Professional Documents

Culture Documents

Dfde Engine

Uploaded by

ARGONAFTISOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dfde Engine

Uploaded by

ARGONAFTISCopyright:

Available Formats

Description of DM:

Keyless propeller mounting procedure

All rights reserved. Nothing from this publication may be reproduced, or disclosed without prior written approval of Wartsila-CME Zhenjiang Propeller Co., Ltd

System code

Info code

System variant

Issue Date

Page

Doc. no.

Rev.

110

720

FPP with keyless fit

2006-03-13

1/4

DMYI000025

00

1.1

Keyless propeller mounting procedure

-For installation sufficient space is needed. -Hoisting facilities must be arranged.

1.1.1 Documents

-Instruction General warnings and cautions. -Drawing Propeller boss. -Drawing Assembly hydraulic nut / ring (if WCZP supply). -Instructions for hydraulic nut / ring (if not WCZP supply). -Propeller pushup diagram. -Procedure Propeller cone fit procedure. -Instruction Tools and equipment for (de-) mounting of propeller.

1.1.2 Preparations

Pay attention to instruction General warnings and cautions. Tools provided with the propeller (see scope of supply for exact WCZP delivery). Lifting eyebolt for propeller. Pressure gauges and high-pressure pumps. Hydraulic hand pump with high-pressure hose.

� Check propeller fit on the shaft cone. Make sure that the fit is according to the classifications requirements. See the procedure Propeller cone fit procedure. � All parts that are fitted for temporary protection, such as covers, caps and plates, have to be left in place as long as possible and are only to be removed for immediate connection to opposite parts. � All pipe ends, O-rings and O-ring grooves are to be inspected for damage before mounting. � All temporarily unprotected parts are to be kept extremely clean. � It is advised to start propeller mounting early in the morning in order to avoid temperature differences between propeller and shaft.

File name:DMYI000025

Description of DM:

Keyless propeller mounting procedure

All rights reserved. Nothing from this publication may be reproduced, or disclosed without prior written approval of Wartsila-CME Zhenjiang Propeller Co., Ltd

System code

Info code

System variant

Issue Date

Page

Doc. no.

Rev.

110

720

FPP with keyless fit

2006-03-13

2/4

DMYI000025

00

1.1.3

Lift and pull the propeller on the shaft cone

Pay attention to instruction General warnings and instructions. 1. 2. 3. 4. 5. 6. 7. 8. 9. Do not unpack propeller hub. Position the propeller at the tapered side of the propeller shaft. Check the port and starboard position if twin propellers, see installation drawings Unpack and clean the propeller shaft cone, check the cone for burrs and damages, repair when necessary, clean and lightly oil the shaft cone. Unpack and clean the propeller bore, check the bore for burrs and damages, repair when necessary, clean and lightly oil the propeller bore. Lift with care the propeller to the proper position in front of the propeller shaft cone. Lifting can be done with slings. Carefully pull the propeller on the propeller shaft cone. Move the propeller on to the shaft until no further movement up the taper is possible. Install the hydraulic nut / ring. The hydraulic nut / ring should have the piston in the fully closed position. Screw the nut / ring to the end of the propeller boss. Remove all plugs of the oil inlet connections in the hub.

10. Provide for all other necessary tools. See instruction Tools and equipment for (de-) mounting of propeller. 1.1.4 Determination of the starting point and of the propeller drive up. For an accurate first determination of the starting point the mounting procedure shall be carried out at least twice. The starting position when compared between first and second push-up may differ more than 5% of the total required axial drive-up because of the possible bedding action of the fitting process. Temperature stabilization Time should be allowed to stabilize the temperatures of the propeller and shaft before commencing any push-up procedure. Record the prevailing ambient temperature. � It is essential to commence the push-up process from the correct axial starting point on the shaft. This is achieved by applying an initial start point load with the hydraulic nut / ring without oil injection into the propeller boss. The start point load is given on the drawing Propeller boss. The start point load is stamped on the propeller hub as well. � To convert pressure as measured by the pressure gauge on the hydraulic hand pump to a load applied by the hydraulic nut / ring, see the drawing Assembly hydraulic nut / ring or to the hydraulic nut / ring suppliers manual. � The appropriate push-up distance has to be determined from the push-up diagram on the drawing Propeller boss. When the ambient temperature is measured the belonging push-up distance can be read out or calculated. � Only the axial drive-up distance will give the right position of the propeller. The theoretical mounting force as given in drawing Propeller boss is only for guidance to get an indication of the required

File name:DMYI000025

Description of DM:

Keyless propeller mounting procedure

All rights reserved. Nothing from this publication may be reproduced, or disclosed without prior written approval of Wartsila-CME Zhenjiang Propeller Co., Ltd

System code

Info code

System variant

Issue Date

Page

Doc. no.

Rev.

110

720

FPP with keyless fit

2006-03-13

3/4

DMYI000025

00

pressure in the nut / ring. � The movement of the piston of the hydraulic nut / ring shall not exceed the maximum value as given on the drawing Assembly hydraulic nut / ring. 1.1.5 Pushup the propeller on the shaft cone WARNINGS MAKE SURE THAT HIGH PRESSURISED OIL CANNOT LEAK. PLACE PROTECTIVE GUARDS IN POSITION. ALWAYS WEAR PROTECTIVE GLASSES AND CLOTHES WHEN YOU WORK ON EQUIPMENT. OIL PIPES OR HOSES OF INSUFFICIENT STRENGTH CAN BURST UNDER PRESSURE. SEVERE INJURY CAN RESULT. DO NOT DISCONNECT HYDRAULIC PIPES OR HOSES WHEN PUMPS ARE OPERATING. MAKE SURE THAT ALL PROTECTIVE GUARDS AND COVERS ARE CORRECTLY INSTALLED. MAKE SURE THAT THE PROPELLER CONE AND SHAFT CONE PRESSURE IS TOTALLY RELEASED BEFORE RELEASING THE NUT PRESSURE. DANGER COULD RESULT IF THE PROCEDURES ARE NOT FOLLOWED. WARTSIAL-CME ZHENJIANG PROPELLER CO.,LTD DOES NOT ACCEPT ANY CLAIM WITH RESPECT TO DAMAGE DONE AS WELL AS TO OPERATIONAL HAZARDS.

