Professional Documents

Culture Documents

2 TX de Temperatura Tf202 Ex

Uploaded by

Jhon Erick Izquierdo SoteloOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 TX de Temperatura Tf202 Ex

Uploaded by

Jhon Erick Izquierdo SoteloCopyright:

Available Formats

Data Sheet

10/11-8.70 EN

Field mounted Temperature Transmitter TF212/TF212-Ex

PROFIBUS PA, Pt 100 (RTD), Thermocouples, 1 or 2 independent channels

Input Resistance thermometer (2, 3, 4-wire circuit) Thermocouples Resistance remote signalling units (0...400 , 0...4000 ) Voltages, mV (-15...+115 mV) Output PROFIBUS PA profile V3.0, type A and B Bus design acc. to IEC 1158-2, 31.25 kbit/s Electrical isolation (I/O) Digital, long-term solid processing of measuring values Customer-specific linearization Continuous sensor and self-monitoring Approvals for explosion protection Intrinsically safe II 2 (1) G EEx ia IIC T6 Flameproof ATEX Dust-explosionproof ATEX Input functionality 1 or 2 channels Redundancy Average value Differential value EMC acc. to EN 50082-2 and NE 21 Reserve voltage protection and solid bus current limitation Parameterization DTM for FDT 0.98-1 and 1.2 interface and DSV4xx (SMART VISION) Siemens Simatic PDM driver for TF12/TF212

P R O F

PROCESS FIELD BUS

B U S

Excellent long term stability Temperature linear output signal Enhanced self diagnostics

Field mounted Temperature Transmitter TF212/TF212-Ex PROFIBUS PA, Pt 100 (RTD), Thermocouples, 1 or 2 independent channels

10/11-8.70 EN

Technical data

Output

Digital output signal PROFIBUS PA profile V3.0, type A and B Transmission rate (baud rate) 31.25 kbit/s Nominal current consumption 11.8 mA Max. current in case of device error 15 mA Damping (programmable) t63 = 0...60 s

Thermocouples

Types B, C, D, E, J, K, L, N, R, S, T, U Voltages -15 mV...+ 115 mV Sensor monitoring current 200 A Input resistance 5 M Input filter 50/60 Hz Internal reference junction Pt 100, programmable

Input

Resistance (temperature linear)

Resistance thermometer Pt 50...Pt 100...Pt 1000 Resistance 0...400 /0...4000 Maximum line resistance (Rw) per core <5 Measuring current 200 A Sensor short-circuit < 5 (for RTD) Sensor break > 5 M

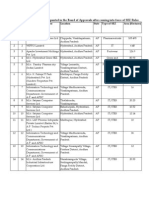

Input element Standard IEC 584-1 Sensor Thermocouple type B Thermocouple type E Thermocouple type J Thermocouple type K Thermocouple type R Thermocouple type S Thermocouple type T Thermocouple type N Thermocouple type C Thermocouple type D Thermocouple type L Thermocouple type U Resistance thermometer Pt 100 Resistance thermometer Pt 1000 Resistance thermometer Pt 100/PT1000 Resistance thermometer Ni 100 2-, 3-, 4-wire

Measuring range 400...+1820 C 100...+1000 C 100...+1200 C 180...+1370 C 50...+1760 C 50...+1760 C 200...+ 400 C 180...+1300 C (+752...+3308 F) (148...+1832 F) (148...+2192 F) (292...+2498 F) ( 58...+3200 F) ( 58...+3200 F) (328...+ 752 F) (292...+2372 F)

Basis Measuring error 0.8 K 0.2 K 0.2 K 0.2 K 0.8 K 0.8 K 0.2 K 0.2 K 0.8 K 0.8 K 0.2 K 0.2 K 0.4 K 0.4 K 0.2 K 0.2 K 0.05 /0.4 20 V

W3, ASTME 998 DIN 43710 IEC 7511)

0...+2300 C (+ 32...+4172 F) 0...+2300 C (+ 32...+4172 F) 100...+ 900 C (148...+1652 F) 200...+ 600 C (328...+1112 F) 200...+ 850 C (328...+1562 F) 200...+ 850 C (328...+1562 F) 100...+ 250 C (148...+ 482 F) 60...+ 250 C ( 76...+ 482 F) 0...400 /0...4000 15 mV...+115 mV

