Professional Documents

Culture Documents

1 8159-51CrV4

Uploaded by

black_absynthOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 8159-51CrV4

Uploaded by

black_absynthCopyright:

Available Formats

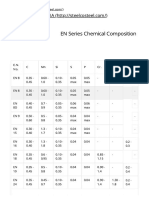

Quality 51CrV4

Technical card

According to standards EN 10083-3: 2006

Lucefin Group

Number 1.8159

Chemical composition

C% Si%

max

Mn% P%

max

S%

max

Cr%

V%

0,47-0,55 0,40 0,70-1,10 0,025 0,025 0,90-1,20 0,10-0,25

0.02 0.03 0.05 + 0.005 + 0.005 0.05 0.02

Product deviations are

allowed

Other elements non mentioned above should not be added to the steel, except for those necessary to casting

Cu + 10Sn < 0,60

Temperature C

Hot-forming Normalizing Quenching

on spring

Tempering Hot moulding

of springs

1050-850 870

air

850-880

oil or polymer

400-450

air

920-830

Soft annealing Isothermal

annealing

Natural state End quench

hardenability test

Pre-heating welding Stress-relieving

after welding

not allowed

AC1 AC3 MS Mf

700

air

(HB max 248)

820 furnace cooling

to 710, then air

(HB max 220)

(HB max 310)

850

water

740 790 280 60

Mechanical and physical properties

Hot-rolled mechanical properties after QT

EN 10083-3: 2006

Values for springs according to Stahlschlssel

2007 standard

Testing at room temperature (longitudinal) size d / t

mm R Rp 0.2 A% C% Kv R Rp 0.2 A% DVM

from to N/mm

2

N/mm

2

min. min. min. J min. N/mm

2

N/mm

2

min min J min

16/8 1100-1300 900 9 40 1400-1700 1200 6 21

16/8 40/20 1000-1200 800 10 45 30

40/20 100/60 900-1100 700 12 50 30

100/60 160/100 850-1000 650 13 50 30

160/100 250/160 800-950 600 13 50 30

d = diameter t = thickness

Table of tempering values obtained at room temperature on round of 10 mm after quenching at 850 C in oil

HB 615 595 577 577 550 525 504 455 421 390 371 344 297 253

HRC 58 57 56 56 54.5 53 51.5 48 45 42 40 37 31.5 25

R N/mm

2

2170 2050 1960 1840 1650 1490 1340 1250 1140 990 850

Rp 0.2 N/mm

2

1500 1590 1700 1750 1750 1720 1650 1530 1400 1270 1170 1130 900 700

A % 6.8 7.6 7.8 8.0 8.5 9.8 11.2 12.5 14.6 19.0 22.5

Kv J 8 10 16 16 15 16 26 28 31 38 46 94 135

Tempering at C 50 100 150 200 250 300 350 400 450 500 550 600 650 700

Mod. of elasticity +20 C Flat products

thickness mm

Round products

mm

GPa

E long. G tang.

Max thickness and diameter

recommended for the spring

to obtain, after quenching, internal

hardness of 52 HRC

25 38

210 80

51CrV4 1.8159 Lucefin Group

Cold-drawn + quenched and tempered +C +QT EN 10277-5: 2008 Hot-rolled annealed + peeled-reeled +A +SH

Testing at room temperature (longitudinal)

e)

e)

size

mm R Rp 0.2 A% HB R Rp 0.2 A% HB

from to N/mm

2

N/mm

2

min min for inf. N/mm

2

N/mm

2

min min max

b)

16 1100-1300 900 9 331-380 248

16 40 1000-1200 800 10 298-359 248

40 80 900-1100 700 12 271-331 248

b)

for thickness < 5 mm, mechanical properties can be agreed before order placement

e)

values valid also for +C+QT+SL

Hot-rolled, quenched and tempered, cold-drawn +QT +C Hot-rolled annealed + cold-drawn +A +C

Testing at room temperature (longitudinal) size

mm R Rp 0.2 A% HB R Rp 0.2 A% HB

from to N/mm

2

N/mm

2

min min N/mm

2

min N/mm

2

min min max

b)

16 311

16 40 293

40 80 287

b)

for thickness < 5 mm, mechanical properties can be agreed before order placement

Forged quenched and tempered EN 10250-3: 2001

Testing at room temperature size

mm R Rp 0.2 A% A% Kv +20 C Kv +20 C HB

from to N/mm

2

min N/mm

2

min min L min T J min L J min T min

250/160 800 600 13 9 30 16 240

250/160 500/330

500/330 750/500

L = longitudinal T = tangential

EN 10083-3: 2006 Jominy test HRC grain size 5 min.