THE INFORMATION GIVEN IN THIS CHAPTER IS FOR GUIDANCE ONLY. THE RESPONSIBILITY FOR FITTING REMAINS IN THE HANDS OF THE SHIPYARD AND TO THE SATISFACTION OF THE OWNERS AND THE CLASSIFICATION SOCIETIES, UNLESS AGREED OTHERWISE. 1. 2. 3. Bleed all air from the hydraulic nut / ring. Slowly inject oil into the hydraulic nut / ring to meet the predetermined start point load pressure. No oil injection in the boss is required. If the propeller moves up the taper without any significant pressure recorded on the hydraulic nut / ring, this indicates a lack of full mechanical contact between bore and shaft. The tightening of the propeller shaft nut might be insufficient. Tighten the nut and repeat from point 1. When the start point load is reached, set the dial gauge to zero. Inject oil into the boss, with the center vent plug removed, until all air is bled from the center vent hole, then plug center vent hole. Continue pumping until oil bleeds at the forward end of the propeller boss. Record the hydraulic nut / ring pressure and all boss injector pump pressures during the axial movement of the propeller at steps of 1 mm. The pressure difference between the two boss injectors should not exceed 10%, as the pressures become higher. Increase pressure in the hydraulic nut / ring and the boss injectors in the same ratio. Operate all pumps i.e. boss injector pumps and hydraulic nut / ring pump.

3

4. 5.

6.

File name:DMYI000025

Description of DM:

Keyless propeller mounting procedure

All rights reserved. Nothing from this publication may be reproduced, or disclosed without prior written approval of Wartsila-CME Zhenjiang Propeller Co., Ltd

System code

Info code

System variant

Issue Date

Page

Doc. no.

Rev.

110

720

FPP with keyless fit

2006-03-13

4/4

DMYI000025

00

7.

When the maximum piston movement is reached release boss injector pressures while maintaining the hydraulic nut / ring pressure, allowing the boss to settle and oil to drain off for a period of not less than 30 minutes. Record the dial gauge reading. Release pressure from the hydraulic nut / ring. Screw on the hydraulic nut / ring till the piston is again in fully closed position. Repeat the procedure as described in 5 and 6. Add new dial gauge readings to the already recorded readings.

8. 9.

10. When the required axial driveup is achieved, release boss injector pressures while maintaining the hydraulic nut / ring pressure, allowing the boss to settle and oil to drain off for a period of not less than 30 minutes. Record the dial gauge reading. 11. Release the pressure in the hydraulic nut / ring by slowly opening the pump return valve. Record the dial gauge reading. At first drive up 12. Remove the propeller; see instruction Keyless propeller demounting procedure. 13. Fit the propeller by repeating all steps 1 to 11. 14. In case a hydraulic nut is applied, tighten the nut on to the boss. In case of a hydraulic ring is applied, unscrew the propeller nut. Remove the hydraulic ring and screw on the propeller nut again. 15. Tighten the nut with a wire rope around the nut groove to about 1 ton tension. 16. Fit all plugs in the oil inlet connections. Secure by punch mark. 17. Remove the hoisting facilities from the propeller. 18. If applicable, remove the lifting eyebolt and fit the plug. Secure by punch mark. 19. Clean and store all tools and auxiliary equipment. 20. Continue with mounting the propeller cap, connection of the aft seal liner and installation of the rope guard.

File name:DMYI000025

Description of DM:

Propeller cone fit procedure

All rights reserved. Nothing from this publication may be reproduced, or disclosed without prior written approval of Wrtsil Propulsion Netherlands B.V

System code

Info code

System variant

Issue Date

Page

Doc. no.

Rev.

110

271

FPP propeller

2001-10-16

1/2

DMYI000060

04

1.1

Propeller cone fit procedure

For installation sufficient space is needed. Hoisting facilities must be arranged.

1.1.1

Documents

Instruction General warnings and cautions. Drawing Propeller boss.

1.1.2

Required conditions

The shaft hole in the propeller boss is either pre-machined to a scraping tolerance or is finish machined. When the shaft hole is finish machined by WPNL, a blue fit test on the propeller shaft hole has been carried out. A classification surveyor has witnessed the result of this test. In most cases the yard has to perform the blue fit test for a local classification surveyor, even when WPNL already obtained approval of the fit. The contract indicates whether the propeller cone is delivered pre- or finish machined.

1.1.3

Preparations

Pay attention to instruction General warnings and cautions. Prepare required tools and blue fit paste. Sufficient space. Cleaning material.

1.1.4

Procedure; Fitting of propeller by means of scraping

The shaft hole in the boss is pre-machined to a specified scraping tolerance on the inner diameter. For an accurate fit between propeller and shaft cone an additional scraping shall be carried out. The result of scraping has to be checked by means a blue fit test. In order to reduce the possibility of a premature oil leak it is important to avoid linear grooves to the extreme forward and aft ends of the propeller bore. See drawing Propeller boss. The effect of the scraping shall be regularly checked, by means of a template, cone or shaft fit.

1.1.5

Blue fit test

A classification representative shall witness and approve the results of the blue fit test. The propeller is not pushed up the shaft cone. For the purpose of contact area determination only the shaft shall be put into the propeller shaft hole. When the blue fit test is carried out in a machine shop, it is advised to position the propeller (exactly) horizontal on the floor. The shaft is lifted in vertical position above the propeller shaft hole. 1. 2. Clean the shaft or gauge and the propeller cone hole with solvent cleaner. Apply a thin layer of blue fit paste on the shaft or gauge cone.

