Professional Documents

Culture Documents

Data Rates-Dam Works-Part 2

Uploaded by

vpmohammedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Rates-Dam Works-Part 2

Uploaded by

vpmohammedCopyright:

Available Formats

DAM ALLIED WORKS

6 to 7 m for effective blasting to minimise digging and loading cycle of shovel. Consider 6 m length and 15 m width of excavation per blast. Depth of drilling per hole including depth of sub-drilling : 6.00 m Effective depth of hole for jack hammer drilling ( 6.0 - 0.6 ) : 5.40 m The burden ( distance of hole from free face of excavation ) is considered at 20 times diameter of hole and spacing of holes is considered at 1.25 times burden. Burden for 100 mm dia waggon drill holes : 2.00 m Spacing of holes @ 1.25 times burden : 2.50 m Grid spacing of holes in m : 2.00 x 2.50 m Quantity of excavation per blast ( 15 x 6 x 5.4 ) say : 480 cum Further, consider loading of about 95 percent excavated rock by shovel and 5 percent excavated rock mainly consisting of trimmed bed material and blasted boulders etc., by manual labour. Daily quantity of excavation in hard rock ( 480 / 0.95 ) say : 500 cum Consider 500 cum for rate analysis. 2. Drilling and Blasting: Grid spacing of holes for 100 mm dia Waggon drill holes : 2.00 x 2.50 m Consider 3 burden distance for excavation per blast. Rate of drilling in hard rock per hour by Waggon drill : 12.00 m Rate of drilling per hour with 50 min per hour working ( 12 x 50 / 60 ) : 10 m Length of excavation for 3 burden distance ( 3 x 2.00 ) : 6.00 m No. of blast holes in 3 rows for 2 x 2.5 m grid ( 90 / 5 ) : 18 holes Length of drilling for 18 holes ( 18 x 6 ) say : 108 m Consider 2 waggon drills for drilling main holes and 2 jack hammers for secondary holes. Time for drilling 108 m for 2 Waggon drill @ 10 m / hour : 5.4 hours Drilling for secondary blasting for 5% qty @ 0.6 m / cum : 14.4 m No.of blast holes for secondary blasting @ 0.6 m / hole ( 15 / 0.6 ) : 24 holes Time for drilling 25 m for 2 jack hammers @ 6 m / hour : 2.0 hours 3. Disposal of excavated rock: Capacity of shovel bucket : 0.85 cum Capacity of shovel bucket under heaped condition : 1.00 cum Capacity of tipper : 5.00 cum Lead for disposal of excavated rock rock : Upto 1 km Speed for loaded tipper intake / power house excavation condition : 15 km / hr Speed for empty tipper under intake / power house excavation condition : 20 km / hr Turning and unloading time : 2.00 min Shovel digging and loading cycle per bucket : 45 sec In-situ qty / bucket for 40 % bulkage of hard rock ( 1 / 1.40 ) : 0.71 cum In-situ qty per load for 40 % bulkage of hard rock ( 5 / 1.40 ) : 3.57 cum Number of buckets per load ( 3.57 / 0.71 ) say : 5 buckets Ideal cycle time for loading 5 buckets ( 5 x 45 / 60 ) : 3.75 min The ideal cycle time for shovel requires spotting of a tipper within 3.75 minutes near the shovel. However, in practice for dam or canal excavation the space available may not permit positioning

of tippers on either side of the shovel. Generally one tipper has to move after loading to position next tipper for loading. Assuming one loading cycle extra, the corrected cycle time for shovel will be ( 6 x 45 / 60 ) 4.50 min Round trip cycle time for tipper: Cycle time of shovel for digging & loading : 4.50 min Time for 1 km haulage under load ( 60 / 15 ) : 4.00 min Time for turning and un-loading : 2.00 min Time for 1km return trip ( 60 / 20 ) : 3.00 min Time for turning and spotting : 0.50 min

20

DAM ALLIED WORKS

4.

5.

6.

7.

Total : 14.00 min No.of tippers to match corrected cycle time of shovel (14.0 / 4.5) : 3.11 Nos Output of tipper / hr with 50 min working / hr ( 50 x 3.57 / 14.00 ) : 12.75 cum Time for disposal of 485 cum muck by 3 tippers ( 485 / 12.75 / 3 ) say : 12.7 hours Requirement of materials : 100 mm dia TC bit : 108 m drilling Extension rods with sleeve : 108 m drilling Jack hammer drill rod : 15 m drilling Quantity of Explosive @ 0.5 kg / cum for 480 cum : 240.00 kg Consider 20 % high strength ANFO booster for priming ANFO. : 48.00 kg Consider 80 % ANFO mixed with diesel oil for colunm. : 192.00 kg Diesel oil @ 180 ml per kg of ANFO : 35.00 ltrs Quantity of Explosive @ 0.2 kg / cum for secondary blast : 5 kg Ordinary detonators for secondary blasting : 24 Nos. Detonating cord for 18 holes in 3 rows : 150 Rm. Detonating fuse coil for secondary blasting : 24 Rm Requirement of machinery : Deploy 0.85 cum capacity shovel for 13 hours for digging and loading 480 cum. Deploy 3 tippers 5 cum capacity for 13 hours for disposal of 480 cum. Deploy 1 tipper for 5 hours for disposal of 20 cum trimmed muck. Deploy 2 air compressors 8.5 cmm capacity for 5.5 hours for waggon drill holes. Deploy 2 waggon drills for 5.5 hours for drilling main blast holes. Deploy 1 air compressor 8.5 cmm capacity for 2 hours for jack hammer holes. Deploy 2 jack hammers for 2 hours for drilling secondary blast holes. Deploy 1 angle dozer for 2.5 hour for levelling muck in dump area. Requirement of workforce ( other than machinery crew ) : Deploy 2 Crowbarman, 2 Stone breaker for 1 day for trimming. Deploy 5 heavy and 5 light mazdoors for disposal of 20 cum residual muck and other works. Deploy 1 blaster and 1 blasting helper for loading and blasting. Deploy 1 Maistry. Use rate of materials : Cost of T.C bit 100 mm dia @ Rs: 9615.00 / Each Rs: 9615.00 Life of drill bit for drilling in hard rock : 80 m Use rate of T.C bit per Rm drilling ( Cost / Life ) Rs: 120.19 Cost of extn rod with sleeve 4.5 m @ Rs: 3300.00 / Rm Rs: 14850.00 Life of extension rod : 1500 m Use rate of extension rod per Rm drilling ( Cost / Life ) Rs: 9.90 Cost of 1.5 m drill rod @ Rs: 3400.00 / Each Rs: 3400.00 Life of drill rod for drilling in hard rock with reconditioning : 150 m Use rate of drill rod per Rm drilling ( Cost / Life ) Rs: 22.67 Length of air hose for drilling for each jack hammer : 50 m Cost of 50 m air hose 25 mm dia @ Rs: 150.00 / Rm Rs: 7500.00

Life of air hose Use rate of air hose per hr Cost of 50 m air hose 50 mm dia @ Life of air hose Use rate of air hose per hr

Rs:

( Cost / Life ) 197.00 / Rm ( Cost / Life ) UNIT : Unit Quantity

: 800 hours Rs: 9.38 Rs: 9850.00 : 800 hours Rs: 12.31 500.00 cum Rate in Rs. Amount in Rs.

