Professional Documents

Culture Documents

Valves in Piping Design

Uploaded by

dasubhaiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valves in Piping Design

Uploaded by

dasubhaiCopyright:

Available Formats

VALVES IN PIPING DESIGN

Valves are used for these purposes:

1) Process control during operation 2) Controlling services and utilities-steam, water, air, gas and oil 3) Isolating equipment or instruments, for maintenance 4) Disc arging gas, vapor or liquid !) Draining piping and equipment on s utdown ") #mergenc$ s utdown in t e event of plant mis ap or fire

WHICH SIZE VALVE TO

SE!

%earl$ all valves will &e line si'e ( one e)ception is control valves, w ic are usuall$ one or two si'es smaller t an line si'e* never larger+ ,t control stations and pumps it as &een almost traditional to use line-si'e isolating valves+ -owever, some companies are now using isolating valves at control stations t e same si'e as t e control valve, and at pumps are using .pump si'e/ isolating valves at suction and disc arge+ 0 e c oice is usuall$ an economic one made &$ a pro1ect engineer+ 0 e si'es of &$pass valves for control stations are given in "+1+4, under .Control 2valve) stations/+

WHE"E TO PLACE VALVES

3ee "+3+1 for valving pumps, under .Pump emplacement 4 connections/+ Prefera&l$, place valves in lines from eaders 2on piperac5s) in ori'ontal rat er t an vertical runs, so t at lines can drain w en t e valves are closed+ 2In cold climates, water eld in lines ma$ free'e and rupture t e piping6 suc lines s ould &e traced ( see "+7+2) 0o avoid spooling unnecessar$ lengt s of pipe, mount valves directl$ onto flanged equipment, if t e flange is correctl$ pressure-rated+ 3ee "+!+1 under .%o''le loading/ , relief valve t at disc arges into a eader s ould &e placed ig er t an t e eader in order to drain into it+ 8ocate eav$ valves near suita&le support points+ 9langes s ould &e not closer t an 12 inc es to t e nearest support, so t at installation is not ampered 9or appearance, if practica&le, 5eep centerlines of valves at t e same floor, and in-line on plan view eig t a&ove

OPE"ATING ACCESS TO VALVES

Consider frequenc$ of operation w en locating manuall$-operated valves 8ocate frequentl$-operated valves so t e$ are accessi&le to an operator from grade or platform+ ,&ove t is eig t and up to 2: ft, use c ain operators or e)tension stem+ ;ver 2: ft, consider a platform or remote

VALVE OPE"ATING HEIGHTS #

Infrequentl$-used valves can &e reac ed &$ a ladder ( &ut consider alternatives Do not locate valves on piperac5s, unless unavoida&le <roup valves w ic would &e out or reac so t at all can &e operated &$ providing a platform, if automatic operators are not used If a c ain is used on a ori'ontall$ mounted valve, ta5e t e &ottom of t e loop to wit in 3 ft of floor level for safet$, and provide a oo5 near &$ to old t e c ain out of t e wa$ ( see 3+1+2, under .C ain/ Do not use c ain operators on screwed valves, or on an$ valve 1= inc es and smaller >it lines andling dangerous materials it is &etter to place valves at a suita&l$ low level a&ove grade, floor, platform, etc+, so t at t e operator does not ave to reac a&ove ead eig t

ACCESS TO VALVES IN HAZA"DO S A"EAS

8ocate main isolating valves w ere t e$ can &e reac ed in an emergenc$ suc as an out&rea5 of fire mis ap+ ?a5e sure t at personnel will &e a&le to reac valves easil$ &$ wal5wa$ or automo&ile 8ocate manuall$-operated valves at t e plant perimeter, or outside t e a'ardous area #nsure t at automatic operators and t eir control lines will &e protected from t e effects of fire ?a5e use of &ric5 or concrete walls as possi&le fire s ields for valve stations Inside a plant, place isolating valves in accessi&le positions to s ut feed lines for equipment and processes aving a fire ris5 Consider t e use of automatic valves in fire-fig ting s$stems to release water, foam and ot er fire-fig ting agents, responding to eat-fusi&le lin5s, smo5e detectors etc+, triggered &$ fire or undue rise in temperature+

