Professional Documents

Culture Documents

Jindal Hydrogen Gas Dryer

Uploaded by

Lakshmi NarayanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jindal Hydrogen Gas Dryer

Uploaded by

Lakshmi NarayanCopyright:

Available Formats

Refrigerated Hydrogen Gas Dryer

We offer qualitative refrigerated hydrogen gas drier that is immensely used to assure low humidity level inside the generators. Our hydrogen gas drier is also used to increase the prevention process of corrosion and stress in rolor retaining ring. Manufactured from the premium quality raw materials, our refrigerated air dryers are highly durable and reliable. Refrigerated hydrogen gas drier provided by us is highly efficient, thus needs less energy and provides excellent performance. Refrigerated hydrogen gas drier is very easy to use and install. We are well renowned as one of the overriding refrigerated hydrogen gas drier manufacturers, based in India. Application To ensure very low humidity levels inside the generator and improvement in instalation also enhances prevention of stress and corrosion rolor retaining. Operation The system comprises two heat exchangers.the hydrogen shell and lube type called precooler in which temperature of hydrogen reduces around 25 to 30oC the cooled hydrogen now enters the second heat exchanger named evaporator further cooling up to 0oC to 3oC is accomplished in this h.e. the set dew point is adjustable.the cooling coil inside the evaporator have propelled through a refrigeration system due to low temperature in evaporator the moisture in the H 2 condeneses and converts in water form the water is collected in a well protected condensate collector and can be drained out when desired leaving the evaporater H 2 again travels to pre cooler where it has dual functions of cooling the input H 2 and outgoing leaving dry H 2 is again rises to a safe tem H 2 of around 25oC to 40oC before entering the generator to reduce stress on the system. Advantage of Jindal Refrigerated Driers Over Conventional Driers

Highly efficient in taking away moisture from gas. Only 8 Hrs. per day (24 Hrs.) service is sufficient No need to replace or regenerate silica gel Energy efficient and have great saving in energy consumption

Refrigerated Type Hydrogen Drier Specifications. Model 200101 Hydrogen Gas Flow Rate Temperature of H2 Gas at intel Temperature of H2Gas at outlet Pressure of H2Gas at inlet Thermal Load Design Pressure Flange Connection Dew point at evaporator Power point at evaporator Designed for maximum ambient Temperature Dimensions of the system Total pressure drop in Drier H2Circuit Power consumption Colour : Shade Welds : All Butt welds All fillet welds 40Nm 3/Hr 60oC 30oC 4Kg/cm2C 130 kgal/hr(Min) 10kg./cm2C NB 50 3o to 5o C(Adjustable) 415VAC 50H 2 -3c 50oC As per DRG No. 200101Jel/HD /99/06 8MM wg. 2KVA (Max ) 280(IS - 5) 100% X-Ray Tested. 100% DPT Tested

You might also like

- Advantages of hydrogen cooling in large generatorsDocument5 pagesAdvantages of hydrogen cooling in large generatorsUsMan ZaFarNo ratings yet

- Generator Construction 210 MWDocument33 pagesGenerator Construction 210 MWPradeep_Vashist100% (1)

- Procedure of Deaerator Charging in Power Plant - ASKPOWERPLANTDocument16 pagesProcedure of Deaerator Charging in Power Plant - ASKPOWERPLANTOtuagaNo ratings yet

- WHRB SopDocument13 pagesWHRB SopShambhu Mehta100% (2)

- 600MW Final Scheme Tracing Book - by JIPT PDFDocument123 pages600MW Final Scheme Tracing Book - by JIPT PDFAnudeep ReddyNo ratings yet

- (Triveni) Rajashri Power 10 MW For ACC byDocument32 pages(Triveni) Rajashri Power 10 MW For ACC bynogeshwar50% (2)

- 210 MW Seal Oil SystemDocument6 pages210 MW Seal Oil Systemmag_ktps20021520No ratings yet

- 20mw Operation ManualDocument54 pages20mw Operation Manualrenjithkvpgdca27494% (18)

- 2.3 Principle of Turbine Governing CompressedDocument54 pages2.3 Principle of Turbine Governing Compressedabhaymehta67100% (1)

