Professional Documents

Culture Documents

Inspection of Anchorages Supporting Waterside

Uploaded by

Liliana RibeiroOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection of Anchorages Supporting Waterside

Uploaded by

Liliana RibeiroCopyright:

Available Formats

Mothersille and Barley

Inspection of Anchorages Supporting Waterside Structures

Devon Mothersille, Geoserve Global Ltd, England Tony Barley, Single Bore Multiple Anchor Ltd, England

Abstract

From 1969 ground anchorages were installed at Aberdeen Harbour to accommodate increases in quay wall depth brought on by accommodating a fully tidal harbour. For the majority of these anchorages, the corrosion protection measures employed would be judged inadequate by todays standards. The paper assesses the results of visual inspections and metallographic examinations, undertaken in 1991 and aimed at identifying the nature of corrosion on samples of strand that failed during testing. Observations are compared with a similar programme of inspections, carried out on 35 year old anchorages on the River Thames in London, and undertaken in 2005. Observations confirmed that, the anchor head protection on both contracts was not fit for extended use and were all in various states of corrosive degradation. The paper also describes the rating system, developed to create objective consistency in the inspection process, and the procedure used to extend the service life of the existing anchorages.

Introduction

The effective maintenance of waterside infrastructure is a matter of increasing concern particularly when considered in the context of climatic change and associated flood risks. Over the last 40 years UK engineers have routinely used ground anchorage technology to provide structural support to various types of waterside structure such as quay walls (Weerasinghe and Anson, 1997, Barley, 1992 and 1997, Littlejohn and Truman-Davies, 1974,). Despite the success of these applications in providing a cost effective solution, questions have been raised about the sustainability of the early systems. This is particularly relevant when new developments are planned that rely on the integrity of the existing infrastructure or when changes in environmental conditions increase the demand on the existing systems. For these reasons inspections and testing programmes are crucial activities in assessing the condition of existing anchorages and, where appropriate, to establish suitable remedial measures. This paper describes experiences with anchorage inspections at two UK sites; Aberdeen Harbour, Scotland and Greenhithe, London.

Mothersille and Barley

Aberdeen Harbour, Scotland

Between 1969 and 1982 over 360No ground anchorages were installed at Aberdeen Harbour to accommodate changes in quay wall loading brought on by changes in tidal conditions. These anchorages supported nine quay walls within the harbour complex and were routinely exposed to conditions that could create extensive corrosion of steel components in a highly aggressive marine environment. The anchorages were installed in two phases of development of anchorage corrosion requirements; between 1969-1976 and 1976-1982. During both phases of construction, contract specifications called for corrosion protection measures that would be judged inadequate or borderline by todays standards. The following sections focus on some key aspects of the inspection and testing works associated with this study. Anchorage construction Fixed anchor length protection The fixed anchor construction for the Aberdeen anchorages were of two types. Generally, the anchorages constructed during the first phase comprised fixed anchor protection that relied on the cement grout only and the cements alkalinity in providing a corrosion inhibiting environment. The fixed anchor lengths for the anchorages in the second phase of construction were encapsulated. Although these encapsulations were in early stages of development, the strands were protected by polyester resin within a galvanized cabco steel duct, and later by cement grout within a single corrugated plastic duct. Free anchor length protection Although it was not common practice prior to 1970, the free anchor lengths were protected, from that date, generally by greased sheathing. This was confirmed by inspection below the bearing plates in all the inspected quay walls. Underhead and Overhead protection In the underhead area protection was initially provided by cement grout and some partially effective ducting or sheathing. Between 1976-1982 a combination of cement grout and injected resin in the anchorages in combination with quality sheathing was developed. In the overhead areas, the anchors installed between 1969-1976 were either left unprotected or protected by means of bituminous paint applied to head plates, barrel and wedges and protruding strands or in some cases wrapped in grease impregnated tape. Anchors installed between1976-1982 were protected using screw on grease filled steel caps. Metallurgical examination of strand samples To improve understanding of the extent of corrosive damage, sections of free length strand with barrel and wedge attached were subjected to detailed examination. The samples were extracted from an anchor that had failed during routine proof load testing (Figure 1). Proof testing was undertaken to investigate debonding in the fixed anchor and to check that the fixed anchor was performing as designed. The sample was removed from a section of sheathed strand and visual inspection had confirmed that the sheathing

