Professional Documents

Culture Documents

Design of Agitator

Uploaded by

kirandas_mullasseryCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Agitator

Uploaded by

kirandas_mullasseryCopyright:

Available Formats

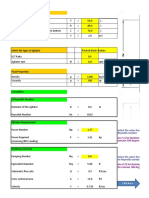

Example Data Batch Volume Vessel Diameter Specific Gravity difference Viscosity Ratio Density Viscosity

8840 9.5 0.4 1200 1100 15000

gal ft

33.46294 m3 2.8956 m

1180.83 ft3

kg/m3 cp

15 kg/m s

Enter value in colored cell

Step-1 Defining the intensity of mixing

0.4

ft/sec Specific Gravity Difference Less than 0.1 Less than 0.1

Mixing Scale 1 2 3 4 5 6 7 8 9 10

Bulk Velocity (ft/sec) Application 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 Miniumum Liquid Motion Miniumum Liquid Motion

Characteristic of most agitation used in chemical industry Less than 0.6

Requires high degree of agitation Less than 1.0

Viscosity Ratio Less than 100 Less than 100

Others

Less than 10000

Suspend trace solids less than 2% with settling rate of 2 to 4 ft/min

Less than 100000

Suspend trace solids less than 2% with settling rate of 4 to 6 ft/min

Step-2 Calculating Teq assuming square batch tank Volume of the contents Equivalent Diameter Volumetric flow rate V Teq Q = = = = 1180.825 ft3 11.45791 ft 41.22306 ft3/sec 2473.384 ft3/min 3.49237 m

Dont alter any value

Step-3 Selecting Agitator Dia Agitator Type D/T ratio W/D Select Ratio of D/T Impeller Dia Impeller Width

Pitched Blade Impeller with 4 blades 0.2 to 0.6 1/5 0.4 1.4 m 0.28 m 55.0 in 11.0 in

Step-4 Calculation of Required rpm Iteration Assume initial rpm Impeller reynolds Number From graph, impeller pumping number Recalculating the rpm required Difference Step-5 Closest standard rpm Reynolds number Viscosity correction factor Power Number Power Requirement 68 rpm 162.2 1.35 1.85 15755.1 kg m2 / s3 15755.1 Watts 21.1 hp 85 24.9 hp 25 hp 1.133 rpm 1 100 238.5 0.44 58.4 41.6 2 90 214.7 0.43 59.7 30.3 3 70 167.0 0.4 64.2 5.8 4 65 155.0 0.395 65.0 0.0

Assume loading % HP Required

4.58 ft

Step-6 Deciding number of impellers Calculated rpm Power required Calculating Height of the tank Vessel Dia For 1 in height, Volume occupied For occupying Height will be Height to Diameter ratio No of Impeller required Z Z/T V 0.16717853 m3 33.462936 m3 200.162876 in 1.75581471 2 5.084137 T 2.8956 m N P 68 rpm 25 hp 1.133333

Load shared by each impeller Initial estimate of diameter Power Number Diameter Impeller Reynolds number For the above reynolds number, Viscosity correction factor Power Number Recalculating Diameter Lower Impeller Location from bottom Upper Impeller Location from bottom

10.563798 hp

7877.553

1.8495 1.21611392 m 122.915771 47.87841

1.47 2.0139 1.19557699 m 0.9652 m 3.38942471 m 47.06987 37.99992 133.4417

Instead of I no of

55.00 in Impeller, two nos with

rps

Viscosity,cp <25000 <25000 >25001 >25001

Maximum Level,Z/T 1.4 2.1 0.8 1.6

No of Impeller 1 2 1 2

kg m2 / s3

in

in in in

, two nos with

47.06987 in diameter is required to provide the same agitation degree

Impeller clearance Lower Upper Z/3 T/3 (2/3) Z Z/3 T/3 (2/3) Z

Pumping Number curve for 4 blade pitched blade turbine impeller (Np = 1.37)

Viscosity correction factor as a function of reynolds number

Values of turbulent power number NP for various impeller geometries. Note: W/D is actual blade-width-to-impeller-diameter ratio.