- Boiler Design and Operation ParametersDocument88 pagesBoiler Design and Operation ParametersNavneet SinghNo ratings yet

- ESP Charging ProcedureDocument3 pagesESP Charging ProcedurevikramshounNo ratings yet

- SADC System ExplainedDocument8 pagesSADC System ExplainedpallavishraddhaNo ratings yet

- Design & Constructional Features of Turbogenerators: Kapil Narula Sr. Engr./EME HEEP, BHEL HardwarDocument92 pagesDesign & Constructional Features of Turbogenerators: Kapil Narula Sr. Engr./EME HEEP, BHEL HardwarAmit BiswasNo ratings yet

- SOP for ACW system operationDocument7 pagesSOP for ACW system operationsambhu100% (1)

- Electro Static Precipitator: Operation and MaintenanceDocument33 pagesElectro Static Precipitator: Operation and MaintenancePrashant Kumar mishraNo ratings yet

- 210 MW Generator Operating Instructions Stage-2Document9 pages210 MW Generator Operating Instructions Stage-2raghavendran raghuNo ratings yet

- Hydraulic turning gear operation and logicsDocument5 pagesHydraulic turning gear operation and logicsSai Swaroop50% (2)

- Generator ChemisDocument86 pagesGenerator ChemisVasudevan Krishnan100% (6)

- Emergency Procedure For Total Station Power FailureDocument4 pagesEmergency Procedure For Total Station Power FailureSelva Manian100% (1)

- Turbogenerators Gyanendra Sharma NPTI DelhiDocument36 pagesTurbogenerators Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Design & Construction Features of TurbogeneratorsDocument92 pagesDesign & Construction Features of TurbogeneratorsArpit Kumar100% (1)

- Turbogenerator Design and Construction Gyanendra Sharma NPTI DelhiDocument92 pagesTurbogenerator Design and Construction Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Prsentation: Ball and Tube MillDocument39 pagesPrsentation: Ball and Tube MillmkoelrealNo ratings yet

- Horn Drop TestDocument5 pagesHorn Drop Testptiwari2808100% (1)

- Testing of TurbogeneratorDocument77 pagesTesting of Turbogeneratorsaitejajosyula100% (3)

- SteamTurbineGenerator Datasheet 210MWDocument8 pagesSteamTurbineGenerator Datasheet 210MWParantap RahaNo ratings yet

- DehDocument34 pagesDehAnand Swami100% (1)

- Boiler ProblemsDocument59 pagesBoiler ProblemsDharmendra BurraNo ratings yet

- Rgmo FgmoDocument24 pagesRgmo FgmoVishal Kumar Laddha53% (15)

- Spiral Wall System PDFDocument22 pagesSpiral Wall System PDFSomdeb Banerjee100% (1)

- Boiler Turbine Generator: Unit Trip Report-Draft STPP, 2X600 MWDocument5 pagesBoiler Turbine Generator: Unit Trip Report-Draft STPP, 2X600 MWVishal Kumar Laddha100% (1)

- Relocating Emergency DPR Valve Overcomes High Head IssueDocument4 pagesRelocating Emergency DPR Valve Overcomes High Head IssueAdnan Habib Khan100% (2)

- Difference Between AFBC and CFBCDocument3 pagesDifference Between AFBC and CFBCAamirMalik86% (7)

- Lube Oil Cooler Change OverDocument5 pagesLube Oil Cooler Change Oversambhu100% (1)

- TURBINE Logics and Interlocks PDFDocument62 pagesTURBINE Logics and Interlocks PDFLakshmi Narayan100% (1)

- Micro Oil Ignition System (MOIS) : Minimising Fuel Oil ConsumptionDocument19 pagesMicro Oil Ignition System (MOIS) : Minimising Fuel Oil Consumptionravi singh100% (1)

- Features & Working of Bowl MillsDocument64 pagesFeatures & Working of Bowl Millssatendra_gangwarNo ratings yet

- Operation Manual: Lqs-Iicsa Refrigerating Hydrogen DryerDocument35 pagesOperation Manual: Lqs-Iicsa Refrigerating Hydrogen Dryerdsinghrpd100% (1)

