Professional Documents

Culture Documents

Assignment 1faef

Uploaded by

Sri RamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assignment 1faef

Uploaded by

Sri RamCopyright:

Available Formats

Decision Making Under Certainty, PGP 2013-14 Problem Set 1, Due 11:59 pm, Friday, December 06, 2013

Wherever asked to construct a Mathematical Programming Model, clearly define the indices, parameters and decision variables. Describe in words what is implied by your objective function and each of the constraints. Also, clearly report the final solution obtained from the solver. Upload all your submissions (Solution Presentation in word and Implementation in Excel) as a zipped folder on moodle. Name the folder as MD_A1_<section>_<group no.>.

1. A company manufactures mechanical heart valves from the heart valves of pigs. Different heart operations require valves of different sizes. The company purchases pig valves from three different suppliers. The cost and size mix of the valves purchased from each supplier are given in the Table below. Each month, the company places an order with each supplier. At least 500 large, 300 medium, and 300 small valves must be purchased each month. Because of the limited availability of pig valves, at most 500 valves per month can be purchased from each supplier. Construct a Linear Programming Model and solve it using Solver to help the company acquire the required valves at a minimum cost.

Supplier 1 Supplier 2 Supplier 3

Cost/valve % small % medium % large $20 40 40 20 $16 30 35 35 $12 20 20 60

2. A paper recycling plant processes box board, tissue paper, newsprint, and book paper into pulp that can be used to produce three grades of recycled paper. The prices per ton and the pulp contents of the four inputs are shown in the Table below. Two methods, de-inking and asphalt dispersion, can be used to process the four inputs into pulp. It costs $20 to de-ink a ton of any input. The process of de-inking removes 10% of the inputs pulp, leaving 90% of the original pulp. It costs $15 to apply asphalt dispersion to a ton of material. The asphalt dispersion process removes 20% of the inputs pulp. At most, 3000 tons of input can be run through the asphalt dispersion process or the de-inking process. Grade 1 paper can be produced only with newsprint or book paper pulp; grade 2 paper only with book paper, tissue paper, or box board pulp; grade 3 paper only with newsprint, tissue paper, or box board pulp. To meet its current demands, the company needs 500 tons of pulp for grade 1 paper, 500 tons of pulp for grade 2 paper, and 600 tons of pulp for grade 3 paper. Construct a Linear Programming Model and solve it using Solver to determine how to minimize the cost of meeting the demands for pulp.

Cost per ton Pulp content

Box board $5 15%

Tissue paper $6 20%

Newsprint $8 30%

Book paper $10 40%

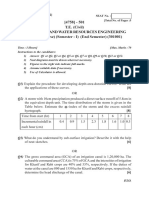

3. A company has two factories, one at Liverpool and one at Brighton. In addition it has four depots with storage facilities at Newcastle, Brimingham, London and Exeter. The company sells its product to six customers C1, C2, ..., C6. Customers can be supplied either from a depot or from the factory direct (see figure below). The distribution costs (which are borne by the company) are known; they are given in the table below (in per ton delivered). Each factory has a monthly capacity given below that cannot be exceeded: Liverpool 150000 tons Brighton 200000 tons

New Castle

C1 C2

Liverpool

Brimingha m

C3 C4 C5

London

Brighton

Exeter

C6

Factories

Depots Supplier Newcastle Brmingham Depot Depot

Customers

Supplied to Depots Newcastle 0.5 -Brmingham 0.5 0.3 London 1.0 0.5 Exeter 0.2 0.2 Customers C1 1.0 2.0 -1.0 --C2 --1.5 0.5 1.5 -C3 1.5 -0.5 0.5 2.0 0.2 C4 2.0 -1.5 1.0 -1.5 C5 ---0.5 0.5 0.5 C6 1.0 -1.0 -1.5 1.5 A dash indicates the impossibility of certain suppliers for certain depots or customers.

Liverpool Factory

Brighton Factory

London Depot

Exeter Depot

Each depot has a maximum monthly throughput given below that cannot be exceeded: Newcastle 70000 tons Birmingham 50000 tons London 100000 tons Exeter 40000 tons Each customer has a monthly requirement given below that must be met: C1 50000 tons C2 10000 tons C3 40000 tons C4 35000 tons C5 60000 tons C6 20000 tons The company would like to determine the distribution pattern that would minimize overall cost. Report your Linear Programming Model and the resulting solution using Solver.

