Professional Documents

Culture Documents

Recovery Boiler Chemical Process (Tappi)

Uploaded by

pwmvsiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Recovery Boiler Chemical Process (Tappi)

Uploaded by

pwmvsiCopyright:

Available Formats

4.

4-1

RECOVERY BOILER CHEMICAL

PRINCIPLES

Mikko Hupa

bo Akademi University

Department of Chemical Engineering

SF-20520 Turku, Finland

1. INTRODUCTION

A black liquor recovery boiler has two main

functions. On one hand, it generates steam from the

heat energy liberated upon combustion of the

organic constituents of black liquor burned in the

boiler, whereby the recovery boiler serves as a

steam boiler. On the other hand, the chemicals from

pulp digesting - sulphur and sodium - are recovered

from the black liquor, the recovery boiler then

serving as a chemical reactor. This double function

makes the design of a recovery boiler rather

complex and the operation of such a boiler much

more complicated than that of, for instance, a power

plant boiler burning conventional fuels.

When viewing the recovery boiler as a chemical

reactor, its construction is quite unique. In the

recovery boiler furnace, to a great extent in the same

space and at the same time, a number of entirely

separate physiochemical processes take place:

- feeding of air and mixing it with the furnace

gases

- feeding of black liquor and dispersing it into

droplets

- drying of the black liquor droplets

- pyrolysis of the black liquor and combustion of

the pyrolysis gases

- gasification and combustion of the char residue

- reduction of the liquor sulphur compounds to

sulphide

- tapping the molten salt consisting of sodium

sulphide and sodium carbonate from the furnace

bottom

Further, as a more or less undesired side effect:

- vaporization or "fuming" of sodium and sulphur

compounds (and to a lesser extent of chlorine

and potassium compounds) and the vapours and

fume escaping to the top of the furnace in the

flue gases.

Traditionally, recovery furnaces have been designed

and operated based on practical and empirical

experience from full scale recovery furnaces rather

than based on detailed information of the

physicochemical phenomena involved in the

process. However, this situation is about to change.

Large amounts of completely new, fundamental

information about the recovery furnace processes

have very recently been produced in several

research laboratories.

bo Akademi University in Turku, Finland, has

during the past years had several major research

programs concerning the high temperature chemistry

in recovery furnaces and the physicochemical

behaviour of black liquor during combustion or

gasification. This research together with recent work

elsewhere, particularly at the Oregon State

University, at the Institute of Paper Science and

Technology, and at the University of Toronto, in

Canada, has considerably sharpened our picture of

the chemistry in a recovery furnace.

This information is already clearly affecting and

changing the recovery boiler operation and design.

This paper gives a short overview of the picture

evolving from the recent research. Various schemes

and diagrams are made use of to summarize the

chemistry of sulphur and sodium, the main

chemicals of the process. Also, the most important

foreign elements in black liquor and their behaviour

in the boiler is shortly discussed.

Research continues to be lively, and the latest results

may quite soon further clarify our ideas of some of

the key processes, e.g. those which govern the

release of sodium and sulphur into the gas phase in

the furnace.

2. SODIUM AND SULPHUR BALANCE IN A

KRAFT RECOVERY BOILER

Table 1 shows the black liquor elemental

composition for a typical open cycle kraft process.

The contents of sodium and sulphur in black liquor

vary considerably from one process to another.

From the point of view of the recovery boiler

chemistry, the molar ratio between total sulphur and

sodium in the black liquor, S/Na

2

, is a useful

parameter. As will become evident later on, this

relation largely governs the chemistry of the sulphur

and sodium in the recovery boiler.

Table 1. An example of kraft black liquor elemental

composition. Sample before the mixing tank.

Wt% dry solids

C 38.2

H 3.4

O 31.1

N 0.1

S 5.2

Na 19.8

K 1.9

Cl 0.10

Others (Ca,Si,Fe,Mg,Al,Mn) 0.2

S/Na

2

=0.38 mol/mol

4.4-2

There is a considerable variation in the sulphur-

sodium ratio between different processes. High

sulphidity in pulping and the oxidized sulphur-

sodium salts (Na

2

SO

4

, Na

2

SO

3

) in the recovery

cycle increase the S/Na

2

ratio. The sulphidity of the

processes of Scandinavian pulp mills as well as the

S/Na

2

ratios of their black liquors are, in general,

notably higher than those found in North America.

In Scandinavia, the S/Na

2

range is typically 0.35 to

0.5, whereas the corresponding variation at mills in

North America is typically 0.2 to 0.3. Table 2 gives

an example of the various sulphur compounds in

kraft black liquor.

Table 2. An example of distribution of sulphur

compounds in kraft black liquor /1/.

% sulphur of

total sulphur

Sulphide, S

2-

11

Thiosulphate, S

2

O

3

2-

36

Sulphite, SO

3

2-

13

Sulphate, SO

4

2-

5

Organic sulphur (balance) 35

Total 100

In an ideal recovery boiler process, all the diverse

sulphur and sodium compounds would be

transformed to sodium sulphide (Na

2

S) and sodium

carbonate (Na

2

CO

3

) and be contained in the smelt

on the furnace bottom.

In a real recovery boiler, however, the process is

more complicated. Figure shows an example of

sulphur and sodium balances in a typical recovery

boiler. This example could describe a process

operated at nominal load and where the S/Na

2

ratio

is about 0.4 and the dry substance of the black liquor

at the sprays is about 70 %. It is to be noted here that

Fig. 1 represents only a single case and certain

conditions. The flow rates of sodium and sulphur

vary greatly from one process to another, or even in

the same process, depending on the operation

strategy of the boiler.

The figure shows clearly a deviation from the ideal

process referred to above. For one thing, the sulphur

does not occur in the molten salt bound only in

sulphide but also in sulphate. The reduction, or

molar ratio (Na

2

S)/(total S) in the smelt of actual

processes is typically about 90 - 95 %.

A substantial part of the sulphur and the sodium is

carried by the combustion gases into the boiler flue,

mainly in the form of sodium sulphate dust and

sulphur-containing gases. These compounds are the

cause of most fireside problems, such as fouling of

heat transfer surfaces and corrosion.