Mothersille and Barley

had sustained damage exposing the steel strand beneath. The location of the failure was just below the anchor head which was known to be a vulnerable location for corrosion related failures. Visual examination showed the failed strand to be extensively corroded with areas covered in shades of red and brown corrosion deposits, indicating localised contact with water, probably as a result of voids in the cement grout or poor quality construction operations. After removal of the corrosion product using inhibited acid, it was found that four of the seven wires showed evidence of pre existing cracks on the fractures faces (Figure 2a and 2b). The points of origin of the various cracks were found to be in the strand interstices, not in the outside facing regions. Observed distortion of the king wire suggests that the strand may have been loaded for some time with at least one of the peripheral wires broken. A longitudinal metallographic section, taken through one of the wire fractures, revealed the presence of several partially propagated cracks close to the fracture. The investigative report suggested that failure was due to a combination of corrosive attack in an area where corrosion protection had been damaged, exposing the strand, and fatigue mechanisms.

Figure 1 Failed 15mm diameter strand sample submitted for examination During routine proof load testing, to loads between working load and 1.33 times working load on another quay wall, failures occurred in 2 of the 15 strands tested. One failure occurred in the upper free length and the other above the barrel. The failed samples were visually examined with the aid of a low power binocular microscope. They were then cleaned in solvent and re-examined. Metallographic sections were taken from two of the wires and, after preparation, were examined using conventional optical microscope.

Mothersille and Barley

Figure 2a Fractured wire showing the presence of several cracks on the wire surface

Figure 2b As Figure 2a but cracks appear at a point some distance from the fracture face

Some slight corrosion pitting was observed on the Dyform face in close proximity to the corroded areas. After cleaning it was found that even in these areas only the outward facing surfaces had corroded and that the inside of the strand was free from corrosion. It was also noted that the grease was partially emulsified with water. All six wire fractures were found to be ductile tensile overload breaks (Figure3).

Figure 3 Sample of failed strand showing failure face

Figure 4 Localised corrosion in failed wire

Metallographic examination confirmed the non-existence of pre-existing surface defects and the corrosion appeared to have taken place by general dissolution of the surface rather than preferential crack formation and propagation. Conclusions from the specialist

Mothersille and Barley

test report were that the tensile failures resulted from loss of section due to corrosion (Figure 4) which itself was caused by the absence of protective grease from that section of strand.

Figure 5 Seaweed covered caps confirm highly aggressive marine environment for corrosion of steel in the lower tidal range

Figure 6 Correctly protected anchor head barrel/wedges exposed after 16 years in service are corrosion free

However, the effective use of a protective cap filled with corrosion protection compound was clearly demonstrated at another location on this site. Figure 5 shows the conditions under which the anchors were subjected and Figure 6 shows the condition of the protruding strands and barrel/wedges beneath the protective cap after some 16 years in service. Clearly, the strands and barrel and wedges are in bright steel condition having suffered no corrosive degradation at all.

Greenhithe, London, UK

The anchors heads for anchorages supporting retaining walls on the River Thames, at Greenhithe, were inspected and photographed as a preliminary phase to allow grading of the anchor head corrosion. In view of the fact that there is no method established in the anchorage industry for predicting the future performance of corroded anchor components reliance was initially placed on a qualitative assessment of the anchor heads based on the visual inspection. In a subsequent phase of the works, selected anchorages will be subjected to lift-off tests to ascertain residual load levels.

Mothersille and Barley

General Observations Circa 1976, the Greater London Council issued the first Ground Anchorage Specification in the UK demanding a precise corrosion protection system around the full length of the anchor tendon. It is noteworthy that no British Standard or related document existed until 1981 (DD81 Draft for Development). The first British Standard for Ground Anchorages (BS8081:1989) was not published until 1989. With this in mind the quality of post 1976 anchorages on the Thames should be superior to those pre 1976 in Aberdeen.

