Professional Documents

Culture Documents

HTR India - Products - Wire Wound Resistors - Silicone Coated Resistors - HFA (English)

Uploaded by

crplzCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HTR India - Products - Wire Wound Resistors - Silicone Coated Resistors - HFA (English)

Uploaded by

crplzCopyright:

Available Formats

www.htr-india.

com

WIRE WOUND RESISTORS SILICONE COATED TYPE

Alloy Resistance Wire Wound On Fibre Glass Core

Mechanically Crimped Termination Assembly Flame Retardant Silicone Coating/ Uncoated Depending On Application

Especially designed for kitchen appliances sector Available uncoated if required 1W to 10W R10 to 51K

HFA SERIES

e : info@htr-india.com

www.htr-india.com

PHYSICAL CONFIGURATION

WIRE WOUND RESISTORS SILICONE COATED TYPE

HFA

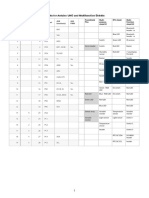

HTR TYPE F-1 F-2 F-3 F-5 F-7 F-9 F-10

POWER RATING at 70C 1W 2W 3W 5W 7W 9W 10W

DIMENSIONS (mm)

RESISTANCE RANGE

L (max)

15.0 18.0 20.0 27.0 38.0 47.0 53.0

D (max)

4.5 4.5 5.50 5.50 5.50 5.75 5.75

l 2

38 38 38 38 38 38 38

LM 1

35 35 40 45 60 65 70

d 0.05

0.8 0.8 0.8 1.0 1.0 1.0 1.0

min

R10 R10 R20 R27 R47 R47 R60

max

6K8 8K6 12K 20K 30K 40K 51K

TYPICAL WEIGHT PER PC (gms) 1.18 1.20 1.24 1.60 1.90 2.22 2.34

ELECTRICAL & ENVIRONMENTAL CHARACTERISTICS / DATA

PARAMETER/PERFORMANCE TEST & TEST METHOD Power Rating (Rated Ambient Temperature) Resistance Tolerances Available Operating Temperature Range Voltage Rating / Limiting Voltage/ Max Working Voltage Voltage Proof / Dielectric Withstanding Voltage (based on limiting voltage x 2 for 60 secs) Short Time Overload (5 x Rated Power upto 2 watts and 10 x Rated Power 3 watts and above for 5 secs) Temperature Co-efficient of Resistance Thermal Shock [From -55C to +275C, 5 cycles, 30 min. dwell time] Damp Heat (Steady State) / Humidity (70C at 95% R.H for 250 hours) Endurance - Load Life (70C with limiting voltage - 1.5 hours on / 0.5 hours off for 1000 hours) Solvent Resistance [IPA for 60 secs 10 secs] PERFORMANCE REQUIREMENTS Full Power dissipation at 70C and linearly derated to zero at 275C (Refer Derating Curve above) 10% (K); 5% (J) -55C to +275C with suitable derating as per derating curve V= PxR R [2% + R05] - No flashover, mechanical damage, arcing or insulation breakdown R [3% + R05] - Average 60 to 500 ppm/C (Depending on resistance value) R [5% + R05] R [5% + R05] R [5% + R05] - Average No effect on coating / marking

MECHANICAL SPECIFICATIONS

PARAMETER/PERFORMANCE TEST & TEST METHOD Pull Test / Robustness of Terminations (Direct load 2 to 4.5 kgs depending on size for 15 secs) Resistance to Soldering Heat (260C - 270C for 4 secs) Solderability (As per IEC - 60068 - 2 - 20Ta) Marking PERFORMANCE REQUIREMENTS No effect R [2.5% + R05] - Typical Must meet the requirements laid down As per IEC Pub. 60062

e : info@htr-india.com

www.htr-india.com

TYPICAL APPLICATIONS

Kitchen Appliances : Mixers, Blenders, Percolators, Cooking Ranges, Toasters and Deep Fryers. Automotive Equipment : Horns, Ignitions, Voltage Regulators, Instrument Gauges and Windshield Wipers. These resistors can also be used as a resistor cum fuse. In order to ensure that the device functions as it should, the device needs to be tailor-made for each particular application. Please consult factory. Depending on application, the resistor terminations may be tin plated copper clad steel (copperweld) instead of tin plated copper. Note: 1. The leads of the resistor can be bent and cut as per requirements for quick PCB mounting. Please send detailed drawings of the type of preforming required. 2. Types F1, F2, F3, F5, F7, F9 & F10 can be supplied in taped form. Please refer to tape / ammo pack specifications. Tape / Reel on request.

