Professional Documents

Culture Documents

Strengthening of Masonry Walls by Transverse Connection Through Afrp Rods: Experimental Tests and Analytical Models

Uploaded by

rashidkingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strengthening of Masonry Walls by Transverse Connection Through Afrp Rods: Experimental Tests and Analytical Models

Uploaded by

rashidkingCopyright:

Available Formats

This paper proposes a partial-destructive method for connecting adjacent orthogonal

masonry walls by means of aramid fibre reinforced polymer (AFRP) rods, in order to

improve the overall performance of masonry buildings under horizontal forces. The proposed

method is supported by an experimental campaign to assess the effectiveness of the

strengthening measure, and by an analytical study to develop equations suitable for design.

The experimental tests showed that the connection between adjacent masonry walls is

actually effective in increasing both their strength and stiffness. It is also shown that the

developed analytical equations satisfactorily predict the relevant design quantities.

Keywords: connection of adjacent walls; strengthening of URM; improvement of flexural behaviour;

out of plane overturning collapse; FRP strengthening.

1. INTRODUCTION

It is common to find in our cities old buildings with load bearing masonry walls that were designed

only to resist vertical loads and with no consideration of horizontal loads. This is usually reflected

in the arrangement of walls perpendicular to each other, which are not clamped along the edges.

This lack of connection may be found either in backbone (or main) walls that intersect with each

other, or in other walls considered as secondary, but made of stone that are given a structural

function, or even in walls that were independent in the original construction, because designed as

vertical load bearers or because partly independent and without a load-bearing function.

When seismically retrofitting these buildings, it may be convenient to take advantage of all existing

walls to provide resistance to horizontal forces by connecting them to each other at their intersections.

By doing so, two originally unconnected walls are made into a single one with a T-shaped cross-

section. The result is that the strength and the stiffness of each single wall are increased. This allows

avoiding insertion of additional walls or thickening of the existing ones, with all the obvious

difficulties related to these strategies. In the past, such strengthening measures were carried out by

STRENGTHENING OF MASONRY WALLS BY TRANSVERSE CONNECTION

THROUGH AFRP RODS: EXPERIMENTAL TESTS AND ANALYTICAL MODELS

NED UNIVERSITY JOURNAL OF RESEARCH, THEMATIC ISSUE ON EARTHQUAKES, 2012 61

Marco Vailati

1

, Giorgio Monti

2

Manuscript received on 17

th

June 2012, reviewed and accepted on 21

st

August 2012 as per publication policies

of NED University Journal of Research.

ABSTRACT

1

Post-Doctoral Researcher, Department of Structural and Geotechnical Engineering, Sapienza University of Rome, Italy. Ph. (+39) 06 49919254,

Fax. (+39) 06 3221449, Email: marco.vailati@uniroma1.it.

2

Full Professor, Department of Structural and Geotechnical Engineering, Sapienza University of Rome, Italy. Ph. (+39) 06 49919197,

Fax. (+39) 06 3221449, Email: giorgio.monti@uniroma1.it.

M. Vailati and G. Monti

NED UNIVERSITY JOURNAL OF RESEARCH, THEMATIC ISSUE ON EARTHQUAKES, 2012 62

Marco Vailati is a Post Doctoral Researcher in the Department of Structural Engineering and

Geotechnics at Sapienza University of Rome, Italy where he received his Masters in Innovation

in Design, Rehabilitation and Control of Structures: Assessment and Retrofitting in Seismic

Areas and PhD in Structural Engineering, respectively, in 2004 and 2011. His research Interests

include earthquake risk assessment of building structures, and strengthening of masonry walls

and reinforced concrete structures with advanced techniques.

drilling holes and inserting metal bars in them, which were then partially filled with mortar injections.

However, metal bars are often subjected to corrosion if not properly injected.

Therefore, a technique to connect two originally unconnected walls into a T-shaped layout has been

studied and tested, which makes use of thin rods of aramid fibre reinforced polymer (AFRP) inserted

in small holes drilled in the flange wall. These rods are then anchored to the lateral surfaces of the

web wall through spread fibres, which are then glued onto the web wall surface, thus providing

efficient anchorage. Since the connection has to restrain the vertical sliding between the connected

walls, the rods are placed at 45, so as to provide tension components in both sliding verses.

In this way, the strengthening technique maximizes the capacity of the existing structural walls with

minimum invasivity.