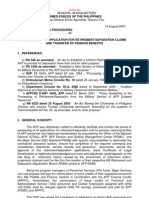

RATE ANALYSIS A. MATERIALS: Sl No Perticulars

21

DAM ALLIED WORKS

1 2 3 4 5 6 7 8 9 10 11 12

Use rate of T.C bit 100 mm dia Use rate of Extension rod with sleeve Use rate of Jack hammer drill rod 1.5 m Reconditioning charges @ 10 % Use rate of air hose for waggon drill Use rate of 25 m air hose for JH 2 Nos High strength ANFO booster ANFO Diesel oil Explosive small dia ( Kelvex-220 ) Ordinary detonators D-cord Detonating fuse coil Sundries Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

Rm Rm Rm Hour Hour kg kg ltr kg Nos Rm Rm LS

108.00 108.00 15.00 11.00 4.00 48.00 192.00 35.00 5.00 24.00 150.00 24.00 5.00

120.19 9.90 22.67 12.31 9.38 50.00 32.00 40.00 45.00 5.50 8.00 8.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

1% 10% 5% Total cost of Materials :

12980.25 1069.20 340.00 34.00 135.44 37.50 2400.00 6144.00 1400.00 225.00 132.00 1200.00 192.00 150.00 26439.39 264.39 2643.94 1321.97 30669.69

B. MACHINERY: Sl No 1 2 3 4 5 6

Description

Unit Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour

Quantity 44.00 44.00 13.00 13.00 2.50 2.50 13.00 13.00 11.00 11.00 4.00 4.00

Tippers 5 cum capacity Fuel / Energy charges Shovel 0.85 cum capacity Fuel / Energy charges Angle dozer Fuel / Energy charges Air compressor 8.5 cmm ( ele ) Fuel / Energy charges Waggon drill Fuel / Energy charges Jack hammer Fuel / Energy charges

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery :

Rate in Rs. 271.00 208.00 1199.00 605.00 1154.00 423.00 108.00 282.00 216.00 9.00 14.00 5.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 11924.00 9152.00 15587.00 7865.00 2885.00 1057.50 1404.00 3666.00 2376.00 99.00 56.00 20.00 56091.50 560.92 2185.95 2804.58 61642.94

C. LABOUR: Sl No 1 2 3 4 5 6 7 8

Description

Unit Hour Hour Hour Hour Hour Hour Day Day

Quantity 44.00 13.00 2.50 13.00 11.00 4.00 1.00 1.00

Crew for Tipper Crew for Shovel Crew for Dozer Crew for Air compressor Crew for Waggon drill Crew for Jack hammer Maistry Blaster

Rate in Rs. 56.70 77.50 77.50 56.40 89.50 111.90 141.50 147.00

Amount in Rs. 2494.80 1007.50 193.75 733.20 984.50 447.60 141.50 147.00

22

DAM ALLIED WORKS

9 10 11 12 13

Helper blaster Crowbarman Stone breaker Heavy mazdoor Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for additional hidden cost on Labour @ Add for Contractor's Overheads @

Day Day Day Day Day

1.00 2.00 2.00 5.00 5.00

1% 10% 15% 5% 5% Total cost of Labour :

141.50 141.50 146.00 132.00 130.50 Total Rs: Rs: Rs: Rs: Rs: Rs: Rs:

141.50 283.00 292.00 660.00 652.50 8178.85 81.79 817.89 1226.83 408.94 408.94 11123.24

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour

Rs: 30669.69 Rs: 61642.94 Rs: 11123.24 TOTAL Rs: 103435.87 Add for other enabling works @ 1.40% Rs: 1448.10 Total cost for 500.00 cum Rs: 104883.97 Rate per cum Rs: 210.00 Consider average rate ( excavation by deploying Jack hammer & Waggon drill ) for SR. Rate per cum ( 283.00 + 210.00 ) / 2 Rs: 247.00 Rate approved per cum Rs: 247.00 SECTION: DAM AND ALLIED WORKS. YEAR : 2010-11 ITEM No: 4.b

ITEM: Excavation for foundation in hard rock of all toughness including boulders above 0.6 m dia. ( 0.113 cum ) by approved controlled blasting methods including control of vibration by use of delay detonators and control of fly-rock by muffling for dam, spillway, intake structure, surface power house and other appurtenant structures etc., adopting only jack hammer holes and minimising damage to rock beyond excavation line by adopting any one or combination of line drilling / pre-splitting / smooth blasting techniques and stacking the excavated rock neatly in approved dump area as directed etc., complete with initial lead upto 1 km and all lifts. DATA: Generally for dam works excavation in hard rock is for limited depth to remove top jointed and skin material to expose fresh rock for seating of structure. Therefore, the depth of hole is limited to 0.90 m for rate analysis. Consider drilling by Jack hammers and mucking by deploying Shovel and tippers.

Excavation in hard rock by controlled blasting method with arrangements for control of fly-rock is generally adopted where there are structures very close to dam site or for foundation excavation for dam blocks in flood gap portion or for excavation of power house pit / sluice structures near toe of dam blocks. Work requires: - Limiting the depth of holes and use of delay detonators to minimise explosive energy to reduce ground vibrations. - covering blasting area with chain link mesh or waste conveyor belts or waste tyres and sand bags to prevent flying of rock fragments during blasting. Capacity of shovel bucket : 0.85 cum Capacity of shovel bucket under heaped condition : 1.00 cum Capacity of tipper : 5.00 cum

23

DAM ALLIED WORKS

Lead for disposal of excavated hard rock : Upto 1 km Speed for loaded tipper under haul road condition : 15 km / hr Speed for empty tipper under haul road condition : 20 km / hr Turning and unloading time : 2.00 min Shovel digging and loading cycle per bucket : 45 sec 1. Quantity of excavation : In-situ quantity / bucket for 40 % bulkage on unloading ( 1 / 1.40 ) : 0.71 cum In-situ quantity per load for 5 cum of hard rock ( 5 / 1.40 ) : 3.57 cum Number of buckets per load ( 3.57 / 0.71 ) say : 5 buckets Ideal cycle time for loading 5 buckets ( 5 x 45 / 60 ) : 3.75 min The ideal cycle time for shovel requires spotting of a tipper within 3.75 minutes near the shovel. However, in practice for dam or canal excavation, the space available may not permit positioning of tippers on either side of the shovel. Generally one tipper has to move after loading to position the next tipper for loading. Assuming one extra cycle for shovel, the corrected cycle time for the shovel will be : : 4.50 min Round trip cycle time for tipper: Cycle time of shovel for digging & loading : 4.50 min Time for 1km haulage under load ( 60 / 15 ) : 4.00 min Time for turning and un-loading : 2.00 min Time for 1 km return trip ( 60 / 20 ) : 3.00 min Time for turning and spotting : 0.50 min Total : 14.00 min No.of tippers to match corrected cycle time of shovel (14.0 / 4.5) : 3.11 Nos Output of tipper / hr with 50 min working / hr ( 50 x 3.57 / 14.00 ) : 12.75 cum Time for disposal of 91 cum muck by 3 tippers ( 91 / 12.75 / 3 ) say : 2.5 hours Further, consider loading of about 95 percent excavated rock by shovel and 5 percent excavated rock mainly consisting of trimmed bed material and blasted boulders etc., by manual labour. Daily quantity of excavation in hard rock ( 91 / 0.95 ) say : 96 cum Consider 96 cum for rate analysis. 2. Drilling and Blasting : Depth of drilling per hole : 0.90 m Effective depth of hole for jack hammer drilling ( 0.9 - 0.1 ) : 0.80 m The burden ( distance of hole from free face of excavation ) is considered at 30 times diameter of hole and spacing of holes is considered at 1.20 times burden. Burden for 32 mm dia jack hammer holes say : 1.00 m Spacing of holes @ 1.20 times burden : 1.20 m Grid spacing of holes in m : 1.00 x 1.20 m For a dam of medium height the width of foundation will be about 30 to 35 m.