DIN 437602) Resistance Voltage

1) 2)

a = 0.00385 a = 0.00618

Field mounted Temperature Transmitter TF212/TF212-Ex PROFIBUS PA, Pt 100 (RTD), Thermocouples, 1 or 2 independent channels

10/11-8.70 EN

Power supply (at transmitter terminals)

Supply voltage (poling protected) Non-Ex-application Us = 9...32 V DC For Ex-Application, max. Ui = 9...17.5 V DC

Influences

Influence of ambient temperature (related to 25 C) Pt 100 20 ppm/K related to 1050 C Thermocouple 40 ppm/K related to the defined thermocouple measuring range (IEC 584)

General characteristics

Rise time < 0.1...1.25 s Vibration resistance Vibration in operation Electrical isolation (I/O) 1.5 kV 2g nach DIN IEC 68T.2-6

Characteristics at rated conditions

acc. to IEC 770, related to 25 C) Measuring error incl. characteristic deviation Pt 100 (within range -100...+250 C) 0.2 K resistance measurement 0...400 0.05 0...4000 0.4 Thermocouple e. g. type K voltage measurement 0.2 K -15...+115 mV 20 V

Environment conditions

Ambient temperature range -40...+85 C Transport and storage temperature -40...+100 C Relative humidity < 100 % (100 % humidtiy with isolated terminals only) Condensation Permitted

Additional influence of the internal reference junction Pt 100 DIN IEC 751 cl. B

Mechanical construction

Housing material aluminium / stainless steel Color (EPOYXY) light grey (RAL 9002) Weight 1.250 g (without accessories) Electrical connection Thread M20 x 1.5 1/2 NPT, 3/4 NPT, 1/2 GK Cable glands (cable 3,5...8,7 mm) see ordering information Ground screw ext./int. 6 mm2 M5 / 2.5 mm2 M4 Terminals 2.5 mm2, screw terminals

Field mounted Temperature Transmitter TF212/TF212-Ex PROFIBUS PA, Pt 100 (RTD), Thermocouples, 1 or 2 independent channels

10/11-8.70 EN

Explosion protection

Intrinsically safe (ATEX)

Marking EC-Type-Examination certificate Temperature class T6/T4 II 2 (1) G EEx ia IIC T6 ZELM 99 ATEX 0021 < 60 C/85 C

Parameterization/structure

Type of inputs (2 independent channels), measuring range, input filter, damping, alarm function, limit values, compensation for ageing, saving of all data proof against mains failure.

Standard parameters (factory setting)

Channel 1 Pt 100, 3-wire circuit L-L/L/H/H-H-Lim = -200 C/-200 C/850 C/850 C Damping 0 s, dimension C Channel 2 Pt 100, 3-wire circuit L-L/L/H/H-H-Lim = -200 C/-200 C/850 C/850 C Damping 0 s, dimension C Default address 126

Suitable for connceting to fielbus systems according to FISCO model Supply circuit Max. voltage Short-circuit current Max. power Internal inductance Internal capacitance Output [ia] Ui = 17.5 V Ii = 360 mA Pi < 2.52 W Li < 10 H Ci = 1.2 nF Input [ia] Uo = 5.9 V Io = 17 mA Po < 26 mW neglectable neglectable

Flameproof (ATEX)

Marking Temperature class EC-Type-Examination certificate II 2 G EEx d IIC T6 T6/T5/T4 <50 C/65 C/85 C PTB 99 ATEX 1144 X

Process Control System (PCS)

A cyclic communication can be established with all PROFIBUS compatible PCSs. Acyclic communication requires a Master Cl. 2, the communication may be established on the basis of the generic slave (to be in acc. to Profile 3.0; only standard parameters) or a TF 12 specific driver. Those drivers are available for following PCSs: Freelance 2000/Control Builder F (DTM or template) Symphony (Composer via DTM) Siemens (via PDM)

Dust-explosionproof (ATEX)

Zone 20: Intrinsically safe type Marking EC-Type-Examination certificate II 1 D IP 65 T 135 C II 2 G EEx ia IIC T6 DMT 02 ATEX E248 and Zelm 99 ATEX 0021

Configuration-tools

DTM for FDT 0.98-1 and 1.2 interface and DSV4xx (SMART VISION) Siemens Simatic PDM driver for TF12/TF212

Zone 20: Non intrinsically safe type Marking II 1 D IP 65 T 135 C EC-Type-Examination certificate DMT 02 ATEX E248

Electromagnetic compatibility (EMC)

