Professional Documents

Culture Documents

AGMA Unbalance

Uploaded by

knsvel2000Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AGMA Unbalance

Uploaded by

knsvel2000Copyright:

Available Formats

AGMA Limits

http://alciotola.com/site2/agma.html

800.890.7325

After Hours Emergency

800.876.6173

AGMA Limits

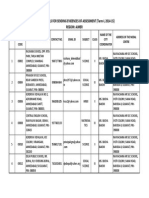

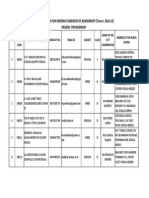

The American Gear Manufacturers Association (AGMA) has issued Standard 9000-C90, which establishes, in graph form, the maximum potential unbalance as a function of operating speed and coupling weight. The graph is divided into seven zones; once a zone is selected, the class of balance is determined from the Chart 1 given below, which includes the machine sensitivity to coupling unbalance. AGMA's guidelines are commented by the author: Shaft Flexibility. Long and slender shafts are very sensitive, while short and rigid shafts (such as electric motors) have a low sensitivity to unbalance. Bearing Loads. The smaller the ratio between the coupling weight and total rotor weight, the less sensitive the machine is to residual unbalance. For example, single stage centrifugal pumps have a rotor that is seldom heavier than the coupling; hence pumps are very sensitive to the coupling's residual unbalance. Machine and Foundation Rigidity. Heavy machines with a rigid frame attached to a solid foundation are not very sensitive to residual unbalance. Resonance. Systems are designed to operate at speeds that are removed from lateral vibration resonances. The close a machine operates to any resonant frequency, the more sensitive it is to residual unbalances. Coupling Length. Large shaft separations make machines and couplings sensitive to residual unbalance. Shaft Configuration. The longer the span between bearings, as compared with the overhung portion on which couplings are installed, the more sensitive a machine is to unbalance. Once the class of coupling unbalance is determined, the maximum displacement of the mass center to the rotation center is determined from the chart below. This "displacement" method is slightly tedious to calculate.

The principle involved can be understood using the single disk, and the following relations can be written: e.W=M.R where e = eccentricity from its geometrical axis W= Weight of the mass (in pounds) M= weight added at Radius R Disk's unbalance is Us = M . R Total Disk Weight is (W + M) It can be assumed that the unbalance is generated by the total disk weight (rather than the weight M), rotating at an eccentricity "e" from its geometrical axis. Therefore: Us = M . R = (W + M) . e From these formulae, the theoretical displacement can be calculated: e = Us / (W + M)

AGMA Standard 9000-C90 classes of Coupling Balance

AGMA Coupling Balance Class 4 5 6 7 8 9 10 11

Maximum Displacement of Principal Inertia Axis at Balancing Planes (rms micro inches) over 32,000 0.2500 16,000 8,000 4,000 2,000 1,000 500

1 of 2

1/31/2014 11:57 PM

AGMA Limits

http://alciotola.com/site2/agma.html

2011 Frontline Industiries Inc.. The significance of AGMA standard is that, rather thansimply establishing limits for unbalances, it also incorporates all possible factors that can create a

12

250

potential unbalance. Among the factors analyzed are:

Pilot surface eccentricity Pilot surface clearance Hardware displacement Hardware weight differences

2 of 2

1/31/2014 11:57 PM

You might also like

- Wheel Rim FatigueDocument9 pagesWheel Rim FatigueThanakorn Vichiensamuth100% (1)

- Torque and Inertia CalculationsDocument20 pagesTorque and Inertia Calculationsmanfredm6435No ratings yet

- Flexible RotorDocument22 pagesFlexible RotormghgolNo ratings yet

- Balancing Basic Part IIDocument6 pagesBalancing Basic Part IIAbdul KurniadiNo ratings yet

- Chapter Three: Analysis of Ride Comfort Using Conventional DamperDocument16 pagesChapter Three: Analysis of Ride Comfort Using Conventional DamperBejai Alexander MathewNo ratings yet

- DESIGN OF MAIN GIRDER FOR EOT CRANEDocument7 pagesDESIGN OF MAIN GIRDER FOR EOT CRANESatyajeet BeheraNo ratings yet

- Cam BasicsDocument50 pagesCam Basicsmass3444No ratings yet

- How Unbalance Affects Bearing LifeDocument8 pagesHow Unbalance Affects Bearing Lifeagrocel_bhv5591No ratings yet

- Use of Duty Cycles or Measured Torque Time Data With Agma RatingsDocument8 pagesUse of Duty Cycles or Measured Torque Time Data With Agma RatingsKarthikeyan NatarajanNo ratings yet

- Shock Speed ArticleDocument10 pagesShock Speed ArticleKathryn Workman100% (1)