Vessel Dia ft m 3 0.91 3.5 1.07 4 1.22 4.5 1.37 5 1.52 5.5 1.68 6 1.83 6.5 1.98 7 2.13 7.5 2.29 8 2.44 8.5 2.59 9 2.74 9.5 2.90 10 3.05 11 3.35 11.5 3.51 12 3.66

Volume m3/in gal/in 0.02 4.40 0.02 5.99 0.03 7.83 0.04 9.91 0.05 12.23 0.06 14.80 0.07 17.62 0.08 20.68 0.09 23.98 0.10 27.53 0.12 31.32 0.13 35.36 0.15 39.64 0.17 44.16 0.19 48.94 0.22 59.21 0.24 64.72 0.27 70.47

m3 0.60 0.95 1.42 2.03 2.78 3.70 4.80 6.10 7.62 9.38 11.38 13.65 16.20 19.06 22.23 29.59 33.81 38.41

Square batch gal 158.55 251.77 375.82 535.10 734.03 976.99 1268.40 1612.65 2014.17 2477.34 3006.57 3606.27 4280.84 5034.68 5872.21 7815.91 8930.89 10147.17

L 600 953 1423 2026 2779 3698 4801 6105 7624 9378 11381 13651 16205 19058 22229 29586 33807 38411

Scale up ratio

Assume Volume

DT1 V1

= = =

H1 0.785* DT1 * H1 0.785* DT1

(original vessel is standard cylindrical )

Ratio of volume

V2

DT2

V1 Scale up ratio, R =

DT1 V2 V1 =

Using this ratio for all factors, ex Da2 J2 = = R Da1 R J1

Agitator Speed,

n=1 for equal liquid motion, 3/4 for equal suspension of solid, 2/3 for equal mass transfer

n=2/3, power per unit volume is constant n=1, tip speed is constant

For Mild agitation and blending For vigarous agitation For intense agitation

0.1 to 0.2 0.4 to 0.6

KW/m3 of fluid KW/m3 of fluid

(Mass transfer is importanr0

0.8 to 2

KW/m3 of fluid

Example

Agitator Type Dia of Tank Dia of agitator Height of the Tank Width No of Baffles Baffle width Speed Viscosity Density

Flat blade turbine agitator Dt1 1.83 m Da1 0.61 m H1 1.83 m W1 0.122 m 4 J1 0.15 m N1 90 rpm 10 CP 929 kg/m3

1.5 rps 0.01 Kg / m s

Scale up for 3 times larger for 1)Equal rates of mass transfer is required 2) Equal liquid motion is required

Solution -1

Original Volume Scale up volume Ratio Da2 For equal mass transfer N2

V1 V2 1.442 0.879772 n 1.175072

4.810862 m3 14.43259 m3

m = rps

0.667 70.504 rpm

Reynolds Number

Nre

84492.96

Np

Power required

3972.189

J/sec

3.97 KW

5.33

Solution -2

Original Volume Scale up volume Ratio Da2 For equal liquid motion N2

V1 V2 1.442 0.880 n 1.040042

4.810862 m3 14.43259 m3

m = rps

1 62.403

Reynolds Number

Nre

74783.72

Np

Power required

2754.162

J/sec

2.75 KW

3.70

ssel is standard cylindrical )

DT2

DT1

hp

hp

You might also like

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 pagesAgitator Power Requirement and Mixing Intensity Calculation황종서100% (1)

- Design and Calculation AgitationDocument18 pagesDesign and Calculation AgitationDavid Lambert67% (3)

- Mixing: Aeration and Agitation in A Stirred Tank ReactorDocument15 pagesMixing: Aeration and Agitation in A Stirred Tank Reactorshankarbt8350% (4)

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 pagesAgitator Power Requirement and Mixing Intensity Calculationmpshah29860% (5)

- Design of AgitatorDocument3 pagesDesign of Agitatorkaps12No ratings yet

- Agitator DesignDocument9 pagesAgitator DesignDeepika100% (1)

- Agitator - Anchor - Highly ViscousDocument2 pagesAgitator - Anchor - Highly ViscousWade ColemanNo ratings yet

- Agitator Design CalcDocument5 pagesAgitator Design Calcranjit34380% (5)

