Professional Documents

Culture Documents

Grating Design Data

Uploaded by

ericastorgalucoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Grating Design Data

Uploaded by

ericastorgalucoCopyright:

Available Formats

Grating Design Data

DESIGN NOMENCLATURE

b = thickness of rectangular bearing bar, inches d = depth of bearing bar, inches Aw = center to center distance between bearing bars in welded and press-locked gratings, inches C = concentrated load at midspan = 4FSw/L pounds per foot of width (pfw) Dc = deflection under concentrated load = CL3/48 EIw inches Du = deflection under uniform load = 5UL4/12(384)EIw inches E = modulus of elasticity, pounds per square inch (psi) Steel: E = 29,000,000 psi = 29 (10)6 Stainless Steel: E = 28,000,000 psi = 28 (10)6 Aluminum: E = 10,000,000 psi = (10)7 F = allowable fiber unit stress, psi ASTM A-1011: F = 18,000 psi (Steel, Carbon Hot Rolled Sheet and Strip, Commercial Quality AISI 1020) ASTM A-36: F = 20,000 psi (Structural Steel (Bars only)) ASTM A167: F = 20,000 psi (Type 304 and 316, Stainless Steel) F = 16,500 psi (Type 304L and 316L, Stainless Steel) ASTM B-221: F = 12,000 psi (6061-T6 Alloy) F = 10,000 psi (6063-T6 Alloy) Ib = moment of inertia of a rectangular bar = bd3/12 in4 Iw = moment of inertia of grating per foot of width = KI in4 K = number of bearing bars per foot of grating width = 12/Aw L = span of grating between reaction points, inches Mb = maximum bending moment of bearing bar, in-lbs Mw = maximum bending moment of grating per foot of width, in-lbs Mu = maximum bending moment under uniform load = FSw = UL2/96 in-lbs Mc = maximum bending moment under concentrated load = FSw = CL/4 in-lbs Sb = section modulus of a rectangular bar = bd2/6 in.3 Sw = section modulus per foot of grating width = KSb in.3 U = uniform load = 96fSw/L2 psf = 96M/L2 pounds per square foot (psf)

SAMPLE CALCULATION: STEEL

Type of Grating = 19-W-4-63 welded carbon steel grating Size of Bar = 1-1/2 x 3/16 Span = 54 inches Aw = bearing bar spacing = 1.1875 inches K = number of bearing bars in panel width = 12/Aw = 12/1.1875 = 10.105 F = allowable fiber stress = 18,000 psi E = 29,000,000 psi Sw = section modulus of grating per foot of width = Kbd2/6 = 10.105 x 0.1875 (1.5)2/6 = 0.711 in.3 Iw = moment of inertia of grating per foot of width = Kbd3/12 = 10.105 x 0.1875 (1.5)3/12 = 0.533 in.3 Mw = maximum bending moment for grating per foot of width = FSw = 18,000 x 0.711 = 12,800 in.-lbs. Allowable Concentrated Load and Deflection for 19-W-4-63: C = allowable load = 4Mw/L = 4 x 12,800/54 = 948 pfw Dc = deflection = CL3/48EIw = 948 x 543/(48 x 29 x 106 x 0.533) = 0.201 inches Allowable Uniform Load and Deflection for 19-W-4-63: U = allowable load = 96Mw/L2 = 96 x 12,800/542 = 421 psf Du = deflection = 5UL4/4608EIw = 5 x 421 x 544/(4608 x 29 x 106 x 0.533) = 0.251 inches