WIRE WOUND RESISTORS SILICONE COATED TYPE

HFA

ORDERING INFORMATION

Series Type Packing Resistance Value Tolerance HFA F2 / F2* 1. For RoHS Version F2 * 2. For Tape & Reel - F2 TR 3. For Tape & Ammo pack - F2 T Bulk F2 / F2* 100R K Tape & Ammo F2T / F2*T Tape & Reel F2TR / F2*TR

e : info@htr-india.com

You might also like

- HTR India - Products - Current Sense Resistors - Electron Beam Welded - HTE (English)Document3 pagesHTR India - Products - Current Sense Resistors - Electron Beam Welded - HTE (English)crplzNo ratings yet

- HTR India - Products - Current Sense Resistors - Electron Beam Welded - HRE (English)Document3 pagesHTR India - Products - Current Sense Resistors - Electron Beam Welded - HRE (English)crplzNo ratings yet

- Saraswat Mandal Nagpur Newsletter July 2014 SaSnehDocument8 pagesSaraswat Mandal Nagpur Newsletter July 2014 SaSnehcrplzNo ratings yet

- RSA Industries - Textile - Different Substrates - Processing of Woven Cotton - Soaping Agent For Dyeing & Printing - R-WASH-37Document2 pagesRSA Industries - Textile - Different Substrates - Processing of Woven Cotton - Soaping Agent For Dyeing & Printing - R-WASH-37crplzNo ratings yet

- RAN Chemicals - Textile - Printing Thickners - Softner - Pigment Printing Additive - RAN-PPADocument2 pagesRAN Chemicals - Textile - Printing Thickners - Softner - Pigment Printing Additive - RAN-PPAcrplzNo ratings yet

- RAN Chemicals - Textile - Levelling - Polyester - Dispersing & Leveling Agent For Polyester - RFT-250 (S)Document4 pagesRAN Chemicals - Textile - Levelling - Polyester - Dispersing & Leveling Agent For Polyester - RFT-250 (S)crplzNo ratings yet

- RAN Chemicals - Textile - Levelling - Polyester - Disperse Dyeing Aid - RS-75Document3 pagesRAN Chemicals - Textile - Levelling - Polyester - Disperse Dyeing Aid - RS-75crplzNo ratings yet

- RSA Industries - Textile - Different Substrates - Processing of Woven Cotton - Finishing Softener For Textile - RSF-At-40-SSDocument3 pagesRSA Industries - Textile - Different Substrates - Processing of Woven Cotton - Finishing Softener For Textile - RSF-At-40-SScrplzNo ratings yet

- RAN Chemicals - Textile - Levelling - Polyester - Dispersing Leveling Agent - RFT-100-SDocument5 pagesRAN Chemicals - Textile - Levelling - Polyester - Dispersing Leveling Agent - RFT-100-Scrplz100% (1)

- RSA Industries - Industrial - Carpet Backing - Polyester Resin For Binding of Non-Woven Fabrics R-COAT CDocument2 pagesRSA Industries - Industrial - Carpet Backing - Polyester Resin For Binding of Non-Woven Fabrics R-COAT CcrplzNo ratings yet

- RSA Industries - Textile - Different Substrates - Processing of Polyester - Scouring Cum Swelling Agent - RAN-SC-1094-PSDocument3 pagesRSA Industries - Textile - Different Substrates - Processing of Polyester - Scouring Cum Swelling Agent - RAN-SC-1094-PScrplzNo ratings yet

- RAN Chemicals - Textile - Finishing - Ready To Use - Silicone - Hydrophilic (For Terry Towel) - Finishing Softener For Textile - RSF-AT-40-SDocument3 pagesRAN Chemicals - Textile - Finishing - Ready To Use - Silicone - Hydrophilic (For Terry Towel) - Finishing Softener For Textile - RSF-AT-40-ScrplzNo ratings yet

- RAN Chemicals - Textile - Leveling - Acrylic - Retarding Agent For Dyeing - R-290-RTADocument2 pagesRAN Chemicals - Textile - Leveling - Acrylic - Retarding Agent For Dyeing - R-290-RTAcrplzNo ratings yet

- RAN Chemicals - Textile - Washing - Polyester - Reduction Clearing Agent - RSW-900-YCDocument3 pagesRAN Chemicals - Textile - Washing - Polyester - Reduction Clearing Agent - RSW-900-YCcrplzNo ratings yet