Consider half width of the block for drilling and blasting at a time. No. of holes in a row for 17 m width @ 1.2 m C/C ( 17 / 1.2 ) : 14 Nos. Generally, the length of excavation in hard rock at a time will be limited to 6 to 7 rows for effective blasting to minimise digging and loading cycle of shovel. Consider 7 m length of excavation per blast. No. of rows of holes for 7 m width @ 1 m burden (7/1) : 7 rows Drilling and Blasting pattern : Pattern of holes : Staggered Hole initiation : Bottom Initiation system : Short delay detonators Delay system : 25 ms interval Initiation pattern : Straight line row by row Nos. of main blast holes for 7 rows ( 4 x 14 + 3 x 13 ) : 95 Nos.

24

DAM ALLIED WORKS

Area of excavation for 95 holes ( 95 x 1.2 x 1.0 ) : 114 sqm Quantity of excavation for 0.8 effective depth ( 114 x 0.8 ) say : 91 cum Secondary blasting may be necessary after main blasting to break any large rock fragments. Quantity for secondary blasting @ 5 % ( 91 x 0.05 ) : 5 cum. Nos. of secondary blast holes @ 1 per cum for 9 cum (5x1) : 5 Nos. Depth of drilling for main blast ( 95 x 0.9 ) : 85.50 m Depth of drilling for secondary holes @ 0.6 m / cum ( 5 x 0.6 ) say : 3.00 m Total depth of drilling for main and secondary blasting : 88.50 m Consider 2 Nos. 8.5 cmm air compressors and 4 jack hammers for drilling. Rated rate of drilling in hard rock by jack hammer : 6 m / hour Rate of drilling in hard rock with 50 min / hr working ( 6 x 50 / 60 ) : 5 m / hour Time required for drilling with 4 jack hammers ( 88.5 / 4 / 5 ) say : 4.5 hours 3. Muffling arrangements: For controlling flying of rock fragments during blasting consider covering the blasting area with 20 guage 50 x 50 mm opening chain link mesh and sand bags. Consider spreading chain link mesh 0.5 m beyond excavation area. Area of chain link mesh ( 17 +1 ) x ( 7 + 0.5 ) : 135 sqm Add for overlaps @ 10 % say : 15 sqm Total : 150 sqm Sand bags at 1 per hole : 95 Nos. Add for additional sand bags along edge of wire mesh @ 20 % say : 19 Nos Total : 114 Nos 4. Requirement of materials: Jack hammer drill rods for drilling : 88.5 m drilling Air hose for supplying air to 4 jack hammers ( 4.5 x 4 ) : 18 hours Quantity of Explosive @ 0.5 kg / cum for 96 cum : 48.00 kg Consider 20 % high strength ANFO booster for priming ANFO. : 10.00 kg Consider 80 % ANFO mixed with diesel oil for colunm. : 38.00 kg Diesel oil @ 180 ml per kg of ANFO : 7.00 ltrs Explosive at 0.20 kg / cum for 5% secondary blast ( 91x0.05x0.2 ) : 1.00 kg Ele.short delay detonators at 1 per hole for 95 holes ( 95 x 1 ) : 95 Nos. Ord.detonators @ 1 per hole for 5 secondary holes (5x1) : 5 Nos. Detonating fuse coil : 120 Rm 50 x 50 mm wire mesh : 150 sqm Sand bags 114 Nos. 5. Requirement of machinery : Deploy 2 air compressors 8.5 cmm capacity for 4.5 hours for drilling.

Deploy 4 jack hammers for 4.5 hours for drilling. Deploy 0.85 cum capacity shovel for 2.5 hours for digging and loading 91 cum. Deploy 3 tippers of 5 cum capacity for for 2.5 hours for disposal of 91 cum. Deploy 1 tipper of 5 cum capacity for 1 hours for 5 cum trimmed rock. Deploy 1 dozer for 0.5 hour for levelling dumped rock in dump area. 6. Requirement of workforce ( other than machinery crew ) : Deploy 1 crowbarman, 1 stone breaker for trimming bed for 5 cum. Deploy 1 blaster and 1 blasting helper for loading explosive materials and blasting. Deploy 2 heavy and 2 light mazdoors for disposal of trimmed muck and for spreading / placing and removing wire mesh / sand bags. Deploy 1 maistry. 7. Use rate of materials : Cost of drill rod 1.5 m long @ Rs: 3400.00 / Each Rs: 3400.00 Life of drill rod for drilling in hard rock with reconditioning : 150 m

25

DAM ALLIED WORKS

Use rate of drill rod per Rm drilling ( cost / life ) Length of 25 mm dia air hose for drilling for each jack hammer Cost of 50 m air hose @ Rs: 150.00 / Rm Life of air hose Use rate of 25 mm dia air hose per hr ( cost / life ) Cost of 20 gauge wire mesh @ Rs: 150.00 / sqm Less salvage value @ 10 % Add for replacement of damaged mesh @ 10%

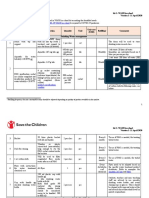

Life of wire mesh Use rate of wire mesh / use / sqm ( cost / life ) Cost of empty cement bag @ Rs: 1.50 Cost of sand / bag for 0.025 cum @ Rs: 154.00 / cum Add for 1 km lead / loading / unloading charges for 0.025 cum Filling charges @ 2 heavy mazdoors per 100 bags/ day Total cost per bag Life of sand bag Use rate of sand bag / use / bag ( cost / life ) RATE ANALYSIS A. MATERIALS: Sl No 1 2 3 4 3 4 5 6 7 Perticulars Unit Rm Hour sqm Nos kg kg ltr kg Nos Quantity 88.50 18.00 150.00 114.00 10.00 38.00 7.00 1.00 5.00 UNIT :

Rs: : Rs: : Rs: Rs: ( - ) Rs: Total Rs: Rs: Total Rs: : Rs: Rs: Rs: Rs: Rs: Rs: : Rs:

22.67 50 m 7500.00 800 hours 9.38 150.00 -15.00 135.00 13.50 148.50 3 uses 49.50 1.50 3.85 2.12 2.64 10.11 1 use 10.11

96.00 cum Rate in Rs. 22.67 9.38 49.50 10.11 50.00 32.00 40.00 45.00 5.50 Contd Amount in Rs. 2006.00 200.60 168.75 7425.00 1152.83 500.00 1216.00 280.00 45.00 27.50

Use rate of drill rod 1.5 m length Reconditioning charges @ 10 % Use rate of 25 mm dia air hose 4 Nos. Use rate of 20SWG chain link wiremesh Use rate of sand bag High strength ANFO booster Ammonium nitrate ( ANFO ) Diesel Explosive small dia. Ordinary detonators

A. MATERIALS ( Contd ) : Sl No Perticulars

Unit

Quantity

8 9 10

Electric short delay detonators Fuse coil Sundries Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

Nos Rm LS

95.00 120.00 3.00

1% 10% 5% Total cost of Materials :

Rate in Rs. Contd 18.00 8.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 1710.00 960.00 90.00 15781.68 157.82 1578.17 789.08 18306.74

B. MACHINERY: Sl No

Description

Unit

Quantity

Rate

Amount

26

DAM ALLIED WORKS

1 2 3 4 5 6

Shovel 0.85 cum capacity Fuel / Energy charges Angle dozer 90 hp Fuel / Energy charges Tippers 5 cum capacity 3 Nos. Fuel / Energy charges Tipper 5 cum capacity 1 No Fuel / Energy charges Air compressor 8.5 cmm ( ele ) 2 Nos Fuel / Energy charges Jack hammers 4 Nos. Fuel / Energy charges

Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour

2.50 2.50 0.50 0.50 7.50 7.50 1.00 1.00 9.00 9.00 18.00 18.00

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4 5 6 7 8 9 10 11

in Rs. 1199.00 605.00 1154.00 423.00 271.00 208.00 271.00 208.00 108.00 282.00 14.00 5.00 Total Rs: Rs: Rs: Rs: Rs:

in Rs. 2997.50 1512.50 577.00 211.50 2032.50 1560.00 271.00 208.00 972.00 2538.00 252.00 90.00 13222.00 132.22 612.00 661.10 14627.32

Description

Unit Hour Hour Hour Hour Hour Hour Day Day Day Day Day

Quantity 2.50 0.50 7.50 1.00 9.00 18.00 1.00 1.00 1.00 1.00 1.00

Crew for Shovel Crew for Angle dozer Crew for Tipper Crew for Tipper Crew for Air compressor Crew for Jack hammer Maistry Blaster Helper blaster Crowbarman Stone breaker

Rate in Rs. 77.50 77.50 56.70 56.70 56.40 111.90 141.50 147.00 141.50 141.50 146.00 Contd

Amount in Rs. 193.75 38.75 425.25 56.70 507.60 2014.20 141.50 147.00 141.50 141.50 146.00

C. LABOUR ( Contd ) : Sl No Description

Unit

Quantity

13 14

Heavy mazdoor Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for additional hidden cost on labour @ Add for Contractor's Overheads @

Day Day

2.00 2.00

1% 10% 15% 5% 5% Total cost of Labour :

Rate in Rs. Contd 132.00 130.50 Total Rs: Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 264.00 261.00 4478.75 44.79 447.88 671.81 223.94 223.94 6091.10

ABSTRACT: A. Cost of Materials

Rs:

18306.74

27

DAM ALLIED WORKS

B. Hire charges of Machinery C. Cost of Labour TOTAL Add for enabling works @ Total cost for 1.40% 96.00 cum Rate per cum Rate approved per cum YEAR : 2010-11

Rs: Rs: Rs: Rs: Rs: Rs: Rs:

14627.32 6091.10 39025.16 546.35 39571.52 412.00 412.00 ITEM No: 5

SECTION: DAM AND ALLIED WORKS.

ITEM: Preparing foundation bed for masonry or concrete by removing all loose material by wedging / chiselling and disposing off the same as directed and cleaning the surface with air and water jet etc.,complete with initial lead upto 50 m and all lifts. DATA: Preparation of foundation bed for laying concrete / masonry involves benching and stepping the foundation area, removing all loose material by wedging / chiselling and disposing off the same followed by cleaning the area with air and water jet. Coonsider preparation of 100 sqm area for rate analysis. 1. Requirement of materials: Air and water hoses for air / water jet cleaning. : 1 hour use 2. Requirement of machinery : Deploy 1 air compressor 8.5 cmm capacity for 1 hour for air supply. Deploy 5 hp pump for 1 hour for water supply. 3. Requirement of workforce ( other than machinery crew ) : 1 Crowbarman, 1 stone breaker and 1 heavy mazdoor prepare 50 sqm per day. Deploy 2 crowbarman, 2 stone breakers and 2 heavy mazdoors for 100 sqm preparation. 4. Use rate of materials : Length of 25 mm dia air hose for air jet cleaning. : 50 m Cost of 25 m air hose @ Rs: 150.00 / Rm Rs: 3750.00 Life of air hose : 800 hours Use rate of 25 mm dia air hose per hr ( cost / life ) Rs: 4.69 Length of 20 mm dia water hose for water jet cleaning. : 50 m Cost of 25 m water hose @ Rs: 128.00 / Rm Rs: 3200.00

Life of water hose Use rate of 20 mm dia water hose per hr RATE ANALYSIS A. MATERIALS: Sl No 1 2 Perticulars Unit Hour Hour

( cost / life ) UNIT : Quantity 1.00 1.00

: 800 hours Rs: 4.00 100.00 sqm Rate in Rs. 4.69 4.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 4.69 4.00 8.69 0.09 0.87 0.43 10.08

Use rate of 25 mm dia air hose Use rate of 20 mm dia. water hose Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

1% 10% 5% Total cost of Materials :

B. MACHINERY: Sl No

Description

Unit

Quantity

Rate

Amount

28

DAM ALLIED WORKS

1 2

Air compressor 8.5 cmm ( ele ) Fuel / Energy charges Pump 5 hp ( ele ) Fuel / Energy charges

Hour Hour Hour Hour

1.00 1.00 1.00 1.00

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4 5

in Rs. 108.00 282.00 3.00 25.00 Total Rs: Rs: Rs: Rs: Rs:

in Rs. 108.00 282.00 3.00 25.00 418.00 4.18 30.70 20.90 473.78

Description

Unit Hour Hour Day Day Day

Quantity 1.00 1.00 2.00 2.00 2.00

Crew for Air compressor Crew for Pump Stone breaker Heavy mazdoor Crowbar man Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add additional hidden cost on labour @ Add for Contractor's Overheads @

1% 10% 15% 5% 5% Total cost of Labour :

Rate in Rs. 56.40 26.90 146.00 132.00 141.50 Total Rs: Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 56.40 26.90 292.00 264.00 283.00 922.30 9.22 92.23 138.35 46.12 46.12 1254.33

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour TOTAL

Rs: Rs: Rs: Rs:

10.08 473.78 1254.33 1738.19

Add for enabling works @ Total cost for

1.40% 100.00 sqm Rate per sqm Rate approved per sqm YEAR : 2010-11

Rs: Rs: Rs: Rs:

24.33 1762.52 18.00 18.00 ITEM No: 6

SECTION: DAM AND ALLIED WORKS.

ITEM: Preparing foundation bed for cut-off trench filling in rock portion by removing all loose materials by wedging / chiselling and disposing off the same as directed etc., complete with initial lead upto 50 m and all lifts. DATA: Preparation of foundation bed for cut-off trench in rock portion involves removing all loose material by wedging / chiselling and disposing off the same. Coonsider preparation of 100 sqm area for rate analysis. 1. Requirement of materials: No materials required. 2. Requirement of machinery : No machinery required.

29

DAM ALLIED WORKS

3. Requirement of workforce : 1 Crowbarman, 1 stone breaker and 1 heavy mazdoor prepare 50 sqm per day. Deploy 2 crowbarman, 2 stone breakers and 2 heavy mazdoors for 100 sqm preparation. RATE ANALYSIS A. MATERIALS: Sl No 1 Perticulars NIL Unit Quantity 0.00 0.00 1% 10% 5% Total cost of Materials : UNIT : 100.00 sqm Rate in Rs. 0.00 0.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 0.00 0.00 0.00 0.00 0.00 0.00 0.00

Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

B. MACHINERY: Sl No 1

Description NIL

Unit

Quantity 0.00 0.00

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 Crowbar man

Rate in Rs. 0.00 0.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 0.00 0.00 0.00 0.00 0.00 0.00 0.00

Description

Unit Day

Quantity 2.00

Rate in Rs. 141.50 Contd

Amount in Rs. 283.00

C. LABOUR ( Contd ) : Sl No Description

Unit

Quantity

2 3

Stone breaker Heavy mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for additional hidden cost on labour @ Add for Contractor's Overheads @

Day Day

2.00 2.00

1% 10% 15% 5% 5% Total cost of Labour :

Rate in Rs. Contd 146.00 132.00 Total Rs: Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 292.00 264.00 839.00 8.39 83.90 125.85 41.95 41.95 1141.04

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour TOTAL

Rs: Rs: Rs: Rs:

0.00 0.00 1141.04 1141.04

30

DAM ALLIED WORKS

Add for enabling works @ Total cost for

1.40% 100.00 sqm Rate per sqm Rate approved per sqm YEAR : 2010-11

Rs: Rs: Rs: Rs:

15.97 1157.01 12.00 12.00 ITEM No: 7

SECTION: DAM AND ALLIED WORKS.