Overhead and Underhead Condition From visual inspection of the anchorages on the site there was every indication that the anchor head corrosion protection was consistent with that recommended in BS8081:1989. The protective caps, installed circa 1978 were bitumen coated steel caps threaded onto short male thread length of a steel tube itself welded to the anchor head plate. These anchor head caps and threaded bases have generally served their purpose for a thirty year period but in the majority of cases require replacement since it is essential that the anchor head components maintain this protection for a further lengthy period of possibly 50 years. In all cases the anchor head components including protective caps, bearing plate, gusset plates and welds all show visible signs of surface corrosive damage with bitumen coating either removed or flaking off (Figure 7). This included section loss, laminated expansion of the corroded anchor cap steel and crevices and pitting up to 10mm on the 40mm thick bearing plate. In marine environments the effective life of the protective cap is judged to be limited in but the over design of bearing plate may tolerate some pitting.

Figure 7 Severe deterioration of bituminous paint on corroded protective cap

Mothersille and Barley

Figure 8 Exposed strands and barrel and wedges containing remnant grease after loss of protective cap

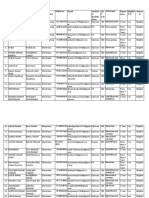

On site every anchor head and cap was visually inspected and its state, with regard to current and future performance graded. In 10% of the anchor heads inspected protective caps had corroded so severely that they had fallen off leaving the strands, barrel and wedges and remnant grease exposed (graded D see Table 1) as shown in Figure 8. The raised barrel shown in this figure was due to damage sustained in the free length by subsequent, non-anchor related, building operations. Table1 Grading system adopted for inspections

Grade category

A B

Description

Good condition with superficial surface rust Satisfactory condition with more extensive corrosion evident. Anticipated future lifespan of steel component in aggressive marine environment could be limited. Poor condition with evidence of deep corroded surfaces. Some section loss and small crevices also visible. Anticipated lifespan of the steel component is short. Very poor condition. Severe and significant section loss evident with deep pitting and crevices. Immediate replacement would need to be considered to prevent corrosive deterioration of steel component.

Mothersille and Barley

On the basis that corroded anchor head protection is required to be appropriately uprated to provide an extension to service life, the following procedure is recommended (Figure 9): 1. 2. 3. Uncover all anchor head recesses within the sheet pile wall Clear and dry all recesses and anchor head components Investigate presence of voids below anchor head plates by probing through grout holes. Advance rigid plastic tube, probably aided by air flush to maximum depth possible. Grout up to free length void with net cement grout, changing to 1:1 sand:cement grout should take become excessive. Withdraw nominal volume of grout nominal volume of grout from immediately below head plate to allow later injection of grease. Note that this procedure was adopted specifically for the anchorages at Aberdeen harbour where underhead tendon failure had occurred. Blast clean all exposed steel surfaces (bearing plates, barrel, wedges and strand) to remove all existing coating and other contaminants If required drill and tap holes for new protective cover bolts Apply two coats of appropriate epoxy resin coal tar or approved bituminous paint to bearing plate With suitable gasket seal fit glass reinforced plastic protective cap filled with corrosion inhibiting grease and secure with galvanised bolts.

4. 5. 6. 7.

The use of fibre glass protective caps fabricated to recognised standards, e.g. ISO 122151(2000) was pioneered in the UK in the 1980s.

Mothersille and Barley

Figure 9 Sequence of remedial measures for corroded anchor head after loss of protective cover in service as constructed by Keller Ground Engineeering (After Littlejohn and Mothersille, 2007)