- RAN Chemicals - Textile - Finishing - Ready To Use - Cationic - Hydrophilic - Finishing Softener For Textile - RSF-AT-40-SHDocument3 pagesRAN Chemicals - Textile - Finishing - Ready To Use - Cationic - Hydrophilic - Finishing Softener For Textile - RSF-AT-40-SHcrplzNo ratings yet

- RAN Chemicals - Textile - Pre-Treatment - Sequestering Agent - RAN-SEQUESTERDocument2 pagesRAN Chemicals - Textile - Pre-Treatment - Sequestering Agent - RAN-SEQUESTERcrplzNo ratings yet

- RAN Chemicals - Textile - Printing Thickners - Softner - Pigment Printing Additive - RAN-PPADocument2 pagesRAN Chemicals - Textile - Printing Thickners - Softner - Pigment Printing Additive - RAN-PPAcrplzNo ratings yet

- RAN Chemicals - Textile - Washing - Polyester - Reduction Clearing Agent - RSW-900-YCDocument3 pagesRAN Chemicals - Textile - Washing - Polyester - Reduction Clearing Agent - RSW-900-YCcrplzNo ratings yet

- RAN Chemicals - Textile - Pre-Treatment - Scouring Agent For Woven Cotton - RAN-SC-1091-DDocument2 pagesRAN Chemicals - Textile - Pre-Treatment - Scouring Agent For Woven Cotton - RAN-SC-1091-DcrplzNo ratings yet

- RAN Chemicals - Textile - Washing - Cotton - Soaping Agent For Dyeing Printing - R-WASH-40Document2 pagesRAN Chemicals - Textile - Washing - Cotton - Soaping Agent For Dyeing Printing - R-WASH-40crplzNo ratings yet

- RAN Chemicals - Textile - Levelling - Cotton - Lubricating - Leveling Agent - RL-290Document2 pagesRAN Chemicals - Textile - Levelling - Cotton - Lubricating - Leveling Agent - RL-290crplzNo ratings yet

- RAN Chemicals - Textile - Washing - Cotton - Soaping Agent For Dyeing Printing - RAN-1098-RDocument3 pagesRAN Chemicals - Textile - Washing - Cotton - Soaping Agent For Dyeing Printing - RAN-1098-RcrplzNo ratings yet

- RAN Chemicals - Textile - Pre-Treatment - Scouring Cum Swelling Agent For Polyester - RAN-SC-1094-PDocument3 pagesRAN Chemicals - Textile - Pre-Treatment - Scouring Cum Swelling Agent For Polyester - RAN-SC-1094-Pcrplz100% (1)

- RAN Chemicals - Textile - Pre-Treatment - Amylase Enzyme For Desizing of Woven Cotton - RAN-EZ-SPLDocument3 pagesRAN Chemicals - Textile - Pre-Treatment - Amylase Enzyme For Desizing of Woven Cotton - RAN-EZ-SPLcrplzNo ratings yet

- RAN Chemicals - Textile - Pre-Treatment - Wetting Scouring Agent For Yarn - RAN-SC-1090-YNDocument2 pagesRAN Chemicals - Textile - Pre-Treatment - Wetting Scouring Agent For Yarn - RAN-SC-1090-YNcrplzNo ratings yet

- Ran Chemicals - Textile - Pre-Treatment - Wetting Scouring Agent For Woven Cotton - RAN-SC-1095 (DC)Document2 pagesRan Chemicals - Textile - Pre-Treatment - Wetting Scouring Agent For Woven Cotton - RAN-SC-1095 (DC)crplzNo ratings yet

- RAN Chemicals - Textile - Pre-Treatment - Scouring Agent For Cotton Knits - RAN-SC-1092-HDocument2 pagesRAN Chemicals - Textile - Pre-Treatment - Scouring Agent For Cotton Knits - RAN-SC-1092-HcrplzNo ratings yet

- RAN Chemicals - Textile - Pre-Treatment - Peroxide Stabilizer - RAN-STAB-IIDocument2 pagesRAN Chemicals - Textile - Pre-Treatment - Peroxide Stabilizer - RAN-STAB-IIcrplzNo ratings yet

- RAN Chemicals - Textile - Pre-Treatment - Hydrogen Peroxide Killer - RAN-PER-KILLERDocument2 pagesRAN Chemicals - Textile - Pre-Treatment - Hydrogen Peroxide Killer - RAN-PER-KILLERcrplzNo ratings yet

- RSA Industries, India - Products - Textile - Sizing - Sizing Lubricant (RSL-100 (P) )Document2 pagesRSA Industries, India - Products - Textile - Sizing - Sizing Lubricant (RSL-100 (P) )crplzNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- RE 2558 Manual V1.0 01Document68 pagesRE 2558 Manual V1.0 01Hamilton GutierrezNo ratings yet