File name:DMYI000060_05, Last printed 17-03-03 9:37

Document title

Propeller cone fit procedure

Doc. no. DMYI000060 Rev. 04 Page

2/2

3.

Gently insert the shaft or gauge cone into the propeller. Do not force the shaft or gauge. Only the own shaft or gauge weight is applied during the fit test. If the propeller has to be fitted in horizontal position (for instance behind the ship), the propeller must be pushed onto the shaft using the hydraulic nut. Use in this case the start point load as an alternative for the shaft weight that is used in case of vertical fitting. Protect the propeller blades to prevent damaging. When the cone is completely in the shaft hole, hit one of the propeller blades with a soft hammer. These vibrations will lead to a reliable marking. Check the markings at the propeller cone hole. The fit is acceptable when markings are obtained over a 50 mm band at the extreme forward and aft ends of the propeller cone and on at least 70% of the total cone surface. In case the fit is not acceptable, scrape the propeller cone surface where required. Continue with point 1 and repeat this procedure until satisfactory result. Check the linear grooves to the extreme forward and aft ends of the propeller bore. After approval, clean all cone surfaces and protect all cones against any dirt and damage.

4.

5.

6. 7. 8. 9.

17-03-03 DMYI000060_05

Tools and equipment for (de-) mounting of propeller

All rights reserved. Nothing from this publication may be reproduced, or disclosed without prior written approval of WARTSILA CME Zhenjiang Propeller Co. Ltd

System variant

Issue Date

Page

Doc. No.

Rev.

FPP

2006-08-04

1/2

DMYI000061

00

1.1 Tools and equipment for (de-) mounting of propeller

Mount the hydraulic ring or nut (8) on the shaft. The hydraulic ring / nut should have the piston in the fully closed position. Screw the hydraulic ring / nut (8) against the aft end of the propeller. Connect the hydraulic hand pump (9) with the high-pressure hose to the hydraulic ring or nut (8). Connect the hydraulic hand pump (1) with the high-pressure hose to the propeller boss. Fit the connection between the hoses (3) and propeller boss. Connect to the aft most and forward connection of the hub. The middle injection hole on the hub is for air venting. Secure a thermometer (yard supply) to the propeller boss with putty (A good surface contact is required) Install a micrometer gauge (7) (yard supply) with sufficient stroke on the hydraulic ring / nut pointing at the fwd face of hub. The micrometer is used to measure the push-up distance.

Tools and equipment for (de-) mounting of propeller

All rights reserved. Nothing from this publication may be reproduced, or disclosed without prior written approval of WARTSILA CME Zhenjiang Propeller Co. Ltd

System variant

Issue Date

Page

Doc. No.

Rev.

FPP

2006-08-04

2/2

DMYI000061

00

Item no. 1 2 3 4 5 6 7 8 9

Name Hydraulic hand pump Pressure gauge Flexible hose Quick connection nipple Quick connection coupling Seals Micrometer gauge Hydraulic nut Hydraulic hand pump

Quantity 1 2 3 7 7 7 1 1 1

Notes:

- Item numbers not listed have not been used in this install. - The quantities shown on the parts list are believed to be correct; the quantities shown on the drawing are for illustration only. END OF LIST

Description of DM:

Keyless propeller demounting procedure

All rights reserved. Nothing from this publication may be reproduced, or disclosed without prior written approval of Wartsila-CME Zhenjiang Propeller Co., Ltd

System code

Info code

System variant

Issue Date

Page

Doc. no.

Rev.

110

520

Keyless propellers

2006-03-13

1/3

DMYI000062

00

1.1

Keyless propeller demounting procedure

-For demounting sufficient space is needed. -Hoisting facilities must be arranged.

1.1.1

Documents

-Instruction General warnings and cautions. -Drawing Propeller boss. -Drawing Assembly of hydraulic nut / ring (if WCZP supply). -Instructions for hydraulic nut / ring / (if not WCZP supply). -Propeller pushup diagram (located on drawing Propeller boss). -Instruction Tools and equipment for (de-) mounting of propeller.

1.1.2

Preparations

Pay attention to instruction General warnings and cautions. Tools provided with the propeller (see scope of supply for exact WCZP delivery) Lifting eyebolt for propeller. Pressure gauges and high-pressure pumps. Hydraulic hand pump with high-pressure hose.

All parts that are fitted for temporary protection, such as covers, caps and plates, have to be left in place as long as possible and are only to be removed for immediate connection to opposite parts. All temporarily unprotected parts are to be kept extremely clean.

1.1.3

Preparations to loosen the propeller from the shaft cone

1. Secure the propeller shaft against accidental rotation and axial movement. 2. Remove the plug and fit the lifting eyebolt (if applicable). 3. Connect the hoisting facilities to the propeller. 4. Remove the rope-guard and dis-connect the aft seal liner from the propeller.

File name:DMYI000062.doc

Description of DM:

Keyless propeller demounting procedure

All rights reserved. Nothing from this publication may be reproduced, or disclosed without prior written approval of Wartsila-CME Zhenjiang Propeller Co., Ltd

System code

Info code

System variant

Issue Date

Page

Doc. no.

Rev.

110

520

Keyless propellers

2006-03-13

2/3

DMYI000062

00

5. Clean the propeller boss, cap and shaft. 6. Remove the propeller cap. 7. Unscrew the nut by a distance equal to the axial drive-up plus 3 mm minimum, but not more than the maximum distance as given on the drawing Assembly hydraulic nut or in the instruction manual of the hydraulic nut / ring. 8. Loosen and remove all plugs from the oil inlet connections. 9. Provide for all other necessary tools. See instruction Tools and equipment for (de-) mounting of propeller. 10.Bleed all air from the hydraulic nut / ring. 11.Pump the piston of the hydraulic nut / ring forward just enough to regain contact with the aft face of the propeller boss.