2. TESTING SET-UP

The tests described below have been carried out at the Department of Structural and Geotechnical

Engineering of the Faculty of Architecture of the Sapienza University of Rome, Italy.

2.1 Geometry and Boundary Conditions

The configuration of the testing rig with the walls is shown in Figure 1.

The boundary conditions are: F

V

= o

0

.

t

.

l; u

v1

= u

v2

= 0; u

h

= imposed; F

h

= measured.

where o

0

is the average stress in the web wall cross-section; t and l are the web thickness and length,

respectively; u

v1

and u

v2

are the vertical imposed displacements at the two flanges; u

h

is the horizontal

imposed displacement; F

h

is the horizontal measured force. Therefore, it can be understood that all

tests were performed under displacement control, in order to follow any possible degrading branch

in the wall response.

Figure 2 shows a typical wall configuration, along with a detail of the connection with the anchorage.

The measuring equipment is constituted by five strain gauges, numbered from 1 to 5; the first four

measure the vertical relative displacements between web and flange, while the last measures the

horizontal absolute displacement.

Giorgio Monti is a Full Professor at Sapienza University of Rome, Italy. His research interests

include modelling, analysis and assessment of reinforced concrete and masonry structures

under seismic excitation, structural health monitoring, strengthening techniques with innovative

materials (FRP), strategies for the preservation of historical towns, and reliability analysis of

structures and infrastructures in seismic zones. He is an active member of national and

international committees for the development of seismic design codes.

Figure 1. Configuration of testing rig and walls.

NED UNIVERSITY JOURNAL OF RESEARCH, THEMATIC ISSUE ON EARTHQUAKES, 2012 63

2.2 Materials

Clay bricks with premixed mortar were used to build the walls, while AFRP rods were used to

connect them. The walls mean mechanical properties were: compressive strength (f

d

) = 6.00 MPa

(0.87 ksi); shear strength (t

d

) = 1.38 MPa (0.2 ksi); Youngs modulus (E) = 2,700 MPa (392 ksi);

shear modulus (G) = 900 MPa (131 ksi).

The AFRP rod properties were: tensile strength (f

yd,c

) = 1400 MPa (203 ksi); Youngs modulus (E

d,c

)

= 60,000 MPa (8.7x10

6

ksi)

The total tensile strength of the connection system was: (a) configuration 1 R

T,1

= 32 kN (7 kips);

(b) configuration 2 R

T,2

= 16 kN (3.6 kips).

In configuration 1, the spread of the terminal anchors lays along the bar axis, while in configuration

2 it is arranged at 90 (Figure 3).

2.3 Connections between web and flange walls

The connection between web and flange walls is constructed in few simple steps (Figure 4). The

details of these phases are as under

Phase a: drilling holes from the outer face of the flanges, tangent to the web wall faces

Phase b: inserting the rods through the flanges and fixing them in the hole with mortar

Phases c and d: gluing the spread ends to the surface of both walls

Phases e and f: applying aramid sheets with vinylester resin to cover and strengthen the anchorages

The AFRP rods were of 5.5 mm (0.22 in.) diameter, while the holes crossing through the flange

were of 7 mm (0.28 in.) diameter.

3. TEST RESULTS

The walls specimens consist of one web wall and two flange walls at its ends. They are instrumented

as shown in Figure 2.

Figure 2. Displacement transducers on a masonry wall specimen. At top right the anchorage

detail of the rods.

Note: All dimensions are in mm; 25.4 mm = 1 in.

NED UNIVERSITY JOURNAL OF RESEARCH, THEMATIC ISSUE ON EARTHQUAKES, 2012 64

M. Vailati and G. Monti

Figure 4. Construction phases of the connections between flanges and web walls.

Figure 3. Detail of AFRP rod anchorage: the two reference configurations (above), the test

configuration (below).

NED UNIVERSITY JOURNAL OF RESEARCH, THEMATIC ISSUE ON EARTHQUAKES, 2012 65

With reference to Figure 2, transducers 1, 2 and 3, 4 are used to measure the relative displacement

between the web wall and flanges, while transducer 5 measures the horizontal displacement between

foundation and wall head.

The global effects of this strengthening method are illustrated in Figure 5-7. Figure 5 shows the

comparison at the first cycle between unstrengthened and strengthened wall. In the strengthened

wall, the improved collaboration between the orthogonal walls gives rise to an increase in the initial

stiffness. Note that, in the strengthened wall, the stiffness is increased approximately by 40%.

