 pagesPresentation1. AEC GeoTech LANDFILLAyan BorgohainNo ratings yet

- Bio HGHDocument19 pagesBio HGHapi-240332064No ratings yet

- Chemical, Physical, and Baking Properties of Apple FiberDocument4 pagesChemical, Physical, and Baking Properties of Apple FiberHector FloresNo ratings yet

- Volcanic Eruptions NotesDocument24 pagesVolcanic Eruptions NotesKarthikesan MakNo ratings yet

- Mineral-rich Bilimbi fruit analysisDocument3 pagesMineral-rich Bilimbi fruit analysisveronica francisNo ratings yet

- Top 305 Companies in Pune RegionDocument39 pagesTop 305 Companies in Pune RegionNiraj Thakkar0% (1)

- Properties of WaterDocument3 pagesProperties of WaterLupis HernándezNo ratings yet

- Identify Hazards and Risks in the WorkplaceDocument7 pagesIdentify Hazards and Risks in the WorkplaceLeah Rizza CabaliwNo ratings yet

- Applied Energy: Zhang Bai, Qibin Liu, Jing Lei, Hui Hong, Hongguang JinDocument10 pagesApplied Energy: Zhang Bai, Qibin Liu, Jing Lei, Hui Hong, Hongguang JinEko RaharjoNo ratings yet

- Johnson Industrial Screens PDFDocument20 pagesJohnson Industrial Screens PDFjaime palenzuela rodriguezNo ratings yet

- Organic Name Reactions GuideDocument12 pagesOrganic Name Reactions GuidechinmayaNo ratings yet

- Chinese GMP 2010Document115 pagesChinese GMP 2010Atul SharmaNo ratings yet

- Successful Intraoral RadiographyDocument19 pagesSuccessful Intraoral RadiographyMonica Agustine HartonoNo ratings yet

- Farmacologia en ArdillasDocument3 pagesFarmacologia en ArdillasIvan Gonzalez BernalNo ratings yet

- Expwb3ans eDocument67 pagesExpwb3ans eOlivia LinNo ratings yet

- 2 Basic Clinical Genetic - ppt-1Document24 pages2 Basic Clinical Genetic - ppt-1Najib M. NauvalNo ratings yet

- Galvanic Series: Why Metals Corrode?Document7 pagesGalvanic Series: Why Metals Corrode?Rey Francis FamulaganNo ratings yet