Org-S

S

S O

SO

SO

Na SO

52

3

Na S

Na SO

N

a

S

O

NaSO

SO

H S

(100mg/m )

(200ppm)

(50ppm)

MAKE UP

SMELT

B. L.

EMISSIONS

2 4

2

2

3

2

2

4

2 4

2-

2-

4

2 3

2-

2

4

0.01

0.06

0.01

NaSO

SO

H S

2 4

2

2

0.08

12

55

67

5

50

2-

3

Na SO

Na SO (100mg/m )

MAKE UP

SMELT

B. L.

EMISSIONS 2 4

3

2 4

0.01

Na SO

Na CO

2 4

2 3

0.01

18

7

Na

+

200

207

225

Na CO

Na S

Na SO

2

4

2

2

3 128

75

4

A

B

Org-S

S

S O

SO

SO

Na SO

52

3

Na S

Na SO

N

a

S

O

NaSO

SO

H S

(100mg/m )

(200ppm)

(50ppm)

MAKE UP

SMELT

B. L.

EMISSIONS

2 4

2

2

3

2

2

4

2 4

2-

2-

4

2 3

2-

2

4

0.01

0.06

0.01

NaSO

SO

H S

2 4

2

2

0.08

12

55

67

5

50

2-

3

Na SO

Na SO (100mg/m )

MAKE UP

SMELT

B. L.

EMISSIONS 2 4

3

2 4

0.01

Na SO

Na CO

2 4

2 3

0.01

18

7

Na

+

200

207

225

Na CO

Na S

Na SO

2

4

2

2

3 128

75

4

A

B

Figure 1. A) (upper) Sulphur, and B) (lower)

Sodium balance in a typical kraft recovery process.

Numbers refer to grams of S or Na per kilogram of

black liquor solids.

Most of the dust falls out of the flue gases into dust

hoppers or is captured by electrostatic precipitators.

From these the dust is fed back into the boiler by

mixing the dust with the infeed black liquor.

Roughly 10 % of the sodium contained in the black

liquor is typically in this circulation.

Correspondingly, the part of the sulphur carried

away by the combustion gases ranges from 20 to 40

%, depending on circumstances.

Finally, a small portion of both sodium and sulphur

leaves the process as flue gas emissions. The main

emission components are glauber salt dust

(Na

2

SO

4

), sulphur dioxide gas (SO

2

), and reduced

sulphur gases, hydrogen sulphide (H

2

S), methyl

mercaptan (CH

3

SH), etc. The emissions depend

strongly on the process conditions and, of course,

the performance of the flue gas purification

equipment.

3. FURNACE BOTTOM AND CHAR BED

The lower furnace and the char bed are crucial for

the entire recovery boiler process. The conditions in

the lower furnace determine almost exclusively the

performance of the process, that is, how the flows of

sulphur and sodium as shown in Figure 1 are

distributed in each case. The conditions in the

furnace are chiefly influenced by the technique of

4.4-3

liquor spraying and the introduction of combustion

air into the furnace. Also the black liquor properties,

particularly its dry solids content, of course, affect

the conditions in the furnace.

3.1 Equilibrium Composition in the Lower

Furnace

Figures 2 and 3 by Pejryd and Hupa /2/ show the

composition at the bottom of the furnace, on one

hand, as a function of the lower furnace air factor

(Fig. 2) and, on the other hand, as a function of

temperature (Fig. 3). The bottom parts of the figures

describe the smelt bed composition as mole

fractions. The top part of the figures gives the

composition of the gas phase near the bed. The

figures are based on theoretical thermodynamic

equilibrium calculations. Such calculations assume

an isothermal process with perfect mixing, where all

chemical reactions reach equilibrium. Although

these conditions are not actually achieved in the

bottom part of any actual recovery boiler furnace,

some useful conclusions may be drawn from above

figures.

10

10

10

10

10

10

10

1.0

0.8

0.6

0.4

0.2

0.0

10%

1%

1000ppm

100ppm

10ppm

1ppm

100%

AIR/FUEL RATIO, %THEORETICAL AIR

C

O

M

P

O

S

I

T

I

O

N

,

M

O

L

E

F

R

A

C

T

I

O

N

P

A

R

T

I

A

L

P

R

E

S

S

U

R

E

,

A

T

M

V

O

L

U

M

E

C

O

N

C

E

N

T

R

A

T

I

O

N

0

-1

-2

-3

-4

-5

-6

NaOH(l)

Na CO (l)

Na S(l)

2 3

2

0 20 40 60 80 100 120

0 20 40 60 80 100 120

Na SO (l)

C (s)

2 4

CO

N

CO

H O

H

O

H S

N

a

C

H

NaOH

NaH

Na

COS

N

H SO

NO

2

2

2

2

2

2 4

2

3 2

Figure 2. Equilibrium composition of smelt (mole

fraction, lower graph) and lower furnace gas (partial

pressure, upper graph) as function of air/fuel ratio.

Temperature 1000 C, molar ratio S/Na

2

in black

liquor 0.30 /2/.

TEMPERATURE, C

C

O

M

P

O

S

I

T

I

O

N

,

M

O

L

E

F

R

A

C

T

I

O

N

P

A

R

T

I

A

L

P

R

E

S

S

U

R

E

,

A

T

M

V

O

L

U

M

E

C

O

N

C

E

N

T

R

A

T

I

O

N

10

10

10

10

10

10

10

1.0

0.8

0.6

0.4

0.2

0.0

600 800 1000 1200

600 800 1000 1200

10%

1%

1000ppm

100ppm

10ppm

1ppm

100%

0

-1

-2

-3

-4

-5

-6

N H O

CO

CO

H

N

a

N

aO

H

H S

COS

C

H

NH

S

O

NaOH(l)

Na CO (l)

Na S(l)

Na CO (s)

Na S(s)

2

2

2

2

2

4

3

2

2 3

2 3

2

2

Figure 3. Equilibrium composition of smelt (mole

fraction, lower graph) and lower fumace gas (partial

pressure, upper graph) as function of temperature.

Molar ratio S/Na

2

in black liquor 0.70, air/fuel ratio

0.70 /2/.

Firstly, the figures show all the significant chemical

compounds which may occur in the lower furnace.

In addition to the aforesaid sodium sulphide, sodium

carbonate, and sulphate, also solid elemental carbon

(C) may be present in the bed under extreme

conditions. Figure 3 also shows that solid

compounds begin to form in the bed, i.e. the bed

starts "freezing" when the temperature drops below

approximately 800 degrees C.

The main components of the flue gases are natural

products of air-deficient combustion, i.e. nitrogen

(N

2

), carbon monoxide (CO), carbon dioxide

(CO

2

), hydrogen (H

2

), and water (H

2

O).