Acc. to NAMUR NE 21 recommendation. With Pt 100 sensor Type of test Burst to signal/ data lines Static discharge contact discharge to: contact plate terminals for supply Radiated field 80 MHz...1 GHz Coupling 150 kHz - 80 MHz Degree 1 kV Standard EN 61000-4-4 EN 50082-2 EN 61000-4-2 8 kV 6 kV EN 61000-4-3 10 V/m EN 61000-4-6 10 V

Field mounted Temperature Transmitter TF212/TF212-Ex PROFIBUS PA, Pt 100 (RTD), Thermocouples, 1 or 2 independent channels

10/11-8.70 EN

Block diagram

Offset Secondary_Value_1 / SV 1 Sensor 1; (T1) Function Block 2 FB2 Temperature 1 + Status

Transducer Block TB

PV=SV1: Secondary Value 1 PV=SV2: Secondary Value 2 PV=SV1 - SV2: Difference PV=SV2 - SV1: Difference PV=1/2 x (SV1+SV2): Average PV=1/2 x (SV1+SV2): Average / Redundance

Primary_Value / PV

Function Block 1 FB1

Calculated Temperature + Status

Secondary_Value_2 / SV2 Sensor 2; (T2)

Function Block 3 FB3

Temperature 2 + Status

Offset

Connection diagram

Output

Microprocessor

1 Input 2 3

2 3

2 3

2 3

K1

+ 2

3

+ 2

3

+ 2

3

2 3

K1

4 4

K1

4 5 6

PROFIBUS PA V3.0

4 5 Reference junction 6

a) b) c)

K2

K2 f)

K2 g) h) i)

d)

e)

a) b) c) d) e) f) g)

Resistance thermometer, 2-wire circuit Resistance thermometer, 3-wire circuit Resistance thermometer, 4-wire circuit Double resistance thermometer, 2-wire circuit Double resistance thermometer, 3-wire circuit Thermocouple Double resistance thermometer

h) Combination resistance thermometer thermocouple i) Combination thermocouple resistance thermometer Resistance measurement analogos to resistance thermometer circuits a) to f) Voltage measurement analogos to thermocouples circuits f) to i)

Z-20158

+ 5

Field mounted Temperature Transmitter TF212/TF212-Ex PROFIBUS PA, Pt 100 (RTD), Thermocouples, 1 or 2 independent channels

10/11-8.70 EN

Communication/Parameterization

Engeneering Tool PROFIBUS PA PROFIBUS DP

Line resistance and 1) cable type

Z-20173

Segmentcoupler

Bus termination

PC with PROFIBUS DP Boards is_PRO Multiboard (ifak) PROFIBOARD (softing) and Software DSV4xx (SMART VISION)

1)

The PROFIBUS standard EN 61158-2 requires the use of shielded bus cables. Please refer to the user manual in regards to the required shielding measures.

Dimensional diagram (dimensions in mm)

90

11

4 97

2 3

2 48 1 1

115

Wall mounting 1 2 3 4 electrical connections thread equipotential bonding screw M5 lock screw

40

M8 40

72

38 ~20

27

115

Pipe mounting

Field mounted Temperature Transmitter TF212/TF212-Ex PROFIBUS PA, Pt 100 (RTD), Thermocouples, 1 or 2 independent channels

10/11-8.70 EN

Ordering information

Catalog No. TF212/TF212-Ex V11524Without explosion protection without explosion protection 1 TF212 With explosion protection Type of protection: intrinsic safety Zelm / ATEX II 2 (1) G EEx ia IIC T6 (Zone 1) 5 TF212-Ex Type of protection: flameproof PTB / ATEX II 2 G EEx d IIC T6 D TF212-Ex d (Zone 20) Type of protection: dust-explosionproof ATEX DMT/ATEX II 1 D IP 65 T 135 C and S TF212-Ex II 2 G EEx ia IIC T6 (intrinsically safe type) II 1 D IP 65 T 135 C (Non intrinsically safe type) G TF212-Ex D DMT/ATEX Display / construction AGLF/AGSF housing without display N Material Aluminum A Stainless steel E Connections with cable screw connections / PA-connector 2 pieces: M20 x 1.5 or pressure-proof 1) N M-connector for PROFIBUS PA (Weidmller) and M 20 x 1.5 W Thread (without cable-screw-connection) M20 x 1.5 1 1/2" NPT 2 3/4" NPT 3 1/2" GK 4 Mounting field housing without 1 Wall mounting (carbon steel) 2 Wall mounting (stainless steel) 3 2" Pipe mounting (carbon steel) 4 2" Pipe mounting (stainless steel) 5 Programming Factory standard parameter default address 126 S Channel 1: Pt100, 3-wire circuit, damping off, unit C L-L // L / H // H-H = -200 C // -200 C / 850 C // 850 C Channel 2: Pt100, 3-wire circuit, damping off, unit C L-L // L / H // H-H = -200 C // -200 C / 850 C // 850 C Customer-specified parameter definition (all parameter without user curve) K Extended customer-specified parameter definition (all parameter including user curve) L 1) Metal screw connection EEx e or EEx d (cable-diameter 3.58.7 mm)