ITEM: Drilling 50 mm dia holes vertical or inclined upto 10 degrees to vertical in rock / masonry / concrete by percussion drilling using waggon drill or any other suitable equipment including cost of all materials, machinery, labour, redrilling through partially set grout wherever required etc., complete. for drilling upto 6 m depth from surface. NOTE:The item rate for drilling through rock / masonry / concrete includes redrilling through partially set grout, if any, in the portion of hole already grouted. DATA: The rated output of waggon for drilling in rock / masonry / concrete in open area will be about 20 m per hour. Consider drilling and grouting of holes in 6 m stages. Consider 70 percent job / management efficiency and 50 minutes per hour working. Rate of drilling by waggon drill per hour ( 20 x 0.7 x 50 / 60 ) say : 12 m Out put of 1 waggon drill per day ( 8 x 12 ) : 96 m Consider 50 m long 50 mm dia air hose for supply of air to waggon drill. For 6 m drilling average 4.5 m extension rods with coupling sleeves required. For drilling in hard rock beyond 6 m from surface increase the basic rate per Rm of previous stage by 10 percent for next stage of 6 m beyond previous stage towards redrilling in partially set grout / additional extension rods / reduction in progress etc. Consider 96 m ( 16 holes of 6 m depth each ) drilling for rate analysis. 1. Requirement of materials: Cross bit 50 mm dia. : 96 m use Extension rod with coupling sleeve 4.5 m : 96 m use Air hose 50 mm dia for air supply : 8 hours use

2. Requirement of machinery : Deploy 1 air compressor 8.5 cmm capacity for 8 hour for air supply. Deploy 1 waggon drill for 8 hour for drilling holes. 3. Requirement of workforce ( other than machinery crew ) : Deploy 2 heavy mazdoors for assisting drilling crew. 4. Use rate of materials : Cost of 50 mm dia cross bit @ Rs: 3485.00 / Each Life of cross bit 50 mm dia in rock Use rate of cross bit per m drilling ( cost / life ) Cost of extension rod 4.5 m @ Rs: 3300.00 / Rm Life of extension rod with coupling sleeve Use rate of 4.5 m extn rod per m drilling ( cost / life ) Cost of 50 mm dia air hose 50 m @ Rs: 197.00 / Rm Life of air hose Use rate of 50 mm dia air hose per hour ( cost / life ) RATE ANALYSIS A. MATERIALS: Sl No Perticulars Unit Quantity UNIT :

Rs: 3485.00 : 80 m Rs: 43.56 Rs: 14850.00 : 1500 m Rs: 9.90 Rs: 9850.00 : 800 m Rs: 12.31 96.00 Rm Rate in Rs. Amount in Rs.

31

DAM ALLIED WORKS

1 2 3

Use rate of cross bit 50 mm dia Use rate of 50 mm dia air hose 50 m Use rate of extension rod 4.5 m Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

Rm Hour Rm

96.00 8.00 96.00

1% 10% 5% Total cost of Materials :

43.56 12.31 9.90 Total Rs: Rs: Rs: Rs: Rs:

4182.00 98.50 950.40 5230.90 52.31 523.09 261.55 6067.84

B. MACHINERY: Sl No 1 2 3

Description

Unit Hour Hour Hour Hour LS

Quantity 8.00 8.00 8.00 8.00 2.00

Waggon drill Fuel / Energy charges Air compressor 8.5 cmm ( ele ) Fuel / Energy charges Sundries

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2

Rate in Rs. 216.00 9.00 108.00 282.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 1728.00 72.00 864.00 2256.00 60.00 4980.00 49.80 238.80 249.00 5517.60

Description

Unit Hour Hour

Quantity 8.00 8.00

Crew for Waggon drill Crew for Air compressor

Rate in Rs. 89.50 56.40 Contd

Amount in Rs. 716.00 451.20

C. LABOUR ( Contd ) : Sl No Description

Unit

Quantity

Heavy mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for additional hidden cost on labour @ Add for Contractor's Overheads @

Day

2.00

1% 10% 15% 5% 5% Total cost of Labour :

Rate in Rs. Contd 132.00 Total Rs: Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 264.00 1431.20 14.31 143.12 214.68 71.56 71.56 1946.43

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour TOTAL Add for enabling works @ Total cost for Upto 6 m from surface 1.40% 96.00 Rm Rate per Rm

Rs: Rs: Rs: Rs: Rs: Rs: Rs:

6067.84 5517.60 1946.43 13531.88 189.45 13721.32 143.00

32

DAM ALLIED WORKS

Rate approved per Rm Beyond 6 m upto 12 m from surface : Upto 6 m from surface Rate per Rm Add for redrilling through partially set grout / additional extension rods / reduction in rate of drilling etc @ 10% Beyond 6 m upto 12 m from surface Rate / Rm Rate approved per Rm Beyond 12 m upto 18 m from surface : For 6 m to 12 m from surface Rate per Rm Add for redrilling through partially set grout / additional extension rods / reduction in rate of drilling etc @ 10% Beyond 12 m upto 18 m from surface Rate / Rm Rate approved per Rm Beyond 18 m upto 24 m from surface : For 12 m to 18 m from surface Rate per Rm Add for redrilling through partially set grout / additional extension rods / reduction in rate of drilling etc @ 10% Beyond 18 m upto 24 m from surface Rate / Rm Rate approved per Rm Beyond 24 m upto 30 m from surface : For 18 m to 24 m from surface Rate per Rm Add for redrilling through partially set grout / additional extension rods / reduction in rate of drilling etc @ 10% Beyond 24 m upto 30 m from surface Rate / Rm Rate approved per Rm

Rs:

143.00

Rs: Rs: Rs: Rs:

143.00 14.30 157.00 157.00

Rs: Rs: Rs: Rs:

157.00 15.70 173.00 173.00

Rs: Rs: Rs: Rs:

173.00 17.30 190.00 190.00

Rs: Rs: Rs: Rs:

190.00 19.00 209.00 209.00

Beyond 30 m upto 36 m from surface : For 24 m to 30 m from surface Rate per Rm Add for redrilling through partially set grout / additional extension rods / reduction in rate of drilling etc @ 10% Beyond 30 m upto 36 m from surface Rate / Rm Rate approved per Rm Beyond 36 m upto 42 m from surface : For 30 m to 36 m from surface Rate per Rm Add for redrilling through partially set grout / additional extension rods / reduction in rate of drilling etc @ 10% Beyond 36 m upto 42 m from surface Rate / Rm Rate approved per Rm Beyond 42 m upto 48 m from surface : For 36 m to 42 m from surface Rate per Rm Add for redrilling through partially set grout / additional extension rods / reduction in rate of drilling etc @ 10% Beyond 42 m upto 48 m from surface Rate / Rm Rate approved per Rm

Rs: Rs: Rs: Rs:

209.00 20.90 230.00 230.00

Rs: Rs: Rs: Rs:

230.00 23.00 253.00 253.00

Rs: Rs: Rs: Rs:

253.00 25.30 278.00 278.00

33

DAM ALLIED WORKS

SECTION: DAM AND ALLIED WORKS.