In the gas phase, sulphur occurs as hydrogen

sulphide (H

2

S), carbonyl sulphide (COS), and, at

high air factors, as sulphur dioxide (SO

2

). The most

important gaseous sodium compounds are sodium

hydroxide (NaOH) and metallic sodium (Na).

3.2 Reduction of the Smelt

Figure 2 further shows that, in principle, under

equilibrium conditions, complete smelt reduction

may be obtained when the (local) air factor remains

below approximately 0.8. In the actual process,

however, the limited rate of the reduction reactions,

i.e. kinetics, prevents complete reduction.

Some information is available on the char bed

reduction reaction rate /3-6/. In principle, the

sulphate contained in a partly burned black liquor

droplet entering the bed may be reduced either by

means of (l) reducing gases (CO or H

2

) or (2) the

solid carbon (char) in the bed. A comparison by

Adams and Frederick of laboratory test results found

in the literature /6/ shows that the reduction of

sulphate by means of char is about two orders of

magnitude faster than a corresponding reduction

with reducing gases. These authors concluded that

the gas reactions become dominant in the reduction

process only after 99 % of the char in the smelt bed

has been consumed. At that stage, however, the

whole reduction process is apparently very slow,

and insignificant for any practical purposes.

Consequently, a prerequisite for efficient smelt

reduction is a sufficient amount of char continuously

on the bed surface. This means in practice that the

spraying of black liquor should be arranged in such

a way that a significant fraction of the droplets hit

the bed surface at the stage when the char burning is

still incomplete. The limit here will naturally be the

capacity of the bed to burn char. An excessive flow

of char onto the bed would result in an unwanted

growth of the bed.

Another important factor with respect to efficient

smelt reduction is the bed temperature. The rate of

4.4-4

the reduction reaction is strongly dependent on

temperature (the process activation energy ranges

from 120 to 170 kJ /mol /5/). The reduction rate

roughly doubles each time the temperature is

increased 50 - 60 degrees C. There are many ways

to control the bed temperature /6/, but they are not to

be dealt with here.

The reduction of the smelt is to some extent

counteracted by reoxidation of the smelt near the

furnace walls and smelt spouts. In normal practice,

however, such reoxidation is of little significance.

3.3 Vaporization of Sulphur and Sodium

Compounds

In the lower furnace, part of the sodium and sulphur

is transferred into the flue gases and will not return

to the char bed. Of the compounds so carried away

by the combustion gases, the most important sulphur

compounds are H

2

S and COS, and, for sodium

compounds, gaseous Na and NaOH. The main factor

controlling the vaporization of the sulphur and

sodium compounds is the temperature. In Figure 3,

the equilibrium concentration of the gaseous

compounds is given on the logarithmic axis. The

figure shows how the concentration of gaseous

sodium compounds steeply rises with rising

temperature. The concentration of sulphur

compounds decreases with rising temperature. These

two trends have a great significance with respect to

fireside chemistry, and they will be discussed in

closer detail below.

The equilibrium curves for sulphur and sodium

compounds as a function of temperature in Figure 3

have been transposed on the linear vertical axis in

Figure 4. One reads from this illustration that the

equilibrium content of sodium compounds in

gaseous form doubles when the bed temperature

increases approximately 50 degrees C. The opposite

decreasing trend for sulphur is less steep, and it

levels off at higher temperatures.

10 000

5 000

800 1000 1200

S (eq)

tot

2Na (eq)

tot

0

S (actual)

tot

2

N

a

(a

c

tu

a

l)

to

t

TEMPERATURE, C

C

O

N

C

E

N

T

R

A

T

I

O

N

,

p

p

m

Figure 4. Sulphur and sodium release in recovery

furnaces as function of temperature. Equilibrium

values and typical actual boiler data.

The increasing and decreasing trends of vaporizing

sodium and sulphur, respectively, with rising

temperature has been observed also in operating

boilers. It is generally known that when operating a

boiler at a low temperature because of low heat

value of black liquor or some other reason, flue

gases of considerably high sulphur content are

produced. It is also known that increasing the

furnace temperature, e.g. by increasing the dry

substance content of the black liquor, increases the

rate of sodium vaporization and thereby the rate of

dust circulation in the combustion gases.

In Figure 4, typical sulphur and sodium trends have

been given for an operating boiler. These trends are

based on the results of numerous flue gas surveys

conducted on boilers of different types and sizes.

Field observations deviate markedly from the results

of the equilibrium calculations in two important

respects:

(1) The concentration of fine sulphate dust

condensed from the vapour state and collected in the

electrostatic precipitator is typically in the range of 5

to 15 g/m

3

of flue gas. This indicates clearly that the

release of sodium and sulphur into vapour state is 3

or 4 times higher than the results of the equilibrium

calculations show.

(2) Field experience also indicates that the

concentration of sodium in the flue gas does nor

respond to changes in temperature so sharply as

could be expected when studying the equilibrium

curves. In converting boilers to ultra high dry solids

firing, the sodium concentration increase does

usually not exceed some 30 - 40 % from the figure

before the conversion even though the furnace

temperature in such cases rises at least 100 degrees

C, possibly more. According to equilibrium

calculations this should result in a 400 % increase in

sodium concentration.

One proposed explanation for these deviations is

formation of dust due to oxidation of sulphite in the

smelt /8,9/. This oxidative fume as a phenomenon

has been verified under laboratory conditions but its

significance in an actual furnace is unknown.

Recent laboratory work, however, suggest a

different explanation. Measurements done on

individual droplets indicate that already in the earlier

phases of combustion, considerable amounts of

sulphur and sodium are released from the black

liquor droplets, especially during the pyrolysis stage

/9/. This vaporization is controlled by kinetics only,

and it takes place, as it were, before the black liquor

droplet enters the vicinity of the bed surface.

Consequently, one could think that the sodium and

sulphur in the flue gas originate in two distinctly

different sources. On one hand, they are vaporized

4.4-5

in the lower furnace from the surface of the smelt,

possibly much in accordance with the equilibrium

calculations. On the other hand, significant amounts

of sulphur and sodium are released from the black

liquor spray in connection with the complex

pyrolysis reactions. The latter source, pyrolysis,

probably accounts for substantially larger amounts

of released sulphur and sodium than the amounts

vaporized from the surface of the smelt.