$A%E $AINTENANCE SI$PLE

Provide access for mo&ile lifting equipment to andle eav$ valves Consider providing lifting davits for access is restricted eav$ valves difficult to move &$ ot er means if

If possi&le, arrange valves so t at supports will not &e on remova&le spools6 , plug valve requiring lu&rication must &e easil$ accessi&le, even t oug it ma$ not &e frequentl$ operated+

$A%E $AINTENANCE SA&E

@se line-&lind valves, spectacle plates or t e .dou&le &loc5 and &leed/ w ere positive s utoff is required eit er for maintenance or process needs ( see 2+A

O"IENTATION O& VALVE STE$S

Do not point valve stems into wal5wa$s, truc5wa$s, ladder space, etc+ @nless necessar$, do not arrange gate and glo&e valves wit downward 2at an$ angle &elow t e ori'ontal), as61) 2) t eir stems pointing

3ediment ma$ collect in t e gland pac5ing and score t e stem+ , pro1ecting stem ma$ &e a a'ard to personnel+ If an inverted position is necessar$, consider emplo$ing a drips ield6

CLOSING DOWN LINES

Consider valve closing time in s utting down or t rottling large lines+ Bapid closure of t e valve requires rapid dissipation of t e liquid/s 5inetic energ$, wit a ris5 of rupturing t e line+ 8ong distance pipelines present an e)ample of t is pro&lem+ , liquid line fitted wit a fast-closing valve s ould &e provided wit a stand pipe upstream and close to t e valve to a&sor& t e 5inetic energ$ of t e liquid+ , standpipe is a closed vertical &ranc on a line6 air or ot er gas is trapped in t is &ranc to form a pneumatic cus ion+

I& THE"E IS NO P ' ID

Provide valves at eaders, pumps, equipment, etc+, to ensure t at t e s$stem will &e pressure tig t for $drostatic testing and to allow equipment to &e removed for maintenance wit out s utting down t e s$stem Provide isolating valves in all small lines &ranc ing from figure "+12 eaders(for e)ample, see

Provide isolating valves at all instrument pressure points for removal of instruments under operating conditions Provide valved drains on all tan5s, vessels, etc+, and ot er equipment w ic ma$ contain or collect liquids Protect sensitive equipment &$ using a fast-closing c ec5 valve to stop &ac5flow &efore it can gat er momentum Consider &utt-welding or ring-1oint flanged valves for lines containing .searc ing/ fluids+ -$drogen is especiall$ lia&le to lea5 a'ardous or

Consider seal welding screwed valves if used in $drocar&on service see c art 2+3 2inset s5etc ) Provide sufficient valves to control flows Consider providing a concrete pit 2usuall$ a&out 4 ft ) 4 ft) for a valve w ic is to &e located &elow grade Consider use of temporar$ closures for positive s utoff-see 2+A Provide a &$pass if necessar$ for equipment w ic ma$ &e ta5en out of service Provide a &$pass valve around control stations if continuous flow is required+ 3ee "+1+4 and figure "+"+ 0 e &$pass s ould &e at least as large as t e control valve, and is usuall$ glo&e t$pe, unless " inc or larger, w en a gate valve is normall$ used 2see 3+1+4, under .<ate valve/) Provide an upstream isolating valve wit a small valved &$pass to equipment w ic ma$ &e su&1ect to fracture if eat is too rapidl$ applied on opening t e solating valve+ 0$pical use is in steam s$stems to lessen t e ris5 of fracture of suc t ings as castings, vitreous-lined vessels, etc+ Consider providing large gate valves wit a valved &$pass to equali'e pressure on eit er side of t e disc to reduce effort needed to open t e valve