68

Grating Design Data

SAMPLE CALCULATION: ALUMINUM

For a span of 5'-0", the minimum size bearing bar to sustain 225 psf load is: Type of Grating = 19-SI-4-64 aluminum swage-locked grating Size of I-Bar = 1-1/2 x 1/4 Equivalent Rectangular Bar for calculation purposes = 1-1/2 x 3/16 (see note 3) Span = 60 inches Aw = bearing bar spacing = 1.1875 inches K= number of bearing bars in panel width = 12/Aw = 12/1.1875 = 10.105 F= allowable fiber stress = 12,000 psi E= 10,000,000 psi Sw = section modulus of grating per foot of width = Kbd2/6 = 10.105 x 0.1875 (1.5)2/6 = 0.711 in3 Iw = moment of inertia of grating per foot of width = Kbd3/12 = 10.105 x 0.1875 (1.5)3/12 = 0.533 in3 Mw = maximum bending moment for grating per foot of width = FSw = 12,000 x 0.711 = 8,532 in-lbs Allowable Uniform Load and Deflection for 19-SI-4-64: U = allowable load = 96Mw/L2 = 96 x Mw/602 = 96 x 12,000 x 0.711/602 = 227.5 psf Du = deflection = 5UL4/4608EIg = 5 x 227.5 x 604/(4608 x 10 x 106 x 0.533) = 0.6 inches Deflection is directly proportional to load (actual load/allowable load): Dactual = Du x Uactual/Uallowable = 0.6 x 225/227.5 = 0.5934 inches Dactual = 0.5934 inches > recommended limitation of deflection = L/240=.25 inches Try a grating with a larger moment of inertia to reduce deflection: 19-SI-4-64 (1-1/2 x 3/16 equivalent rectangular bar): If Du = .25 inches, then Iw required = 5UL4/4608EDu = 5 x 225 x 604/(4608 x 10 x 106 x .25) = 1.2656 in4 Using a larger size: 19-SI-4-94 (Rectangular bar equivalent = 2-1/4 x 3/16) Iw = K x Ib = 10.105 x 0.1780 = 1.799 in4 Allowable Uniform Load and Deflection for 19-SI-4-94: U = allowable load = 512 lbs D = deflection = 5UL4/4608EIg = 5 x 512 x 604/(4608 x 10 x 106 x 1.799) = 0.40 inches Deflection is directly proportional to load (actual load/allowable load): Du = Du x Uactual/Uallowable = 0.40 (225)/512 = 0.176 inches OK deflection < L/240 (.25 inches)

Notes: 1) For additional information, see NAAMMs MBG-534, Engineering Design Manual 2) Uniform loads in these examples and in the standard load tables include the weight of the gratings. In designing for uniform loads, the weight of the grating, as well as any other dead load, must be added. 3) Aluminum I-Bar Grating Design Information

Comparable Rectangular Bar Size 1" x 3/16" 1-1/4" x 3/16" 1-1/2" x 3/16" 1-3/4" x 3/16" 2" x 3/16" 2-1/4" x 3/16" 2-1/2" x 3/16" Weight (plf) .144 .180 .216 .252 .288 .324 .360

I-Bar Size 1" x 1/4" 1-1/4" x 1/4" 1-1/2" x 1/4" 1-3/4" x 1/4" 2" x 1/4" 2-1/4" x 1/4" 2-1/2" x 1/2"

Area (in2) .120 .150 .180 .210 .240 .270 .300

I (in4) .0156 .0305 .0507 .0837 .1250 .1780 .2441

S (in3) .0313 .0488 .0703 .0957 .1250 .1582 .1953

This table is to be used by engineers to select aluminum I-bar sizes through hand calculations. In most cases, the Load and Span tables in the front of this catalog can be used for product selection.

OTHER CALCULATIONS

For partially distributed uniform loads, forklift and other wheeled loads (carts, pallet jacks, etc.), and other load calculations, contact AMICO-Klemps engineering departments for assistance.