Investigations on the vaporization of sodium and

sulphur in the furnace continue, and more light is

expected to be shed on the matter quite soon.

From the viewpoint of practical applications, the

following may be stated:

- Sulphur is vaporized in a furnace mainly as

hydrogen sulphide, whereas sodium is vaporized

as sodium hydroxide and metallic sodium.

- The concentration of sulphur in the flue gas

increases with decreasing furnace temperature.

The trend for the sodium is in the opposite

direction.

- The ratio of concentrations of sulphur and

sodium in the flue gas controls, to a great extent,

the entire flue gas and dust chemistry. This ratio

in terms of moles varies from one boiler or

process to another, typically from 0.8 to 1.5. The

ratio is lower at high furnace temperature and at

low sulphidity in the black liquor.

The effect of the S/Na

2

ratio on the flue gas

chemistry is studied to closer detail below in the

section which follows.

4. CHEMISTRY OF FLUE GAS AND DUST

The formation of dust in a recovery boiler and the

boiler flue gas emissions are discussed here. Part of

the dust consists of fine particles condensed from

vapour. The particle size of these particles is

typically 0.2 to 1 m, and the dust captured by

means of electrostatic precipitators consists almost

entirely of this type of dust. In addition to this dust,

coarser particles, in the size range of 10 to 100 m,

occur in large amounts in the superheater area and in

the first dust hoppers. This coarser dust consists of

carry-over liquor particles, that is, inorganic residue

of black liquor droplets which have escaped from

the sprays. These are of special significance,

especially with respect to fouling of superheaters.

The fouling behaviour of carry-over particles is

treated to more detail in a number of references /10-

16/, but these are not to be discussed here.

4.1 Reactions in the Flue Gas and the S/Na

2

Ratio of the Flue Gas

Under the reducing conditions in the lower furnace,

sulphur occurs in the form of hydrogen sulphide,

and sodium mainly as metallic sodium and sodium

hydroxide. When the lower furnace gases rise to the

upper furnace and their combustion is completed,

the sulphur and sodium compounds are transformed

and they react with each other. The final flue gas

dust compounds and the sulphur emission

compounds are produced in these reactions which

take place in the upper furnace and, partly, in the

superheater zone.

Figures 5 A and B illustrate the principle reactions

of sulphur and sodium in the flue gas, beginning

with sodium vapours and hydrogen sulphide formed

in the bottom part of the furnace. The figures are

based partly on theoretical calculations, partly on

results of field measurements /9,11,17,18/.

C

200

400

600

800

1000

LOWER

FURNACE

TERT.

AIR

SUPER

HEATER

BOILER

BANK

ECONO-

MIZER

H S(g) SO (g) Na SO (s) Na CO (s)

H S(g)

SO (g)

Na SO (l,s)

Na CO (l,s)

2NaOH(g)

O (g)

O (g)

CO (g)

2

2

2

2

2 4

2 3

2

2 2 2 4 2 3

2NaHSO

(l,s)

4

SO (g) 3

NaHSO (s)

O (g) 2

H O (g) 2

SO (g) 3 4

C

200

400

600

800

1000

LOWER

FURNACE

TERT.

AIR

SUPER

HEATER

BOILER

BANK

ECONO-

MIZER

H S(g) SO (g) Na SO (s) Na CO (s)

H S(g)

SO (g)

Na SO (l,s)

Na CO (l,s)

2NaOH(g)

O (g)

O (g)

CO (g)

2

2

2

2

2 4

2 3

2

2 2 2 4 2 3

A

B

C

200

400

600

800

1000

LOWER

FURNACE

TERT.

AIR

SUPER

HEATER

BOILER

BANK

ECONO-

MIZER

H S(g) SO (g) Na SO (s) Na CO (s)

H S(g)

SO (g)

Na SO (l,s)

Na CO (l,s)

2NaOH(g)

O (g)

O (g)

CO (g)

2

2

2

2

2 4

2 3

2

2 2 2 4 2 3

2NaHSO

(l,s)

4

SO (g) 3

NaHSO (s)

O (g) 2

H O (g) 2

SO (g) 3 4

C

200

400

600

800

1000

LOWER

FURNACE

TERT.

AIR

SUPER

HEATER

BOILER

BANK

ECONO-

MIZER

H S(g) SO (g) Na SO (s) Na CO (s)

H S(g)

SO (g)

Na SO (l,s)

Na CO (l,s)

2NaOH(g)

O (g)

O (g)

CO (g)

2

2

2

2

2 4

2 3

2

2 2 2 4 2 3

A

B

Figure 5. Reactions of sulphur and sodium in

recovery furnace and flue gases.

A) (upper) Molar ratio in flue gases: S/Na

2

=1.5

(Cool bed, high sulphidity).

B) (lower) Molar ratio in flue gases: S/Na

2

=0.8 (Hot

bed, low sulphidity).

Based on /17,10,19/.

Moving up on the diagram means moving up from

the bottom part of the furnace, and further into the

flue duct. The top of the diagram shows the final

sulphur and sodium compounds in the flue gas at the

4.4-6

entrance to the dust collecting system. Each of the

boxes in the diagram describe chemical reactions.

The reactants participating in the reactions enter the

boxes through the bottom or the sides. The reaction

product is indicated as the label of the box. The

product always leaves the box up through the top.

The width of the line describing a material flow is

proportional to the magnitude of the flow.

The reactions which take place in the flue gases are

dependent on the molar ratio of total sulphur and

total sodium entrained in these gases. Therefore,

Figure 5 shows the reactions separately for two

extreme conditions. Figure 5 A describes the

reactions under conditions where the S/Na

2

ratio in

the flue gases is very high, clearly exceeding unity.

These conditions prevail in boilers where the

furnace temperature is low and/or the black liquor

sulphidity is high. Figure 5 B describes the opposite

case, where the furnace temperature is high and/or

the black liquor sulphidity is low. Actual boilers

generally operate somewhere between these two

extremes.

The first reaction in both diagrams is the oxidation

of hydrogen sulphide into sulphur dioxide. This

takes place by means of tertiary air in the top part of

the furnace, and the completeness of this oxidation

depends only on the efficiency of mixing the air

with the combustion gases. Any hydrogen sulphide

not oxidized at this point will not be oxidized later

on in the cooling flue gases but will remain as a

constituent of the flue gas and forms the main

component of the TRS "total reduced sulphur"

emissions of the boiler.

