Professional Documents

Culture Documents

Ohtl Hi Voltage Conductors TR 5 04e 080709 Rev A

Uploaded by

Sumer LandOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ohtl Hi Voltage Conductors TR 5 04e 080709 Rev A

Uploaded by

Sumer LandCopyright:

Available Formats

TEKNISK RIKTLINJE

1 (15)

Enhet, verksamhetsomrde Datum Version

NT, Teknik

08-07-09 A TR 5-04E

Samrd

CONDUCTORS

FOR 220 kV AND 400 kV OH LINES

Introduction

This document in English shall be regarded as a translation of the corresponding

guidelines in Swedish. The aim of the translation is to provide support to foreign

manufacturers. The wording in Swedish and the interpretation thereof shall govern

contract and legal relations between the parties of the purchasing process.

These guidelines describe the requirements on steel-, aluminium- (AAC), aluminium

conductors steel reinforced (ACSR) and all aluminium alloy (AAAC) conductors for

overhead transmission lines and cover design and inspection. The guidelines intend to

guarantee satisfactory performance of conductors during the lifetime of the overhead

line and shall be used at purchasing of conductors.

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

2 (15)

CONTENT PAGE

4.1 References ................................................................................................3

4.2 Scope.........................................................................................................4

4.3 Definitions .................................................................................................4

4.4 Description................................................................................................4

4.4.1 Steel conductors................................................................................................................. 4

4.4.2 Aluminium conductors (AAC).............................................................................................. 4

4.4.3 Aluminium conductors steel reinforced (ACSR) ................................................................. 4

4.4.4 aluminium alloy conductors (AAAC)................................................................................... 4

4.5 Requirements ...........................................................................................4

4.5.1 Steel conductors................................................................................................................. 4

4.5.2 All Aluminium conductor (AAC) .......................................................................................... 5

4.5.3 Aluminium conductors steel reinforced (ACSR) ................................................................. 5

4.5.4 AlMgSi, All aluminium alloy conductor, (AAAC) ................................................................. 6

4.5.5 Al 59, All aluminium alloy conductor, (AAAC)..................................................................... 6

4.6 Type test ....................................................................................................7

4.6.1 General ............................................................................................................................... 7

4.6.2 J oints in strands before stranding....................................................................................... 7

4.6.3 Stress Strain curve .......................................................................................................... 7

4.6.4 Breaking load...................................................................................................................... 7

4.6.5 Creep.................................................................................................................................. 7

4.7 Sample test ...............................................................................................8

4.7.1 General ............................................................................................................................... 8

4.7.2 Tests on strands before stranding...................................................................................... 8

4.7.3 Cross-sectional area........................................................................................................... 8

4.7.4 Conductor diameter ............................................................................................................ 8

4.7.5 Mass per unit length............................................................................................................ 8

4.7.6 Breaking load of strands from conductor............................................................................ 8

4.7.7 Surface condition................................................................................................................ 8

4.7.8 Lay ratio and direction of lay............................................................................................... 8

4.7.9 Grease content................................................................................................................... 8

4.8 Certificate of delivery ...............................................................................8

4.8.1 General ............................................................................................................................... 8

4.8.2 Documentation.................................................................................................................... 9

4.9 Installation ................................................................................................9

4.10 Tables ......................................................................................................10

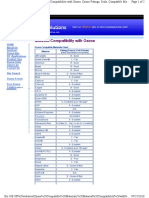

Table 1 Steel conductor (Fe 140) .................................................................................................. 10

Table 2 All aluminium conductor (AAC), (AL1).............................................................................. 10

Tabell 3 Stlaluminiumlinor (AL1/ST1A)......................................................................................... 11

Table 4a AlMgSi-linor....................................................................................................................... 12

Table 4b AlMgSi-linor (AL7)............................................................................................................. 12

Table 5 Al59-linor........................................................................................................................... 13

4.11 Figures ....................................................................................................14

Figure 1 Steel conductors............................................................................................................... 14

Figure 2 All aluminium (AAC), All aluminium alloy (AAAC) conductors.......................................... 14

Figure 3 Aluminium conductors steel reinforced (ACSR) ............................................................... 14

Figure 4 Conductors, greasing........................................................................................................ 15

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

3 (15)