You might also like

- Transporatation Problems ExercisesDocument38 pagesTransporatation Problems ExercisesAshish Dhote100% (1)

- 1 Simplex Method: Maximization ProblemDocument10 pages1 Simplex Method: Maximization ProblemSayed AlhussainiNo ratings yet

- Advanced Road Design For AutocadDocument35 pagesAdvanced Road Design For AutocadValéry MbraNo ratings yet

- 3d ConcreteDocument20 pages3d ConcreteManu S NadesanNo ratings yet

- Transcad Notes For Nodes&CentroidsDocument8 pagesTranscad Notes For Nodes&CentroidsIvan SilvaNo ratings yet

- School of Engineering Wireless Communication Lab 1: Wireless LAN (WLAN)Document7 pagesSchool of Engineering Wireless Communication Lab 1: Wireless LAN (WLAN)Liecell CabalesNo ratings yet

- Handout 6901 CI6901-L AU 2012-OgdenDocument28 pagesHandout 6901 CI6901-L AU 2012-OgdenericfgNo ratings yet

- Ssas MDX Query Interview Questions and AnswersDocument8 pagesSsas MDX Query Interview Questions and AnswersSai KumarNo ratings yet

- 9 Hma KeyDocument864 pages9 Hma KeyPhùng Văn Thường100% (1)

- Concrete Mix DesignDocument20 pagesConcrete Mix DesignM Pabire AllanNo ratings yet

- Design Guidelines FOR Accessible Bus Stops: BC Transit Municipal Systems ProgramDocument29 pagesDesign Guidelines FOR Accessible Bus Stops: BC Transit Municipal Systems ProgramAndresNo ratings yet

- AirForceBinPacking PDFDocument135 pagesAirForceBinPacking PDFgouthamNo ratings yet

- Conprint 3DDocument30 pagesConprint 3DManu S NadesanNo ratings yet

- Martello, S., Pisinger, D., & Vigo, D. (2000) - The Three-Dimensional Bin Packing ProblemDocument13 pagesMartello, S., Pisinger, D., & Vigo, D. (2000) - The Three-Dimensional Bin Packing Problemomega uniqueNo ratings yet

- Zeiss Gear Pro 2016 Release Infomation enDocument56 pagesZeiss Gear Pro 2016 Release Infomation enyraju88100% (1)

- CPCCBC4012 Student Assessment Task 1Document39 pagesCPCCBC4012 Student Assessment Task 1SIMRAN SINGHNo ratings yet

- Human Induced Vibrations On Footbridges: Application and Comparison of Pedestrian Load ModelsDocument140 pagesHuman Induced Vibrations On Footbridges: Application and Comparison of Pedestrian Load ModelsktricoteNo ratings yet

- Gallery of Named Graphs: With Tkz-Berge - Sty by Alain MatthesDocument104 pagesGallery of Named Graphs: With Tkz-Berge - Sty by Alain MatthesneoferneyNo ratings yet

- Wiley - Model Building in Mathematical Programming - 5ed 2013-292-Merged-3FINALSDocument4 pagesWiley - Model Building in Mathematical Programming - 5ed 2013-292-Merged-3FINALSRhoi FernandezNo ratings yet

- Optimal Distribution Patterns and Depot LocationsDocument4 pagesOptimal Distribution Patterns and Depot LocationsRhoi FernandezNo ratings yet

- r7410301 Operations ResearchDocument5 pagesr7410301 Operations ResearchsivabharathamurthyNo ratings yet

- 5 6314393805420232845 PDFDocument11 pages5 6314393805420232845 PDFTaruna BajajNo ratings yet

- Find Initial Basic Feasible Solutions (I) North - West Corner Method (Ii) Matrix Minima Method (Iii) Vogel's Approximation MethodDocument6 pagesFind Initial Basic Feasible Solutions (I) North - West Corner Method (Ii) Matrix Minima Method (Iii) Vogel's Approximation MethodAlem Abebe AryoNo ratings yet

- TextbooksDocument482 pagesTextbooksJuan PertuzNo ratings yet

- MRP, Jit, ErpDocument26 pagesMRP, Jit, ErpRupendra TripathiNo ratings yet

- RC 2 2015 16 Chapter 2 Example 2Document18 pagesRC 2 2015 16 Chapter 2 Example 2Abuye HD100% (1)