The sulphur dioxide produced as a result of

oxidation of hydrogen sulphide reacts with the

sodium compounds also in the oxidizing

environment of the upper furnace and sodium

sulphate is produced. In the furnace this sodium

sulfate will be in molten state, but will solidify as

the combustion gases cool down. After this reaction,

the entire chemistry of the furnace gases depends on

whether they originally contained a surplus of

sulphur or sodium.

In the case of Figure 5 A, practically all of the

sodium is bound in this reaction to sodium sulphate,

and a surplus of sulphur dioxide remains. This

sulphur dioxide is often a cause of trouble when the

combustion gases cool down. A surplus of sulphur

dioxide may change the sulphate dust into sticky,

acidic sulphate (bisulphate). Acidic sulphates may in

the worst case cause rapid fouling of the

economizer, and boiler bank corrosion /19/.

Moreover, this surplus of sulphur dioxide, as a rule,

finally ends up in the atmosphere as flue gas

emission.

In the case of Figure 5 B the reaction producing

sodium sulphate consumes practically all of the

sulphur dioxide and the surplus reacts with CO

2

to

form sodium carbonate dust. In this case the sulphur

dioxide emission of the flue gas will remain very

low. Acidic sulphates cannot be produced in this

case. The conditions involved in Figure 5 B

correspond to those experienced with high dry solids

firing. Under these, the content of SO

2

in flue gas

may drop below the detection limit (<1 ppm) and

the carbonate content of the dust may rise to exceed

10 % /20/.

At actual boiler operation it would be advisable to

aim at a low S/Na

2

molar ratio in the gases, below

1.0 if at all possible. Increasing the dry solids

content above 70 %, even above 80 %, would be

helpful in lowering the sulphur/sodium ratio. The

favourable conditions as in Figure 5 B have been

achieved with extremely high dry solids content in

spite of the liquor having a high sulphidity /21/.

4.2 Dust pH

A simple and quick way to monitor the flue gas and

the dust chemistry is to measure the pH-value of a

water solution of a dust sample taken from the flue

gas duct or the electrostatic precipitator.

The "dust pH" indicates readily on which side of the

dust chemistry the boiler is operated, i.e. does the

dust contain carbonate in addition to the sulphate, or

does it contain acidic sulphate. The presence of

carbonate produces alkaline pH water solution.

Correspondingly, only a few percent of bisulphate

drops the pH of the dust/water solution several units

below neutral. If the dust would consist of pure

sodium sulphate, water solution pH would be 7.

Such a pH, however, is very unstable and

uncommon. The relation between the dust

composition and the pH-value of its water solution

has been drawn in Figure 6. The pH-curve has been

calculated for a 1 percent dust solution.

14

12

10

8

6

4

2

0

10 5 0 5 10 wt% wt%

pH

Na SO

2 4

NaHSO Na CO

2 3 4

Figure 6. Dust pH as function of dust carbonate

(Na

2

CO

3

) or bisulphate (NaHSO

4

) content. (Water

solution with 1% dust).

4.4-7

The dust sample may be taken at different locations

using different sampling techniques. It is easy, of

course, to take the samples from below the

electrostatic precipitator or from the flue duct ash

hoppers. The problem with such samples, however,

is a long and poorly defined time of contact with the

combustion gases before sampling. Prolonged

contact with the combustion gases may substantially

lower the dust/ water solution pH-value.

It is to recommend to take the sample from the flue

gas flow directly using a suitable sampling device,

for instance a suction probe.

The pH-value of the dust solution varies greatly

between boilers and processes in the field. In kraft

boilers, the pH typically varies between 7 and 12

(l% water solution).

It is impossible to give any generally applicable

guide value for the pH of the dust. In most cases pH

10 to pH 11 (l% solution) should be optimal. Lower

pH than this indicates that the process is not far from

the point where acidic sulphate begins to appear, i.e.

from the steep part of the pH-curve in Figure 6. The

local conditions in some part of the flue duct may

differ from the average conditions. This makes it

possible that acidic sulphates may be produced

somewhere locally (or at times) even though the pH

of an average sample collected would still be

slightly alkaline.

A very high pH-value (pH >12, l% solution) may

also indicate potential trouble. One reason for high

alkalinity may be a high carry-over of black liquor

droplets which escape the furnace and may be

carried over all the way to the end of the flue duct.

The content of carbonate is high in the carry-over

particles and their high proportion in the dust sample

raises the sample pH value markedly. Another

potential reason for high alkalinity is an unusually

high rate of vaporization of sodium in the furnace,

which results in high dust concentrations in the flue

gas and thereby, possibly, in precipitator problems.

5. FOREIGN COMPONENTS

In addition to the main chemicals, sodium and

sulphur, many other elements participate in the

recovery process. The chief foreign elements are

chlorine and potassium. This section treats briefly

the behaviour of chlorine and potassium in a

recovery boiler. Other minor elements in the process

are calcium, silicon, aluminum, iron, etc. However,

these substances have seldom any significance in the

recovery boiler process itself, and shall not be

discussed any further here.

The chlorine is present in wood, but may also

originate in wood floated in sea water, in make-up

chemicals, or possibly in pulp bleaching process

waters which have been brought into the recovery

cycle. The concentration of chlorine in black liquor

varies greatly from one process to another. The

chlorine content in mills is usually quite low,

typically 0.1 to 0.5 % of the liquor dry solids. In the

mills on the west coast of North America, the

chlorine content of the liquor dry solids has been

found to be as high as to 3 - 5 %, and in closed cycle

(that is bleach plant effluent recovery) processes it

may rise even higher /22,23/.

Potassium enters the process mainly as a natural

mineral component of the wood raw material. The

potassium content in mills is typically 1 to 3 % of

the liquor dry solids content. In more closed

processes, the content of potassium easily rises

substantially higher /22/.

5.1 Chloride Vapours

Chlorine occurs in the lower part of the furnace

almost exclusively as alkali chlorides NaCl and KCl.

The vapour pressure of these is markedly higher

than those of other sodium and potassium

compounds. The chlorine compounds are therefore

enriched into gas phase in the furnace. A factor

describing the enrichment is

(Cl/Na) in gas

(Cl/Na) in smelt

which according to field measurements typically

ranges from 2 to 4 /6,8,22,24/.