1.1.4

Loosen and demount the propeller from the shaft cone

WARNINGS MAKE SURE THAT HIGH PRESSURISED OIL CANNOT LEAK. PLACE PROTECTIVE GUARDS IN POSITION. ALWAYS WEAR PROTECTIVE GLASSES AND CLOTHES WHEN YOU WORK ON EQUIPMENT. OIL PIPES OR HOSES OF INSUFFICIENT STRENGTH CAN BURST UNDER PRESSURE. SEVERE INJURY CAN RESULT. DO NOT DISCONNECT HYDRAULIC PIPES OR HOSES WHEN PUMPS ARE OPERATING. MAKE SURE THAT ALL PROTECTIVE GUARDS AND COVERS ARE CORRECTLY INSTALLED. MAKE SURE THAT THE PROPELLER CONE AND SHAFT CONE PRESSURE IS TOTALLY RELEASED BEFORE RELEASING THE NUT PRESSURE. DANGER COULD RESULT IF THE PROCEDURES ARE NOT FOLLOWED. WRTSIL PROPULSION NETHERLANDS BV DOES NOT ACCEPT ANY CLAIM WITH RESPECT TO DAMAGE DONE AS WELL AS TO OPERATIONAL HAZARDS.

THE INFORMATION GIVEN IN THIS CHAPTER IS FOR GUIDANCE ONLY. THE RESPONSIBILITY FOR FITTING REMAINS IN THE HANDS OF THE SHIPYARD AND TO THE SATISFACTION OF THE OWNERS AND THE CLASSIFICATION SOCIETIES.

� The protrusion of the piston of the hydraulic nut / ring shall not exceed the maximum value as given

on the drawing Assembly hydraulic nut / ring or see the supplier's manual. 1. Inject oil into the propeller boss by means of the oil injectors. The grip stress given on the drawing Propeller boss gives an indication of the required pressure level to be injected into the boss before the propeller start to loosen. The grip stress for the ambient temperature (in N/mm2, times 10 for bar) increased with an additional 15 % will be sufficient in most cases.

File name:DMYI000062.doc

Description of DM:

Keyless propeller demounting procedure

All rights reserved. Nothing from this publication may be reproduced, or disclosed without prior written approval of Wartsila-CME Zhenjiang Propeller Co., Ltd

System code

Info code

System variant

Issue Date

Page

Doc. no.

Rev.

110

520

Keyless propellers

2006-03-13

3/3

DMYI000062

00

2. The propeller should soon start to move down the taper against the cushioning effect of the oil in the hydraulic nut / ring. After the propeller has moved the pump valve can be opened allowing oil to be ejected from the hydraulic nut / ring. The propeller should now move rapidly afterwards. It is important to keep pressure on the boss injectors during loosening of the propeller. Note If the propeller fails to move immediately, maintain the pressure at the maximum until it does move. 3. When the piston of the hydraulic nut / ring is fully closed and the propeller is not yet in its free position, release boss injector pressures while maintaining the hydraulic nut / ring pressure. Allow the propeller boss to settle and oil to drain off for a period of not less than 30 minutes. After that repeat steps 1 and 2. 4. Disconnect all hoses. 5. Put all plugs of the oil inlet connections into place. 6. Carefully pulloff the propeller from the shaft cone. 7. Put the propeller carefully in a safe position. 8. Clean the propeller bore, check the bore for burrs and damages, repair when necessary, clean and lightly oil the propeller bore. Pack the propeller hub. 9. Clean the propeller shaft cone, check the cone for burrs and damages, repair when necessary, clean and lightly oil the shaft cone. Pack the shaft cone. 10.Clean and store all tools and auxiliary equipment.

File name:DMYI000062.doc

Document title:

General warnings & cautions

All rights reserved. Nothing from this publication may be reproduced, or disclosed without prior written approval of Wrtsil Propulsion Netherlands B.V.

System code

Info code

System variant

Issue Date

Page

Doc. no.

Rev.

S110

F012

Fpp propeller with shaft line

2002-07-03

1/2

DMYI000063

01

1.1

WARNINGS

ALWAYS BE CAREFULL WHEN WORKING AROUND ROTATING COMPONENTS. CHECK THE EQUIPMENT FREQUENTLY TO PREVENT POSSIBLE DANGEROUS CONDITIONS. FOLLOW THE DIRECTIONS IN THE MANUAL. USE APPROVED HOISTING POINTS AND CERTIFIED LIFTING EQUIPMENTOF ADEQUATE CAPACITY. MAKE SURE THAT EQUIPMENT CAN NEITHER TILT NOR MOVE DURING LIFTING. MAKE SURE THERE IS SUFFICIENT SPACE AND THAT WORKERS ARE IN SAFE POSITIONS. MAKE SURE THAT YOU SHUT OFF THE PRIME MOVERS AND ALL PUMPS, DISCONNECT THE ELECTRIC POWER SUPPLY AND CLOSE ALL RELEVANT VALVES, WHEN YOU WORK ON EQUIPMENT MAKE SURE THAT THE PRIME MOVER CANNOT BE ACCIDENTALLY STARTED. PUT WARNING SIGNS IN POSITION. MAKE SURE THAT NO ONE IS WORKING ON THE EQUIPMENT BEFORE STARTING THE PRIME MOVER. DO NOT, UNDER ANY CIRCUMSTANCES, START THE PRIME MOVER OR OPERATE EQUIPMENT WHEN A WARNING SIGN IS ATTACHED. MAKE SURE THAT HIGH PRESSURISED OIL CAN NOT LEAK. PLACE PROTECTIVE GUARDS IN POSITION. ALWAYS WEAR PROTECTIVE GLASSES AND CLOTHES WHEN YOU WORK ON EQUIPMENT. OIL PIPES OR HOSES OF INSUFFICIENT STRENGTH CAN BURST UNDER PRESSURE. SEVERE INJURY CAN RESULT. DO NOT DISCONNECT HYDRAULIC PIPES OR HOSES WHEN PUMPS ARE OPERATING. MAKE SURE THAT ALL PROTECTIVE GUARDS AND COVERS ARE CORRECTLY INSTALLED. MAKE SURE THAT SHAFT ROTATION IS NOT POSSIBLE. MAKE SURE THAT ACCIDENTAL AXIAL MOTION OF SHAFTS IS NOT POSSIBLE. DO NOT MIX METRIC FASTENERS WITH OTHER (STANDARD) FASTENERS. MISMATCHED OR INCORRECT FASTENERS WILL CAUSE DAMAGE TO OR MALFUNCTION OF EQUIPMENT OR CAN RESULT IN INJURY.