Field mounted Temperature Transmitter TF212/TF212-Ex PROFIBUS PA, Pt 100 (RTD), Thermocouples, 1 or 2 independent channels

10/11-8.70 EN

Accessories

Catalog No. Surge / Lightning protection for M20 x 1.5 cable -entry-glands, Non Ex-Version Type DPI MD 24 M 2 S Surge / Lightning protection for M20 x 1.5 cable -entry-glands, Ex-Version Type DPI MD EX 24 M 2 Device Management Tool DSV4xx (SMART VISION) and DTM TF12/TF212 TF12/TF212 Siemens Simatic PDM 5.02 + SP1 device driver can be downloaded free of license costs from http://www.abb.com/instrumentation 7964116 7964115 see Data Sheet 10/63-1.20 EN

Note: Surge/lightning protection is permitted only for ATEX intrinsically safe devices which will be installed in zone 1 or 2. Measuring circuit of these devices with surge/lightning protection can also be used for zone 0 if allowed in the ATEX approval of this device type

The IndustrialIT wordmark is a registered or pending trademark of ABB. ABB has Sales & Customer Support expertise in over 100 countries worldwide. www.abb.com/instrumentation

The Companys policy is one of continuous product improvement and the right is reserved to modify the information contained herein without notice. Printed in the Fed. Rep. of Germany (09.05) ABB 2005

ABB Ltd. Salterbeck Trading Estate Workington, Cumbria, CA14 5DS UK Tel: +44(0)1946-830-611 Fax: +44(0)1946-832-661

ABB Inc. 125 E. County Line Road Warminster, PA 18974 USA Tel: +1 215-674-6000 Fax: +1 215-674-7183

ABB Automation Products GmbH Borsigstr. 2 63755 Alzenau Germany Tel: +49 551 905-534 Fax: +49 551 905-555 CCC-support.deapr@de.abb.com

10/11-8.70 EN Rev. A

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Špricrore PDFDocument29 pagesŠpricrore PDFIvan KokićNo ratings yet

- Case Study AppleDocument5 pagesCase Study AppleKim Ericka Bautista100% (1)

- ACER 230V (LIFE) AC4R DL Motor Za Vrata UputstvaDocument36 pagesACER 230V (LIFE) AC4R DL Motor Za Vrata UputstvaToni011973No ratings yet

- 5080021-04-GB Operating Instructions Lab. & Pharmaceutical Units - g210Document24 pages5080021-04-GB Operating Instructions Lab. & Pharmaceutical Units - g210Jhon Erick Izquierdo SoteloNo ratings yet

- Gauge Pressure Transmitter Data Sheet EJADocument10 pagesGauge Pressure Transmitter Data Sheet EJAJhon Erick Izquierdo SoteloNo ratings yet

- Micropilot M FMR 230-245Document92 pagesMicropilot M FMR 230-245jimmy_kennedy_15No ratings yet

- Totalflow Abb Xfc6200Document168 pagesTotalflow Abb Xfc6200Jhon Erick Izquierdo SoteloNo ratings yet

- 4 TX de Presion DiferencialDocument36 pages4 TX de Presion DiferencialJhon Erick Izquierdo SoteloNo ratings yet

- Diaphragm Seals for Food and Pharma IndustriesDocument4 pagesDiaphragm Seals for Food and Pharma IndustriesJhon Erick Izquierdo SoteloNo ratings yet

- Cfs10 Coriolis 2inDocument24 pagesCfs10 Coriolis 2inJhon Erick Izquierdo SoteloNo ratings yet

- Transm Is or CoriolisDocument16 pagesTransm Is or CoriolisJhon Erick Izquierdo SoteloNo ratings yet