4.1 REFERENCES

Note that standards, regulations etc. which are referred to in these

guidelines are subject to continuous change and can be withdrawn,

revised or replaced. It is the obligation that the contractor immediately

will inform the client of such changes

SS-EN 50182 Round wire concentric lay overhead electrical

stranded conductors

SS-EN 50183 Conductors for overhead lines - Aluminium-

magnesium-silicon alloy wires

SS-EN 50189 Conductors for overhead lines - Zinc coated steel

wires

SS-EN 50326 Conductors for overhead lines - Characteristics of

greases

SS-EN 60889 Hard-drawn aluminium wire for overhead line

conductors

SS-EN 61395 Overhead electrical conductors - Creep test

procedures for stranded conductors

SS-EN 60865-1 Short-circuit currents - Calculation of effects -

Part 1: Definitions and calculation methods

IEC/TR 60865-2 Short-circuit currents - Calculation of effects -

Part 2: Examples of calculation

SS-EN ISO 9001 Quality management systems - Requirements

SS ISO 5455 Technical drawings - Scales

SS 424 08 05 Hard zinc-coated steel wire for stranded

conductors and wire strands for overhead lines -

Fe140 wire

SS 424 08 06 Hard zinc-coated steel wire strands for overhead

lines - Fe140 wire strands

SS 424 08 11 Aluminium alloy wire for stranded conductors for

overhead lines - AlMgSi wire

SS 424 08 12 Aluminium alloy stranded conductors for

overhead lines - AlMgSi conductors

SS 424 08 13 Aluminium alloy wire for stranded conductors for

overhead lines - Al 59 wire

SS 424 08 14 Aluminium alloy stranded conductors for

overhead lines - Al 59 conductors

SvK TR 5-07E Technical guidelines - J oints

SvK TR 5-09E Technical guidelines Vibration dampers

SvK TR 5-13E Technical guidelines Earthing

SvK TR 8E Technical guidelines Documentation

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

4 (15)

4.2 SCOPE

These guidelines are applicable to steel, aluminium, steel reinforced

aluminium and aluminium alloy conductors for overhead lines and

comprise design and testing.

The intention of the specification is to guarantee satisfactory performance

of the conductors during the lifetime of the overhead line.

For conductors to be buried underground refer to SvK TR 5-13E.

4.3 DEFINITIONS

Technical terms and definitions used in these guidelines:

Creep

Permanent elongation under constant stress over a period of time.

4.4 DESCRIPTION

4.4.1 STEEL CONDUCTORS

Conductors consisting of several layers of strands made from hot-dip

galvanised steel. See Figures 1a and 1b.

4.4.2 ALUMINIUM CONDUCTORS (AAC)

Conductors consisting of several layers of strands made from aluminium.

See Figure 2.

4.4.3 ALUMINIUM CONDUCTORS STEEL REINFORCED (ACSR)

Conductors having a core consisting of a strand, or several layers of

strands, made from hot-dip galvanised steel and with one or several outer

layers of strands made from aluminium. See Figures 3a and 3b.

4.4.4 ALUMINIUM ALLOY CONDUCTORS (AAAC)

4.4.4.1 AlMgSi conductors

Conductors consisting of several layers of strands made from AlMgSi.

See Figure 2.

4.4.4.2 Al 59 conductors

Conductors consisting of several layers of strands made from Al 59. See

Figure 2.

4.5 REQUIREMENTS

4.5.1 STEEL CONDUCTORS

4.5.1.1 Strand

Strands shall be manufactured from high strength steel in accordance

with SS 424 08 05.

4.5.1.2 Dimensions

Conductors shall have dimensions in accordance with SS 424 08 06, See

Table 1.

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

5 (15)

4.5.1.3 Design

Conductors shall comply with the requirements in accordance with SS

424 08 06.

4.5.1.4 Breaking load

Conductors shall comply with the breaking load requirements in

accordance with SS 424 08 06, See Table 1.

4.5.1.5 Resistance

Conductors shall comply with the resistance requirements in accordance

with Table 1.

4.5.2 ALL ALUMINIUM CONDUCTOR (AAC)

4.5.2.1 Strand

Strands shall be manufactured in accordance with SS-EN 60889.

4.5.2.2 Dimensions

Conductors shall have dimensions in accordance with SS-EN 50182, See

Table 2.

4.5.2.3 Design

Conductors shall comply with the requirements in accordance with SS-

EN 50182, AL1.

4.5.2.4 Breaking load

Conductors shall meet the requirements of strength in accordance with

SS-EN 50182, See Table 2.

4.5.2.5 Resistance

Conductors shall meet the requirements of resistance in accordance with

SS-EN 50182, See Table 2.

4.5.2.6 Greasing

When greasing of conductors is requested they shall be greased in

accordance with SS-EN 50182 Annex B, Case 4, See Figure 4.

Grease shall meet the requirements in accordance with SS-EN 50326.

4.5.3 ALUMINIUM CONDUCTORS STEEL REINFORCED (ACSR)

4.5.3.1 Strand

Steel strands shall be manufactured in accordance with SS-EN 50189

Class ST1A.

Aluminium strands shall be manufactured in accordance with SS-EN

60889.

4.5.3.2 Dimensions

Conductors shall have dimensions in accordance with SS-EN 50182, See

Table 3.