File name:DMYI000063_01, Last printed 10-03-03 15:35

Document title:

General warnings & cautions

Doc. no. DMYI000063 Rev. 01 Page

2/2

MAKE SURE THAT THE PROPELLER CONE AND SHAFT CONE PRESSURE IS TOTALLY RELEASED BEFORE RELEASING THE NUT PRESSURE. MAKE SURE THAT NO PERSONNEL IS STANDING CLOSE TO ANY PART OF THE PROPELLER DURING WITHDRAWING.

1.2

CAUTIONS

ALWAYS ATTACH LIFTING EQUIPMENT TO THE LIFTING POINTS OR TO PLACES INDICATED ON THE (TRANSPORT) DRAWINGS. USE SHACKLES OR SLINGS. DO NOT ATTACH LIFTING EQUIPMENT TO MACHINED SURFACES, SHAFT ENDS, PIPING WORK OR OTHER EXTERNALLY MOUNTED EQUIPMENT. MAKE SURE THAT YOU PLACE SUFFICIENTLY SIZED OIL OR FLUID CATCH TANK(S). ALWAYS COLLECT AND REMOVE SPILLED OIL OR FLUID FROM (DIS)-ASSEMBLY PROCEDURES. MAKE SURE THAT YOU DRAIN SYSTEM OIL OR FLUID BEFORE EQUIPMENT DISASSEMBLY. DO NOT USE ALKALINE OR CHEMICAL DETERGENTS TO CLEAN, RUBBER, SYNTHETIC OR PAINTED COMPONENTS. THEY CAN CAUSE DAMAGE TO EQUIPMENT. WIPE WITH A DRY CLOTH ONLY. ALWAYS EARTH SCREENED CABLES EXCLUSIVELY AT CABINET SIDE, NEVER AT PANEL NOR COMPONENT SIDE. ALWAYS CONNECT TO A GOOD EARTH POINT WHEN WELDING, CLOSE TO THE WELDING AREA TO AVOID DAMAGE TO EQUIPMENT SURFACES. WHEN WELDING PROTECT THE SURROUNDING FROM WELDING SPATTERS.

10-03-03 DMYI000063_01

Hoisting bolt for propeller boss

All rights reserved. Nothing from this publication may be reproduced, or disclosed without prior written approval of Wrtsil CME Zhenjiang Propeller Co. Ltd

System variant

Issue Date

Page

FPP

2006-11-2

1/1

WCZP article WZJ00000221 WZJ00000222 WZJ00000223

Mass (kg) 2,8 6,8 8,0 12,8 25,4 45,0

Thread size M48 M64 M72x6 M80x6 M100x6 M120x6

Length (mm) 140 190 205 225 280 330

Diameter (mm) 80 110 110 135 170 200

Work load (ton) 10,3 18,9 24,7 31,3 51,2 76,2

WZJ00000224

WZJ00000225 WZJ00000226

Push-up Diagram & Stamp data

axial displacement 17.5 axial displacement [mm] 17.0 16.5 16.0 15.5 15.0 14.5 0 5 10 15 20 temperature [degr. C] push up load 25 30 35

7800 7600 push up load [kN] 7400 7200 7000 6800 6600 0 5 10

15 20 temperature [degr. C] gripp stress

25

30

35

80 78 gripp stress [N/mm2] 76 74 72 70 68 66 0 5 10

15 20 temperature [degr. C]

25

30

35

Push-up distance at 15 degr. C.: 15.98 mm The propeller should have the following information hard stamped on the outside of the boss: C06 Start point load 660 kN Diam. 7400 mm Axial push-up at 0 degr. C. 16.92 mm Pitch Mean 4968 mm Axial push-up at 35 degr. C. 14.73 mm AE/AO 0.569 Class stamp Mass 30826 kg Certificate No. J 78928 kgm2 (in air) Class surveyor No. Material: Cu3 Date: Revision Date Comment

Mod. Form

Article number:

07131

Hull No.

0311501~515,518

Mod.:

Drawn: LiYing Checked:

Date: 3/12/2007

All rights reserved. Nothing from this publication may be reproduced, or disclosed without prior written approval of Wartsila-CME Zhenjiang Propeller Co., Ltd

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Dmyi 000025Document4 pagesDmyi 000025Sandeepa NimansithNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- REXROTH Service Manual PVC PSSFDocument6 pagesREXROTH Service Manual PVC PSSFRaghavendra DeshpandeNo ratings yet

- Pump-Elite - Operating InstructionsDocument12 pagesPump-Elite - Operating Instructionsbookslover1No ratings yet

- Elgin Centrifugal Pump Manual - 052018Document37 pagesElgin Centrifugal Pump Manual - 052018Andrew GoadNo ratings yet

- Manual For Steering Gear. 1 To 4 Rudders (2014)Document12 pagesManual For Steering Gear. 1 To 4 Rudders (2014)RomanNo ratings yet

- Manual Hydrill K20-5000Document16 pagesManual Hydrill K20-5000IgorCencič100% (3)

- Actuador de Válvula FlowserveDocument8 pagesActuador de Válvula FlowserveemanuellesanchezNo ratings yet