Figure 5. Comparison between strengthened and unstrengthened wall at the first cycle: increase

of stiffness.

Figure 6. Horizontal force vs. relative displacement between web and flanges walls.

Figure 7. Comparison between strengthened and unstrengthened wall at ultimate: increase

of flexural capacity. At top left: detail of crushing of masonry.

Note: 25.4 mm = 1 in.; 4.448 kN = 1 kips

Note: 25.4 mm = 1 in.; 4.448 kN = 1 kips

Note: 25.4 mm = 1 in.; 4.448 kN = 1 kips

NED UNIVERSITY JOURNAL OF RESEARCH, THEMATIC ISSUE ON EARTHQUAKES, 2012 66

M. Vailati and G. Monti

For low horizontal forces, the two curves are practically coincident; however, when passing 30%

of the unstrengthened wall failure load, the connections modify the wall system response. This delay

could eventually be avoided, if need, by pretensioning the rods. In fact, a truss-like mechanism can

be activated only when the rods are sufficiently stressed in tension.

In Figure 6, the difference in terms of relative displacement between the web and flange walls can

be observed: for the unstrengthened configuration it is 0.31 mm (0.01 in.), while in the other one

it is 0.02 mm (7.8x10

-4

in.). The smaller displacement in the strengthened case is due to the presence

of the rods.

Initially, the contacting surfaces slip relatively one to each other, however, when the rods start being

pulled, they provide their contribution by imposing compatibility of the displacements of both

surfaces. After this stage, the wall system shows a significant increase of strength and ductility, as

shown in Figure 7.

In Figure 7, the curves were obtained by inverting the load path at yield displacement (curve 1),

at 50% of ultimate displacement (curve 2), at ultimate displacement (curve 3). Note that each reversal

point is marked by a circle.

As observed from the tests performed, the strengthening effectiveness strongly depends on the

correct application of the rods. In order to exploit the material mechanical properties, the rods are

inserted at 45. As a matter of fact, for a plane stress state in shear, the maximum tensile force

is inclined at 45 with respect to the vertical, as shown in Figure 8.

Two effects can be observed when reaching the ultimate limit state

1) Detachment from the wall of the aramid sheet that covers the rods anchor;

2) Loss of the flange wall verticality

In Figure 9b, a tension failure of a rod is shown, with clear signs of breakage in its cross-section.

Figure 8. Shear transfer mechanism between web wall and flange.

NED UNIVERSITY JOURNAL OF RESEARCH, THEMATIC ISSUE ON EARTHQUAKES, 2012 67

Figure 9. Collapse by flexural mechanism of wall: (a) collapse of masonry with expulsion of

material to external direction; (b) traction failure of a rod.

4. COMPARISON WITH ANALYTICAL MODEL

4.1 Unconnected Walls

The stiffness obtained from the experimental results is compared to the analytical model proposed

by Tomazevic [3]

(1)

Figure 10 shows the comparison between experimental and predicted stiffness.

It can be seen in Figure 10 that Eq. (1) accurately predicts the elastic experimental stiffness, while

a 50% reduction gives a good estimate of the ultimate displacement.

Figure 10. Comparison between experimental and predicted stiffness and peak strength at

first cycle.

G

.

A

W

K

I

G h

l E

2

2h 1 1

+

o

=

.

. . . .

q r o p

Note: 25.4 mm = 1 in.; 4.448 kN = 1 kips

(a) (b)

NED UNIVERSITY JOURNAL OF RESEARCH, THEMATIC ISSUE ON EARTHQUAKES, 2012 68

M. Vailati and G. Monti

The wall capacity is assessed by considering two possible failure mechanisms [1, 2] that may

develop, i.e., flexural and diagonal shear, respectively, as follows

(2)

(3)

The prevailing collapse mechanism is the one with lower capacity.

Table 1 contains the parameters used to calculate the stiffness (Eq. (1)) and the capacities (Eqs. (2)

and (3)).

For the case at hand, the capacities are: f

yF

= 64.6 kN; f

yV

= 390.8 kN. Therefore, it is recognized

that failure is of the flexural type.

The experimental test on the unstrengthened walls exactly shows this behaviour, for a horizontal

force equal to 70 kN (15.7 kips), very close to the analytically predicted value. Figure 11 shows

the crack pattern, typical of a flexural failure mechanism (note that the flange walls, though present,

are not connected).

4.2 Connected Walls

The connection of the web wall to the flange walls improves the performance of the overall system,

by increasing its bending capacity thanks to the change in shape of the base cross-section, which is

h

mm

(ft.)