4.5.3.3 Design

Conductors shall meet the requirements in accordance with SS-EN 50182

AL1/ST1A. A core consisting of only one steel strand shall have no

joints.

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

6 (15)

4.5.3.4 Breaking load

Conductors shall meet the requirements of strength in accordance with

SS-EN 50182, See Table 3.

4.5.3.5 Resistance

Conductors shall comply with the resistance requirements of Table 3.

4.5.3.6 Greasing

When greasing of the steel core of conductors is requested it shall be

greased in accordance with SS-EN 50182 Annex B, Case 1, See Figure 4.

Grease shall meet the requirements in accordance with SS-EN 50326.

4.5.4 ALMGSI, ALL ALUMINIUM ALLOY CONDUCTOR, (AAAC)

4.5.4.1 Strand

Strands shall be manufactured in accordance with SS 424 08 11

Alternatively shall the strand be in accordance with SS-EN 50183-AL7.

4.5.4.2 Dimensions

Conductors shall have measurements in accordance with SS 424 08 12,

See Table 4A.

Alternatively shall the conductor have dimensions in accordance with

SS-EN 50182-AL7, See Table 4B.

4.5.4.3 Design

Conductors shall comply with the requirements of SS-EN 50182.

4.5.4.4 Breaking load

Conductors shall meet the requirements of strength in accordance with

SS 424 08 12, See Table 4A.

Alternatively shall the conductor meet the requirements for rated

strength in accordance with SS-EN 50182-AL7, See Table 4B.

4.5.4.5 Resistance

Conductors shall meet the requirements of resistance in accordance with

SS 424 08 12, See Table 4A.

Alternatively shall the conductor meet the requirements for resistance in

accordance with SS-EN 50182-AL7, See Table 4B.

4.5.4.6 Greasing

When greasing of conductors is requested they shall be greased in

accordance with SS-EN 50182 Annex B, Case 4, See Figure 4.

Grease shall meet the requirements in accordance with SS-EN 50326.

4.5.5 AL 59, ALL ALUMINIUM ALLOY CONDUCTOR, (AAAC)

4.5.5.1 Strand

Strands shall be manufactured in accordance with SS 424 08 13.

4.5.5.2 Dimensions

Conductors shall have dimensions in accordance with SS 424 08 14, See

Table 5.

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

7 (15)

4.5.5.3 Design

Conductors shall comply with the requirements of SS-EN 50182.

4.5.5.4 Breaking load

Conductors shall meet the requirements of strength in accordance with

SS 424 08 14, See Table 5.

4.5.5.5 Resistance

Conductors shall meet the requirements of resistance in accordance with

SS 424 08 14, See Table 5.

4.5.5.6 Greasing

When greasing of conductors is requested they shall be greased in

accordance with SS-EN 50182 Annex B, Case 4, See Figure 4.

Grease shall meet the requirements in accordance with SS-EN 50326.

4.6 TYPE TEST

4.6.1 GENERAL

Type tests are to be performed in accordance with SS-EN 50182 as stated

in clauses 4.6.2 4.6.4 below. In addition for conductors made from Al

59 tests in accordance with clause 4.6.5 shall be performed.

4.6.2 JOINTS IN STRANDS BEFORE STRANDING

This test shall be performed in accordance with SS-EN 50182.

4.6.3 STRESS STRAIN CURVE

This test shall be performed in accordance with SS-EN 50182. All

measurements taken shall be recorded and submitted to the client.

Calculated curve of the third degree for the stress respectively strain,

connecting the recorded values of stress strain, including the formulas

shall be included.

4.6.4 BREAKING LOAD

This test shall be performed in accordance with SS-EN 50182.

4.6.5 CREEP

This test shall be performed in accordance with SS-EN 61395 and the

parameters shall be in accordance with SS 424 08 14. The creep shall be

measured at intervals of time evenly logarithmically distributed over the

entire testing time. All readings of temperature, strain and time shall be

shown in tabular form. The linear regression shall be calculated for all

the measured strain readings. It shall also be calculated for the measured

strain readings from 50 hours after start to the end of the test.

When calculating the linear regression, the value z shall be added to

every reading such that, at the time t=87600 hours (10 years), the creep

will be equal for the two regression curves. Calculated values for k and

b, in addition to the calculated creep from fifty hour to ten years, are to

be presented to the client.

The creep shall be calculated according to the formula:

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

8 (15)

b k

t * 10 =

where

= conductor creep during time t

k = point of intersection between the line and the y-axis

b = line slope

t = time for which creep shall be calculated

4.7 SAMPLE TEST

4.7.1 GENERAL

The sample test shall be performed in accordance with SS-EN 50182.

4.7.2 TESTS ON STRANDS BEFORE STRANDING

The tests shall show that strands comply with the requirements of clauses

4.5.1.1, 4.5.2.1, 4.5.3.1, 4.5.4.1 and 4.5.5.1.