- Cold startup procedure for 250 MW coal power plantDocument2 pagesCold startup procedure for 250 MW coal power plantPranay Patel100% (5)

- INTERLOCK PROTECTION DIARY-tur1Document153 pagesINTERLOCK PROTECTION DIARY-tur1Amit Biswas50% (2)

- Back Pressure TurbinesDocument4 pagesBack Pressure TurbinesSharath Kota100% (1)

- CMC NTPC UnchaharDocument8 pagesCMC NTPC UnchaharDino100% (1)

- DMCW System in Thermal Power PlantDocument2 pagesDMCW System in Thermal Power PlantKomma Ramesh88% (8)

- Unit Lightup Synchronisation & ShutdownDocument42 pagesUnit Lightup Synchronisation & ShutdownAshvani ShuklaNo ratings yet

- 10 SOP of CEP PumpDocument4 pages10 SOP of CEP Pumppriyanka singhNo ratings yet

- Boiler Turbine Protection,,,EHC, Hydraullic-2Document21 pagesBoiler Turbine Protection,,,EHC, Hydraullic-2Balvir GangarNo ratings yet

- TDBFP Writeup KorbaDocument15 pagesTDBFP Writeup Korbamkgchem100% (2)

- Chapter 14 Governing SystemDocument7 pagesChapter 14 Governing Systemsambhu100% (1)

- Stage 2 TDBFPDocument56 pagesStage 2 TDBFPvijaykrishnatenneti100% (2)

- Tech Diary of Turbine & AuxiliaryDocument70 pagesTech Diary of Turbine & AuxiliarysambhuNo ratings yet

- Advanced Control Systems For ESP 3Document97 pagesAdvanced Control Systems For ESP 3Sam0% (1)

- An Overview of CFBC Boiler: By-Mukesh JhaDocument88 pagesAn Overview of CFBC Boiler: By-Mukesh Jhabalaji krishnan100% (2)

- PocketDiary SantaldihDocument198 pagesPocketDiary SantaldihJoydev GangulyNo ratings yet

- Hydrogen Gas Dryer IndiaDocument2 pagesHydrogen Gas Dryer IndiatpplantNo ratings yet

- A Flooded Screw ChillerDocument29 pagesA Flooded Screw ChillerDiêm Công Việt100% (3)

- ChillerDocument24 pagesChillerLaboratório Ouro DieselNo ratings yet

- Hydrogen Cooling of Electrical GeneratorsDocument80 pagesHydrogen Cooling of Electrical GeneratorsFahad Khalil75% (4)

- Refrigration Saving HeatDocument39 pagesRefrigration Saving HeatTanviNo ratings yet

- 12 Air Cooled Screw Chiller PresentationDocument48 pages12 Air Cooled Screw Chiller PresentationLeed EN100% (3)

- Centifugal+Chiller+ (1000+ +10000+kW) MideaDocument35 pagesCentifugal+Chiller+ (1000+ +10000+kW) MideaevrimkNo ratings yet

- 2011AppliedPhysicsBInvestigationofunburnedcarbonparticlesinflyashbymeansoflaserlightscatteringDocument10 pages2011AppliedPhysicsBInvestigationofunburnedcarbonparticlesinflyashbymeansoflaserlightscatteringLakshmi NarayanNo ratings yet

- DSH CatalogueDocument20 pagesDSH Catalogueनिखिल बायवारNo ratings yet

- Guidelines For House Load OperationDocument5 pagesGuidelines For House Load OperationLakshmi NarayanNo ratings yet

- Syllabus Business CommerceDocument101 pagesSyllabus Business CommerceLakshmi Narayan100% (1)

- BYJUS IAS Explained 3 Farm LawsDocument18 pagesBYJUS IAS Explained 3 Farm LawsLakshmi NarayanNo ratings yet

- CRHsteamforsootblowing PDFDocument9 pagesCRHsteamforsootblowing PDFUdhayakumar VenkataramanNo ratings yet