Mothersille and Barley

10

Summary and Closing Remarks

A comprehensive visual inspection has shown that whilst the majority of anchor head caps were in place, at Greenhithe and on one wall in Aberdeen, and were still making some contribution as a retention unit for the corrosion inhibiting compound. However, they were all, without exception, in a state of corrosive degradation. A site trial on cap replacement has proved successful and will provide a basis for the consideration of a more extensive program of cap replacement, particularly on the Thames Bank Raising Anchorages and other flood defenses. The bearing plates and gusset plates were also included in the anchor head inspections. Generally, the condition of these components is judged to be medium to poor. The marine environment has accentuated the degree of corrosive degradation to an extent that section loss has occurred on many components. Although it would appear that the gusset plates and bearing plates are still functioning as load bearing elements, the longevity of the anchor head systems, particular that of the inaccessible underheads, could be questioned. In order to confirm the extent of corrosive degradation detailed metallurgical tests are recommended. In the case of ground anchorages installed with limited or no corrosion protection, it is not possible to inspect or assess the extent of corrosion over the full tendon. Thus it is not possible to guarantee the ultimate capacity of the steel components in the current or future state, even though in the recommended environment further corrosion may be retarded. In Aberdeen Harbour, anchorages fall into this category having served their useful purpose for over thirty years. It is judged that the remedial measures employed at both sites will serve to prolong the effective service life of the anchorages. Recently on the River Clyde an investigation was carried out involving inspections and the testing to failure of removed sections of strand, barrel and wedges (Mothersille et al, 2007). The extent of corrosion on the River Clyde anchorages was of a similar order to that observed at Greenhithe and the unprotected anchorages at Aberdeen Harbour and provides an indication as to what can be expected on sites which depend on anchorages installed around the same time and in a similar environment. In essence this paper provides in insight into important aspects of ground anchorage maintenance and describes the procedures and approaches to testing, inspection, assessment and provides guidance to those embarking upon similar engineering assessments in the future.

Mothersille and Barley

11

Acknowledgements

The authors wish to thank Keller-Ground Engineering for their assistance with the site based operations at the Greenhithe site.

References

BARLEY, A.D. (1992) The use of Ground Anchorages in Waterfront Structures Presented at the International Shipping and Marine Technology Market with Congress, Hamburg, September October. BARLEY, A.D. (1997) The failure of a 20 year old anchored sheet pile quay wall on the Thames. Ground Engineering, March issue, 42-45. BS DD81 (1982) Recommendations for ground anchorages. British Standard Draft for Development British Standards Institution, London. BS ISO 12215-1 (2000) Small craft. Hull construction and scantlings. Materials. Thermosetting resins, glass-fibre reinforcement, reference laminate British Standards Institution, London. BS8081 (1989) Code of practice for ground anchorages. British Standards Institution, London. ICE (1997) Ground anchorages and anchored structures. Proc. Int. Conf. organised by the Institution of Civil Engineers (editor G S Littlejohn), Thomas Telford, London (644p) LITTLEJOHN, G.S. and MOTHERSILLE, D.K.V. (2007) "Maintenance Testing and Service Behaviour Monitoring of Permanent Ground Anchorages". Geotechnical Engineering, (to be published). LITTLEJOHN, G.S. AND TRUMAN-DAVIS, C (1974), Ground Anchors at Devonport Nuclear Complex, Ground Engineering, 7 (6) pp 19-24 MOTHERSILLE, D.K.V., JACKMAN, S and FERRIER, J (2007) Performance and condition assessment of 30 year old anchorages, River Clyde, Glasgow Proc. Int. Conf. Ground anchorages and anchored structures in service, Institution of Civil Engineers, London. WEERASINGHE, R.B and ANSON, R.W.W (1997) Investigation of the long term performance and future behaviour of existing ground anchorages Proc. Conf. on Ground Anchorages and Anchored Structures. ICE. Thomas Telford, London.

You might also like

- 357.3r 14 Guide For Design and Construction of Waterfront and Coastal Concrete Marine StructuresDocument52 pages357.3r 14 Guide For Design and Construction of Waterfront and Coastal Concrete Marine StructuresAdel A. Abdelaziz100% (1)

- Biaxial GeogridsDocument20 pagesBiaxial GeogridsLiliana RibeiroNo ratings yet

- Marine Pile Repairs by Concrete Encasement - Hawkswood 2011Document13 pagesMarine Pile Repairs by Concrete Encasement - Hawkswood 2011chakfarmerNo ratings yet

- Design and Construction of Driven Pile Foundations VolumeIDocument968 pagesDesign and Construction of Driven Pile Foundations VolumeIAyoNo ratings yet