CONT"OL (VALVE) STATIONS

, control station is an arrangement of piping in w ic a control valve is used to reduce and regulate t e pressure or rate of flow of steam, gas, or liquid+ Control stations s ould &e designed so t at t e control valve can &e isolated and removed for servicing+ 0o facilitate t is, t e piping of t e stations s ould &e as fle)i&le as circumstances permit+ 9igure "+! s ows wa$s of permitting control valve removal in welded or screwed s$stems+ 9igure "+" s ows t e &asic arrangement for control station piping+

0 e two isolating valves permit servicing of t e control valve+ 0 e emergenc$ &$pass valve is used for manual regulation if t e control valve is out of action+ 0 e &$pass valve is usuall$ a glo&e valve of t e same si'e and pressure rating as t e control valve+ 9or manual regulation in lines " inc and larger, a gate valve is often t e more economic c oice for t e &$pass line-refer to 3+1+4, under .<ate valve/+ 9igures "+A-11 s ow ot er wa$s of arranging control stations-man$ more designs t an t ese are possi&le+ 0 ese illustrations are all sc ematic and can &e adapted to &ot welded and screwed s$stems+

DESIGN POINTS

9or &est control, place t e control station close to t e equipment it serves, and locate it at grade or operating platform level Provide a pressure-gage connection downstream of t e station/s valves+ Depending on t e operation of t e plant, t is connection ma$ eit er &e fitted wit a permanent pressure indicating gage, or &e used to attac a gage temporaril$ 2for c ec5ing purposes) Prefera&l$, do not .sandwic / valves+ Place at least one of t e isolating valves in a vertical line so t at a spool can &e ta5en out allowing t e control valve to &e removed If t e equipment and piping downstream of t e station is of lower pressure rating t an piping upstream, it ma$ &e necessar$ to protect t e downstream s$stem wit a pressure relief valve Provide a valved drain near to and upstream of t e control valve+ 0o save space, t e drain is placed on t e reducer+ 0 e drain valve allows pressure &etween t e isolating valve2s) and control valve to &e released+ ;ne drain is used if t e control valve fails open, and two drains 2one eac side of t e control valve) if t e control valve fails closed 8ocate stations in rac5 piping at grade, ne)t to a &ent or column for eas$ supporting+

TILIT* STATIONS

, utilit$ station usuall$ comprises t ree service lines carr$ing steam, compressed air and water+ 0 e steam line is normall$ C inc minimum, and t e ot er two services are usuall$ carried in 1 inc lines+ 0 ese services are for cleaning local equipment and osing floors+ 29irewater is ta5en from points fed from an independent water suppl$+) 0 e steam line is fitted wit a glo&e valve and t e air and water lines wit gate valve+ ,ll are terminated wit ose connections a&out 3= ft a&ove floor or grade+ , utilit$ station s ould &e located at some convenient steel column for supporting, and all areas it is to serve s ould &e reac a&le wit a !: ft ose+

You might also like

- 2018 COE Troubleshooting 1 - ENG PDFDocument886 pages2018 COE Troubleshooting 1 - ENG PDFThanh Hoang67% (3)

- Pipe DesignDocument6 pagesPipe DesignmaneeshmsanjagiriNo ratings yet

- Valve SelectionDocument5 pagesValve SelectionmansurNo ratings yet

- RCC Thumb RuleDocument7 pagesRCC Thumb RuleRahat ullah100% (6)

- Digital PID ControllersDocument21 pagesDigital PID Controllerssopan saNo ratings yet

- Instrument Installation Hook Up DrawingsDocument0 pagesInstrument Installation Hook Up DrawingsHicoolguy Riq33% (3)