The distribution of chlorine between smelt and

furnace gas is strongly dependent on temperature. At

high temperatures, the main part of the chlorine is

vaporized, which is illustrated by Figure 7 based on

the equilibrium calculation. Several indications have

been obtained that the vaporization of chlorine in a

recovery boiler conforms well to the equilibrium

values /2,8/.

100

80

60

40

20

700 900 1100 1300

BED TEMPERATURE, C

C

H

L

O

R

I

N

E

,

%

Flue

Gas

HCl

Dust

(Na,K) Cl

Bed

(Na,K) Cl

Figure 7. Distribution of chlorine between smelt

bed, dust and flue gases. Based on an equilibrium

model by /23/.

The chlorides being vaporized into the gas phase are

condensed as the flue gases cool, thus forming dust.

4.4-8

Even small amounts of chloride in the dust

substantially change the behaviour of the dust in the

flue gas duct. Chloride, particularly in combination

with potassium, lowers the melting temperature

range of dust significantly and makes the dust more

sticky and fouling /16,23/.

5.2 Hydrochloric Acid, HCI

If free sulphur dioxide remains in the boiler flue gas

(see Section 3), the chloride dust resulting from

condensation is partially transformed in the upper

furnace and flue gas duct into sulphate:

2 NaCl +SO

2

+1/2 O

2

+H

2

O Na

2

SO

4

+2 HCl

As a result of this reaction, gaseous hydrogen

chloride is formed. This chlorine contained in the

hydrogen chloride passes the dust removal devices

and exits the process as flue gas emission. Through

this reaction it is, in principle, actually possible to

facilitate the removal of the chlorine from the

recovery cycle /24/. The reaction is discussed more

closely below.

The reaction referred to above requires - as

mentioned - the presence of sulphur dioxide in the

flue gases. The content of sulphur dioxide remaining

free in the flue gases is in the end determined by the

ratio of sulphur and sodium entrained in the

combustion gases (see Section 3). Thus the S/Na

2

ratio in the flue gases turns out to be a significant

parameter also from the viewpoint of the chlorine

chemistry.

Figure 7 may also be used when examining the

practical significance of the hydrochloric acid

reaction. The figure is drawn based on equilibrium

calculations and some additional assumptions /23/.

At low furnace temperatures, the amount of chlorine

released in gaseous form is quite small. On the other

hand, this chlorine released mainly as alkali chloride

later transforms practically completely into

hydrochloric acid, through the sulphation reaction

above. The amount of alkali chloride vaporized at

high temperatures is, of course, large. Moreover,

due to high bed temperatures, the S/Na

2

ratio in the

combustion gases remains low. Thus little or no free

sulphur dioxide is left in the flue gas after the

reactions which take place in the furnace (see

Section 3 and Fig. 5 B). Therefore, the alkali

chloride vapour released in the lower furnace will

not be sulphated but is condensed as such into alkali

chloride dust.

5.3 Potassium

Potassium behaves in a recovery boiler process

much like sodium. Potassium compounds, however,

are more volatile than sodium compounds.

Potassium is, therefore, also enriched in the dust.

Values for the enrichment factor, defined as for

chlorine above, range according to field

measurements from 2 to 4, i.e. much the same as for

chlorine /6,22/.

The chief potassium compounds in the lower

furnace are K and KOH and, if the chlorine content

of the liquor is even a little higher, also KCl.

As was established above, potassium - especially in

combination with chlorine - tends to lower the

melting temperature of the dust and thereby

increases its fouling tendency.

6. CONCLUSIONS

The complicated chemistry of the recovery boiler

has become much clearer in the past few years.

Interesting further research is being done, and more

information is expected to be available, particularly

concerning the release of sulphur and sodium

contained in black liquor.

The most important process in a recovery boiler, the

reduction of sulphur compounds into molten

sulphide, is mainly achieved by means of the char in

the black liquor. To ensure an efficient reduction,

the char content of the smelt bed must be maintained

at a sufficient level.

The sulphur and sodium compounds in the flue

gases are formed as the hydrogen sulphide and the

sodium vapours released in the lower furnace react

with each other. The reactions proceed in different

ways depending on the ratio of sulphur to sodium in

the combustion gases.

The S/Na

2

ratio in the flue gas is high at low

furnace temperatures or high sulphidities of the

black liquor. In cases like this, there will be a

surplus of sulphur dioxide, which may turn the dust

into acidic sulphate, with resulting fouling and

corroding effects.

The S/Na

2

ratio in the furnace gases is low at high

furnace temperatures or low sulphidities of the black

liquor. Under these conditions the sodium

compounds of the combustion gases bind virtually

all the sulphur dioxide. Then, acidic sulphates will

not be formed, and the sulphur dioxide emission

with the flue gas will be completely eliminated.

The pH-value of dust is a sensitive indicator for the

sulphur/sodium chemistry of the flue gases. The dust

samples should be taken fresh, directly from the flue

gas before the electrostatic precipitators. High pH

(>10) indicates that the S/Na

2

ratio in the flue gases

is less than unity. Low pH (<7), again, indicates that

this ratio is high, with an increased tendency for

formation of acidic sulphates.

4.4-9

Foreign elements potassium and chlorine are

enriched into gaseous form in the lower furnace,

mainly as alkali chlorides. If the S/Na

2

ratio of the

combustion gases is sufficiently high, the alkali

chlorides transform at a later stage into hydrochloric

acid and alkaline sulphate.

The presence of potassium and chlorine in the dust -

especially in combination - lowers the dust melting

temperature range, which results in increased

sticking and fouling tendencies.

ACKNOWLEDGEMENT

The author is particularly grateful for the many

valuable and inspiring discussions with Professor

J ames W. Frederick, Dr. Rainer Backman and Mr.

Paavo Hyty. The author also wants to thank

Professor Douglas Reeve for his many useful

suggestions. Financial support from Finland's

Combustion Research Program LIEKKI and from

Tampella Power Ltd is also acknowledged.

REFERENCES

1. Forssn, M., M. Eng. Thesis, bo Akademi

University, Department of Chemical Engineering,

Turku, Finland 1991.

2. Pejryd, L., Hupa, M., "Bed and furnace gas

composition in recovery boilers - Advanced

equilibrium calculations," 1984 TAPPI Pulping

Conf., San Fransisco, CA, (November 1984).

3. Cameron, J .H., and Grace, T.M., Tappi, 65(7):

84-87 (1982).

4. Cameron, J . H., and Grace, T.M., Ind. Eng. Chem.

Fundamentals, 22(4): 486-94 (1983).