69

You might also like

- Grating DesignDocument1 pageGrating DesigngaratetaNo ratings yet

- Bolt Grip Length PDFDocument1 pageBolt Grip Length PDFmatthewwalls4386100% (2)

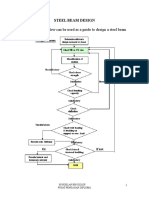

- Steel Beam DesignDocument27 pagesSteel Beam DesignSyazwi Akram Ab RazakNo ratings yet

- Column SpliceDocument6 pagesColumn SplicedudoodooNo ratings yet

- IIT Hyderabad Faculty Housing Design CalculationsDocument33 pagesIIT Hyderabad Faculty Housing Design CalculationssmijusNo ratings yet

- Combining StressesDocument31 pagesCombining StressesYOGESH GOPALNo ratings yet

- Bracing ConnectionsDocument3 pagesBracing ConnectionspradeeshNo ratings yet

- Bolt Tensioning: What is it and how does it workDocument2 pagesBolt Tensioning: What is it and how does it work4jawwy markme026No ratings yet

- Combined Footing Using Mathcad PrimeDocument6 pagesCombined Footing Using Mathcad PrimeYan YanNo ratings yet

- Online steel calculation tool covers carbon equivalents, phase transformationsDocument1 pageOnline steel calculation tool covers carbon equivalents, phase transformationshaharameshNo ratings yet

- Lecture 15A.7-Tubular Joints in Offshore StructuresDocument23 pagesLecture 15A.7-Tubular Joints in Offshore StructuresLinh TranNo ratings yet

- Design and Verification of Lifting LugsDocument3 pagesDesign and Verification of Lifting LugsFabio Okamoto100% (1)

- Weld StressDocument9 pagesWeld StressArvindNo ratings yet

- PV Elite Vessel Analysis Program: Input DataDocument30 pagesPV Elite Vessel Analysis Program: Input DatachampNo ratings yet

- Tank Lifting Design PDFDocument47 pagesTank Lifting Design PDFDavid PuenNo ratings yet

- Project USAN padeye calculationDocument5 pagesProject USAN padeye calculationMarvan100% (1)

- Lifting Lug Calculation Rev - 1Document2 pagesLifting Lug Calculation Rev - 1WijayantoNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part4-Blow Out Strength in TensionDocument3 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part4-Blow Out Strength in TensionVenu GopalNo ratings yet

- Welded ConnectionsDocument42 pagesWelded ConnectionsumeshapkNo ratings yet

- Design Gusset Plate JointsDocument59 pagesDesign Gusset Plate JointsVaibhav SharmaNo ratings yet

- Grating Design ReportDocument28 pagesGrating Design ReportnvnagarajuNo ratings yet

- Zub Indeterminate Truss DegDocument13 pagesZub Indeterminate Truss DegAnonymous jmo0bcjAsNo ratings yet

- Shear Strength of High-Strength BoltsDocument61 pagesShear Strength of High-Strength Boltsloox600No ratings yet

- Lux Simulation Report 10.8.2018wDocument12 pagesLux Simulation Report 10.8.2018wChi Kit PhoonNo ratings yet

- Steel Beam Flexural CapacityDocument6 pagesSteel Beam Flexural CapacitykstayroskNo ratings yet

- Welded connection designDocument16 pagesWelded connection designAnkit SinghNo ratings yet

- Materials Engineering: Proceedings of the First International Symposium, University of the Witwatersrand, Johannesburg, South Africa, November 1985From EverandMaterials Engineering: Proceedings of the First International Symposium, University of the Witwatersrand, Johannesburg, South Africa, November 1985J. V. BeeNo ratings yet

- Doubler Plate CheckDocument3 pagesDoubler Plate CheckkarthickNo ratings yet

- Flange DesignDocument2 pagesFlange DesignMitesh PatelNo ratings yet

- Welding SymbolsDocument12 pagesWelding SymbolsrsrtnjNo ratings yet

- Semi Pit WeighbridgesDocument2 pagesSemi Pit WeighbridgesAntónio FontesNo ratings yet

- Transmission Line Design and Steel Pole StructuresDocument27 pagesTransmission Line Design and Steel Pole StructuresDanNo ratings yet