- Computational Fluid Dynamics - Getting Started Quickly With ANSYS CFX 18 Through Simple Examples - Stefan Lecheler - Springer (2023)Document211 pagesComputational Fluid Dynamics - Getting Started Quickly With ANSYS CFX 18 Through Simple Examples - Stefan Lecheler - Springer (2023)Trịnh Thanh Tùng100% (1)

- Design Input - Pressure Reducing ValveDocument8 pagesDesign Input - Pressure Reducing ValvekausikrNo ratings yet

- Welding Consumable Storage and Handling ProceduresDocument27 pagesWelding Consumable Storage and Handling ProceduresKannan MurugesanNo ratings yet

- Thumb Rules For Designing A Column Layout - Civil Engineering - Civil Engineering ProjectsDocument6 pagesThumb Rules For Designing A Column Layout - Civil Engineering - Civil Engineering ProjectsThulasi Raman Kowsigan0% (1)

- Unit 2: - Control ValvesDocument21 pagesUnit 2: - Control ValvesCarn Joseph100% (1)

- Fundamentals of Welding TechDocument29 pagesFundamentals of Welding TechAshwani DograNo ratings yet

- P&id - 1Document5 pagesP&id - 1dasubhai100% (1)

- Control Valves BasicsDocument203 pagesControl Valves Basicszeeshansuboor100% (1)

- How To Select An ActuatorDocument12 pagesHow To Select An Actuatorforevertay2000100% (1)

- Microsoft Word - SVDocument62 pagesMicrosoft Word - SVaftabulalamNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Control Valve Actuators and PositionersDocument23 pagesControl Valve Actuators and PositionersPg LisenNo ratings yet

- Plot PlanDocument5 pagesPlot PlandasubhaiNo ratings yet

- Plot PlanDocument5 pagesPlot PlandasubhaiNo ratings yet

- Baby Mait PDFDocument2 pagesBaby Mait PDFChris LuNo ratings yet

- Sizing and Selection of Actuators For Valves: Nidhin ManoharDocument62 pagesSizing and Selection of Actuators For Valves: Nidhin Manoharsaiful anwarNo ratings yet

- Piping Layout: Philosophy of Yard PipingDocument11 pagesPiping Layout: Philosophy of Yard PipingdasubhaiNo ratings yet

- Valves Terminology and SymbolsDocument1 pageValves Terminology and SymbolsHardik AcharyaNo ratings yet

- ACI - 318 - 05 Design of Slab PDFDocument24 pagesACI - 318 - 05 Design of Slab PDFtaz_taz3No ratings yet

- DRESSER ControlValveCavitationDocument10 pagesDRESSER ControlValveCavitationLindsey PatrickNo ratings yet

- Mio Sport 2006Document58 pagesMio Sport 2006Despri Dsp100% (1)

- Plant Operation Systems OverviewDocument32 pagesPlant Operation Systems Overviewarunkumar23101No ratings yet

- Importance of Control ValvesDocument31 pagesImportance of Control ValvesIndranil Hatua100% (1)

- Instrumentation Advance Course Part 2Document69 pagesInstrumentation Advance Course Part 2FACE BOOKNo ratings yet

- Equpment LayoutDocument6 pagesEqupment LayoutdasubhaiNo ratings yet

- المحاضره 2Document26 pagesالمحاضره 2Mohammed AlkhafajiNo ratings yet

- 190 SpagesDocument4 pages190 SpagesIván López Pavez100% (1)

- PRESSURE DROP CALCULATION FOR DRILL WATER PIPEDocument9 pagesPRESSURE DROP CALCULATION FOR DRILL WATER PIPEdasubhaiNo ratings yet

- Electrical Works 2003Document15 pagesElectrical Works 2003dasubhaiNo ratings yet

- Control Valve OcrDocument14 pagesControl Valve OcrpathakshashankNo ratings yet

- Emergency Shut Down Valves - ESDDocument2 pagesEmergency Shut Down Valves - ESDLaxman Singh SankhlaNo ratings yet