- SB388CDocument13 pagesSB388CBenjamin LeedsNo ratings yet

- Olaer Charging KitDocument4 pagesOlaer Charging KitA.m. Senthil KumarNo ratings yet

- Hydraulic Bottle Jack ManualDocument8 pagesHydraulic Bottle Jack ManualAlex Lake100% (1)

- Actuator - 655R IOMDocument14 pagesActuator - 655R IOMvkeie0206No ratings yet

- Operation and Maintenance Instructions: Top Collar Hydraulic NUT HNIC6190700CDocument0 pagesOperation and Maintenance Instructions: Top Collar Hydraulic NUT HNIC6190700CLoveNo ratings yet

- Troubleshooting VTP Vertical Turbine PumpDocument20 pagesTroubleshooting VTP Vertical Turbine PumpKrrish100% (1)

- Roots Blower Operating ManualDocument15 pagesRoots Blower Operating Manualanup_nairNo ratings yet

- 1528224612cooper SP-550 Rig601 2Document352 pages1528224612cooper SP-550 Rig601 2Schneider GaviriaNo ratings yet

- Pilot Pressure To The Main Control Valve - CheckDocument8 pagesPilot Pressure To The Main Control Valve - CheckMiguel Angel Moreno100% (8)

- SC4503-401-11SM PropellerDocument7 pagesSC4503-401-11SM PropellerLam Phuc TuNo ratings yet

- Sulzer Vertical Pump TroubleshootingDocument20 pagesSulzer Vertical Pump TroubleshootingNguyễn Thanh SơnNo ratings yet

- Mud Pumps Manual PDFDocument48 pagesMud Pumps Manual PDFMohamed Benlarbi100% (5)

- Pages From NSH-SAOMPP-QCP-PI-021 Hydratight Procedure For Flange Hydraulic Torque TighteningDocument2 pagesPages From NSH-SAOMPP-QCP-PI-021 Hydratight Procedure For Flange Hydraulic Torque TighteningRajis Rahim100% (1)

- Iom Manual 250 Series Centrifugal Pump: M15794, Rev 0Document17 pagesIom Manual 250 Series Centrifugal Pump: M15794, Rev 0hebert perez50% (2)

- PVV 540 PumpDocument14 pagesPVV 540 PumpMONANo ratings yet

- 950H WHEEL LOADER J5J00001-UP (MACHINE) POWERED BY C7 ENGINE (XEBP8563 - 00) - DocumentationDocument12 pages950H WHEEL LOADER J5J00001-UP (MACHINE) POWERED BY C7 ENGINE (XEBP8563 - 00) - DocumentationMohamed ZohierNo ratings yet

- CVS Type 667 Diaphragm Actuator: Instruction ManualDocument8 pagesCVS Type 667 Diaphragm Actuator: Instruction Manualsalmo83:18No ratings yet

- Operating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpDocument10 pagesOperating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpdocrafiNo ratings yet

- 99 AX Booster Assembly ManualDocument34 pages99 AX Booster Assembly ManualFernando NunezNo ratings yet

- TEEL BRONZE ROTARY PUMP Manual & Parts ListDocument8 pagesTEEL BRONZE ROTARY PUMP Manual & Parts ListMoToBunnYNo ratings yet

- AttTesting and AdjustingDocument8 pagesAttTesting and Adjustingchanlin100% (1)

- Installation of A Solid Shaft DriverDocument11 pagesInstallation of A Solid Shaft Driverrizal_mufidNo ratings yet

- Power - Grip Clutches, Installation and MantenanceDocument6 pagesPower - Grip Clutches, Installation and MantenancemanuelNo ratings yet

- FVCPDocument14 pagesFVCPmichaelxiaoNo ratings yet

- deltaSeriesTensioner OperationManualDocument26 pagesdeltaSeriesTensioner OperationManualAlan100% (1)

- Bolt Tensioners ManualDocument8 pagesBolt Tensioners ManualPV_ENGGNo ratings yet

- Catálogo Anderson Greenwood 400sDocument32 pagesCatálogo Anderson Greenwood 400sDaniela BeltranNo ratings yet

- Multiplex Plunger Pumps: Installation, Care and Operation ManualDocument0 pagesMultiplex Plunger Pumps: Installation, Care and Operation ManualDavid Rios CruzNo ratings yet

- Goulds Pumps: G&L Series SSH-C and SSH-FDocument36 pagesGoulds Pumps: G&L Series SSH-C and SSH-F1luckywolfNo ratings yet

- Catalogo NationalDocument76 pagesCatalogo NationalleonardoNo ratings yet

- 499839Document8 pages499839Virginia Venus Visuette MarínNo ratings yet

- Service Instruction: LycomingDocument4 pagesService Instruction: LycomingGANo ratings yet

- Olivals Fm-II Manual (Final)Document8 pagesOlivals Fm-II Manual (Final)Shahir HarunNo ratings yet

- Instruccion Manual Quincy QSTDocument36 pagesInstruccion Manual Quincy QSTJavier CevallosNo ratings yet

- dp7490 Pump ManualDocument16 pagesdp7490 Pump Manualvipequi50No ratings yet

- National Oilwell 165T Reciprocating-Plunger-Pumps-Installation-Care-and-Operation-Manual PDFDocument82 pagesNational Oilwell 165T Reciprocating-Plunger-Pumps-Installation-Care-and-Operation-Manual PDFAndres Eduardo100% (2)

- 3116 Cat Valvuklas Calibre PDFDocument4 pages3116 Cat Valvuklas Calibre PDFsergio blandon l100% (1)

- 3Pfr Plunger Pump Service Manual: 3 Frame Split Manifold: 230, 240, 270, 231, 241, 271, 237, 247, 277, 279Document8 pages3Pfr Plunger Pump Service Manual: 3 Frame Split Manifold: 230, 240, 270, 231, 241, 271, 237, 247, 277, 279yorgo7002No ratings yet