- Pipe Rack Design Calculation for 54Document4 pagesPipe Rack Design Calculation for 54moseslugtu6324No ratings yet

- Bethlehem Structural Shapes Catalogue 1911Document122 pagesBethlehem Structural Shapes Catalogue 1911Alberto ChazarretaNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- DmTank Ring Wall Foundation+&+Annular+RaftDocument5 pagesDmTank Ring Wall Foundation+&+Annular+RaftRM PaduaNo ratings yet

- H-Shape, Channel Sections SpecsDocument2 pagesH-Shape, Channel Sections Specsallen2912No ratings yet

- Weld stress calculation guideDocument10 pagesWeld stress calculation guideKevin BaxterNo ratings yet

- PIPE SUPPORT SPANDocument75 pagesPIPE SUPPORT SPANMarius GhitaNo ratings yet

- Codes and Standards - SenegalDocument8 pagesCodes and Standards - SenegalRamachandran SundararamanNo ratings yet

- Marine Propulsion System Failures-A Review: Marine Science and EngineeringDocument14 pagesMarine Propulsion System Failures-A Review: Marine Science and EngineeringDavid NuñezNo ratings yet

- Comp 2Document9 pagesComp 2YYo YudiNo ratings yet

- Embedded PlateDocument2 pagesEmbedded PlateAlma M. LaraNo ratings yet

- Jacket Miscellaneous Structure DesignDocument6 pagesJacket Miscellaneous Structure DesignBolarinwaNo ratings yet

- AISC Properties ViewerDocument3 pagesAISC Properties Viewerchriscivil12No ratings yet

- Study & Analysis of Transportation SkidDocument10 pagesStudy & Analysis of Transportation SkidJay PNo ratings yet

- Lift & Tail CalcsDocument3 pagesLift & Tail CalcsguravdrNo ratings yet

- Maximum PressureDocument83 pagesMaximum Pressureanhhung80No ratings yet

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 5Document2 pages9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 5Ahmad Badsha QuadriNo ratings yet

- Flat End PlatesDocument4 pagesFlat End Platesb_wooNo ratings yet

- Super Clamps-General Clamp Industries IncDocument19 pagesSuper Clamps-General Clamp Industries IncTagor SianiparNo ratings yet

- Clamp Design-2Document6 pagesClamp Design-2Harpreet SinghNo ratings yet

- Trolley Winch DesignDocument16 pagesTrolley Winch DesignUtaya Kumar VeelmuruganNo ratings yet

- MBG - 534 - 12 - Manual Diseño de GratingDocument24 pagesMBG - 534 - 12 - Manual Diseño de GratingEnergia_XNo ratings yet

- Engineering Design Manual: Metal BAR GratingDocument24 pagesEngineering Design Manual: Metal BAR GratingAhsan Sattar100% (4)

- LST StraightSections 5NEMAVE 1LoadingDepthDocument1 pageLST StraightSections 5NEMAVE 1LoadingDepthCRISTIANCORTES28No ratings yet

- Design of Steel Beam 89edDocument5 pagesDesign of Steel Beam 89edAdi SatriaNo ratings yet

- Papeo Asme b30Document22 pagesPapeo Asme b30greelmindNo ratings yet

- CALCULATING FORKLIFT LOADS ON STEEL DECK FLOORSDocument7 pagesCALCULATING FORKLIFT LOADS ON STEEL DECK FLOORSJurie Sulistio KumaraNo ratings yet

- Bandejas Portacables Aluminio Acero B LineDocument46 pagesBandejas Portacables Aluminio Acero B LineJose NavíoNo ratings yet

- Tabla de Aproximación - Porcentaje A Grados y Al RevesDocument2 pagesTabla de Aproximación - Porcentaje A Grados y Al RevesericastorgalucoNo ratings yet

- GB1 Plan SubgradesDocument11 pagesGB1 Plan SubgradesericastorgalucoNo ratings yet