- Application and Improvement of Face Load Factor Determination Based On Agma 927Document19 pagesApplication and Improvement of Face Load Factor Determination Based On Agma 927Nursena SEVİNÇNo ratings yet

- Power System StabilityDocument9 pagesPower System StabilityराघवतोतलाNo ratings yet

- IIT Gandhinagar: ME304: Kinematics and Dynamics of Machines March 19, 2013Document1 pageIIT Gandhinagar: ME304: Kinematics and Dynamics of Machines March 19, 2013Shubhangi BansudeNo ratings yet

- Naf Ems 2013 RotorDocument12 pagesNaf Ems 2013 Rotorletter_ashish4444No ratings yet

- Estimation of Electropneumatic Clutch Actuator Load CharacteristicsDocument6 pagesEstimation of Electropneumatic Clutch Actuator Load Characteristicsfarid_aragiNo ratings yet

- How to Calculate Motor Torque Needs for CNC MachinesDocument5 pagesHow to Calculate Motor Torque Needs for CNC MachinesmuhdqasimNo ratings yet

- 63 Engineering Mechanics 2e - Chapter 7 PDFDocument34 pages63 Engineering Mechanics 2e - Chapter 7 PDFNarendra Pratap100% (2)

- 14 - CH - 06 Friction and Wear Analysis For BushingDocument18 pages14 - CH - 06 Friction and Wear Analysis For BushingSathish KumarNo ratings yet

- Balance StandardDocument11 pagesBalance StandardKarthik VkNo ratings yet

- Prestressed-Concrete Sleepers: Dr. Stephan Freudenstein, General Manager of Engineering, Rail - One GMBHDocument14 pagesPrestressed-Concrete Sleepers: Dr. Stephan Freudenstein, General Manager of Engineering, Rail - One GMBHsoumyajit maityNo ratings yet

- Balance Quality Requirements of Rigid Rotors - The Practical Application of ISO 1940-1Document11 pagesBalance Quality Requirements of Rigid Rotors - The Practical Application of ISO 1940-1FabbroxNo ratings yet

- Balancing Tip # 105 C D International, IncDocument3 pagesBalancing Tip # 105 C D International, IncAnonymous PVXBGg9TNo ratings yet

- Ahmad ProjDocument11 pagesAhmad ProjSaifNo ratings yet

- Axle ShaftsDocument13 pagesAxle ShaftsankitsarvaiyaNo ratings yet

- Balancing Procedure: PT - Armindo Jaya Mandiri Electro Mechanical WorkshopDocument8 pagesBalancing Procedure: PT - Armindo Jaya Mandiri Electro Mechanical Workshopgst ajahNo ratings yet

- Tire Cornering StiffnessDocument7 pagesTire Cornering Stiffnesstiago2fastNo ratings yet

- Active Magnetic Bearings For Frictionless Rotating Machineries by Joga Dharma SetiawanDocument6 pagesActive Magnetic Bearings For Frictionless Rotating Machineries by Joga Dharma SetiawanNikkizGogasNo ratings yet

- Simple MachinesDocument5 pagesSimple MachinesSherilyn ApostolNo ratings yet

- AGN 008 - VibrationDocument9 pagesAGN 008 - VibrationariwibowoNo ratings yet

- Motor Sizing Basics Part 1-4Document37 pagesMotor Sizing Basics Part 1-4M A JomahNo ratings yet

- Balancing of Shaft CouplingsDocument5 pagesBalancing of Shaft CouplingsSulagna Roy100% (1)

- Brake Design and SafetyDocument20 pagesBrake Design and SafetyLuiz Gustavo MedeirosNo ratings yet

- At 6602 ACCD Imp Qns 2by2resultsDocument3 pagesAt 6602 ACCD Imp Qns 2by2resultsKarthickNo ratings yet

- MANE-4030: Elements of Mechanical Design: Worksheet #16: Min MaxDocument3 pagesMANE-4030: Elements of Mechanical Design: Worksheet #16: Min Maxazizieh5701No ratings yet

- Smoothing The Ride: A Simple ModelDocument16 pagesSmoothing The Ride: A Simple ModelChristian QuitoNo ratings yet

- Torque Calculations For Gearmotor ApplicationsDocument3 pagesTorque Calculations For Gearmotor ApplicationsdilipNo ratings yet

- Stepper Motors Synchronous Motors Technical AppendixDocument5 pagesStepper Motors Synchronous Motors Technical AppendixCARLOSWAR101No ratings yet

- Etabs Column DesignDocument15 pagesEtabs Column Designmagdyamdb100% (1)

- Wright CranesDocument13 pagesWright Craneslandshark004100% (1)

- FORMATO MATPR EES 8-PagDocument8 pagesFORMATO MATPR EES 8-Pagarlette caizaNo ratings yet

- Screw Jack CalculationsDocument6 pagesScrew Jack CalculationsDaniel SherwinNo ratings yet