4.7.3 CROSS-SECTIONAL AREA

This test shall be performed in accordance with SS-EN 50182.

4.7.4 CONDUCTOR DIAMETER

This test shall be performed in accordance with SS-EN 50182.

4.7.5 MASS PER UNIT LENGTH

This test shall be performed in accordance with SS-EN 50182.

4.7.6 BREAKING LOAD OF STRANDS FROM CONDUCTOR

This test shall be performed in accordance with SS-EN 50182.

4.7.7 SURFACE CONDITION

The test shall be performed in accordance with SS-EN 50182.

4.7.8 LAY RATIO AND DIRECTION OF LAY

This test shall be performed in accordance with SS-EN 50182.

4.7.9 GREASE CONTENT

This test shall be performed in accordance with SS-EN 50182.

4.8 CERTIFICATE OF DELIVERY

4.8.1 GENERAL

The client shall, according to these guidelines, approve the conductor

before delivery. For approval the manufacturer shall show that the

conductor conforms to the guidelines.

The manufacturer shall provide documentation in accordance with

clauses 4.8.2.1-4.8.2.5 for approval.

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

9 (15)

The approval of drawings by the client does not release the manufacturer

from his obligation regarding the conductor complying with the

guidelines.

All documentation shall be written in Swedish or English.

4.8.2 DOCUMENTATION

General requirements for documentation see SvK TR 8E.

4.8.2.1 Assembly drawing

The assembly drawing shall have an appropriate scale in accordance with

SS ISO 5455. On the drawing shall be given:

Type

Cross-sectional area and stranding

Mass per km

Resistance

Conductor length per drum

4.8.2.2 List of material

Description of material for included parts.

4.8.2.3 Manufacturing process

Description of the manufacturing process

4.8.2.4 Quality system

Quality system in accordance with SS-EN ISO 9001.

4.8.2.5 Type test report

Type test report in accordance with clause 4.6

4.9 INSTALLATION

Conductors shall be run-out under tension using pilot strands.

The conductor shall be clamped-in within 48 hours after it has been

sagged. If this cannot be done, vibration dampers in accordance with

SvK TR 5-09E shall be installed

Sheaves of running out blocks for the conductor shall be rubber lined and

have a diameter of at least 15 times the conductor diameter.

J oints for conductors shall be in accordance with SvK TR 5-07E. The

conductor ends shall be free from dirt and undamaged when the joint is

installed. Conductor adjacent to the joint shall not have protruding

strands.

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

10 (15)

4.10 TABLES

TABLE 1 STEEL CONDUCTOR (FE 140)

Diameter Calculated

Strand Cond. Mass

Rated

strength

DC

resistanse

1)

Short

circuit

current

2)

Desig-

nation

area

Nos

of

strands

mm mm kg/km kN /km kA

52 7 3,08 9,24 412 71,4 3,705 3,0

68 7 3,52 10,6 538 93,1 2,837 3,9

89 7 4,02 12,1 702 122 2,175 5,1

105 7 4,36 13,1 826 143 1,849 6,0

142 19 3,08 15,4 1127 194 1,375 8,2

185 19 3,52 17,6 1472 253 1,053 10,7

241 19 4,02 20,1 1920 331 0,8074 13,9

284 19 4,36 21,8 2258 390 0,6864 16,4

1) The DC resistance is calculated from the mean value of 192,0 nm

(9,0% IACS) for the individual strand.

2) The short circuit current is the calculated effective value with a

duration of one second at an initial conductor temperature of +30

C and a final temperature of +300 C.

TABLE 2 ALL ALUMINIUM CONDUCTOR (AAC), (AL1)

Diameter Calculated

Strand Cond. Mass

Rated

strength

DC

resistanse

1)

Continuous

current

capacity

2)

Short

circuit

current

3)

Desig-

nation

accord.

EN

Desig-

nation

area

Nos

of

strands

mm mm kg/km kN /km A kA

454-AL1 454 61 3,08 27,7 1256 74,99 0,06366 406 43,5

594-AL1 593 61 3,52 31,7 1641 97,95 0,04874 433 56,9

774-AL1 774 61 4,02 36,2 2140 123,9 0,03737 483 74,2

911-AL1 910 61 4,36 39,2 2517 145,7 0,03177 519 87,3

1) The DC resistance is calculated from the mean value 28.035 nm

(61.5 % IACS) of the individual strand.

2) The continuous current capacity is calculated for a conductor

temperature of +50 C at an ambient temperature of +30C,

frequency 50 Hz, resistivity temperature coefficient 0,00403,

emission factor 0,7, absorption coefficient 0,9, wind velocity 0,6

m/s and at a latitude of 60 (N).