- Mini Excavator Liugong Dressta 9035e Stage VDocument9 pagesMini Excavator Liugong Dressta 9035e Stage VRadu GălățanNo ratings yet

- TransformerDocument25 pagesTransformerJerald SagusayNo ratings yet

- SM MultiV IV Air Outdoor Units 4 15 - 20150414080917Document150 pagesSM MultiV IV Air Outdoor Units 4 15 - 20150414080917Gino Waximinguirijillo Santana100% (3)

- Understanding PC and TroubleshootingDocument8 pagesUnderstanding PC and TroubleshootingDemon God100% (1)

- CKS IP66/IP67 Sealed Rotary Switch SpecsDocument4 pagesCKS IP66/IP67 Sealed Rotary Switch SpecsAF VMNo ratings yet

- CRJ Pre - After Flight ChecklistDocument4 pagesCRJ Pre - After Flight ChecklistCHIMONo ratings yet

- Stacker ManualDocument60 pagesStacker ManualAkhtar QuddusNo ratings yet

- Scrubber Maint Tips: Daily Weekly Monthly CareDocument1 pageScrubber Maint Tips: Daily Weekly Monthly CareImags GamiNo ratings yet

- Electro 3 PrefinalsDocument5 pagesElectro 3 PrefinalsJuan Miguel TorresNo ratings yet

- Control ComponentsDocument74 pagesControl ComponentsJothi PriyaNo ratings yet

- CV Carb Part 2 WebDocument4 pagesCV Carb Part 2 WebkanwarNo ratings yet

- Ventilation Control Panel ProjectDocument4 pagesVentilation Control Panel ProjectHao DinhNo ratings yet

- Modul 1 Introduction To ArduinoDocument17 pagesModul 1 Introduction To ArduinoPrima Aji AkbarNo ratings yet

- Job Hazard Analysis Worksheet: Sequence of Steps or Activities Hazards or Potential For Mishaps Preventive MeasuresDocument1 pageJob Hazard Analysis Worksheet: Sequence of Steps or Activities Hazards or Potential For Mishaps Preventive MeasuresSrayoshi DattaNo ratings yet

- 45 Series F Frame 74cc and 90cc Parts Manual (11007197 Rev AA Feb 2007)Document48 pages45 Series F Frame 74cc and 90cc Parts Manual (11007197 Rev AA Feb 2007)Alaa saidNo ratings yet

- Two-wheeler wiring diagramDocument1 pageTwo-wheeler wiring diagramVivin Maliyekal90% (62)

- WiringDocument10 pagesWiringOlga PlohotnichenkoNo ratings yet

- VOLTAR P086TI G-DRIVE SpecificationsDocument186 pagesVOLTAR P086TI G-DRIVE SpecificationsSilver SilverNo ratings yet

- MHH BOH Katalog (Na Anglijskom) .1093012585Document2 pagesMHH BOH Katalog (Na Anglijskom) .1093012585kethe77No ratings yet

- UTT SBA v10 27th Nov 2016 Revision10Document21 pagesUTT SBA v10 27th Nov 2016 Revision10Mohammed AnasNo ratings yet

- V0D0042305 Projector Services ManualDocument2 pagesV0D0042305 Projector Services ManualkastruiNo ratings yet

- Hyundai 35DS-7 technical manual parts listDocument489 pagesHyundai 35DS-7 technical manual parts listMichał LicznerskiNo ratings yet

- PHL Series Diaphragm Pump Instruction ManualDocument46 pagesPHL Series Diaphragm Pump Instruction ManualnadipallsrirajNo ratings yet

- Sim BP FpgaDocument2 pagesSim BP Fpgailker_osmanNo ratings yet

- Pines Shield Multifuncion PDFDocument3 pagesPines Shield Multifuncion PDFGustavo Portilla MartinezNo ratings yet

- SG40185HF SICOR 11KwDocument2 pagesSG40185HF SICOR 11KwMohammed Mahmoud EissaNo ratings yet

- FGH40N60Document9 pagesFGH40N60Roger FollanoNo ratings yet

- Bearings Seals Greases Chapter 53 Page 762Document13 pagesBearings Seals Greases Chapter 53 Page 762AbdurhamanNo ratings yet

- Posidrive® Mds 5000: Operation ManualDocument132 pagesPosidrive® Mds 5000: Operation ManualHarold Palma SuarezNo ratings yet