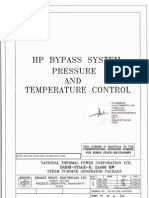

- HPBP Writeup Dadri-IIDocument17 pagesHPBP Writeup Dadri-IIrajan_me083No ratings yet

- Brochure Coal Based Power Plants November2014Document4 pagesBrochure Coal Based Power Plants November2014RajnirathoreNo ratings yet

- Revised Boiler Start Up Procedure For 500 MW BHEL Make UnitsDocument22 pagesRevised Boiler Start Up Procedure For 500 MW BHEL Make Unitsnetygen1No ratings yet

- 500mwboilermahagenco 140115124304 Phpapp02Document38 pages500mwboilermahagenco 140115124304 Phpapp02Lakshmi NarayanNo ratings yet

- Power Plant and Calculations: Danfoss High Pressure PumpsDocument6 pagesPower Plant and Calculations: Danfoss High Pressure PumpsLakshmi NarayanNo ratings yet

- Syllabus Business CommerceDocument101 pagesSyllabus Business CommerceLakshmi Narayan100% (1)

- 500MW Steam Turbine Erection ManualDocument127 pages500MW Steam Turbine Erection ManualRajagopal GanapathyNo ratings yet

- Boiler ControlsDocument27 pagesBoiler ControlsMY NAME IS NEERAJ..:):)No ratings yet

- Heat Treatment ManualDocument29 pagesHeat Treatment ManualAlexis Williams100% (1)

- WELD REPAIR PROCEDURES FOR BOILER COMPONENTSDocument165 pagesWELD REPAIR PROCEDURES FOR BOILER COMPONENTSLakshmi Narayan100% (2)

- CERC Deviation Settlement Mechanism and Related Matters Regulations 2014Document33 pagesCERC Deviation Settlement Mechanism and Related Matters Regulations 2014Lakshmi NarayanNo ratings yet

- BHEL Piping Centre Chennai Pipe ScheduleDocument1 pageBHEL Piping Centre Chennai Pipe ScheduleLakshmi NarayanNo ratings yet

- 07 - Combustion - Optimisation PDFDocument90 pages07 - Combustion - Optimisation PDFLakshmi NarayanNo ratings yet

- Cold StartupDocument12 pagesCold StartupLakshmi NarayanNo ratings yet

- AziDocument2 pagesAziReginNo ratings yet

- Flexible Operation in Coal Based Plant: By-SNEHESH BANERJEE, Operation Services, CCDocument27 pagesFlexible Operation in Coal Based Plant: By-SNEHESH BANERJEE, Operation Services, CCLakshmi NarayanNo ratings yet

- CRHsteamforsootblowing PDFDocument9 pagesCRHsteamforsootblowing PDFUdhayakumar VenkataramanNo ratings yet

- 06 - Water - Tech - Revision - PrintDocument58 pages06 - Water - Tech - Revision - PrintLakshmi NarayanNo ratings yet

- 551 PDFDocument2 pages551 PDFindiaNo ratings yet

- Boiler Fuel Firing System Combustion GuideDocument65 pagesBoiler Fuel Firing System Combustion GuideLakshmi NarayanNo ratings yet

- 500MW Turbine O&M Manual Part#1of3Document170 pages500MW Turbine O&M Manual Part#1of3Lakshmi Narayan100% (1)

- 07 - STLD-Final PDFDocument35 pages07 - STLD-Final PDFLakshmi Narayan0% (1)

- 02 - BTF - Customer - TRG - 230911 PDFDocument110 pages02 - BTF - Customer - TRG - 230911 PDFLakshmi Narayan100% (2)

- Coal Ash Erosion Protection Measures Impact Tube TemperaturesDocument12 pagesCoal Ash Erosion Protection Measures Impact Tube TemperaturesLakshmi NarayanNo ratings yet

- Air Quality Guidelines For EuropeDocument288 pagesAir Quality Guidelines For EuropeAlex OliveiraNo ratings yet

- Failure Analysis and PreventionDocument76 pagesFailure Analysis and PreventionDome Stoi0% (1)

- Introductory Chemistry Atoms First 5th Edition Russo Solutions Manual 1Document10 pagesIntroductory Chemistry Atoms First 5th Edition Russo Solutions Manual 1seanjacksonkwzgnbxift100% (28)