- Repair and Maintenance of BuildingsDocument34 pagesRepair and Maintenance of BuildingsRiddhi Runwal100% (1)

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesFrom EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesRating: 4.5 out of 5 stars4.5/5 (5)

- Handbook of Scour Countermeasures Designs PDFDocument213 pagesHandbook of Scour Countermeasures Designs PDFLiliana RibeiroNo ratings yet

- Article Marine Pile Repairs by Concrete Encasement PDFDocument13 pagesArticle Marine Pile Repairs by Concrete Encasement PDFChen Wai Peng100% (1)

- Concrete CracksDocument54 pagesConcrete CracksMedhat HasanainNo ratings yet

- Grout Specification Test MethodDocument1 pageGrout Specification Test MethodBhuidhar VermaNo ratings yet

- Silver Bridge Collapse 1967Document11 pagesSilver Bridge Collapse 1967Lefteris Charalambous0% (1)

- 100-Year Design Life of Rock Bolts and Shotcrete - 5th Ground Support in Mining Underg ConstDocument6 pages100-Year Design Life of Rock Bolts and Shotcrete - 5th Ground Support in Mining Underg Consteep1977No ratings yet

- Paint Evaluation ReportDocument22 pagesPaint Evaluation ReportSethuraman Saravanakumar100% (1)

- Internal Resistance To Corrosion in Structural Hollow Sections PDFDocument48 pagesInternal Resistance To Corrosion in Structural Hollow Sections PDFjemanuelvNo ratings yet

- Electric House - Company ProfileDocument16 pagesElectric House - Company ProfileDushyant RawalNo ratings yet

- Buckling of MicropilesDocument19 pagesBuckling of MicropilesAamir TauqeerNo ratings yet

- Tainter Gate Operation and MaintenanceDocument14 pagesTainter Gate Operation and Maintenancechutton681No ratings yet

- Case Study Repair Internal CorrosionDocument26 pagesCase Study Repair Internal CorrosionSandra Prasetyo0% (1)

- Silver Bridge Collapse 1967Document11 pagesSilver Bridge Collapse 1967Jatin ChaudharyNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- FHWA Micropile Design and Construction (2005 Version) PDFDocument456 pagesFHWA Micropile Design and Construction (2005 Version) PDFKai Ho100% (2)

- 17 - Repairing Internal Corrosion Defects in Pipelines - A Case Study PDFDocument26 pages17 - Repairing Internal Corrosion Defects in Pipelines - A Case Study PDF김원재100% (4)

- Cable Stays of Cable-Stayed Bridges (T 5140.25)Document9 pagesCable Stays of Cable-Stayed Bridges (T 5140.25)Mohamed BahgatNo ratings yet

- Splash Zone Michels PowellDocument18 pagesSplash Zone Michels PowellMohammed Shareef ShaikhNo ratings yet

- Method Statement Asphalt PavingDocument3 pagesMethod Statement Asphalt PavingHussam WaleedNo ratings yet

- Fhwa - Hoek Y Bray - Rock Slopes EngineeringDocument548 pagesFhwa - Hoek Y Bray - Rock Slopes Engineeringwaberoya2009100% (10)

- Fhwa - Hoek Y Bray - Rock Slopes EngineeringDocument548 pagesFhwa - Hoek Y Bray - Rock Slopes Engineeringwaberoya2009100% (10)

- 2011 Bridge KlopperDocument13 pages2011 Bridge KlopperIndra MishraNo ratings yet

- Ground Anchor Tendon Protected Against Corrosion and Damage by A Double Plastic Layer A D Barley Presented at The Ice Conference London 1997Document13 pagesGround Anchor Tendon Protected Against Corrosion and Damage by A Double Plastic Layer A D Barley Presented at The Ice Conference London 1997Kenny CasillaNo ratings yet

- Repair and Maintenance of Berth No 6, Port of PortlandDocument5 pagesRepair and Maintenance of Berth No 6, Port of Portlandmehdi_hoseineeNo ratings yet