- Agitator LATESTDocument17 pagesAgitator LATESTHARIPRASAD100% (1)

- Power Requirement (Agitator and High-Torque Stirrer)Document8 pagesPower Requirement (Agitator and High-Torque Stirrer)DozdiNo ratings yet

- Agitator Vessel (Design&Costing)Document34 pagesAgitator Vessel (Design&Costing)imrancenakk100% (2)

- Agitator Power Requirement and Mixing Intensity CalculationDocument28 pagesAgitator Power Requirement and Mixing Intensity Calculationcandra100% (3)

- Guid For The Selection of Agitator, Design Formula and Scale UpDocument60 pagesGuid For The Selection of Agitator, Design Formula and Scale Upscranderi100% (1)

- Mechanical Design of Shaft For Anchor AgitatorDocument11 pagesMechanical Design of Shaft For Anchor AgitatorRafique AjmeriNo ratings yet

- Agitator Design CalculationDocument21 pagesAgitator Design CalculationRupesh Ubale94% (36)

- Agitator Data (Fluid Properties, Client Data) 50Document23 pagesAgitator Data (Fluid Properties, Client Data) 50Mangesh Mandge100% (2)

- Design of AgitatorDocument12 pagesDesign of AgitatorPatil HemantNo ratings yet

- Calculation and Design of Speed and Power AgitatorDocument4 pagesCalculation and Design of Speed and Power Agitatorkamlesh luharNo ratings yet

- Existing:-Pitch Blade Turbine AgitatorDocument5 pagesExisting:-Pitch Blade Turbine AgitatorPrathmesh Gujarati100% (1)

- Agitator DesignDocument7 pagesAgitator DesignTint Tiger100% (4)

- Agitator Calculation. - SPLDocument2 pagesAgitator Calculation. - SPLAbarajithan RajendranNo ratings yet

- Design of AgitatorDocument4 pagesDesign of AgitatoralexnomitaNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument26 pagesAgitator Power Requirement and Mixing Intensity CalculationWael Abdel-Mageed100% (1)

- Calculation and Design of Critical Speed and Power AgitatorDocument4 pagesCalculation and Design of Critical Speed and Power AgitatorFrendy RianNo ratings yet

- Agitator CalculationDocument4 pagesAgitator CalculationAnkur Koul100% (4)

- Agitator Power Requirementand Mixing Intensity CalculationDocument26 pagesAgitator Power Requirementand Mixing Intensity Calculationkkaranag100% (1)

- Design of Agitator 8 Batch Volume PDFDocument3 pagesDesign of Agitator 8 Batch Volume PDFakash kumarNo ratings yet

- Design of AgitatorDocument3 pagesDesign of AgitatorManish PatelNo ratings yet

- Agitator DesignDocument3 pagesAgitator DesignSmrutiNo ratings yet

- Agitator Spreadsheet DetailsDocument7 pagesAgitator Spreadsheet DetailsAndrewNo ratings yet

- Agitator DesignDocument5 pagesAgitator DesignSaepul RochmanNo ratings yet

- Agitator Full Design PDFDocument8 pagesAgitator Full Design PDFRajesh KumarNo ratings yet

- Calculation AgitatorDocument3 pagesCalculation AgitatorKrishnaAgarwalNo ratings yet

- Design of AgitatorDocument3 pagesDesign of AgitatorDanEstradaNo ratings yet

- AgitatorDocument2 pagesAgitatorThiruvilan Arakkonam Mohan100% (1)

- 16 - Blending and AgitationDocument20 pages16 - Blending and AgitationRafael ReyesNo ratings yet

- CalculationDocument8 pagesCalculationmahaveenNo ratings yet

- 5 4801 857Document14 pages5 4801 857nurul9535No ratings yet

- Vortex FlowmeterDocument16 pagesVortex FlowmeterBiswajit DebnathNo ratings yet

- Hydraulic CalculationsDocument20 pagesHydraulic CalculationsJayesh ChandranNo ratings yet

- Grit Removal DesignDocument5 pagesGrit Removal Designnassif75No ratings yet

- Design and Calculation AgitationDocument25 pagesDesign and Calculation Agitationibson045001256No ratings yet