- Dynamic Balancing EccentricityDocument11 pagesDynamic Balancing EccentricitygrahazenNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Shape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationFrom EverandShape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationNo ratings yet

- Standard-Slope Integration: A New Approach to Numerical IntegrationFrom EverandStandard-Slope Integration: A New Approach to Numerical IntegrationNo ratings yet

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- Easy(er) Electrical Principles for General Class Ham License (2015-2019)From EverandEasy(er) Electrical Principles for General Class Ham License (2015-2019)Rating: 5 out of 5 stars5/5 (1)

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Exceeding and Challenging Performance Benchmarks, The Bosch WayDocument4 pagesExceeding and Challenging Performance Benchmarks, The Bosch Wayknsvel2000No ratings yet

- Iso 18436Document2 pagesIso 18436knsvel20000% (3)

- List of Schools For Sending Evidences of Assessment (Term I, 2014 15) Region: AjmerDocument152 pagesList of Schools For Sending Evidences of Assessment (Term I, 2014 15) Region: Ajmerknsvel2000No ratings yet

- Commercial Documents Fibre Optic Gen End Winding System 1410253633Document54 pagesCommercial Documents Fibre Optic Gen End Winding System 1410253633knsvel2000No ratings yet

- CPIOListDocument5 pagesCPIOListknsvel2000No ratings yet

- List of schools for sending evidences of assessmentDocument60 pagesList of schools for sending evidences of assessmentknsvel2000No ratings yet

- List of Schools For Sending Evidences of Assessment (Term I, 2014 15) Region: DehradunDocument67 pagesList of Schools For Sending Evidences of Assessment (Term I, 2014 15) Region: Dehradunknsvel2000100% (1)

- User Manual ADS v3.0Document15 pagesUser Manual ADS v3.0knsvel2000No ratings yet

- List of Schools For Sending Evidences of Assessment (Term I, 2014 15) Region: GuwahatiDocument44 pagesList of Schools For Sending Evidences of Assessment (Term I, 2014 15) Region: Guwahatiknsvel2000100% (2)

- List of Schools For Sending Evidences of Assessment (Term I, 2014 15) Region: TrivandrumDocument84 pagesList of Schools For Sending Evidences of Assessment (Term I, 2014 15) Region: Trivandrumknsvel2000No ratings yet

- Viibratiion DiiagnostiicsDocument113 pagesViibratiion DiiagnostiicsDanielAvellanedaNo ratings yet

- Technical Documents Fibre Optic Gen End Winding System 1410253648Document11 pagesTechnical Documents Fibre Optic Gen End Winding System 1410253648knsvel2000No ratings yet

- ISR Revised FinalDocument332 pagesISR Revised Finalknsvel2000No ratings yet

- Fem To Cell Solutions BrochureDocument4 pagesFem To Cell Solutions Brochureknsvel2000No ratings yet

- Relationship: of Influence Coefficients Between Static-Couple and Multiplane Methods On Two-Plane BalancingDocument14 pagesRelationship: of Influence Coefficients Between Static-Couple and Multiplane Methods On Two-Plane BalancingHimanshu VarshneyNo ratings yet

- Probe 3300xl 8mm PtsDocument29 pagesProbe 3300xl 8mm Ptsknsvel2000No ratings yet

- Aepona V1 0 Femto Zonal Presence RESTDocument21 pagesAepona V1 0 Femto Zonal Presence RESTknsvel2000No ratings yet

- 2012 Certification Handbook-Fina - 030612l1Document28 pages2012 Certification Handbook-Fina - 030612l1knsvel2000No ratings yet

- Eureka Design Public Company LimitedDocument2 pagesEureka Design Public Company Limitedknsvel2000No ratings yet

- India Wood Related Markets 2011Document135 pagesIndia Wood Related Markets 2011Pallavi Patil0% (1)

- ISR Revised FinalDocument332 pagesISR Revised Finalknsvel2000No ratings yet

- CMJDocument2 pagesCMJknsvel2000No ratings yet

- ICRA Report 2 WheelersDocument6 pagesICRA Report 2 WheelersMayank JainNo ratings yet

- Vibrational Analysis of Flexible Coupling by Considering UnbalanceDocument10 pagesVibrational Analysis of Flexible Coupling by Considering Unbalanceknsvel2000No ratings yet

- ICRA Report 2 WheelersDocument6 pagesICRA Report 2 WheelersMayank JainNo ratings yet

- Tuv Bank AccountsDocument1 pageTuv Bank Accountsknsvel2000No ratings yet

- Flender CatalogFLENDERCouplingsDocument280 pagesFlender CatalogFLENDERCouplingsknsvel2000No ratings yet

- Mass Centering Crankshaft BalancerDocument2 pagesMass Centering Crankshaft Balancerknsvel2000No ratings yet