- Foundation Engineering II Tutorial For Exit Exam April, 2023Document126 pagesFoundation Engineering II Tutorial For Exit Exam April, 2023Estifanos SeidNo ratings yet

- FFODocument31 pagesFFOBhakti Mahbubani0% (1)

- Craft and AldepDocument29 pagesCraft and AldepdeekshithNo ratings yet

- Group 4: Answer Questions Number 1 To 6 Using The Given DataDocument4 pagesGroup 4: Answer Questions Number 1 To 6 Using The Given DataDame Chala100% (1)

- Sigma Modeling PDFDocument215 pagesSigma Modeling PDFYuri Gutierrez PerezNo ratings yet

- Acm FormatDocument2 pagesAcm FormatMico Ganzon0% (1)

- 100000Document76 pages100000Dandu ManNo ratings yet

- Using Dynamic MeshDocument34 pagesUsing Dynamic MeshIssah M. Al HamadNo ratings yet

- Exam2 Practice FEADocument5 pagesExam2 Practice FEAdrsarajiNo ratings yet

- MIT 2.810 Homework 9 Solutions Process Control ChartsDocument8 pagesMIT 2.810 Homework 9 Solutions Process Control ChartsWinpee SacilNo ratings yet

- Step by Step ALLPLAN 2019: Bridge and Civil EngineeringDocument68 pagesStep by Step ALLPLAN 2019: Bridge and Civil EngineeringMilan UljarevicNo ratings yet

- 2017 Winter Model Answer Paper PDFDocument12 pages2017 Winter Model Answer Paper PDFabdul rehman syed parvezNo ratings yet

- T.E Question Papers (2012 Pattern) May 2015Document297 pagesT.E Question Papers (2012 Pattern) May 2015Prof. Avinash MahaleNo ratings yet

- GeoprocessingDocument6 pagesGeoprocessingYusfaryan DisaputraNo ratings yet

- Design of RC ShellsDocument9 pagesDesign of RC Shellscacrcarlos100% (1)

- CLUSTER ANALYSIS DevashishDocument4 pagesCLUSTER ANALYSIS DevashishRaman KulkarniNo ratings yet

- Helical SpringDocument2 pagesHelical SpringMuhammad Usman0% (1)

- Linear Programming Graphical MethodDocument45 pagesLinear Programming Graphical Methodprasobh911No ratings yet

- V. S. B Engineering College CAD/CAM Lab ManualDocument121 pagesV. S. B Engineering College CAD/CAM Lab ManualvinodkumarNo ratings yet

- Two Dimensional CFD Analysis of A Hydraulic Gear PumpDocument18 pagesTwo Dimensional CFD Analysis of A Hydraulic Gear PumpsaravanaNo ratings yet

- Projectwise Design Integration: Connect Edition Update 3.2Document262 pagesProjectwise Design Integration: Connect Edition Update 3.2Daria GlagolNo ratings yet

- Config Cppudm Model Load Userssoft - DLL Gen Zone Bric Size 2 2 2 Model UserssoftDocument13 pagesConfig Cppudm Model Load Userssoft - DLL Gen Zone Bric Size 2 2 2 Model Userssoftdce_40No ratings yet

- Flac 3D 2Document2 pagesFlac 3D 2Robert AguedoNo ratings yet

- Introduction To Operations Research, 7th EditionDocument6 pagesIntroduction To Operations Research, 7th EditionelcboyNo ratings yet

- Mech6441 Project eDocument6 pagesMech6441 Project eDaniel100% (1)

- Bentley SewerCAD V8i SELECTseries 4 ReadmeDocument8 pagesBentley SewerCAD V8i SELECTseries 4 ReadmeDianna VillavicencioNo ratings yet

- The Yield-Line Method For Concrete Slabs: Automated at LastDocument11 pagesThe Yield-Line Method For Concrete Slabs: Automated at LastMudassar KhanNo ratings yet

- Packet 2 LP Problem Set 2Document11 pagesPacket 2 LP Problem Set 2Prince JainNo ratings yet

- Integer Programming QuestionsDocument15 pagesInteger Programming QuestionsAishwarya SrivastavaNo ratings yet

- Notes 1Document8 pagesNotes 1Mido ManNo ratings yet

- Assignment On RMG Related Industry in BangladeshDocument20 pagesAssignment On RMG Related Industry in BangladeshAsm Towheed100% (1)