- Process Flow Diagram: Fig: Process Flow Sheet Made With Help of ASPENDocument42 pagesProcess Flow Diagram: Fig: Process Flow Sheet Made With Help of ASPENSwarnim RajNo ratings yet

- Name, Symbol, Dimensions Conversion Formula: Formulas For Unit ConversionsDocument3 pagesName, Symbol, Dimensions Conversion Formula: Formulas For Unit ConversionsQedew ErNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 pagesAgitator Power Requirement and Mixing Intensity CalculationElizabeth Allende CéspedesNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 pagesAgitator Power Requirement and Mixing Intensity CalculationSampathkumar AttuluriNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 pagesAgitator Power Requirement and Mixing Intensity Calculation@sssNo ratings yet

- A - Conversion FactorsDocument14 pagesA - Conversion Factorssaeed65No ratings yet

- Heat Transfer Coeficient in ReactorDocument2 pagesHeat Transfer Coeficient in ReactorDavid LambertNo ratings yet

- 16 - Blending and AgitationDocument27 pages16 - Blending and AgitationSimon Tin Hann PyngNo ratings yet

- Semler ChartDocument1 pageSemler ChartAjit MokalNo ratings yet

- Mixing: Aeration and Agitation in A Stirred Tank ReactorDocument15 pagesMixing: Aeration and Agitation in A Stirred Tank ReactorAixa BerchiNo ratings yet

- Hydraulic Formula CalculatorDocument3 pagesHydraulic Formula CalculatorHarshal Jadhav86% (14)

- Sizing For Vaporiser/Flash Vessel: InputsDocument3 pagesSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranNo ratings yet

- Serva Cementing 113015 LR Pages PDFDocument16 pagesServa Cementing 113015 LR Pages PDFAnonymous uKoNmLxkNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument28 pagesAgitator Power Requirement and Mixing Intensity CalculationJon AguirreNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument28 pagesAgitator Power Requirement and Mixing Intensity CalculationVasu DevanNo ratings yet

- Flexibond Agitator ModificationDocument26 pagesFlexibond Agitator ModificationGLENDA CASINONo ratings yet

- Mixing CalculationDocument31 pagesMixing CalculationTubagus100% (1)

- Mixing Calculation-1 PDFDocument31 pagesMixing Calculation-1 PDFdella kusuma0% (1)

- CP S HW CH 9 DetailedDocument6 pagesCP S HW CH 9 Detailedkirandas_mullasseryNo ratings yet

- Design of AgitatorDocument23 pagesDesign of Agitatorkirandas_mullassery100% (3)

- Performance of One Unit Shell Side Tube SideDocument1 pagePerformance of One Unit Shell Side Tube Sidekirandas_mullasseryNo ratings yet

- Limpet Coil CalculationDocument1 pageLimpet Coil Calculationkirandas_mullassery100% (1)

- Shell & Dish ThicknessDocument3 pagesShell & Dish Thicknesskirandas_mullasseryNo ratings yet

- Ccs 125m FundingDocument3 pagesCcs 125m Fundingkirandas_mullasseryNo ratings yet

- Guide To Inspecting The WorkplaceDocument29 pagesGuide To Inspecting The Workplacekirandas_mullasseryNo ratings yet

- Material Safety Data Sheet: Product Name: Mobil Stern Tube LubricantDocument9 pagesMaterial Safety Data Sheet: Product Name: Mobil Stern Tube Lubricantkirandas_mullasseryNo ratings yet

- Productflyer - 978 0 7923 1202 4Document1 pageProductflyer - 978 0 7923 1202 4kirandas_mullasseryNo ratings yet

- 2010 Rockwell Collins Shuttle Badminton LeagueDocument2 pages2010 Rockwell Collins Shuttle Badminton Leaguekirandas_mullasseryNo ratings yet

- ALL Purspose Excel SheetDocument224 pagesALL Purspose Excel SheetAmresh PradhanNo ratings yet

- Preetham Ullal: Nyle Adnan Hazza Building, Muwelih Area, SharjahDocument3 pagesPreetham Ullal: Nyle Adnan Hazza Building, Muwelih Area, Sharjahkirandas_mullasseryNo ratings yet