mm distance from quenched extremity

1.5 3 5 7 9 11 13 15 20 25 30 35 40 45 50 Symbol

min 57 56 56 55 53 52 50 48 44 41 37 35 34 33 32

max 65 65 64 64 63 63 63 62 62 62 61 60 60 59 58

H

min 60 59 59 58 56 56 54 53 50 48 45 43 43 42 41

max 65 65 64 64 63 63 63 62 62 62 61 60 60 59 58

HH

min 57 56 56 55 53 52 50 48 44 41 37 35 34 33 32

max 62 62 61 61 60 59 59 57 56 55 53 52 51 50 49

HL

EUROPE EN ITALY UNI CHINA GB GERMANY DIN FRANCE AFNOR U.K. B.S. RUSSIA GOST USA AISI/SAE

51CrV4 50CrV4 50CrVA 50CrV4 50CV4 735A50 50HGF 6150

You might also like

- C43Document1 pageC43rudramansingh123No ratings yet

- Material spec sheet for 51CrV4 steelDocument3 pagesMaterial spec sheet for 51CrV4 steelanilNo ratings yet

- Din 17100Document4 pagesDin 17100Sheby SandyNo ratings yet

- 006 DEW Kaltarbeitsstahl GBDocument96 pages006 DEW Kaltarbeitsstahl GBhelderfsnNo ratings yet

- Din 1.4003Document2 pagesDin 1.4003Dhaniel100% (1)

- Stainless Steel Alloys Comparsion ChartDocument3 pagesStainless Steel Alloys Comparsion Chartsengcyan100% (1)

- CK45 (1.1191)Document3 pagesCK45 (1.1191)alextentwentyNo ratings yet

- Hot Rolled Carbon Steel Strip and Sheet (IS: 1079-1968)Document1 pageHot Rolled Carbon Steel Strip and Sheet (IS: 1079-1968)H & H GRSENo ratings yet

- GX300CrMo15 3Document1 pageGX300CrMo15 3jdash0904No ratings yet

- Technical Delivery Conditions for Steel FastenersDocument5 pagesTechnical Delivery Conditions for Steel FastenersDorota HONo ratings yet

- Tata Steel - YMPRESS S500MC - Data SheetDocument2 pagesTata Steel - YMPRESS S500MC - Data SheetpnagarajjNo ratings yet

- Equivalent Steel GradesDocument6 pagesEquivalent Steel GradesPapaiNo ratings yet

- Nisshin Cold-Rolled Special Steel GuideDocument28 pagesNisshin Cold-Rolled Special Steel GuideekopujiantoeNo ratings yet

- Equivalent Grades of Gray IronDocument2 pagesEquivalent Grades of Gray Ironsujay13780100% (1)

- Thermanit 17-06 (Boehler)Document1 pageThermanit 17-06 (Boehler)queno1No ratings yet

- Knife Steel DatasheetDocument3 pagesKnife Steel DatasheetsondeadorNo ratings yet

- CK 45 (Germany / DIN) : Material PropertiesDocument5 pagesCK 45 (Germany / DIN) : Material PropertiesmiladrahimianNo ratings yet

- SWRCH18A Steel DatasheetDocument2 pagesSWRCH18A Steel DatasheetHari SuthanNo ratings yet

- Ferrous Metals: General Grade Cast IronsDocument8 pagesFerrous Metals: General Grade Cast IronskkamalakannaNo ratings yet

- SIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Document5 pagesSIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Rajoo PrajapatiNo ratings yet

- RJR PMMTDocument16 pagesRJR PMMTArun PrasadNo ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)Deepak ChaurasiaNo ratings yet

- Images 1 - LefleatsDocument11 pagesImages 1 - LefleatsJeric Judalena SevillanoNo ratings yet

- Wave Washer For BearingsDocument2 pagesWave Washer For Bearingspradipbhosale81No ratings yet

- SS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Document3 pagesSS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Harish AmpoluNo ratings yet

- PERMA E-622 ElectrodeDocument1 pagePERMA E-622 Electrodepedromiguel20No ratings yet

- 304 DDQ SpecificationDocument1 page304 DDQ Specificationdac_angelovNo ratings yet

- ISOGradeDocument28 pagesISOGradeleo83No ratings yet

- JI S (Japanes E) Stand Ards For ST EE L Ma TE RI ALSDocument2 pagesJI S (Japanes E) Stand Ards For ST EE L Ma TE RI ALSDamar Wardhana100% (1)

- En Series Chemical CompositionDocument3 pagesEn Series Chemical CompositionAyanBiswas22No ratings yet