- Protección Catódica 05-r25Document28 pagesProtección Catódica 05-r25andres floridoNo ratings yet

- Berke, 1992, Estimating Life CycleDocument25 pagesBerke, 1992, Estimating Life CycleÁlvaro MendozaNo ratings yet

- CP Criteria 01Document15 pagesCP Criteria 01Sheik DawoodNo ratings yet

- Investigation of The Failure of Permanent Anchorages Adjacent To A Tidal Surge Barrier A D Barley D Mothersille P Charnley Ice London 2007Document10 pagesInvestigation of The Failure of Permanent Anchorages Adjacent To A Tidal Surge Barrier A D Barley D Mothersille P Charnley Ice London 2007Kenny CasillaNo ratings yet

- Om PrakashDocument14 pagesOm PrakashShivam SinghalNo ratings yet

- SPE 93184 Integrated Analysis of Down-Hole Corrosion Logs To Investigate Casing LeaksDocument7 pagesSPE 93184 Integrated Analysis of Down-Hole Corrosion Logs To Investigate Casing Leaksmsmsoft90No ratings yet

- SPE-182823-MS Pinpointing Irregularities in A Well's Integrity: Case StudyDocument9 pagesSPE-182823-MS Pinpointing Irregularities in A Well's Integrity: Case StudyAnonymous VNu3ODGavNo ratings yet

- Seaview Wharf: A Concrete CP Case StudyDocument8 pagesSeaview Wharf: A Concrete CP Case StudyLy KhoaNo ratings yet

- Spe 125060 MS P PDFDocument13 pagesSpe 125060 MS P PDFDamir986No ratings yet

- FRP Rods For Brittle Fracture ResistantDocument9 pagesFRP Rods For Brittle Fracture Resistantdmsoares1989No ratings yet

- Effect of Pitting Corrosion On Local Strength of Hold Frames of Bulkcarriers (1st Report)Document30 pagesEffect of Pitting Corrosion On Local Strength of Hold Frames of Bulkcarriers (1st Report)Kay WhiteNo ratings yet

- Protecting Prestressing Strand in Transportation Structures and Improving Strand-Concrete BondingDocument13 pagesProtecting Prestressing Strand in Transportation Structures and Improving Strand-Concrete BondingKyle BuschNo ratings yet

- Epoxy Coated RebarDocument10 pagesEpoxy Coated RebarArnold Jose Batista RodriguezNo ratings yet

- Stress Analysis Using Actual Coke DrumDocument11 pagesStress Analysis Using Actual Coke Drumash1968No ratings yet

- Developing Cathodic Protection Based On Disbondment GeometryDocument8 pagesDeveloping Cathodic Protection Based On Disbondment GeometryMarcelo Varejão CasarinNo ratings yet

- Point of View March 2006 PDFDocument5 pagesPoint of View March 2006 PDFMohamedRaahimNo ratings yet

- Adaa Technical Note 4Document3 pagesAdaa Technical Note 4eep1977No ratings yet

- FRP Repair of CorrosionDocument13 pagesFRP Repair of CorrosionahmadlieNo ratings yet

- Faa18007 - Muhamad Zuhairi - Baa4243 - ProjectDocument32 pagesFaa18007 - Muhamad Zuhairi - Baa4243 - ProjectFAAI8007MUHAMAD ZUHAIRI SULAIMANNo ratings yet

- Revaluation of Concrete Design in Marine Engineering: September 8, 2007 5:43 RPS Mtec07 - NewDocument6 pagesRevaluation of Concrete Design in Marine Engineering: September 8, 2007 5:43 RPS Mtec07 - NewAnonymous mcHqIfbnV1No ratings yet

- Durability of SFRC PDFDocument10 pagesDurability of SFRC PDFBehzadDastjerdyNo ratings yet

- Reduction of Corrosion Process in Steel Bars Using InhibitorsDocument17 pagesReduction of Corrosion Process in Steel Bars Using InhibitorsJohn BihagNo ratings yet

- 期刊 - HIDDEN DEFECTS IN BRIDGE COMPONENTS - FORTHCOMING CIRIADocument13 pages期刊 - HIDDEN DEFECTS IN BRIDGE COMPONENTS - FORTHCOMING CIRIAfanfengliNo ratings yet