- Probe 3300xl 8mm PtsDocument29 pagesProbe 3300xl 8mm Ptsknsvel2000No ratings yet

- Automatic Axle Differential BalancerDocument2 pagesAutomatic Axle Differential Balancerknsvel2000No ratings yet

- 1 Structural Steel Management and Detailing - CoursesDocument7 pages1 Structural Steel Management and Detailing - CoursesRicardo Sage2 HarrisNo ratings yet

- Do Deel CDS Activities & GuidelineDocument2 pagesDo Deel CDS Activities & GuidelineSamuel AmureNo ratings yet

- HP Pavilion Dm3 2xxx Flex ArwenDocument33 pagesHP Pavilion Dm3 2xxx Flex Arwenluis carlos sousa nunesNo ratings yet

- OmniMeter Universal Smart Meter User Manual EKM MeteringDocument2 pagesOmniMeter Universal Smart Meter User Manual EKM MeteringChris CalderónNo ratings yet

- HTML tags to create links, forms, lists and tablesDocument3 pagesHTML tags to create links, forms, lists and tablesLiqaa FlayyihNo ratings yet

- 1 Outtrigger PDFDocument7 pages1 Outtrigger PDFSurumi Rasia SalimNo ratings yet

- 8the Difference of Two SquaresDocument14 pages8the Difference of Two SquaresEve Krystel Baya - MamugayNo ratings yet

- TOA Audio CatalogueDocument33 pagesTOA Audio CatalogueM Abbi PratomoNo ratings yet

- Sg60Ktl: String InverterDocument2 pagesSg60Ktl: String InverterEisac SagimanNo ratings yet

- L2 Specific EnergyDocument30 pagesL2 Specific EnergySahil AcharyaNo ratings yet

- I.s.eniso15085 2003+a2 2018+cor 2018Document27 pagesI.s.eniso15085 2003+a2 2018+cor 2018doggenaarmichelNo ratings yet

- AWS DBS-C01 Exam GuideDocument8 pagesAWS DBS-C01 Exam GuideAbed BenamarNo ratings yet

- Astm A 153pdfDocument4 pagesAstm A 153pdfrmsa17No ratings yet

- Cs Unitec Magnetic Drill Accessories-2017Document6 pagesCs Unitec Magnetic Drill Accessories-2017Jonel Carhuaz LozanoNo ratings yet

- Two Types of Mechanical Designs and Programming Methods for PLC SystemsDocument1 pageTwo Types of Mechanical Designs and Programming Methods for PLC SystemsKiruba EathirajNo ratings yet

- PLT To DXFDocument5 pagesPLT To DXFsennirajeshNo ratings yet

- Spotify Premium Method #Noob FriendlyDocument5 pagesSpotify Premium Method #Noob FriendlyJulian SuitsNo ratings yet

- Twin MotionDocument2 pagesTwin MotionJoshelyne Mendoza0% (1)

- Manual TMD-SeriesDocument1 pageManual TMD-SeriesAlex VargasNo ratings yet

- Pc78us-8 PDFDocument6 pagesPc78us-8 PDFadi078No ratings yet

- Heat Pumps Noise Level CalcDocument10 pagesHeat Pumps Noise Level CalcZaid Al RayesNo ratings yet

- Choosing the Right Autopilot SystemDocument3 pagesChoosing the Right Autopilot SystemStas MNo ratings yet

- MCQ in Advanced Engineering Math Part 1Document15 pagesMCQ in Advanced Engineering Math Part 1Catalino Roca, Jr.No ratings yet

- Empower 3 21 CFR Part 11 Compliance Assessment RevA November 2019Document14 pagesEmpower 3 21 CFR Part 11 Compliance Assessment RevA November 2019Nur AcarNo ratings yet

- Mechanical System Design PDFDocument24 pagesMechanical System Design PDFGaurav Kumar GuptaNo ratings yet

- Kumpulan Soal Aspd SMP Bahasa Inggris 2021Document247 pagesKumpulan Soal Aspd SMP Bahasa Inggris 2021arum3695No ratings yet

- Test Bank For Java Software Solutions 7th Edition International Edition John Lewis William LoftusDocument36 pagesTest Bank For Java Software Solutions 7th Edition International Edition John Lewis William Loftussmoteroturier.lcmx5n100% (52)

- 110105139Document946 pages110105139BapudayroNo ratings yet

- Tandag Central Elementary School District III Narrative Report On The Designing and Facilitating Online Class Instruction Lac SessionDocument3 pagesTandag Central Elementary School District III Narrative Report On The Designing and Facilitating Online Class Instruction Lac Sessionrosemarie lozadaNo ratings yet

- Procurement Data Clerk - Supply ChainDocument2 pagesProcurement Data Clerk - Supply ChainFatmata BanguraNo ratings yet