- Ansi 1040Document6 pagesAnsi 1040André Luiz NogueiraNo ratings yet

- Ebco StockDocument7 pagesEbco StockVIKAS KUMARNo ratings yet

- Welding of Cast IronDocument10 pagesWelding of Cast IronKrishnendu RouthNo ratings yet

- Steel Grades 2 PDFDocument2 pagesSteel Grades 2 PDFcanakyuz0% (1)

- Cast IronDocument12 pagesCast Irongaby908No ratings yet

- DanCut Rev1 en PDocument8 pagesDanCut Rev1 en PDaniel ConwayNo ratings yet

- JIS G4801 SUP10 Steel GuideDocument2 pagesJIS G4801 SUP10 Steel GuideĐình Sỹ TTPNo ratings yet

- DIN EN ISO 9013 - Angular Deviation PDFDocument1 pageDIN EN ISO 9013 - Angular Deviation PDFflorinelvvNo ratings yet

- Surface Defects in Steel ProductsDocument41 pagesSurface Defects in Steel ProductsShilaj PNo ratings yet

- Corwire Katalog YiceDocument54 pagesCorwire Katalog YiceAlexandar Marinkovic100% (1)

- All Unified PL On SR RequestDocument87 pagesAll Unified PL On SR RequestRohit Kumar SinghNo ratings yet

- Technical Information: Grade Comparison ChartDocument2 pagesTechnical Information: Grade Comparison ChartsansagithNo ratings yet

- Training ModuleDocument44 pagesTraining ModulegereNo ratings yet

- HOT-ROLLED STEEL PRODUCTSDocument8 pagesHOT-ROLLED STEEL PRODUCTS25091972No ratings yet

- Voestalpine Heavy Plate TTD DUROSTAT E 10042015Document16 pagesVoestalpine Heavy Plate TTD DUROSTAT E 10042015Ella Byla SaraNo ratings yet

- Requirements and properties of structural steel hollow sectionsDocument1 pageRequirements and properties of structural steel hollow sectionsRobin GuNo ratings yet

- Steel GradesDocument2 pagesSteel GradesAmit Rajmane100% (1)

- Hydro Aluminium - AlSi7Mg0.6Document2 pagesHydro Aluminium - AlSi7Mg0.6Raj PrasanthNo ratings yet

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohNo ratings yet

- Technical Requirements for hot dip galvanizingDocument7 pagesTechnical Requirements for hot dip galvanizingArun SharmaNo ratings yet

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDocument2 pagesSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- Geared Motor: Product ManualDocument178 pagesGeared Motor: Product Manualsanjibkrjana100% (1)

- Hex Head Bolts, Steel: Maryland MetricsDocument2 pagesHex Head Bolts, Steel: Maryland MetricsEva Ibáñez Ramos100% (1)

- Equivalent Grades of Gray IronDocument2 pagesEquivalent Grades of Gray Ironkarthisantha100% (2)

- Equivalencia AceroDocument30 pagesEquivalencia AceroJose VelosaNo ratings yet

- Steel grade 1.2312 propertiesDocument4 pagesSteel grade 1.2312 propertiesFrancisco CarrascoNo ratings yet

- 42CrMo4 Datos Tecnicos PDFDocument2 pages42CrMo4 Datos Tecnicos PDFjlplazaolaNo ratings yet

- C55EDocument2 pagesC55EniranjanbmazireNo ratings yet

- 34CrMo4 steel properties and heat treatment guideDocument2 pages34CrMo4 steel properties and heat treatment guideStefan GhNo ratings yet

- Quality E335Document1 pageQuality E335Sivanaga DantuluriNo ratings yet

- W1 Tool SteelDocument2 pagesW1 Tool Steelblack_absynthNo ratings yet

- O1 Tool SteelDocument1 pageO1 Tool Steelblack_absynthNo ratings yet

- T12 SteelDocument2 pagesT12 Steelblack_absynthNo ratings yet

- T10 SteelDocument2 pagesT10 Steelblack_absynthNo ratings yet

- Alloy Steels 52100Document2 pagesAlloy Steels 52100black_absynthNo ratings yet

- T8 SteelDocument1 pageT8 Steelblack_absynthNo ratings yet

- Marci - Oteluri (51CrV4 Vs 60Si15A)Document4 pagesMarci - Oteluri (51CrV4 Vs 60Si15A)Stefan Stoica100% (2)

- Aisi 1060Document3 pagesAisi 1060black_absynth0% (1)

- Bhilai Steel Plant 2.SbDocument15 pagesBhilai Steel Plant 2.Sbkalyan1492No ratings yet