3) The short circuit current is the calculated effective value with

duration of one second at an initial conductor temperature of +50C

and a final temperature of +200C.

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

11 (15)

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

TABLE 3 ALUMINIUM CONDUCTOR STEEL REINFORCED (AL1/ST1A)

S

h

o

r

t

c

i

r

c

u

i

t

c

u

r

r

e

n

t

k

A

4

2

,

2

3

)

5

5

,

2

3

)

7

1

,

9

3

)

8

4

,

5

3

)

1

2

,

8

4

)

2

1

,

8

4

)

3

1

,

0

4

)

C

o

n

t

i

n

u

o

u

s

c

u

r

r

e

n

t

c

a

p

a

c

i

t

y

A

3

8

1

4

0

7

4

6

0

4

9

3

D

C

r

e

s

i

s

t

a

n

c

e

/

k

m

0

,

0

7

1

8

7

0

,

0

5

5

0

3

0

,

0

4

2

1

9

0

,

0

3

5

8

5

0

,

3

2

3

0

0

,

1

8

9

6

0

0

,

1

1

5

2

2

R

a

t

e

d

s

t

r

e

n

g

t

h

k

N

1

2

3

,

8

1

6

1

,

6

2

0

7

,

4

2

4

5

,

8

7

2

,

1

2

1

2

2

,

1

1

1

6

,

3

C

a

l

c

u

l

a

t

e

d

M

a

s

s

k

g

/

k

m

1

5

2

3

1

9

8

9

2

5

9

4

3

0

3

6

6

5

8

1

1

2

1

1

2

3

1

C

o

n

d

.

m

m

2

7

,

7

3

1

,

7

3

6

,

2

3

9

,

3

1

5

,

4

2

0

,

1

2

3

,

2

C

o

r

e

m

m

9

,

2

4

1

0

,

6

1

2

,

1

1

3

,

1

9

,

2

4

1

2

,

1

1

0

,

6

F

e

m

m

3

,

0

8

3

,

5

2

4

,

0

2

2

,

6

2

3

,

0

8

4

,

0

2

3

,

5

2

D

i

a

m

e

t

e

r

S

t

r

a

n

d

A

l

m

m

3

,

0

8

3

,

5

2

4

,

0

2

4

,

3

6

3

,

0

8

4

,

0

2

3

,

1

6

F

e

7

7

7

1

9

7

7

7

N

o

s

o

f

s

t

r

a

n

d

s

A

l

5

4

5

4

5

4

5

4

1

2

1

2

3

2

D

e

s

i

g

-

n

a

t

i

o

n

a

r

e

a

4

5

4

5

9

3

7

7

4

9

1

0

1

4

2

2

4

1

3

1

9

D

e

s

i

g

n

a

t

i

o

n

a

c

c

o

r

d

i

n

g

t

o

E

N

P

h

a

s

e

c

o

n

d

u

c

t

o

r

4

0

2

-

A

L

1

/

5

2

-

S

T

1

A

5

2

5

-

A

L

1

/

6

8

-

S

T

1

A

6

8

5

-

A

L

1

/

8

9

-

S

T

1

A

8

0

6

-

A

L

1

/

1

0

2

-

S

T

1

A

S

h

i

e

l

d

c

o

n

d

u

c

t

o

r

8

9

-

A

L

1

/

5

2

-

S

T

1

A

1

5

2

-

A

L

1

/

8

9

-

S

T

1

A

2

5

1

-

A

L

1

/

6

8

-

S

T

1

A

1

)

T

h

e

D

C

r

e

s

i

s

t

a

n

c

e

i

s

c

a

l

c

u

l

a

t

e

d

f

r

o

m

t

h

e

m

e

a

n

v

a

l

u

e

2

8

,

2

6

4

n

m

(

6

1

,

%

I

A

C

S

)

o

f

t

h

e

i

n

d

i

v

i

d

u

a

l

s

t

r

a

n

d

.

2

)

T

h

e

c

o

n

t

i

n

u

o

u

s

c

u

r

r

e

n

t

c

a

p

a

c

i

t

y

i

s

c

a

l

c

u

l

a

t

e

d

f

o

r

a

c

o

n

d

u

c

t

o

r

t

e

m

p

e

r

a

t

u

r

e

o

f

+

5

0

C

a

t

a

n

a

m

b

i

e

n

t

t

e

m

p

e

r

a

t

u

r

e

o

f

+

3

0

C

,

f

r

e

q

u

e

n

c

y

5

0

H

z

,

r

e

s

i

s

t

i

v

i

t

y

t

e

m

p

e

r

a

t

u

r

e

c

o

e

f

f

i

c

i

e

n

t

0

,

0

0

4

0

3

,

e

m

i

s

s

i

o

n

f

a

c

t

o

r

0

,

7

,

a

b

s

o

r

p

t

i

o

n

c

o

e

f

f

i

c

i

e

n

t

0

,

9

,

w

i

n

d

v

e

l

o

c

i

t

y

0

6

m

/

s

a

n

d

a

t

a

l

a

t

i

t

u

d

e

o

f

6

0

(

N

)