- MEE437 Operations Research / Unit I Tutorial Problems / Darla / SMEC / FS2016-17Document9 pagesMEE437 Operations Research / Unit I Tutorial Problems / Darla / SMEC / FS2016-17Shyloo GsaNo ratings yet

- Optimize profit from manufacturing multiple products with resource constraintsDocument6 pagesOptimize profit from manufacturing multiple products with resource constraintsمحمد احمدNo ratings yet

- UECM2043, UECM2093 Operations Research Tutorial 1Document5 pagesUECM2043, UECM2093 Operations Research Tutorial 1kamun00% (2)

- LP: MAXIMIZE FARMER'S PROFIT GROWING POTATOES & PUMPKINSDocument48 pagesLP: MAXIMIZE FARMER'S PROFIT GROWING POTATOES & PUMPKINSkamran100% (1)

- Linear Programming - Problems - EN - 29-5-2012 PDFDocument50 pagesLinear Programming - Problems - EN - 29-5-2012 PDFVinkal PrasharNo ratings yet

- Distribution ExamplesDocument13 pagesDistribution ExamplesVishwanath VerenkarNo ratings yet

- Honda Activa TVS Jupiter Yamaha Alpha Suzuki Access Vespa LX Honda Dio Hero Maestro Gusto Rodeo RZ Duro DZ Flyte KineDocument1 pageHonda Activa TVS Jupiter Yamaha Alpha Suzuki Access Vespa LX Honda Dio Hero Maestro Gusto Rodeo RZ Duro DZ Flyte KineSri RamNo ratings yet

- Hypothesis 1aDocument2 pagesHypothesis 1aSri RamNo ratings yet

- AFM PSSDDocument3 pagesAFM PSSDSri RamNo ratings yet

- New 1Document1 pageNew 1Sri RamNo ratings yet

- Black Swaption ModadelDocument35 pagesBlack Swaption ModadelSri RamNo ratings yet

- RandomDocument1 pageRandomSri RamNo ratings yet

- v7.0 TutorialDocument24 pagesv7.0 TutorialSri RamNo ratings yet

- Sriram.N (13346) ERI Section BDocument1 pageSriram.N (13346) ERI Section BSri RamNo ratings yet

- Scooter Market Analysis and Customer Insights ReportDocument1 pageScooter Market Analysis and Customer Insights ReportSri RamNo ratings yet

- Not OK OK NP Patronizing Supportive CP Prescriptive Normative A Task Obsessive Problem Solving LP Bohemian Innovative AC Aggressive ConfrontingDocument2 pagesNot OK OK NP Patronizing Supportive CP Prescriptive Normative A Task Obsessive Problem Solving LP Bohemian Innovative AC Aggressive ConfrontingSri RamNo ratings yet

- (DONE) 2008 CF Quiz1 AnkitGarg SolutionDocument4 pages(DONE) 2008 CF Quiz1 AnkitGarg SolutionSri RamNo ratings yet

- zovi.comDocument12 pageszovi.comSanjeev GuptaNo ratings yet

- 2009Document1 page2009Sri RamNo ratings yet

- 1102013Document3 pages1102013Sri RamNo ratings yet

- Individual Assignment 2.xldasdsxDocument3 pagesIndividual Assignment 2.xldasdsxSri RamNo ratings yet

- Answers To Chapter 27 ProblemsDocument2 pagesAnswers To Chapter 27 ProblemsSri RamNo ratings yet

- Income and Balance Sheet AnalysisDocument3 pagesIncome and Balance Sheet AnalysisSri RamNo ratings yet

- APA Format GuideDocument4 pagesAPA Format GuidefilantropiNo ratings yet

- Topic That We Need HelpfdeafaafafDocument1 pageTopic That We Need HelpfdeafaafafSri RamNo ratings yet

- New Amazing Technologies 9824545498 MAYURDocument3 pagesNew Amazing Technologies 9824545498 MAYURSri RamNo ratings yet

- 05 ENeonDocument13 pages05 ENeonSri RamNo ratings yet

- NewsDocument6 pagesNewsSri RamNo ratings yet

- Outline Mep 2012 PDFDocument4 pagesOutline Mep 2012 PDFSri RamNo ratings yet

- ps1 Sol PDFDocument7 pagesps1 Sol PDFSri RamNo ratings yet

- ODY Final AssignDocument2 pagesODY Final AssignSri RamNo ratings yet

- SENECA PAPER COMPANY - DocxsDocument2 pagesSENECA PAPER COMPANY - DocxsSri RamNo ratings yet