- Liquefaction Analysis in PLAXIS 2D PDFDocument1 pageLiquefaction Analysis in PLAXIS 2D PDFericastorgalucoNo ratings yet

- Liquefaction Analysis in PLAXIS 2D PDFDocument1 pageLiquefaction Analysis in PLAXIS 2D PDFericastorgalucoNo ratings yet

- Tutorial 01 Quick Start SwedgeDocument26 pagesTutorial 01 Quick Start SwedgeericastorgalucoNo ratings yet

- Design of Structures and Foundations For Vibrating Machines PDFDocument39 pagesDesign of Structures and Foundations For Vibrating Machines PDFsaputrafrandy_958992No ratings yet

- Typical Values of The Coefficient of Volume Compressibility, M (After Carter 1983) MDocument21 pagesTypical Values of The Coefficient of Volume Compressibility, M (After Carter 1983) MTuanQuachNo ratings yet

- Warranty Toshiba Canvio HDDocument6 pagesWarranty Toshiba Canvio HDAndrew VasylukNo ratings yet

- MP152Document19 pagesMP152ericastorgalucoNo ratings yet

- 6.12 Aboye Et AlDocument12 pages6.12 Aboye Et AlSambit Prasanajit NaikNo ratings yet

- Liquefaction RemediationDocument17 pagesLiquefaction RemediationericastorgalucoNo ratings yet

- Tutorial 10 Water Table StatisticsDocument20 pagesTutorial 10 Water Table StatisticsericastorgalucoNo ratings yet

- Typical Values of The Coefficient of Volume Compressibility, M (After Carter 1983) MDocument21 pagesTypical Values of The Coefficient of Volume Compressibility, M (After Carter 1983) MTuanQuachNo ratings yet

- Mulugeta AnteneDocument121 pagesMulugeta AnteneericastorgalucoNo ratings yet

- Lab9 DistinctElementExerciseDocument15 pagesLab9 DistinctElementExerciseericastorgalucoNo ratings yet

- Int'l Prod List Jun08 ItascaDocument8 pagesInt'l Prod List Jun08 ItascaericastorgalucoNo ratings yet

- GB5 Submission GuidelinesDocument17 pagesGB5 Submission GuidelinesericastorgalucoNo ratings yet

- GB4 Geotechnical InstrumentationDocument41 pagesGB4 Geotechnical InstrumentationericastorgalucoNo ratings yet

- GB6 Shear StrengthDocument7 pagesGB6 Shear StrengthericastorgalucoNo ratings yet

- GB3 Rock Cut SlopesDocument18 pagesGB3 Rock Cut SlopesericastorgalucoNo ratings yet

- GB4 Geotechnical InstrumentationDocument41 pagesGB4 Geotechnical InstrumentationericastorgalucoNo ratings yet

- GB7 Drilled ShaftsDocument60 pagesGB7 Drilled ShaftsericastorgalucoNo ratings yet

- GB2 Special BenchingDocument12 pagesGB2 Special BenchingericastorgalucoNo ratings yet

- GB1 Plan SubgradesDocument11 pagesGB1 Plan SubgradesericastorgalucoNo ratings yet

- Structural Elements in PLAXISDocument13 pagesStructural Elements in PLAXISBojan Bogdanovic100% (2)

- HD Design CriteriaDocument1 pageHD Design CriteriaericastorgalucoNo ratings yet

- 40Document9 pages40ericastorgalucoNo ratings yet

- Jcuprd 049640Document11 pagesJcuprd 049640ericastorgalucoNo ratings yet

- Huang Chwang 1982Document58 pagesHuang Chwang 1982ericastorgalucoNo ratings yet

- Axel LeijonhufvudDocument7 pagesAxel LeijonhufvudDario CoceresNo ratings yet

- 02 - Order Quantities When Demand Is Approximately LevelDocument2 pages02 - Order Quantities When Demand Is Approximately Levelrahma.samyNo ratings yet