3

)

T

h

e

s

h

o

r

t

c

i

r

c

u

i

t

c

u

r

r

e

n

t

i

s

t

h

e

c

a

l

c

u

l

a

t

e

d

e

f

f

e

c

t

i

v

e

v

a

l

u

e

w

i

t

h

d

u

r

a

t

i

o

n

o

f

o

n

e

s

e

c

o

n

d

a

t

a

n

i

n

i

t

i

a

l

c

o

n

d

u

c

t

o

r

t

e

m

p

e

r

a

t

u

r

e

o

f

+

5

0

C

a

n

d

a

f

i

n

a

l

t

e

m

p

e

r

a

t

u

r

e

o

f

+

2

0

0

C

.

4

)

T

h

e

s

h

o

r

t

c

i

r

c

u

i

t

c

u

r

r

e

n

t

i

s

t

h

e

c

a

l

c

u

l

a

t

e

d

e

f

f

e

c

t

i

v

e

v

a

l

u

e

w

i

t

h

d

u

r

a

t

i

o

n

o

f

o

n

e

s

e

c

o

n

d

a

t

a

n

i

n

i

t

i

a

l

c

o

n

d

u

c

t

o

r

t

e

m

p

e

r

a

t

u

r

e

o

f

+

3

0

C

a

n

d

a

f

i

n

a

l

t

e

m

p

e

r

a

t

u

r

e

o

f

+

2

0

0

C

.

12 (15)

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

TABLE 4A ALMGSI-CONDUCTOR

Diameter Calculated Continuous Short-

Desig-

nation

Nos

of

Strand Cond. Mass Rated-

strength

DC

resistance

1)

current

capacity

2)

circuit

current

3)

area strands mm mm kg/km kN /km A kA

454 61 3,08 27,7 1256 125,0 0,06755 393 43,2

593 61 3,52 31,7 1640 157,3 0,05172 419 56,4

774 61 4,02 36,2 2139 197,4 0,03965 471 73,6

910 61 4,36 39,2 2516 232,2 0,03371 503 86,6

1) The DC resistance is calculated from the mean value 30,000 nm (57,5%

IACS) of the individual strand.

2) The continuous current capacity is calculated for a conductor temperature of

+50 C at an ambient temperature of +30C, frequency 50 Hz, resistivity

temperature coefficient 0,0038, emission factor 0,7, absorption coefficient

0,9, wind velocity 0,6 m/s and at a latitude of 60 (N).

3) The short circuit current is the calculated effective value with duration of

one second at an initial conductor temperature of +50C and a final

temperature of +200C.

TABLE 4B ALMGSI-CONDUCTOR (AL7)

Diameter Calculated

Stran

d

Cond. Mass

Rated

strength

DC

resistance

1)

Con-

tinuous

current

capa-

city

2)

Short-

circuit-

current

3)

Desig-

nation

accord.

EN

Desig-

nation

area

Nos

of

strand

mm mm kg/km kN /km A kA

454-AL7 454 61 3,08 27,7 1256 125,0 0,06755 393 43,2

594-AL7 593 61 3,52 31,7 1641 157,3 0,05172 419 56,4

774-AL7 774 61 4,02 36,2 2140 197,4 0,03965 471 73,6

911-AL7 910 61 4,36 39,2 2517 232,2 0,03371 503 86,6

1) The DC resistance is calculated from the mean value 30,000 nm (57,5%

IACS) of the individual strand.

2) The continuous current capacity is calculated for a conductor temperature of

+50 C at an ambient temperature of +30C, frequency 50 Hz, resistivity

temperature coefficient 0,0038, emission factor 0,7, absorption coefficient

0,9, wind velocity 0,6 m/s and at a latitude of 60 (N).

3) The short circuit current is the calculated effective value with duration of

one second at an initial conductor temperature of +50C and a final

temperature of +200C.

13 (15)

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

TABLE 5 AL59-LINOR

Diameter Calculated Continuous Short-

Desig-

nation

Nos

of

Strand Cond. Mass Rated-

strength

DC

resistance

1)

current

capacity

2)

circuit

current

3)

area strands mm mm kg/km kN /km A kA

454 61 3,08 27,7 1250 113,6 0,06532 399 44,1

593 61 3,52 31,7 1640 142,5 0,05001 426 57,6

774 61 4,02 36,2 2140 178,1 0,03834 478 75,1

910 61 4,36 39,2 2510 209,5 0,03260 511 88,3

1) The DC resistance is calculated from the mean value 29,050 nm (59,4%

IACS) of the individual strand.