- KSCE YounDocument15 pagesKSCE YounsdagnihotriNo ratings yet

- Md-89 Offshore Windwills 1Document14 pagesMd-89 Offshore Windwills 1Roger Hazim100% (1)

- Jmse 08 00290Document12 pagesJmse 08 00290Anandro AmellonadoNo ratings yet

- Carbonation of Concrete Structures in Hot Dry Coastal RegionsDocument7 pagesCarbonation of Concrete Structures in Hot Dry Coastal RegionsTarek ChikerNo ratings yet

- 15.03 Ehlers S&Goltz M - UnlockedDocument8 pages15.03 Ehlers S&Goltz M - UnlockedMatthias GoltzNo ratings yet

- Corrosion Performance of Medium-Strength and Silica Fume High-Strength Reinforced Concrete in A Chloride SolutionDocument8 pagesCorrosion Performance of Medium-Strength and Silica Fume High-Strength Reinforced Concrete in A Chloride SolutionanupamrawalNo ratings yet

- Assessment of Reinforcement CorrosionDocument5 pagesAssessment of Reinforcement CorrosionClethHirenNo ratings yet

- Ce Papers - 2023 - HernandezDocument6 pagesCe Papers - 2023 - Hernandezkevin.platinium23No ratings yet

- Cathodicprotection System For Fleet MooringDocument66 pagesCathodicprotection System For Fleet MooringAlberto FozNo ratings yet

- Corrosion Performance of Epoxy Coated Reinforcing Steel - North America ExperienceDocument17 pagesCorrosion Performance of Epoxy Coated Reinforcing Steel - North America ExperiencebrahmabulNo ratings yet

- Case Studies in Construction MaterialsDocument4 pagesCase Studies in Construction MaterialsSaker MohamedNo ratings yet

- Part-9 PG 146-158Document15 pagesPart-9 PG 146-158cjmNo ratings yet

- Review ActDocument3 pagesReview ActHD MOVIESNo ratings yet

- New Examples CRC JointCastDocument12 pagesNew Examples CRC JointCastbansonaugustineNo ratings yet

- MECCOCT18-12285: External Corrosion Investigation of 36 Inch Trunkline Case Study: A Possible AC/DC InterferenceDocument15 pagesMECCOCT18-12285: External Corrosion Investigation of 36 Inch Trunkline Case Study: A Possible AC/DC InterferenceOwais MalikNo ratings yet

- 30-An Experimental Study of Flexural Cracking in ReinDocument49 pages30-An Experimental Study of Flexural Cracking in ReinJan Van MiddendorpNo ratings yet

- May 2017 HCTRA Standard Specifications PDFDocument1,270 pagesMay 2017 HCTRA Standard Specifications PDFLiliana RibeiroNo ratings yet

- KLR-10-56E Ground Improvement Using VibroDocument13 pagesKLR-10-56E Ground Improvement Using VibroLiliana RibeiroNo ratings yet

- Tds - Macgrid BiaxialDocument1 pageTds - Macgrid BiaxialLiliana Ribeiro100% (2)

- Texas Cone Penetration: Test Procedure ForDocument3 pagesTexas Cone Penetration: Test Procedure ForLiliana RibeiroNo ratings yet

- Texas Cone Penetration: Test Procedure ForDocument3 pagesTexas Cone Penetration: Test Procedure ForLiliana RibeiroNo ratings yet

- Some Geotechnical Aspects of Harbor Structures in Karst FormationsDocument10 pagesSome Geotechnical Aspects of Harbor Structures in Karst FormationsLiliana RibeiroNo ratings yet

- Introduction To High Speed Railway Bridges in ChinaDocument33 pagesIntroduction To High Speed Railway Bridges in Chinazhou jieNo ratings yet

- Static Equipment Procedure Hal Oil Fggs - Baghjan Pro Me 012 Rev A With Formats and Risk Assessment Signed 1Document17 pagesStatic Equipment Procedure Hal Oil Fggs - Baghjan Pro Me 012 Rev A With Formats and Risk Assessment Signed 1Devendran MarappanNo ratings yet