- Heat Transfer in Fire Tube Boiler Software SumulationDocument7 pagesHeat Transfer in Fire Tube Boiler Software SumulationLiam Moylan50% (2)

- Trimelitic AcidDocument151 pagesTrimelitic AcidTrimerMixNo ratings yet

- Newlands Law of Octaves Periodic TableDocument5 pagesNewlands Law of Octaves Periodic TablePaarth Saxena X-B RNNo ratings yet

- 21st Century General Chemistry 1Document382 pages21st Century General Chemistry 1Sreedevi Krishnakumar100% (1)

- PREMIUM RELEASE CTG. FOR INDUSTRIAL APPLICATIONSDocument2 pagesPREMIUM RELEASE CTG. FOR INDUSTRIAL APPLICATIONSlucas amorimNo ratings yet

- AMIE Material Science Engineering Notes PDFDocument59 pagesAMIE Material Science Engineering Notes PDFSrimannarayana Nandam100% (4)

- Manufacture of Acrylic Acid Project ReportDocument47 pagesManufacture of Acrylic Acid Project ReportHomesick TutorsNo ratings yet

- x40602 - Concrete Technology PDFDocument12 pagesx40602 - Concrete Technology PDFJay PatelNo ratings yet

- IL-6 Testing ProtocolDocument7 pagesIL-6 Testing ProtocolUMMID WashimNo ratings yet

- Multi-Adaptable Night Tactical Imaging System (MANTIS) GuideDocument2 pagesMulti-Adaptable Night Tactical Imaging System (MANTIS) Guidegoma12345100% (1)

- Revision Test 1-KPT and Separation TechniquesDocument18 pagesRevision Test 1-KPT and Separation TechniquesFangru CaoNo ratings yet

- GGR240L Use and Care ManualDocument2 pagesGGR240L Use and Care ManualBobDewilleNo ratings yet

- Chemical EquilibriumDocument2 pagesChemical EquilibriumDaniel Loh100% (1)

- Foodpharma MaterialoverviewpdfDocument2 pagesFoodpharma MaterialoverviewpdfJai BhandariNo ratings yet

- C C CCCCCCCCCCCC C CDocument62 pagesC C CCCCCCCCCCCC C CGaurav VashishtNo ratings yet

- Alpha Bisabolol Natural (C) LeafletDocument2 pagesAlpha Bisabolol Natural (C) Leafletjcamacho95No ratings yet

- Koopmans' Theorem and Semiempirical Molecular Orbital CalculationsDocument14 pagesKoopmans' Theorem and Semiempirical Molecular Orbital CalculationsRSLNo ratings yet

- BSC 1st Year Notes ChemistryDocument33 pagesBSC 1st Year Notes ChemistrySandipan SahaNo ratings yet

- 2-Mathematical Modeling and Simulation of Hydrotreating Reactors Cocurrent Versus Countercurrent Operations - Art5Document14 pages2-Mathematical Modeling and Simulation of Hydrotreating Reactors Cocurrent Versus Countercurrent Operations - Art5Vicente SosaNo ratings yet

- Chemistry Investigatory ProjectDocument18 pagesChemistry Investigatory ProjectDinesh Singh Choudhary0% (1)

- 3) Cold StorageDocument5 pages3) Cold StorageharshNo ratings yet

- Daily Lesson PlanDocument8 pagesDaily Lesson PlanTamie P. Galindo100% (1)

- CHAPTER 1 PERIODICITYDocument73 pagesCHAPTER 1 PERIODICITYMuhammad ImranNo ratings yet

- 6 Warna Water Based Inkjet InkDocument21 pages6 Warna Water Based Inkjet InksabunbeningNo ratings yet

- Catálogo de Gaviones Tejidos PRODAC (Inglés) PDFDocument9 pagesCatálogo de Gaviones Tejidos PRODAC (Inglés) PDFpapolamNo ratings yet

- Light Fastness of Blue PigmentDocument7 pagesLight Fastness of Blue PigmentShaik DawoodNo ratings yet