- Project Standards and Specifications Layout and Spacing Rev1.0Document17 pagesProject Standards and Specifications Layout and Spacing Rev1.0Mert EfeNo ratings yet

- Part - B: (Control and Instrumentation System)Document267 pagesPart - B: (Control and Instrumentation System)joydrathdey100% (1)

- Piping InfoDocument13 pagesPiping InfodasubhaiNo ratings yet

- API - Valve StandardsDocument38 pagesAPI - Valve StandardsK LandryNo ratings yet

- Norsok L-CR-003Document41 pagesNorsok L-CR-003asoka.pwNo ratings yet

- Fundamentals of Orifice Metering PDFDocument3 pagesFundamentals of Orifice Metering PDFshiryNo ratings yet

- Control ValvesDocument38 pagesControl ValvesSridhar GudapatiNo ratings yet

- Pipe Wall Thickness CalculationDocument17 pagesPipe Wall Thickness CalculationdasubhaiNo ratings yet

- Technical Specifications Valve Actuators ScopeDocument6 pagesTechnical Specifications Valve Actuators ScopeBilalPervezNo ratings yet

- ISA 84.01 GuideDocument24 pagesISA 84.01 GuideObinna Benedict ObiojiNo ratings yet

- Tri Sen Surge ControlDocument4 pagesTri Sen Surge ControlJimmy RumlusNo ratings yet

- Scotch Yoke or Rack-and-Pinion Quarter-Turn Actuator?Document2 pagesScotch Yoke or Rack-and-Pinion Quarter-Turn Actuator?Assured AutomationNo ratings yet

- 10 Ways to Kill a PumpDocument10 pages10 Ways to Kill a PumpBaqirMuhammadNo ratings yet

- Focus On Control ValvesDocument5 pagesFocus On Control Valveswmolinac584366No ratings yet

- Instructivodel Actuador Masoneilan Serie 88Document14 pagesInstructivodel Actuador Masoneilan Serie 88Jhon SanabriaNo ratings yet

- Chapter4 Liquid Level Measurement 09Document50 pagesChapter4 Liquid Level Measurement 09ggleichgesinntenNo ratings yet

- Industrial Instrumentation IIDocument15 pagesIndustrial Instrumentation IIHarsha_2994No ratings yet

- Control Valves - International Site For Spirax SarcoDocument12 pagesControl Valves - International Site For Spirax SarcoOzawa MagooNo ratings yet

- ValvesDocument25 pagesValvesAlbertoNo ratings yet

- Orifice Assembly With Flange TapsDocument1 pageOrifice Assembly With Flange TapsDhanny MiharjaNo ratings yet

- JIS Correspondence Pressure Gauge CatalogDocument50 pagesJIS Correspondence Pressure Gauge Catalogwiyoto 369No ratings yet

- DP Level MeasurementDocument3 pagesDP Level MeasurementBarkhaNo ratings yet

- 6month (Idins) - Control Valve Function Test and Positioner CalibrationDocument3 pages6month (Idins) - Control Valve Function Test and Positioner CalibrationJAGDEV PANESARNo ratings yet

- PICV Guide SpecificationDocument7 pagesPICV Guide Specificationrio jeffryNo ratings yet

- Valves PresDocument287 pagesValves PresEnas Al-khawaldehNo ratings yet

- Fisher GX Control Valve and Actuator SystemDocument28 pagesFisher GX Control Valve and Actuator SystemAmiroucheBenlakehalNo ratings yet

- PRV PetrofacDocument36 pagesPRV PetrofacPradeep MagudeswaranNo ratings yet

- CENTUM CS 3000 ENGINEERING SCHEDULERDocument2 pagesCENTUM CS 3000 ENGINEERING SCHEDULERAbhishek KumarNo ratings yet

- PandID Standard 1Document10 pagesPandID Standard 1Grazel MDNo ratings yet

- Micro Flat Cavitation Product BulletinDocument8 pagesMicro Flat Cavitation Product BulletinAmiroucheBenlakehalNo ratings yet