- A 084 BDocument12 pagesA 084 BDenis JimenezNo ratings yet

- 0013-B-6 Aeromat Valve For BlowerDocument3 pages0013-B-6 Aeromat Valve For BlowerXavi X QunqiNo ratings yet

- 09-2916 Regulador Series Four WaukeshaDocument14 pages09-2916 Regulador Series Four WaukeshaMaria Fernanda Bonilla SalasNo ratings yet

- Clutch ManualDocument16 pagesClutch ManualCO BDNo ratings yet

- Air Hydraulic Pump OTC EnglishDocument8 pagesAir Hydraulic Pump OTC EnglishEdSoloNo ratings yet

- Calibracion de ValvulasDocument3 pagesCalibracion de ValvulasJose FavaNo ratings yet

- Section Iv: MaintenanceDocument16 pagesSection Iv: MaintenanceGLOZOYA25No ratings yet

- VT3651Document21 pagesVT3651Pepe CuelloNo ratings yet

- Bo Cat Retor Excavadora225BDocument46 pagesBo Cat Retor Excavadora225BLaura MendozaNo ratings yet

- Hydraulic Brake Booster Installation LC 200Document17 pagesHydraulic Brake Booster Installation LC 200Yannick de WalqueNo ratings yet

- ATS73 Maint ManDocument12 pagesATS73 Maint Manpr_oilNo ratings yet

- 6.4. Tulsa Service ManualDocument33 pages6.4. Tulsa Service Manualdandisy100% (1)

- Ajuste de VálvulasDocument3 pagesAjuste de VálvulasEmerson MercadoNo ratings yet

- Megger InsulationtesterDocument67 pagesMegger InsulationtesterNh Chuminda YapaNo ratings yet

- No. 28 List of Minimum Recommended Spare Parts For Main Steam Turbines of Ships For Unrestricted Service No. 29Document1 pageNo. 28 List of Minimum Recommended Spare Parts For Main Steam Turbines of Ships For Unrestricted Service No. 29ARGONAFTISNo ratings yet

- Dimensional Analysis & Laws of ComparisonDocument4 pagesDimensional Analysis & Laws of ComparisonARGONAFTISNo ratings yet

- No. 26 List of Minimum Recommended Spare Parts For Essential Auxiliary Machinery of Ships For Unrestricted Service No. 30Document1 pageNo. 26 List of Minimum Recommended Spare Parts For Essential Auxiliary Machinery of Ships For Unrestricted Service No. 30ARGONAFTISNo ratings yet

- Hoover S3285Document7 pagesHoover S3285ARGONAFTISNo ratings yet

- DNV - GL - Webinar - Building A Carbon-Robust Strategy For Shipping - Nov 2018Document28 pagesDNV - GL - Webinar - Building A Carbon-Robust Strategy For Shipping - Nov 2018ARGONAFTISNo ratings yet

- Procedure For Japan Customs ApprovalDocument17 pagesProcedure For Japan Customs ApprovalARGONAFTISNo ratings yet

- BoiloffDocument3 pagesBoiloffARGONAFTISNo ratings yet

- A1 1Document7 pagesA1 1ARGONAFTISNo ratings yet

- Electrical Quick GuideDocument39 pagesElectrical Quick GuideMelvin EsguerraNo ratings yet

- Mooring AftDocument1 pageMooring AftARGONAFTISNo ratings yet

- Homework ProblemDocument19 pagesHomework Problemjaved shaikh chaandNo ratings yet

- Class Guide On Condition MonitoringDocument13 pagesClass Guide On Condition MonitoringARGONAFTIS100% (1)

- Hand To Hand Fighting - Karate, Tae Kwon Do - ST 31-204Document129 pagesHand To Hand Fighting - Karate, Tae Kwon Do - ST 31-204nguyenqnhon100% (3)

- Wartsila SP PPT 2011 Bit VikingDocument14 pagesWartsila SP PPT 2011 Bit VikingARGONAFTISNo ratings yet

- Yin Yang PrimerDocument25 pagesYin Yang PrimerARGONAFTISNo ratings yet

- Notes On Heavy Fuel Oil 1984Document68 pagesNotes On Heavy Fuel Oil 1984mohdfadhirulNo ratings yet

- Fuel Quality and Optimum Fuel Selection by Petrus ScholtzDocument30 pagesFuel Quality and Optimum Fuel Selection by Petrus ScholtzARGONAFTISNo ratings yet

- UstDocument16 pagesUstARGONAFTIS100% (2)

- Pub Iso8217 Fuels SpecsDocument4 pagesPub Iso8217 Fuels SpecsARGONAFTISNo ratings yet

- ODC Presentation (General)Document39 pagesODC Presentation (General)ARGONAFTISNo ratings yet

- BO 018 Drilling OperationsDocument161 pagesBO 018 Drilling OperationsARGONAFTISNo ratings yet

- Ship PerformanceDocument5 pagesShip PerformanceARGONAFTISNo ratings yet

- BO 018 Drilling OperationsDocument161 pagesBO 018 Drilling OperationsARGONAFTISNo ratings yet

- Notes On Heavy Fuel Oil 1984Document68 pagesNotes On Heavy Fuel Oil 1984mohdfadhirulNo ratings yet

- LR HorizonsDocument21 pagesLR HorizonsIrina MaltopolNo ratings yet

- Marine Fuel h2s Round Robin Research Report March 6th 2012Document55 pagesMarine Fuel h2s Round Robin Research Report March 6th 2012ARGONAFTISNo ratings yet

- UstDocument16 pagesUstARGONAFTIS100% (2)

- Ispsd 2002 PaperDocument8 pagesIspsd 2002 PaperARGONAFTISNo ratings yet

- EMD 645 Marine Emissions Kits A4Document2 pagesEMD 645 Marine Emissions Kits A4Martin KratkyNo ratings yet