5. Grace, T.M., Cameron, J .H., and Clay, D.T.,

"Role of the Sulfate/Sulfide Cycle in Char Burning -

Experimental Results and Implications," Proc.

TAPPI Kraft Recovery Operations Seminar, p. 157-

165 (1988).

6. Adams, T.N., Frederick, W.J ., Kraft recovery

boiler physical and chemical processes, American

Paper Institute, New York, NY, 1988.

7. Cameron, J .H., Clay, D.T., and Grace, T.M.,

"Oxidative fuming - the phenomenon and possible

interpretations," TAPPI/CPPA 1985 Int'l. Chemical

Recovery Conference., pp. 435-444, New Orleans,

LA, April 1985.

8. Cameron, J .H., JPPS 14(4): J 76 (1988).

9. Frederick, J ., Hupa, M., Evidence of sodium

fuming during pyrolysis of black liquor, Tappi, in

print 1991.

10. Hupa, M., Backman, R., and Hyty, P.,

"Investigation of fireside deposition and corrosion in

sulphate and sodium sulphite recovery boilers,"

Presented at the Black Liquor Recovery Boiler

Symposium 1982, Helsinki, Aug. 31- Sept. 1,1982.

11. Backman, R., Hupa, M., and Uppstu, E., Tappi,

70 (60): 123-127 (1987).

12. Frederick, W.J ., Noopila, T., Hupa, M., Swelling

of pulping liquor droplets during combustion, JPPS,

in print 1991.

13. Reeve, D.W., Tran, H.N., and Barham, D.,

Tappi, 64(5): 109-113 (1981).

14. Tran, H.N., Reeve, D.W., and Barham, D., Pulp

& Paper Canada, 84(1): T7 (1983).

15. Isaak, H.N., Barham, D., and Reeve, D.W., Pulp

and Paper Sci., 12(3): J 84 (1986).

16. Tran, H.N., Tappi, 69 (11): 102 (1986)

17. Hupa, M., Paperi ja Puu, No. 9, p. 517-521

(1980).

18. Backman, R., Hupa, M., and Uusikartano, T.,

"Kinetics of sulphation of sodium carbonate in flue

gases," Proc. 1985 lnt'l. Recovery Conf., New

Orleans, p. 445-450, April, 1985.

19. Backman, R., Hupa, M., and Hyty, P., Tappi,

67 (12): 60-64 (1984).

20. Hyty, P., Hupa, M., Skrifvars, B-J ., Krki, R.,

Latest experiences of high solids firing,

TAPPI/CPPA 1989 Intnl. Chemical Recovery

Conference., Proceedings p. 169-175 (1989).

21. Bjorklund, H., Warnquist, B., Pettersson, B.,

Inside a kraft recovery boiler - Combustion of

(highsulphidity) black liquor at high dry solids

content, TAPPI/CPPA 1989 Intnl. Chemical

Recovery Conference., Proceedings p. 177-182

(1989).

22. Tran, H., Barham, D., Reeve, D., Chloride and

potassium in the kraft chemical recovery cycle,

TAPPI/CPPA 1989 Intnl. Chemical Recovery

Conference., Proceedings p. 23-28 (1989).

23. Hupa, M., Backman, R., Skrifvars, B-J ., Hyty,

P., Tappi, 73(6): 185-189 (1990).

24. Warnquist, B., and Norrstrom, H., Tappi,

59(11): 89-91 (1976).

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- IEEE STD 835-1994Document66 pagesIEEE STD 835-1994Eduardo Quintana83% (6)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AMOS Bs 8.6 Manual Rev2Document573 pagesAMOS Bs 8.6 Manual Rev2pwmvsi100% (3)

- Astm C361M-14Document26 pagesAstm C361M-14diego rodriguez100% (1)

- Nema Abcde Torque Curves PDFDocument2 pagesNema Abcde Torque Curves PDFvtadlimbekarNo ratings yet

- Sheet 1 Rev 01Document1 pageSheet 1 Rev 01pwmvsiNo ratings yet

- TY341485 - Tote Replacement Gerators - Tender - Rev 01 PDFDocument10 pagesTY341485 - Tote Replacement Gerators - Tender - Rev 01 PDFpwmvsiNo ratings yet

- SD45 3107 Bill of MaterialsDocument2 pagesSD45 3107 Bill of MaterialspwmvsiNo ratings yet

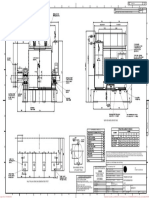

- This Drawing Is For Tender Purposes Only. Dimensions and Data Are Subject To ConfirmationDocument1 pageThis Drawing Is For Tender Purposes Only. Dimensions and Data Are Subject To ConfirmationpwmvsiNo ratings yet

- Synchronous GeneratorsDocument50 pagesSynchronous GeneratorsRajAnandNo ratings yet

- Southern Railway Historical Association Presents - Bob Harpe S Athearn GP-38-2 Modifications Online ClinicDocument26 pagesSouthern Railway Historical Association Presents - Bob Harpe S Athearn GP-38-2 Modifications Online ClinicpwmvsiNo ratings yet

- Bob Harpes Sd45 Project Complete StepsDocument16 pagesBob Harpes Sd45 Project Complete StepspwmvsiNo ratings yet

- Simulation and Speed Control of Induction MotorDocument76 pagesSimulation and Speed Control of Induction MotorNWALLL67% (3)

- This Drawing Is For Tender Purposes Only. Dimensions and Data Are Subject To ConfirmationDocument1 pageThis Drawing Is For Tender Purposes Only. Dimensions and Data Are Subject To ConfirmationpwmvsiNo ratings yet

- Sheet 1 Rev 01Document1 pageSheet 1 Rev 01pwmvsiNo ratings yet

- Estimating Sequence Voltages From DataDocument12 pagesEstimating Sequence Voltages From DatapwmvsiNo ratings yet

- Rotor Particulars D275R14 Generator: Drawn Rev Ecn/Description Approved 00 KMC Original Issue CLDocument1 pageRotor Particulars D275R14 Generator: Drawn Rev Ecn/Description Approved 00 KMC Original Issue CLpwmvsiNo ratings yet

- 3000 Grounding EN PDFDocument32 pages3000 Grounding EN PDFpwmvsiNo ratings yet

- Medium Voltage Transformers: Specification GuideDocument39 pagesMedium Voltage Transformers: Specification GuideRaaj Eng100% (1)