- Kara&Suoglu ProjectreportDocument4 pagesKara&Suoglu ProjectreportRicard Comas xacnóNo ratings yet

- Business Plan1Document38 pagesBusiness Plan1Gwendolyn PansoyNo ratings yet

- SSRN Id26238Document21 pagesSSRN Id26238Ayame KusuragiNo ratings yet

- 04 LimeDocument32 pages04 LimeGoogle user100% (1)

- PHILHIS Executive Summary - EditedDocument7 pagesPHILHIS Executive Summary - EditedMaxy Bariacto100% (1)

- ManuscriptDocument2 pagesManuscriptVanya QuistoNo ratings yet

- Nataraja Stotram - A Hymn Without 'CharaNa' and 'ShRi~NgaDocument8 pagesNataraja Stotram - A Hymn Without 'CharaNa' and 'ShRi~NgaSiva Krishna100% (1)

- Dryers in Word FileDocument5 pagesDryers in Word FileHaroon RahimNo ratings yet

- Food Science, Technology & Nutitions - Woodhead - FoodDocument64 pagesFood Science, Technology & Nutitions - Woodhead - FoodEduardo EstradaNo ratings yet

- Test Fibrain RespuestasDocument2 pagesTest Fibrain Respuestasth3moltresNo ratings yet

- Types of Stress: Turdalieva Daria HL 2-19 ADocument9 pagesTypes of Stress: Turdalieva Daria HL 2-19 ADaria TurdalievaNo ratings yet

- AD 251 - Equivalent Uniform Moment Factor, M (Italic)Document1 pageAD 251 - Equivalent Uniform Moment Factor, M (Italic)symon ellimacNo ratings yet

- Barry Wylant: Design Thinking and The Experience of InnovationDocument13 pagesBarry Wylant: Design Thinking and The Experience of InnovationVanesa JuarezNo ratings yet

- XYZ Company Asset Inventory ReportDocument1 pageXYZ Company Asset Inventory ReportNini KitsNo ratings yet

- Amna Hameed: ObjectiveDocument2 pagesAmna Hameed: ObjectiveSabrina GandapurNo ratings yet

- Gujarat Technological University: Emester ViDocument4 pagesGujarat Technological University: Emester ViPradeep SutharNo ratings yet

- FeatureSelectionAccepted IEEE Review PDFDocument20 pagesFeatureSelectionAccepted IEEE Review PDFrvsamy80No ratings yet

- Monthly Business ReviewDocument36 pagesMonthly Business Reviewmdipu5_948971128No ratings yet

- Remembrance 23 Names PDFDocument1 pageRemembrance 23 Names PDFJennifer ThuncherNo ratings yet

- Prodelin 1385Document33 pagesProdelin 1385bebebrenda100% (1)

- Modesto Mabunga Vs PP (GR 142039)Document3 pagesModesto Mabunga Vs PP (GR 142039)Ericha Joy GonadanNo ratings yet

- Non Deterministic Finite AutomataDocument30 pagesNon Deterministic Finite AutomataAnikNo ratings yet

- Book of Lost Spells (Necromancer Games)Document137 pagesBook of Lost Spells (Necromancer Games)Rodrigo Hky91% (22)

- Acid content in fruitsDocument2 pagesAcid content in fruitsbone fire100% (1)

- What Are Universities ForDocument19 pagesWhat Are Universities ForBikash Ranjan MishraNo ratings yet

- Canna DispensariesDocument35 pagesCanna DispensariesWaf Etano100% (1)

- The Transformation of Metaphysical ScienceDocument7 pagesThe Transformation of Metaphysical ScienceblavskaNo ratings yet

- Philip Larkin: The Art of Poetry 30Document32 pagesPhilip Larkin: The Art of Poetry 30Telmo RodriguesNo ratings yet