- Ford Transit MY 06 ON Fuel Pump LearnDocument2 pagesFord Transit MY 06 ON Fuel Pump LearnLevaniMgebrishviliNo ratings yet

- Aircraft Engines and Gas Turbines: Jack L KerrebrockDocument2 pagesAircraft Engines and Gas Turbines: Jack L KerrebrockSreehari HNo ratings yet

- Ae-2405 Aircraft Systems LaboratoryDocument42 pagesAe-2405 Aircraft Systems LaboratorycalinshabuNo ratings yet

- The Battery Solution For All Driving NeedsDocument8 pagesThe Battery Solution For All Driving Needsfeniks2290No ratings yet

- Wet Riser SpecificationDocument4 pagesWet Riser SpecificationshihabnittNo ratings yet

- How To Clean Oil Catch Tank Y26SEDocument10 pagesHow To Clean Oil Catch Tank Y26SERanopiNo ratings yet

- M.V. Proteus at EnnoreDocument4 pagesM.V. Proteus at EnnoreVikkiVikiNo ratings yet

- Liquefied Gas HandbookDocument38 pagesLiquefied Gas HandbookAndri Suharto100% (1)

- Submitted in Partial Fulfilment For The Award of The Degree ofDocument27 pagesSubmitted in Partial Fulfilment For The Award of The Degree ofJaymit PatelNo ratings yet

- DHU SpesifikasiDocument9 pagesDHU SpesifikasiAinur RohmanNo ratings yet

- 10 Free Energy TechnologiesDocument65 pages10 Free Energy TechnologiesKWojtek91% (22)

- Gas Turbine MaintenanceDocument80 pagesGas Turbine MaintenanceYahya Faiez WaqqadNo ratings yet

- Re Order Sentences-PTEDocument13 pagesRe Order Sentences-PTERICHARDSIBANDA100% (1)

- July 08Document4 pagesJuly 08Mohamed HamedNo ratings yet

- Gas Turbine Power Plant PDFDocument28 pagesGas Turbine Power Plant PDFPao CastillonNo ratings yet

- Operation Manual XMQ6130C 1Document161 pagesOperation Manual XMQ6130C 1Bobby AldNo ratings yet

- Dual Fuel EnginesDocument14 pagesDual Fuel EnginesHarshPatelNo ratings yet

- TGT-P-H01-RP-0002 Rev.0 PDFDocument41 pagesTGT-P-H01-RP-0002 Rev.0 PDFThái Xuân QuangNo ratings yet

- Question AnswersDocument40 pagesQuestion AnswersameyasjoshiNo ratings yet

- System Operation 3516Document14 pagesSystem Operation 3516wagner_guimarães_1No ratings yet

- BVD 2462 GBDocument2 pagesBVD 2462 GBAnonymous P18XRitOPPNo ratings yet

- GPL Landi Renzo System - Renault - 6525A PDFDocument87 pagesGPL Landi Renzo System - Renault - 6525A PDFmoanna100% (1)

- 4GZ Aty Sesv1722 PDFDocument280 pages4GZ Aty Sesv1722 PDFenrique100% (1)

- Drilling Operations: PETE 2050 FALL 2008Document43 pagesDrilling Operations: PETE 2050 FALL 2008Jaiyeola Solomon AdeniyiNo ratings yet

- Reciprocating Compressor Theory PDFDocument33 pagesReciprocating Compressor Theory PDFyeshig200083% (6)

- Mosa 15921-gb - 03-14Document36 pagesMosa 15921-gb - 03-14costelchelariuNo ratings yet

- Tanker Load Disch PlanDocument37 pagesTanker Load Disch PlandanuNo ratings yet

- Draft Survey - Bulk Vessels LoadingDocument5 pagesDraft Survey - Bulk Vessels LoadingSoubam Luxmibai100% (1)

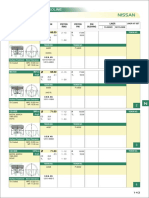

- Teikin Catalog-Automobile NISSANDocument36 pagesTeikin Catalog-Automobile NISSANBruno Andres Miranda Soto100% (7)

- Automotive Electronic Diagnostics (Course 1)From EverandAutomotive Electronic Diagnostics (Course 1)Rating: 5 out of 5 stars5/5 (6)

- Why We Drive: Toward a Philosophy of the Open RoadFrom EverandWhy We Drive: Toward a Philosophy of the Open RoadRating: 4 out of 5 stars4/5 (6)

- CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]From EverandCDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Rating: 5 out of 5 stars5/5 (2)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceFrom EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceNo ratings yet

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (54)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVFrom EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVRating: 5 out of 5 stars5/5 (2)

- Tips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)From EverandTips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)No ratings yet

- The Official Highway Code: DVSA Safe Driving for Life SeriesFrom EverandThe Official Highway Code: DVSA Safe Driving for Life SeriesRating: 3.5 out of 5 stars3.5/5 (25)

- New Hemi Engines 2003 to Present: How to Build Max PerformanceFrom EverandNew Hemi Engines 2003 to Present: How to Build Max PerformanceNo ratings yet

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildFrom EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildRating: 5 out of 5 stars5/5 (1)

- Turbo: Real World High-Performance Turbocharger SystemsFrom EverandTurbo: Real World High-Performance Turbocharger SystemsRating: 5 out of 5 stars5/5 (3)

- Top 21 Hypercars: The Best and Fastest Car Ever MadeFrom EverandTop 21 Hypercars: The Best and Fastest Car Ever MadeRating: 3 out of 5 stars3/5 (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Building Honda K-Series Engine PerformanceFrom EverandBuilding Honda K-Series Engine PerformanceRating: 5 out of 5 stars5/5 (2)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WFrom EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WRating: 4.5 out of 5 stars4.5/5 (6)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

![CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/710834945/198x198/00b81cbbd3/1714482720?v=1)