- Isometer®: Iso685-D iso685W-D Iso685-S iso685W-SDocument62 pagesIsometer®: Iso685-D iso685W-D Iso685-S iso685W-SpwmvsiNo ratings yet

- Coast Guard Updates Natural Gas Fuel System Design CriteriaDocument14 pagesCoast Guard Updates Natural Gas Fuel System Design CriteriapwmvsiNo ratings yet

- Isometer®: Iso685-D iso685W-D Iso685-S iso685W-SDocument62 pagesIsometer®: Iso685-D iso685W-D Iso685-S iso685W-SpwmvsiNo ratings yet

- 3000 Grounding EN PDFDocument32 pages3000 Grounding EN PDFpwmvsiNo ratings yet

- PACSystems RX3i Ethernet Network Interface Unit User's Manual, GFK-2439DGFK2439DDocument357 pagesPACSystems RX3i Ethernet Network Interface Unit User's Manual, GFK-2439DGFK2439DpwmvsiNo ratings yet

- Oem Reference Guide PDFDocument129 pagesOem Reference Guide PDFpwmvsiNo ratings yet

- K-Factor and TransformersDocument6 pagesK-Factor and TransformersasssasasNo ratings yet

- Oem Reference Guide PDFDocument129 pagesOem Reference Guide PDFpwmvsiNo ratings yet

- National Standard Petroleum Oil Tables ReducedDocument185 pagesNational Standard Petroleum Oil Tables ReducedJuan Sebastian DiazNo ratings yet

- GFK-2224U PACS Ethernet Manual PDFDocument311 pagesGFK-2224U PACS Ethernet Manual PDFpwmvsiNo ratings yet

- MV Design Guide - Circuit Breaker SpecificationDocument10 pagesMV Design Guide - Circuit Breaker Specificationhadi saadNo ratings yet

- Addendum 3 LT NI Rev1 PDFDocument26 pagesAddendum 3 LT NI Rev1 PDFpwmvsiNo ratings yet

- Addendum 3 LT NI Rev1 PDFDocument26 pagesAddendum 3 LT NI Rev1 PDFpwmvsiNo ratings yet

- Propylene - Carbonate Data SheetDocument2 pagesPropylene - Carbonate Data SheetcNo ratings yet

- Petroleum Equipment Assembly & Metal Structure JSC: N/A N/ADocument2 pagesPetroleum Equipment Assembly & Metal Structure JSC: N/A N/AKhôi ĐàoNo ratings yet

- JH Sir Ionic DPP 3Document4 pagesJH Sir Ionic DPP 3Tavishi SinghNo ratings yet

- Neutrophiles and ElectrophilesDocument2 pagesNeutrophiles and Electrophileswhydaspam joeNo ratings yet

- Aramco US Vendors For P F FDocument1 pageAramco US Vendors For P F Fhemantmech099200No ratings yet

- Materials: Current Status and Future Prospects of Copper Oxide Heterojunction Solar CellsDocument21 pagesMaterials: Current Status and Future Prospects of Copper Oxide Heterojunction Solar CellsMurat YilmazNo ratings yet

- Steel I-Beam Calculation Design CheckDocument9 pagesSteel I-Beam Calculation Design CheckSuresh DevarajanNo ratings yet

- Mechanics of Materials Beer 7th Edition Solutions ManualDocument5 pagesMechanics of Materials Beer 7th Edition Solutions Manualjosephpetersonjaczgqxdsw100% (45)

- Arandelas Hill Side A325Document1 pageArandelas Hill Side A325Oscar SanabriaNo ratings yet

- ASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedDocument1 pageASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedAmanda Ariesta ApriliaNo ratings yet

- 651 PDFDocument12 pages651 PDFjitendraNo ratings yet

- Alcohols: Properties, Naming and ReactionsDocument15 pagesAlcohols: Properties, Naming and ReactionsPedro Moreno de SouzaNo ratings yet

- Tut 9 - PH 102 - 30052023Document1 pageTut 9 - PH 102 - 30052023PS SuryaNo ratings yet

- Mechanical Design of Overhead LinesDocument26 pagesMechanical Design of Overhead LinesAsheque Iqbal100% (1)

- Mechanical SealDocument64 pagesMechanical SealKhoh Kai ShengNo ratings yet

- Brick Industry Project - Production and Operation ManagementDocument16 pagesBrick Industry Project - Production and Operation ManagementSundar Pro RiderNo ratings yet

- Reaction Mechanisms 1 MSDocument9 pagesReaction Mechanisms 1 MSBeatrice MoyoNo ratings yet

- Brosur Globond Alumunium Composite PanelDocument8 pagesBrosur Globond Alumunium Composite PanelDede SubhanNo ratings yet

- Steel Member Design - Sample Calculation (AS4100)Document5 pagesSteel Member Design - Sample Calculation (AS4100)Tiam MarapeNo ratings yet

- EngineeringDocument208 pagesEngineeringvins4u100% (1)

- Corrosion of Cast Aluminum Alloys in Engine Coolants Under Heat-Rejecting ConditionsDocument4 pagesCorrosion of Cast Aluminum Alloys in Engine Coolants Under Heat-Rejecting ConditionsInsumos GygNo ratings yet

- Bundel Soal Kimia TPBDocument210 pagesBundel Soal Kimia TPBElen Mustika100% (1)

- Pds Tial m80Document2 pagesPds Tial m80Yan FerizalNo ratings yet

- Rheological Properties of Some Oil Based Muds Used in Reservoirs in The Niger Delta, NigeriaDocument6 pagesRheological Properties of Some Oil Based Muds Used in Reservoirs in The Niger Delta, NigeriaNurfatini CheNo ratings yet

- Department of Materials Science and Engineering (MSE)Document11 pagesDepartment of Materials Science and Engineering (MSE)shouvikNo ratings yet

- Design and Manufacturing of Water Chiller For Proc PDFDocument17 pagesDesign and Manufacturing of Water Chiller For Proc PDFzoom_999No ratings yet

- Astm A560 A560m - 12Document3 pagesAstm A560 A560m - 12Leandro Dilkin ConsulNo ratings yet

- NONWOVEN - Vinay Kumar MidhaDocument11 pagesNONWOVEN - Vinay Kumar Midhaglobal-marketin8184No ratings yet

- Aci 318-14 RC-BM-001Document7 pagesAci 318-14 RC-BM-001Bunkun15No ratings yet