YEAR : 2010-11

ITEM No: 8

ITEM: Flushing grout holes of all sizes with water and air jets alternatively for an average period of 30 minutes and observing water intake after flushing, cost of all materials, machinery, labour etc., complete. DATA: Period of flushing with air and water jets alternatively : 30 minutes Stage down grouting in 6 m stages assumed. Flushing of 4 holes at a time with air supply from one 8.5 cmm compressor to 2 holes at a time alternatively assumed. Considering 50 minutes / hour working and time required for water intake observation and shifting from hole to hole etc., 4 holes of 6 m each can be flushed in one hour. Daily progress with 1air compressor and a 5 hp pump (4x6x8) : 192 m Use of 2 Nos .air hoses 50 m each and 2 Nos. water hoses 50 m each considered for flushing 4 holes at a time in 1 hour. Consider 192 m flushing of holes for rate analysis. 1. Requirement of materials: Air hose 25 mm dia for air supply : 16 hours use Water hose 20 mm dia. for supplying water : 16 hours use 2. Requirement of machinery : Deploy 1 air compressor 8.5 cmm capacity for 8 hour for air supply. Deploy 5 hp pump for 8 hour for water supply. 3. Requirement of workforce ( other than machinery crew ) : Deploy 4 heavy mazdoors for washing holes. 4. Use rate of materials : Cost of 25 mm dia air hose 50 m @ Rs: 150.00 / Rm Rs: 7500.00 Life of air hose : 800 hours Use rate of 25 mm dia air hose per hour ( cost / life ) Rs: 9.38 Cost of 20 mm dia water hose 50m@ Rs: 128.00 / Rm Rs: 6400.00

Life of water hose Use rate of 20 mm dia water hose per hour RATE ANALYSIS A. MATERIALS: Sl No 1 2 3 Perticulars Unit Hour Hour LS

( cost / life ) UNIT : Quantity 16.00 16.00 2.00

: 800 hours Rs: 8.00 192.00 Rm Rate in Rs. 9.38 8.00 30.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 150.00 128.00 60.00 338.00 3.38 33.80 16.90 392.08

Use rate of air hose 2 Nos x 8 hrs Use rate of water hose 2 Nos x 8 hrs Sundries Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

1% 10% 5% Total cost of Materials :

B. MACHINERY: Sl No 1 2

Description

Unit Hour Hour Hour

Quantity 8.00 8.00 8.00

Air compressor 8.5 cmm ( ele ) Fuel / Energy charges Pump 5 hp ( ele )

Rate in Rs. 108.00 282.00 3.00

Amount in Rs. 864.00 2256.00 24.00

34

DAM ALLIED WORKS

Fuel / Energy charges Sundries

Hour LS

8.00 2.00

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3

25.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

200.00 60.00 3404.00 34.04 251.60 170.20 3859.84

Description

Unit Hour Hour Day

Quantity 8.00 8.00 4.00

Crew for Air compressor Crew for Pump Heavy mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for additional hidden cost on labour @ Add for Contractor's Overheads @

1% 10% 15% 5% 5% Total cost of Labour :

Rate in Rs. 56.40 26.90 132.00 Total Rs: Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 451.20 215.20 528.00 1194.40 11.94 119.44 179.16 59.72 59.72 1624.38

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour TOTAL

Rs: Rs: Rs: Rs:

392.08 3859.84 1624.38 5876.30

Add for enabling works @ Total cost for

1.40% 192.00 Rm Rate per Rm Rate approved per Rm YEAR : 2010-11

Rs: Rs: Rs: Rs:

82.27 5958.57 31.00 31.00 ITEM No: 9.a

SECTION: DAM AND ALLIED WORKS.

ITEM: Consolidation grouting with neat cement grout mix of suitable consistency under specified pressure as directed in drilled holes by stage grouting method including cost of all materials, machinery, labour, redrilling if necessary etc.,complete with initial lead upto 1 km and all lifts. DATA: Daily progress of grouting assumed for 6 m stage grouting Average grout intake assumed per m depth of hole Quantity of cement grouting per day ( 7 x 6 x 25 ) Consider 1.05 tonne cement grouting for rate analysis. 1. Requirement of materials: Cement with 1 % wastage ( 1050 x 1.01 ) Grout hose 20 mm dia. for supplying grout mix 2. Requirement of machinery : Deploy 1 Grout pump for 8 hour for pumping grout mix. Deploy 5 hp pump for 2 hour for water supply. 3. Requirement of workforce ( other than machinery crew ) : Deploy 1 heavy and 1 light mazdoors for cement handling. : 7 holes : 25 kg : 1050 kg

: 1060 kg : 8 hours use

35

DAM ALLIED WORKS

4. Rehandling lead : As cement is generally stored beyond 150 m from work area and is rehandled, as and when required, rehandling lead of 1km including loading and unloading is considered. 5. Use rate of materials: Cost of grout hose 50 m @ Rs: 128.00 / Rm Rs: 6400.00 Life of pressure hose : 800 hours Use rate of pressure hose per hour ( cost / life ) Rs: 8.00 RATE ANALYSIS A. MATERIALS: Sl No 1 2 3 Perticulars Unit tonne Hour LS Quantity 1.06 8.00 3.00 UNIT : 1.05 tonne Rate in Rs. 4000.00 8.00 30.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 4242.00 64.00 90.00 4396.00 43.96 439.60 219.80 5099.36

Cement with 1 % wastage Use rate of 50 m pressure hose Sundries ( packer assembly etc ) Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

1% 10% 5% Total cost of Materials :

B. MACHINERY: Sl No 1

Description

Unit Hour Hour

Quantity 8.00 8.00

Grouting equipment Fuel / Energy charges

Rate in Rs. 19.00 25.00 Contd

Amount in Rs. 152.00 200.00

B. MACHINERY ( Contd ) : Sl No Description

Unit

Quantity

2 3

Pump 5 hp ( ele ) Fuel / Energy charges Sundries

Hour Hour LS

2.00 2.00 2.00

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4

Rate in Rs. Contd 3.00 25.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 6.00 50.00 60.00 468.00 4.68 31.00 23.40 527.08

Description

Unit Hour Hour Day Day

Quantity 8.00 2.00 1.00 1.00 1% 10% 15%

Crew for Grout pump Crew for Pump Heavy mazdoor ( cement handling ) Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @

Rate in Rs. 89.20 26.90 134.00 130.50 Total Rs: Rs: Rs: Rs:

Amount in Rs. 713.60 53.80 134.00 130.50 1031.90 10.32 103.19 154.79

36

DAM ALLIED WORKS

Add for additional hidden cost on labour @ Add for Contractor's Overheads @

5% 5% Total cost of Labour :

Rs: Rs: Rs:

51.60 51.60 1403.38

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour Add for enabling works @ Add for 1km rehandling lead charges: Cement 1.06 tonne @ Rs: Total cost for

Rs: Rs: Rs: TOTAL Rs: 1.40% Rs: Total Rs: 129.10 / tonne 1.05 tonne Rate per tonne Rate approved per tonne YEAR : 2010-11 Rs: Rs: Rs: Rs:

5099.36 527.08 1403.38 7029.82 98.42 7128.24 136.85 7265.09 6919.00 6919.00 ITEM No: 9.b

SECTION: DAM AND ALLIED WORKS.