- Sea Shanty PrintDocument3 pagesSea Shanty PrintDiego DracvsNo ratings yet

- Research Article: International Research Journal of PharmacyDocument5 pagesResearch Article: International Research Journal of PharmacyAlfrets Marade SianiparNo ratings yet

- Atomic Structure RevisionDocument4 pagesAtomic Structure RevisioncvNo ratings yet

- 14 Parabola Formula Sheets QuizrrDocument9 pages14 Parabola Formula Sheets QuizrrChandanNo ratings yet

- Provisional Restorations in Fixed ProsthodonticsDocument4 pagesProvisional Restorations in Fixed ProsthodonticsPhoebe David100% (1)

- Plugs, Fuses and Household ElectricityDocument4 pagesPlugs, Fuses and Household ElectricityRonald HuynhNo ratings yet

- Chemical Bath DepositionDocument6 pagesChemical Bath DepositionJune AlapaNo ratings yet

- Whitepaper - Loadspreading and SeafasteningDocument3 pagesWhitepaper - Loadspreading and SeafasteningtyuNo ratings yet

- Freedom As A Foundation of EthicsDocument3 pagesFreedom As A Foundation of EthicsGrant Jomar SiadorNo ratings yet

- Coffee Vibes: Here Is Where Your Presentation BeginsDocument86 pagesCoffee Vibes: Here Is Where Your Presentation Beginssyeda salmaNo ratings yet

- VIC Routing Model PreprocessingDocument11 pagesVIC Routing Model PreprocessingpchrisrlNo ratings yet

- SURELAM-380,540II (User Manual)Document25 pagesSURELAM-380,540II (User Manual)kamran.sefyaliyevNo ratings yet

- Heavy Earth Moving MachinaryDocument34 pagesHeavy Earth Moving MachinaryMAZHAR ALAMNo ratings yet

- E9sht I C C I W D SDocument213 pagesE9sht I C C I W D SMAMBO95TLNo ratings yet

- Catalogue Pièces Moteur R984Document150 pagesCatalogue Pièces Moteur R984Eza IR100% (1)

- Class VII Half Yearly Maths, M.junaidDocument4 pagesClass VII Half Yearly Maths, M.junaidmohd junaidNo ratings yet

- Aeration PaperDocument11 pagesAeration PapersehonoNo ratings yet

- 2019 MIPS Quality Historic BenchmarksDocument158 pages2019 MIPS Quality Historic BenchmarksJoe GellatlyNo ratings yet

- Subject: Using Emergency Power With DSD Elevator DrivesDocument4 pagesSubject: Using Emergency Power With DSD Elevator DrivesmehariiNo ratings yet

- Custard The DragonDocument4 pagesCustard The DragonNilesh NagarNo ratings yet

- 8484.sensor CEM Diagnostic Tests User Manual v3.1.0Document28 pages8484.sensor CEM Diagnostic Tests User Manual v3.1.0Edgar FuentesNo ratings yet

- Portégé R930 (3G) PT331A-0DE043: Toshiba Recommends Windows 10Document2 pagesPortégé R930 (3G) PT331A-0DE043: Toshiba Recommends Windows 10josecarlosvjNo ratings yet

- MiniNova GuideDocument41 pagesMiniNova GuideBob FredNo ratings yet

- The Proof of Agricultural ZakatDocument7 pagesThe Proof of Agricultural ZakatDila Estu KinasihNo ratings yet

- Msi MS 7529 Rev 1.1 PDFDocument33 pagesMsi MS 7529 Rev 1.1 PDFMisael Alves67% (3)

- Test Intensiv Engleza 5Document30 pagesTest Intensiv Engleza 5Simona Singiorzan90% (30)

- Cross Border Pack 2 SumDocument35 pagesCross Border Pack 2 SumYến Như100% (1)

- Internment - Samira AhmedDocument254 pagesInternment - Samira Ahmedboop50% (4)

- Craig - 4353 TX CobraDocument3 pagesCraig - 4353 TX CobraJorge ContrerasNo ratings yet

- CERN Courier - Digital EditionDocument33 pagesCERN Courier - Digital EditionFeriferi FerencNo ratings yet