- Science 4th Class 2022 Quide KPK TextbooksDocument40 pagesScience 4th Class 2022 Quide KPK TextbooksBilal KhanNo ratings yet

- Project Digital ClockDocument12 pagesProject Digital ClockMd. Arif Hasan MasumNo ratings yet

- 9661 HF Ground Radio Family 1424Document2 pages9661 HF Ground Radio Family 1424Quoc Mai0% (1)

- WESTERN EDUCATIONAL INSTITUTE END OF TERM 3 EXAMDocument4 pagesWESTERN EDUCATIONAL INSTITUTE END OF TERM 3 EXAMOsmany MadrigalNo ratings yet

- Productivity Tools For AutoCAD Civil 3D 2015Document1 pageProductivity Tools For AutoCAD Civil 3D 2015Arturo Joel Polanco UrracaNo ratings yet

- Road Map To ISO 14001 2004Document1 pageRoad Map To ISO 14001 2004Budi WibowoNo ratings yet

- NetHSM Quick Start GuideDocument4 pagesNetHSM Quick Start GuidegoldminerNo ratings yet

- Volvo XC90 AccessoryDocument4 pagesVolvo XC90 AccessoryTeravut SuwansawaipholNo ratings yet

- Self Driving Car AI MethodsDocument5 pagesSelf Driving Car AI MethodsIndian e-commerce dealsNo ratings yet

- Brochure Wheel Balancers Hofmann enDocument21 pagesBrochure Wheel Balancers Hofmann enANDREA PALLOTTANo ratings yet

- Bim Contract IssuesDocument9 pagesBim Contract IssuesEl ZharNo ratings yet

- List of Formal Approval SEZDocument34 pagesList of Formal Approval SEZsampuran.das@gmail.comNo ratings yet

- Abhinava's Blog - Animated GIF ImageView Library For Android PDFDocument5 pagesAbhinava's Blog - Animated GIF ImageView Library For Android PDFShoaib QuraishiNo ratings yet

- 50 Đề Đột Phá Tiếng Anh Điểm 9 + Bộ Đề Thi Vào 10 Bùi Văn Vinh - Có Đáp ÁnDocument225 pages50 Đề Đột Phá Tiếng Anh Điểm 9 + Bộ Đề Thi Vào 10 Bùi Văn Vinh - Có Đáp ÁnHoài ThuNo ratings yet

- Procedure - Testing and Calibration For Process InstrumentDocument10 pagesProcedure - Testing and Calibration For Process Instrumentjabpun0% (1)

- Manual de Servicio Escaner Scanelite 5400Document34 pagesManual de Servicio Escaner Scanelite 5400erizo999No ratings yet

- FIREWALLDocument33 pagesFIREWALLNOREEN KEITH MAMOLONo ratings yet

- BASDocument178 pagesBASclayjr70No ratings yet

- Conceptual Framework Process ChartDocument2 pagesConceptual Framework Process ChartCarl Michael Robillos100% (6)

- ETSI EG 202 009-3: Final Draft V1.1.0Document25 pagesETSI EG 202 009-3: Final Draft V1.1.0Thomas MpourtzalasNo ratings yet

- Civil Engineering BooksDocument9 pagesCivil Engineering BooksElvi Papaj0% (1)

- Internsship - Project - Arjun Singh FinalDocument78 pagesInternsship - Project - Arjun Singh FinalAnmol DubeyNo ratings yet

- Folded Cascode Operational Transconductance Amplifier ThesisDocument6 pagesFolded Cascode Operational Transconductance Amplifier Thesismelissawardbaltimore100% (1)

- Telstrat EngageDocument4 pagesTelstrat EngageJesse MelloNo ratings yet

- Universiti Tun Hussein Onn Malaysia Faculty of Mechanical and Manufacturing Engineering BDA 24202 Computer Programming Individual Assignment (10%)Document1 pageUniversiti Tun Hussein Onn Malaysia Faculty of Mechanical and Manufacturing Engineering BDA 24202 Computer Programming Individual Assignment (10%)farooq MusaNo ratings yet

- Laser Scanning TechnologyDocument13 pagesLaser Scanning TechnologyVirgilio F. Abundo Jr.No ratings yet

- IPC-TM-650 Test Methods Manual: Contact Tool Contact ToolDocument2 pagesIPC-TM-650 Test Methods Manual: Contact Tool Contact ToolKaja PrelovsekNo ratings yet