- P Control - Tutorial06Document8 pagesP Control - Tutorial06trung2iNo ratings yet

- Masoneilan 21000 CntrlValve Techspec 0912 PDFDocument34 pagesMasoneilan 21000 CntrlValve Techspec 0912 PDFsabNo ratings yet

- ASCO Filter RegulatorDocument4 pagesASCO Filter RegulatorSamuel JohnsonNo ratings yet

- Instrument Power Cable Sizing Part 1Document2 pagesInstrument Power Cable Sizing Part 1Art G. EnziNo ratings yet

- PUB060-001-00 - 1110 RCL NetworksDocument8 pagesPUB060-001-00 - 1110 RCL NetworksapisituNo ratings yet

- DPI610 615 ManualDocument90 pagesDPI610 615 ManualAbd Al-Rahmman Al-qatananiNo ratings yet

- Attachment M - John Fowler - AnnexXRevBDocument5 pagesAttachment M - John Fowler - AnnexXRevBBùi Văn HợpNo ratings yet

- ESD PresentationDocument34 pagesESD PresentationNoman Abu-FarhaNo ratings yet

- 6.6 Control Valve Actuators and Positioners PDFDocument20 pages6.6 Control Valve Actuators and Positioners PDFdanpolymathNo ratings yet

- Cameron Ball ValvesDocument31 pagesCameron Ball ValvesJosé Roberto Alejo MirandaNo ratings yet

- CCI Valve Selection and Sizing Guide EbookDocument16 pagesCCI Valve Selection and Sizing Guide EbookmakamahamisuNo ratings yet

- S-Mass Series Coriolis Mass Flow and Density Meters and SMT Series TransmittersDocument14 pagesS-Mass Series Coriolis Mass Flow and Density Meters and SMT Series TransmittersazitaggNo ratings yet

- از ميترينگ PDFDocument5 pagesاز ميترينگ PDFazitaggNo ratings yet

- Boustead WHCP Esd Catalog With PicturesDocument16 pagesBoustead WHCP Esd Catalog With PicturesbalajiNo ratings yet

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979From EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNo ratings yet

- Control Station Piping LayoutDocument9 pagesControl Station Piping LayoutKrunalpanchalNo ratings yet

- Steam Pipeline SizingDocument25 pagesSteam Pipeline SizingniteshchouhanNo ratings yet

- Materials - and Impact of - : Effects Economic CorrosionDocument5 pagesMaterials - and Impact of - : Effects Economic CorrosiondasubhaiNo ratings yet

- Piping Arrangement System PDFDocument129 pagesPiping Arrangement System PDFdasubhaiNo ratings yet

- Piping Drawing Checking ProcedureDocument2 pagesPiping Drawing Checking Proceduredasubhai100% (1)

- Types of Fluid Flow MetersDocument10 pagesTypes of Fluid Flow MetersdasubhaiNo ratings yet

- Technical 694 Cable - 1Document21 pagesTechnical 694 Cable - 1santoshcutyNo ratings yet

- Approval Process Handbook 2015 16Document193 pagesApproval Process Handbook 2015 16AakashParanNo ratings yet

- Pipe Flow & Pressure Drop CalculatorsDocument7 pagesPipe Flow & Pressure Drop CalculatorsdasubhaiNo ratings yet

- Alzheimer's Disease: Unraveling The Mystery: To Get The Most Out of This BookDocument2 pagesAlzheimer's Disease: Unraveling The Mystery: To Get The Most Out of This BookdasubhaiNo ratings yet

- Calculations For TankDocument6 pagesCalculations For TankdasubhaiNo ratings yet