- RampDocument60 pagesRampSri RamNo ratings yet

- Spoken Business Communication Instructor: Prof. Asha Kaul Academic Associate: Dr. Nameeta Chandra Section-D Sessions Session Name Date Day TimeDocument1 pageSpoken Business Communication Instructor: Prof. Asha Kaul Academic Associate: Dr. Nameeta Chandra Section-D Sessions Session Name Date Day TimeSri RamNo ratings yet

- SENECA PAPER COMPANY - DocxsDocument2 pagesSENECA PAPER COMPANY - DocxsSri RamNo ratings yet

- PMT Paper Reference(sDocument3 pagesPMT Paper Reference(sSHEHAN NITESHNo ratings yet

- Lesson Plan Template 20170831 Mathematical InductionDocument2 pagesLesson Plan Template 20170831 Mathematical Inductionapi-367457807100% (1)

- Answers pt1 PDFDocument33 pagesAnswers pt1 PDFJason SchellerNo ratings yet

- Two Samples (T-Test and Z-Test) - 2Document9 pagesTwo Samples (T-Test and Z-Test) - 2Letlie SemblanteNo ratings yet

- Mabalacat Math 9 Quarterly Exam Covers Exponents, RadicalsDocument3 pagesMabalacat Math 9 Quarterly Exam Covers Exponents, RadicalsMailyn ElacreNo ratings yet

- Comp Neuro Syl Lab Us 2018Document3 pagesComp Neuro Syl Lab Us 2018Andrej IlićNo ratings yet

- Coin Online Survey Questionaire Writing Implements: Engineering Data Analysis 1Document7 pagesCoin Online Survey Questionaire Writing Implements: Engineering Data Analysis 1Samantha SamanthaNo ratings yet

- IB Phys6 1 Planning TiDocument3 pagesIB Phys6 1 Planning TiAlper KarayelNo ratings yet

- Sampling PDFDocument187 pagesSampling PDFAhmed ShujaNo ratings yet

- 204160trigonometry Sheet - 02 - CrwillDocument11 pages204160trigonometry Sheet - 02 - Crwillkeshavrathore2939No ratings yet

- PaythonDocument45 pagesPaythonKajal KachrooNo ratings yet

- Adding and Subtracting Fractions WorksheetsDocument8 pagesAdding and Subtracting Fractions WorksheetsduhyanNo ratings yet

- Level Macmillan Mathematics Level 4 Aampb Cambridge PrimaryDocument11 pagesLevel Macmillan Mathematics Level 4 Aampb Cambridge Primaryroel.martinezNo ratings yet

- Cpa Review School of The Philippines Management Advisory Services Quantitative Methods TheoryDocument19 pagesCpa Review School of The Philippines Management Advisory Services Quantitative Methods TheoryAdèity TVNo ratings yet

- Quantitative TechniquesDocument62 pagesQuantitative TechniquesSteffanie GranadaNo ratings yet

- Demand System Estimation NewDocument13 pagesDemand System Estimation NewGaurav JakhuNo ratings yet

- MAS 408 - Discriminant AnalysisDocument7 pagesMAS 408 - Discriminant AnalysisDorin KatuuNo ratings yet

- DataGridView FAQDocument69 pagesDataGridView FAQyamanoblu100% (1)

- Kinetics of Hexamine Crystallization in Industrial ScaleDocument8 pagesKinetics of Hexamine Crystallization in Industrial ScaleAnggit Dwi WNo ratings yet

- Artificial Neural Networks: ReferencesDocument57 pagesArtificial Neural Networks: Referencesprathap394No ratings yet

- Anel Peralta Participation Activity 2Document7 pagesAnel Peralta Participation Activity 2Indira AlfonsoNo ratings yet

- 1st Periodical TestDocument1 page1st Periodical TestbjnatsNo ratings yet

- Technical Note 35Document13 pagesTechnical Note 35NatrajiNo ratings yet

- Good LabDocument23 pagesGood Labglories_No ratings yet

- 02page SageDocument140 pages02page SageSergio MontesNo ratings yet

- TQM Planning ToolsDocument6 pagesTQM Planning ToolsKaye Joy TendenciaNo ratings yet