2) The continuous current capacity is calculated for a conductor temperature of

+50 C at an ambient temperature of +30C, frequency 50 Hz, resistivity

temperature coefficient 0,0039, emission factor 0,7, absorption coefficient

0,9, wind velocity 0,6 m/s and at a latitude of 60 (N).

3) The short circuit current is the calculated effective value with duration of

one second at an initial conductor temperature of +50C and a final

temperature of +200C.

14 (15)

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

4.11 FIGURES

FIGURE 1 STEEL CONDUCTORS

7 strands 19 strands

FIGURE 2 ALL ALUMINIUM (AAC), ALL ALUMINIUM ALLOY (AAAC)

CONDUCTORS

61 strands

FIGURE 3 ALUMINIUM CONDUCTORS STEEL REINFORCED (ACSR)

Figure 3a Phase conductors

54/7 strands 54/19 strands

Figure 3b Shield conductors

12/7 strands 32/7 strands

15 (15)

Svenska Kraftnt 08-07-09 TR 5-04E rev A

Tekniska Riktlinjer

FIGURE 4 CONDUCTORS, GREASING

Case 1 Case 4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Iec 62271-200 PDFDocument8 pagesIec 62271-200 PDFMutharasan VishnuNo ratings yet

- Cameron Compressor OperationDocument13 pagesCameron Compressor Operationfructora0% (1)

- Fundamentals of Electrical DistributionDocument30 pagesFundamentals of Electrical DistributionPradeep Kumar MaraptlaNo ratings yet

- MCB S For Photovoltaic ApplicationsDocument2 pagesMCB S For Photovoltaic ApplicationsSumer LandNo ratings yet

- Renewables Standards v1 November 2013Document71 pagesRenewables Standards v1 November 2013Sumer LandNo ratings yet

- The FIDIC Suite of ContractsDocument9 pagesThe FIDIC Suite of ContractsRaluca CazanescuNo ratings yet

- HabiTEQ Installers Catalogue Final VersionDocument11 pagesHabiTEQ Installers Catalogue Final VersionSumer LandNo ratings yet

- Relay Selection GuideDocument39 pagesRelay Selection GuideSumer LandNo ratings yet

- Tender On BGJ 2009 10Document51 pagesTender On BGJ 2009 10Sumer LandNo ratings yet

- Overvoltage ProtectionDocument45 pagesOvervoltage Protectionsorry2qazNo ratings yet

- 21 Safety Rules For Working With Electrical EquipmentDocument6 pages21 Safety Rules For Working With Electrical EquipmentSumer LandNo ratings yet

- Procedures For LV CabletestingDocument5 pagesProcedures For LV CabletestingSumer LandNo ratings yet

- Appendix L Construction Method Statement PDFDocument15 pagesAppendix L Construction Method Statement PDFSumer LandNo ratings yet

- TECHNICAL GUIDELINES FOR 400 kV AND 220 kV OH-LINESDocument0 pagesTECHNICAL GUIDELINES FOR 400 kV AND 220 kV OH-LINESSumer LandNo ratings yet

- Ah 000639640Document2 pagesAh 000639640Sumer LandNo ratings yet

- Generalni Katalog GENERAL ELECTRIC - English - Ed02Document530 pagesGeneralni Katalog GENERAL ELECTRIC - English - Ed02Valentina MiljkovicNo ratings yet

- Record Plus - Numerical IndexDocument15 pagesRecord Plus - Numerical IndexSumer LandNo ratings yet

- DC Hi-Pot Testing Rev 1.pdDocument6 pagesDC Hi-Pot Testing Rev 1.pdSumer LandNo ratings yet

- AAC Aluminum Conductors.10-11Document2 pagesAAC Aluminum Conductors.10-11Sumer LandNo ratings yet

- Cable Testing An Overview Low ResDocument28 pagesCable Testing An Overview Low ResSumer LandNo ratings yet

- AAC Aluminum Conductors.10-11Document2 pagesAAC Aluminum Conductors.10-11Sumer LandNo ratings yet

- Generalni Katalog GENERAL ELECTRIC - English - Ed02Document530 pagesGeneralni Katalog GENERAL ELECTRIC - English - Ed02Valentina MiljkovicNo ratings yet

- DC Hi-Pot Testing Rev 1.pdDocument6 pagesDC Hi-Pot Testing Rev 1.pdSumer LandNo ratings yet

- 16 Personal Protective Grounding For Electric Power Facilities and PowerDocument89 pages16 Personal Protective Grounding For Electric Power Facilities and PowerSumer LandNo ratings yet

- GE Multilin Relay Selection GuideDocument40 pagesGE Multilin Relay Selection GuideSaravanan Natarajan100% (1)