ITEM: Curtain grouting with neat cement grout mix of suitable consistency under specified grout pressure as directed in drilled holes by stage grouting method including cost of all materials, machinery, labour, redrilling if necessary etc., complete with initial lead upto 1 km and all lifts. DATA: Daily progress of grouting assumed for 6 m stage grouting Average grout intake assumed per m depth of hole Quantity of cement grouting per day ( 7 x 6 x 25 ) : 7 holes : 25 kg : 1050 kg

Consider 1.05 tonne cement grouting for rate analysis. 1. Requirement of materials: Cement with 1 % wastage ( 1050 x 1.01 ) : 1060 kg Grout hose 20 mm dia. for supplying grout mix : 8 hours use 25 mm dia G.I pipe grout line 400 m long. : 8 hours use 2. Requirement of machinery : Deploy 1 Grout pump for 8 hour for pumping grout mix. Deploy 5 hp pump for 2 hour for water supply. 3. Requirement of workforce ( other than machinery crew ) : Deploy 2 heavy and 1 light mazdoors for cement / G.I pipe handling. 4. Rehandling lead : As cement is generally stored beyond 150 m from work area and is rehandled, as and when required, rehandling lead of 1km including loading and unloading is considered. 5. Use rate of materials : Cost of grout hose 100 m @ Rs: 128.00 / Rm Rs: 12800.00 Life of pressure hose : 800 hours Use rate of pressure hose per hour ( cost / life ) Rs: 16.00 Cost of 25 mm GI pipe 400 m @ Rs: 100.00 / Rm Rs: 40000.00 Life of 25 mm dia GI Pipe : 10000 hours Use rate of 400 m GI pipe 25 mm dia per hour ( cost / life ) Rs: 4.00 RATE ANALYSIS A. MATERIALS: Sl No Perticulars Unit Quantity UNIT : Rate 1.05 tonne Amount

37

DAM ALLIED WORKS

1 2 3 4

Cement with 1 % wastage Use rate of 100 m pressure hose Use rate of 400 m GI pipe Sundries ( packer assembly etc ) Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

tonne Hour Hour LS

1.06 8.00 8.00 3.00

1% 10% 5% Total cost of Materials :

in Rs. 4000.00 16.00 4.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

in Rs. 4242.00 128.00 32.00 90.00 4492.00 44.92 449.20 224.60 5210.72

B. MACHINERY: Sl No 1 2 3

Description

Unit Hour Hour Hour Hour LS

Quantity 8.00 8.00 2.00 2.00 2.00

Grouting equipment Fuel / Energy charges Pump 5 hp ( ele ) Fuel / Energy charges Sundries

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery :

Rate in Rs. 19.00 25.00 3.00 25.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 152.00 200.00 6.00 50.00 60.00 468.00 4.68 31.00 23.40 527.08

C. LABOUR: Sl No 1 2 3 4 5

Description

Unit Hour Hour Day Day Day

Quantity 8.00 2.00 1.00 2.00 1.00

Crew for Grout pump Crew for Pump Pipe fitter Heavy mazdoor ( cement / pipe handling ) Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for additional hidden cost on labour @ Add for Contractor's Overheads @

1% 10% 15% 5% 5% Total cost of Labour :

Rate in Rs. 89.20 26.90 152.50 134.00 130.50 Total Rs: Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 713.60 53.80 152.50 268.00 130.50 1318.40 13.18 131.84 197.76 65.92 65.92 1793.02

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour Add for enabling works @ Add for 1km rehandling lead charges: Cement 1.06 tonne @ Rs: Total cost for

Rs: Rs: Rs: TOTAL Rs: 1.40% Rs: Total Rs: 129.10 / tonne 1.05 tonne Rs: Rs:

5210.72 527.08 1793.02 7530.82 105.43 7636.26 136.85 7773.10

38

DAM ALLIED WORKS

Rate per tonne Rate approved per tonne SECTION: DAM AND ALLIED WORKS. YEAR : 2010-11

Rs: Rs:

7403.00 7403.00 ITEM No: 9.c

ITEM: Cheching against up-heaval of foundation strata during grouting by installing up-heaval gauge including cost of all materials, machinery, labour, equipments etc., complete. DATA: Consider 1 test for rate analysis. 1. Requirement of materials: M.S casing pipe 40 mm dia G.I pipe 15 mm dia Micro meter dial gauge & accessories 2. Requirement of machinery : As this test is carried out during grouting no additional machinery required. 3. Requirement of workforce ( other than machinery crew ) : Deploy 1 heavy mazdoors for assisting testing staff. 5. Use rate of materials : Cost of 40 mm M.S pipe @ Rs: 200.00 / Rm Life of 40 mm dia M.S Pipe Use rate of M.S pipe 40 mm dia per Rm ( cost / life ) Cost of 15 mm G.I pipe @ Rs: 80.00 / Rm Life of 15 mm dia G.I Pipe Use rate of 50 m G.I pipe 15 mm dia per hour ( cost / life )

: 50 m : 50 m : 1 set

Rs: : 2 uses Rs: Rs: : 2 uses Rs:

200.00 100.00 80.00 40.00

RATE ANALYSIS A. MATERIALS: Sl No 1 2 3 4 Perticulars Unit Rm Rm LS LS Quantity

UNIT :

1.00 test Rate in Rs. 100.00 40.00 30.00 30.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 5000.00 2000.00 300.00 150.00 7450.00 74.50 745.00 372.50 8642.00

Use rate of M.S casing pipe 40 mm dia Use rate of G.I pipe 15 mm dia Micro meter dial gauge & accessories Sundries ( packer assembly etc ) Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

50.00 50.00 10.00 5.00

1% 10% 5% Total cost of Materials :

B. MACHINERY: Sl No 1

Description NIL

Unit

Quantity 0.00 0.00

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery :

Rate in Rs. 0.00 0.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 0.00 0.00 0.00 0.00 0.00 0.00 0.00

39

DAM ALLIED WORKS

C. LABOUR: Sl No 1

Description

Unit Day

Quantity 1.00 0.00

Heavy mazdoor

Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for additional hidden cost on labour @ Add for Contractor's Overheads @

1% 10% 15% 5% 5% Total cost of Labour :

Rate in Rs. 130.50 0.00 Total Rs: Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 130.50 0.00 130.50 1.31 13.05 19.58 6.53 6.53 177.48

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour TOTAL Add for enabling works @ Total cost for 1.40% 1.00 test Rate per 1.0 test Rate approved per test

Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs:

8642.00 0.00 177.48 8819.48 123.47 8942.95 8943.00 8943.00

SECTION: DAM AND ALLIED WORKS.

YEAR : 2010-11

ITEM No: 10

ITEM: Providing and fixing 25 mm dia 3 m long cold twisted deformed steel dowel bars with one end driven into 38 mm diameter 1.50 m deep hole drilled in bed rock and other end provided with L-bend for embedding in concrete / masonry of over flow / non-over flow blocks and other appertenant works including cost of drilling and cleaning hole, filling hole with cement slurry, driving anchor rod, cost of all materials, machinery, labour etc., complete with initial lead upto 1 km and all lifts. DATA: Consider 25 anchor rods for analysis. Depth of drilling for 25 holes of 1.5 m depth each ( 25 x 1.5 ) Weight of 25 mm dia rods 3 m long @ 3.85 kg / m ( 3 x 3.85 ) Cement for grouting per hole Rate of drilling by heavy duty Jack hammer / hr with 50 min / hr working Consider 2 heavy duty Jack hammers for drilling. Time for drilling 37.5 m duly considering frequent shifting 1. Requirement of materials: 25 mm dia ribbed steel with 2.5 % wastage ( 25 x 11.55 x 1.025 ) Cement with 1 % wastage ( 25 x 3 x 1.01 ) Air hose 25 mm dia. for supplying air to 2 jack hammers. Use of 38 mm drill rod 2. Requirement of machinery : Deploy 2 heavy duty jack hammers for 3.5 hours for drilling holes. Deploy 8.5 cmm Air compressor for 3.5 hours for air supply. 3. Requirement of workforce ( other than machinery crew ) : Deploy 0.5 barbender for preparing anchor rods. Deploy 0.5 mason Class-II and 1 heavy mazdoor for fixing anchor rods. 4. Rehandling lead :