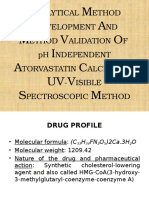

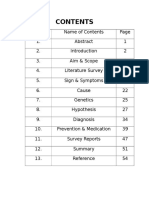

- UV-VIS SPECTROSCOPIC METHOD VALIDATION FOR ATORVASTATIN CALCIUMDocument8 pagesUV-VIS SPECTROSCOPIC METHOD VALIDATION FOR ATORVASTATIN CALCIUMdasubhaiNo ratings yet

- Arijit IndexDocument1 pageArijit IndexdasubhaiNo ratings yet

- Cebora Bravo MIG2235 ManualDocument5 pagesCebora Bravo MIG2235 Manualradu_3g6573100% (1)

- Vibratoin Severity - ISO 2372Document1 pageVibratoin Severity - ISO 2372HARSHANo ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet

- Tico S PDFDocument4 pagesTico S PDFjittshong8072No ratings yet

- YDG2700 / 3700E: Parts CatalogDocument34 pagesYDG2700 / 3700E: Parts CatalogvivsencoNo ratings yet

- ShamrockDocument12 pagesShamrockFerdinand LizadaNo ratings yet

- M100-10 (M-MA Meters) - V3 - 2.11.19 - 1Document28 pagesM100-10 (M-MA Meters) - V3 - 2.11.19 - 1ronald mudimuNo ratings yet

- Caja Transfer MTC - SpecDocument2 pagesCaja Transfer MTC - SpecDanny M Hurtado TaypeNo ratings yet

- Razvodni VentilDocument17 pagesRazvodni VentilalexkeserNo ratings yet

- DowelDocument3 pagesDowelganeshl08No ratings yet

- Testing PDFDocument16 pagesTesting PDFLateef Adewale Kareem0% (1)

- PHYS 343 Midterm Exam Energy Levels Quantized Particle Well Harmonic OscillatorDocument6 pagesPHYS 343 Midterm Exam Energy Levels Quantized Particle Well Harmonic OscillatorSio MoNo ratings yet

- Part Number Per 1 Maret 13Document266 pagesPart Number Per 1 Maret 13Muhammad FaridNo ratings yet

- Permissible Flange Face Imperfections by Pipe SizeDocument1 pagePermissible Flange Face Imperfections by Pipe SizemprabhurajalingamNo ratings yet

- Centrifugal Pump Definition Components Working Priming Advantages Disadvantages and Applications PDFDocument7 pagesCentrifugal Pump Definition Components Working Priming Advantages Disadvantages and Applications PDFMuhammad Yasar JavaidNo ratings yet

- My Elephant Hose Mod Guide for 2007 Grand Cherokee CRDDocument12 pagesMy Elephant Hose Mod Guide for 2007 Grand Cherokee CRDJesusManuelJimenezGallegoNo ratings yet

- Service N ValveDocument30 pagesService N ValvesenamotoNo ratings yet

- 15A03402 Kinematics of MachinesDocument3 pages15A03402 Kinematics of Machinesrammohan reddyNo ratings yet

- Weymouth gas flow equationDocument3 pagesWeymouth gas flow equationPabboji SreenuNo ratings yet

- The Laws and Velocity of Planetary Motion: Section - 10 FDocument3 pagesThe Laws and Velocity of Planetary Motion: Section - 10 FFiyory TassewNo ratings yet

- Rheolube 363F: Rust Inhibited, PTFE FortifiedDocument1 pageRheolube 363F: Rust Inhibited, PTFE FortifiedMed Elhedi NasfiNo ratings yet

- Volvo Service Supplies HandbookDocument10 pagesVolvo Service Supplies HandbookYahdi AzzuhryNo ratings yet

- NATEF Engine Performance Job SheetsDocument13 pagesNATEF Engine Performance Job SheetsAdriRojasNo ratings yet

- 6 Rolled BeamsDocument3 pages6 Rolled BeamsBCXC LLAMNo ratings yet

- CST Solutions for Carel Standard ApplicationsDocument4 pagesCST Solutions for Carel Standard Applicationselshan_asgarovNo ratings yet