- 037 042 PDFDocument6 pages037 042 PDFDevendra Kumar KumawatNo ratings yet

- Comparative Study On Behaviour of Hot and Cold Formed Steel Sections Under Flexure IJERTCONV5IS13158Document9 pagesComparative Study On Behaviour of Hot and Cold Formed Steel Sections Under Flexure IJERTCONV5IS13158samsurendran_mech4020No ratings yet

- Cold Working of Brass PDFDocument8 pagesCold Working of Brass PDFmudassarhussainNo ratings yet

- Electrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetDocument4 pagesElectrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetEvka AkováNo ratings yet

- Materials Science & Engineering A: SciencedirectDocument12 pagesMaterials Science & Engineering A: SciencedirectG SamhithaNo ratings yet

- En 10051Document2 pagesEn 10051sskamalakannanNo ratings yet

- Cotninuous Strip CastingDocument13 pagesCotninuous Strip Castingmtd dataNo ratings yet

- Metal Fabrication Valu Chain Fain AlDocument41 pagesMetal Fabrication Valu Chain Fain AlElias Weldeyohans50% (2)

- Estimation of Load and Torque Hot Rolling Process: by Green and JDocument7 pagesEstimation of Load and Torque Hot Rolling Process: by Green and JAnonymous yjzIf6No ratings yet

- ASTM A480 General Requirements For Flat-Rolled Stainless and HeatResisting Steel Plate, Sheet, and StripDocument25 pagesASTM A480 General Requirements For Flat-Rolled Stainless and HeatResisting Steel Plate, Sheet, and StriphenryNo ratings yet

- Api JSWDocument1 pageApi JSWIrfan MominNo ratings yet

- Cold Rolled SteelDocument13 pagesCold Rolled SteelRanjeet DongreNo ratings yet

- CH 13Document10 pagesCH 13chaitanyachegg100% (1)

- PNS 49 2019 (Preview) PDFDocument3 pagesPNS 49 2019 (Preview) PDFFrancis Bernales25% (4)

- Catalog SAE1075Document84 pagesCatalog SAE1075Woong BangNo ratings yet

- A.S. Precision Machines Profile Contract Manufacturing ISO 9001Document8 pagesA.S. Precision Machines Profile Contract Manufacturing ISO 9001ASprecisionNo ratings yet

- Welding TMCP SteelsDocument7 pagesWelding TMCP SteelsElias Kapa100% (1)

- Structural Works - SharingDocument37 pagesStructural Works - SharingEsvimy Deliquena CauilanNo ratings yet

- Cold Rolled CR Hardness H CA85T-G Steel: General Description Typical UsesDocument1 pageCold Rolled CR Hardness H CA85T-G Steel: General Description Typical UsesBobdNo ratings yet

- 7 Slab Analysis PDFDocument21 pages7 Slab Analysis PDFDr J Kandasamy100% (1)

- Model For Prediction of Microstructural Events During Rod Hot Rolling of Austenitic Stainless SteelDocument9 pagesModel For Prediction of Microstructural Events During Rod Hot Rolling of Austenitic Stainless SteelADRIANONo ratings yet

- Is 7291 1981 PDFDocument38 pagesIs 7291 1981 PDFAnubhav LakhmaniNo ratings yet

- Mumetal Permimphy Supermimphy EngDocument10 pagesMumetal Permimphy Supermimphy Engvsraju2No ratings yet

- Jindal Steel Power Catálogo PDFDocument17 pagesJindal Steel Power Catálogo PDFikamelyaastutiNo ratings yet

- HSN Codes For GST EnrolmentDocument307 pagesHSN Codes For GST EnrolmentMatt AndersonNo ratings yet

- Theory of Metal Cutting, Metal FormingDocument181 pagesTheory of Metal Cutting, Metal Formingprabhjotbhangal100% (1)

- En 10268-2006 - Cold Rolled High Strength - Dual Phase SteelsDocument16 pagesEn 10268-2006 - Cold Rolled High Strength - Dual Phase SteelsSuvro ChakrabortyNo ratings yet

- Ferrous Metals Guide - Classification, Properties and Uses of Iron, Cast Iron, Wrought Iron and SteelDocument18 pagesFerrous Metals Guide - Classification, Properties and Uses of Iron, Cast Iron, Wrought Iron and SteelJohnNo ratings yet

- Material Specifications: Low Carbon Steel, Hot Rolled Sheet and StripDocument5 pagesMaterial Specifications: Low Carbon Steel, Hot Rolled Sheet and Striptim0% (1)