: : : :

37.50 m 11.55 kg 3 kg 6.00 m

say : 3.5 hours : : : : 296 kg 76 kg 7 hours use 37.5 m

40

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Man Machine Interface SafetyDocument9 pagesMan Machine Interface SafetyVidyesh Viswanathan NairNo ratings yet

- Inspection and Maintenance of Steel Girders-4Document10 pagesInspection and Maintenance of Steel Girders-4vpmohammedNo ratings yet

- Is 778 - Copper Alloy ValvesDocument27 pagesIs 778 - Copper Alloy ValvesMuthu KumaranNo ratings yet

- Colibri - DEMSU P01 PDFDocument15 pagesColibri - DEMSU P01 PDFRahul Solanki100% (4)

- Well Stimulation TechniquesDocument165 pagesWell Stimulation TechniquesRafael MorenoNo ratings yet

- Gowtham Kumar Chitturi - HRMS Technical - 6 YrsDocument4 pagesGowtham Kumar Chitturi - HRMS Technical - 6 YrsAnuNo ratings yet

- SOP No. 6Document22 pagesSOP No. 6Eli CohenNo ratings yet

- Inspection and Maintenance of Steel Girders-1Document10 pagesInspection and Maintenance of Steel Girders-1vpmohammedNo ratings yet

- Fire and Life Safety Assessment ReportDocument5 pagesFire and Life Safety Assessment ReportJune CostalesNo ratings yet

- I.V. FluidDocument4 pagesI.V. FluidOdunlamiNo ratings yet

- Strategic Management ModelsDocument4 pagesStrategic Management ModelsBarno NicholusNo ratings yet

- Inspection and Maintenance of Steel Girders-11Document10 pagesInspection and Maintenance of Steel Girders-11vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-13Document10 pagesInspection and Maintenance of Steel Girders-13vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-12Document10 pagesInspection and Maintenance of Steel Girders-12vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-11Document10 pagesInspection and Maintenance of Steel Girders-11vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-11Document10 pagesInspection and Maintenance of Steel Girders-11vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-12Document10 pagesInspection and Maintenance of Steel Girders-12vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-7Document10 pagesInspection and Maintenance of Steel Girders-7vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-9Document10 pagesInspection and Maintenance of Steel Girders-9vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-10Document10 pagesInspection and Maintenance of Steel Girders-10vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-5Document10 pagesInspection and Maintenance of Steel Girders-5vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-8Document10 pagesInspection and Maintenance of Steel Girders-8vpmohammedNo ratings yet

- Fundamentals of Building Orientation 1-2Document11 pagesFundamentals of Building Orientation 1-2vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-9Document10 pagesInspection and Maintenance of Steel Girders-9vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-6Document10 pagesInspection and Maintenance of Steel Girders-6vpmohammedNo ratings yet

- IECRN Building Orientation-5 - 1Document10 pagesIECRN Building Orientation-5 - 1vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-5Document10 pagesInspection and Maintenance of Steel Girders-5vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-7Document10 pagesInspection and Maintenance of Steel Girders-7vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-2Document10 pagesInspection and Maintenance of Steel Girders-2vpmohammedNo ratings yet

- Inspection and Maintenance of Steel Girders-3Document10 pagesInspection and Maintenance of Steel Girders-3vpmohammed100% (1)

- IECRN Building Orientation-5 - 1Document10 pagesIECRN Building Orientation-5 - 1vpmohammedNo ratings yet

- IECRN Building Orientation-5 - 1Document10 pagesIECRN Building Orientation-5 - 1vpmohammedNo ratings yet

- Railway Curves 3 1Document10 pagesRailway Curves 3 1vpmohammedNo ratings yet

- Building Orientation 3 1Document10 pagesBuilding Orientation 3 1vpmohammedNo ratings yet

- Fundamentals of Building Orientation-4-2Document12 pagesFundamentals of Building Orientation-4-2vpmohammedNo ratings yet

- Fundamentals of Building Orientation 1-1Document10 pagesFundamentals of Building Orientation 1-1vpmohammedNo ratings yet

- Rail Steel 4Document6 pagesRail Steel 4vpmohammedNo ratings yet

- Fundamentals of Building Orientation 1-1Document10 pagesFundamentals of Building Orientation 1-1vpmohammedNo ratings yet

- Rail Steel 5Document18 pagesRail Steel 5vpmohammedNo ratings yet

- Chapter 1 Hospital and Clinical Pharmacy Choplete PDF Notes D.Pharma 2nd Notes PDF NoteskartsDocument7 pagesChapter 1 Hospital and Clinical Pharmacy Choplete PDF Notes D.Pharma 2nd Notes PDF NoteskartsDrx Brajendra LodhiNo ratings yet

- Faida WTP - Control PhilosophyDocument19 pagesFaida WTP - Control PhilosophyDelshad DuhokiNo ratings yet

- Invoice Acs # 18 TDH Dan Rof - Maret - 2021Document101 pagesInvoice Acs # 18 TDH Dan Rof - Maret - 2021Rafi RaziqNo ratings yet

- X HM11 S Manual AUpdfDocument228 pagesX HM11 S Manual AUpdfAntonio José Domínguez CornejoNo ratings yet

- A Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentDocument7 pagesA Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentNadiah AUlia SalihiNo ratings yet

- Minas-A6 Manu e PDFDocument560 pagesMinas-A6 Manu e PDFJecson OliveiraNo ratings yet

- Completed NGC3 ReportDocument4 pagesCompleted NGC3 ReportTiCu Constantin100% (1)

- scx4521f SeriesDocument173 pagesscx4521f SeriesVuleticJovanNo ratings yet

- Surge Arrester: Technical DataDocument5 pagesSurge Arrester: Technical Datamaruf048No ratings yet

- Karmex 80df Diuron MsdsDocument9 pagesKarmex 80df Diuron MsdsSouth Santee Aquaculture100% (1)

- RODECaster Pro II - DataSheet - V01 - 4Document1 pageRODECaster Pro II - DataSheet - V01 - 4lazlosNo ratings yet

- Si KaDocument12 pagesSi KanasmineNo ratings yet

- Oops in PythonDocument64 pagesOops in PythonSyed SalmanNo ratings yet

- ESK-Balcony Air-ADocument2 pagesESK-Balcony Air-AJUANKI PNo ratings yet

- IIBA Academic Membership Info-Sheet 2013Document1 pageIIBA Academic Membership Info-Sheet 2013civanusNo ratings yet

- CasesDocument4 pagesCasesNaveen Stephen LoyolaNo ratings yet

- BBCVDocument6 pagesBBCVSanthosh PgNo ratings yet

- Fact Pack Financial Services KenyaDocument12 pagesFact Pack Financial Services KenyaCatherineNo ratings yet

- Brazilian Mineral Bottled WaterDocument11 pagesBrazilian Mineral Bottled WaterEdison OchiengNo ratings yet

- Kit 2: Essential COVID-19 WASH in SchoolDocument8 pagesKit 2: Essential COVID-19 WASH in SchooltamanimoNo ratings yet

- EP2120 Internetworking/Internetteknik IK2218 Internets Protokoll Och Principer Homework Assignment 4Document5 pagesEP2120 Internetworking/Internetteknik IK2218 Internets Protokoll Och Principer Homework Assignment 4doyaNo ratings yet