- Fundamentals of Electrical DistributionDocument30 pagesFundamentals of Electrical DistributionPradeep Kumar MaraptlaNo ratings yet

- Bus Duct ErectionDocument11 pagesBus Duct ErectionkarthiknmanuNo ratings yet

- Petronas Uc-Cm-Userguide Gold v1 1Document40 pagesPetronas Uc-Cm-Userguide Gold v1 1Sumer LandNo ratings yet

- Method Statement Pipeline - Iccp InstallationDocument10 pagesMethod Statement Pipeline - Iccp InstallationSumer LandNo ratings yet

- Ts105 Test Standard Uground Cable NetworksDocument17 pagesTs105 Test Standard Uground Cable NetworksSumer Land100% (1)

- Bend Stretch Forming AluminumDocument8 pagesBend Stretch Forming AluminumMomoNo ratings yet

- MTJ MRJ Series Maintenance and Assembly InstructionsDocument35 pagesMTJ MRJ Series Maintenance and Assembly Instructionsa04205No ratings yet

- Acsr Din en 50182 PDFDocument1 pageAcsr Din en 50182 PDFAdim CoMed ProNo ratings yet

- III. Vacuum Pumps III. Vacuum Pumps: MechanismDocument16 pagesIII. Vacuum Pumps III. Vacuum Pumps: Mechanismnsr2tNo ratings yet

- Reducing Fabric Waste in Cutting Through Marker EfficiencyDocument43 pagesReducing Fabric Waste in Cutting Through Marker EfficiencyMênfës Mgb GèdēchãNo ratings yet

- Reliable Bulletin 741 Rev. A Wet Pilot Line Single Interlock SystemDocument16 pagesReliable Bulletin 741 Rev. A Wet Pilot Line Single Interlock SystemDana Guerrero100% (1)

- 2kw Installation ManualDocument22 pages2kw Installation ManualGratian RealNo ratings yet

- Editable List of Procedure+Document5 pagesEditable List of Procedure+Koya ThangalNo ratings yet

- Fluid Flow OperationDocument2 pagesFluid Flow OperationAshitNo ratings yet

- Worldwide Consultant in Biomass and Waste Projects (EN-V1.1-2019.12.19)Document16 pagesWorldwide Consultant in Biomass and Waste Projects (EN-V1.1-2019.12.19)Kay MohanNo ratings yet

- FEC Problem Set 1Document4 pagesFEC Problem Set 1Buğra MertolNo ratings yet

- CE F426-Geosynthetics and Reinforced Soil Structure-AnasuaDocument3 pagesCE F426-Geosynthetics and Reinforced Soil Structure-AnasuaAbhijeet RoyNo ratings yet

- 11.4 Welding Information Welding Information: Elements of A Typical Weld SymbolDocument1 page11.4 Welding Information Welding Information: Elements of A Typical Weld SymbolLeomarini100% (1)

- O6 Tool Steel: Chemical AnalysisDocument3 pagesO6 Tool Steel: Chemical AnalysischandraNo ratings yet

- Assignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingDocument7 pagesAssignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingAnkesh KapilNo ratings yet

- Social Icons: C-80 GradeDocument3 pagesSocial Icons: C-80 GradeEdward OropezaNo ratings yet

- BM2312 004Document30 pagesBM2312 004julia.sacco.20No ratings yet

- Spitzer Dry Bulk Tankers GuideDocument31 pagesSpitzer Dry Bulk Tankers GuidealiNo ratings yet

- Harmony Xb4 Xb4bd25Document4 pagesHarmony Xb4 Xb4bd25Ismael AhmedNo ratings yet

- D10R PDFDocument35 pagesD10R PDFluishvanegas100% (1)

- Enhanced Oil Recovery (EOR) - Schlumberger GlossaryDocument66 pagesEnhanced Oil Recovery (EOR) - Schlumberger GlossaryDiana La CruzNo ratings yet

- OxoneDocument2 pagesOxoneSha Hriyar HNo ratings yet

- DATABASE Kawasan Industri PolugadungDocument20 pagesDATABASE Kawasan Industri PolugadungRina Rachman100% (1)

- Pruthwiraj PPT On Low Cost HousingDocument14 pagesPruthwiraj PPT On Low Cost HousingpruthwipaikarayNo ratings yet

- Gravimetry Sample ProbDocument1 pageGravimetry Sample ProbRizza Mae RaferNo ratings yet

- FF8.5GX Universal Compressor R134a 115V 60Hz: GeneralDocument2 pagesFF8.5GX Universal Compressor R134a 115V 60Hz: GeneralWin FloresNo ratings yet

- 16 Safety Catalog 101Document18 pages16 Safety Catalog 101bernardardi1No ratings yet

- ASTM C192 (Group 7)Document38 pagesASTM C192 (Group 7)Raine Fair Haven AiNo ratings yet