- Vacono Aluminium Covers: AL-FC QE - Verbindungsplatten AL-FC QE - Connection PlatesDocument16 pagesVacono Aluminium Covers: AL-FC QE - Verbindungsplatten AL-FC QE - Connection PlatesDejan Deki MaticNo ratings yet

- Candidate Email Mobile List2022Document11 pagesCandidate Email Mobile List2022POS-ADSR TrackingNo ratings yet

- Geometric ConstructionDocument7 pagesGeometric ConstructionJohara Bayabao-AngniNo ratings yet

- Purpose and Policy: Project Special ProvisionsDocument4 pagesPurpose and Policy: Project Special Provisionsraditanka aobakweNo ratings yet

- A3-Bill of Quantities (BOQ)Document10 pagesA3-Bill of Quantities (BOQ)Wael Sayed omarNo ratings yet

- Draft Letter - Declination of Additional Work Due To Engineer's InstructionDocument2 pagesDraft Letter - Declination of Additional Work Due To Engineer's InstructionKimberly Mae Borja NuestroNo ratings yet

- Gothic Architecture: 1. Describe in Detail About Reims CathedralDocument6 pagesGothic Architecture: 1. Describe in Detail About Reims CathedralNiharikaNo ratings yet

- Visit Report: Byatarayanapura, BengaluruDocument3 pagesVisit Report: Byatarayanapura, BengaluruSachin Kumar J KNo ratings yet

- Fdot Precast Bent Cap Development and Implementation: AbstractDocument10 pagesFdot Precast Bent Cap Development and Implementation: AbstractCongOanh PHANNo ratings yet

- Fire and Life Safety Director FLSD CurriculumDocument466 pagesFire and Life Safety Director FLSD CurriculumTamara CaseyNo ratings yet

- 2021 International Building Code Illustrated Handbook 1St Edition Douglas W Thornburg Full ChapterDocument51 pages2021 International Building Code Illustrated Handbook 1St Edition Douglas W Thornburg Full Chapterstephen.mcghee528100% (16)

- Characteristics of CorianDocument23 pagesCharacteristics of CorianAnil PatelNo ratings yet

- PDFDocument29 pagesPDFCarlosAlbertoGrimaldoBarajasNo ratings yet

- Directory of Registered Contractors 1Document2 pagesDirectory of Registered Contractors 1tkidapawanNo ratings yet

- A.2 MC Conexion PIPE A W6x22Document7 pagesA.2 MC Conexion PIPE A W6x22Vivaldi ChangraNo ratings yet

- DIS RES STRUCT SDDocument24 pagesDIS RES STRUCT SDSubrata DeyNo ratings yet

- CP../EFDCN.. Series Push Button Stations: Technical FeaturesDocument4 pagesCP../EFDCN.. Series Push Button Stations: Technical FeaturesYao TinchonNo ratings yet

- MC TUFF Luminary® Cable: UL Listed Type MC-PCS (Steel) Technical SpecificationsDocument2 pagesMC TUFF Luminary® Cable: UL Listed Type MC-PCS (Steel) Technical Specificationskevin brentonNo ratings yet

- RCC Notes 3 0ca8fba3e6 Lecture Notes Unit 1Document39 pagesRCC Notes 3 0ca8fba3e6 Lecture Notes Unit 1venu madhavNo ratings yet

- Contract MarysolDocument3 pagesContract MarysolJacqueline Ponce PinosNo ratings yet

- Civil Engineers 05-2019 Room AssignmentDocument44 pagesCivil Engineers 05-2019 Room AssignmentPRC Baguio100% (5)

- BTQS3042 Tutorial Notes 1Document3 pagesBTQS3042 Tutorial Notes 1WEI LI NEOHNo ratings yet

- DO 005 s2017Document195 pagesDO 005 s2017Tina Rosales0% (1)

- Quotation-Municiple Waterproofing WorkDocument3 pagesQuotation-Municiple Waterproofing WorkAnkita Baban GavadeNo ratings yet