1850

(6)

l

mm

(ft.)

1550

(5)

t

mm

(in.)

120

(5)

Aw

mm

(in.)

1.86x10

5

(7x10

3

)

o

0.83

G

MPa

(ksi)

900

(130)

E

MPa

(ksi)

2700

(392)

f

m,d

MPa

(ksi)

6.00

(0.87)

t

0,d

MPa

(ksi)

1.38

(0.20)

o

0

MPa

(ksi)

0.97

(0.14)

Table 1 - Parameters used to evaluate the wall capacity

Figure 11. Crushing of masonry in web wall: left and right side, near foundations.

F

2

=

q r

o

f

y

H

0

p

2

1

1

0 0

0.85 f

d

.

t o o

.

.

V

f

y

t

b

=

1 . . .

.

1 5

d

.

.

1 5

d

1

0

+

o

t

w

t

NED UNIVERSITY JOURNAL OF RESEARCH, THEMATIC ISSUE ON EARTHQUAKES, 2012 69

now T-shaped, with a significant contribution from the compressed flange. The shearing capacity,

however, remains unaffected and equal to that of the web wall, since the flanges do not provide any

contribution to it.

The bending capacity of the T-shaped cross section is obtained by writing the equilibrium equation

of the web and flange system, considered as fully connected. Figure 12 shows a comparison of the

two configurations for adjacent and connected walls.

The equilibrium equation for the T-shaped wall is given in Eq. (4)

V

.

H = N

p

.

e

p

+

N

a

.

e

a

(4)

Rearranging Eq. (4) and introducing non-dimensional notation, the following capacity equation is

obtained

(5)

where M

U,T

is the flexural capacity of strengthened T-shaped wall; M

U,I

is the capacity of the

(unstrengthened) I-shaped wall and is given in Eq. (6); q, t and are non-dimensional factors (Eq.

(7)). Note that the first factor is of mechanical nature whereas the others are related to geometry.

Figure 12. Notation of variables and stress distribution before failure: isolated wall (left);

connected wall (right).

(6)

(7)

Applying Eq. (5) to the specific case of the test walls, characterized by the following parameters:

t= 0.077, = 4.58, q= 0.23, it is possible to assess the magnitude of the force that triggers the

bending failure mechanism (106 kN (23.8 kips)). The result is practically identical to that obtained

in the test, of 110 kN (24.7 kips).

In order to calculate the capacity of the strengthened system, in this case it is also necessary to duly

account for the contribution of the compressed flange. As it is known, Eq. (1) takes into account

both bending (K

B

) and shear (K

S

) stiffness of the walls (Eq. (8)).

(8)

M

U,T

M

U,I

=

.

(1+ t . )

t

2

.

(1 )

q

+ r q

M

U,I

=

1

2

to

0

(1 q)

r q

2

o

0

q = = =

0.85

.

f

d

; t

t

a

1

p

1

a

t

p

;

K

I

=

K

B

+ K

S

=

12EJ

h

3

1.2h

+

GA

NED UNIVERSITY JOURNAL OF RESEARCH, THEMATIC ISSUE ON EARTHQUAKES, 2012 70

M. Vailati and G. Monti

As mentioned above, the presence of the flange only modifies the flexural response of the wall,

leaving the shear behaviour almost unaffected.

It will, therefore, be sufficient to express the second moment of area for a T-shaped section in place

of that for the I-shaped section, in order to predict the stiffness of the strengthened system. The

second moment of area for the T-shaped section is given as

By re-defining Eq. (8) we obtain

(10)

In Eq. (10), o assumes its usual meaning. Note that the second moment of area of the T-shaped

section significantly contributes to the flange width, i.e., the part of the wall at the end involved in

the flexural resisting mechanism.

Although there is a dependency on the thickness ratios of the connected walls this type of problem

requires specific study, which can only be addressed in qualitative terms here. Considering this, it

may be helpful to address the problem according to Tomazevic [3], so that the flange width is defined

as in Figure 13.

The proposed approach must be considered in the context of a more general application of the

method in real cases, for buildings made of bricks.

In the specific case of the walls tested, the problem is not so significant, since all flanges lengths

were entirely involved in the resisting mechanism.

4.3 Design of the connections

Based on the above discussion, a design equation is proposed here for an easy application of the

method. The equation is capable of correlating the sliding force between the faces of the two

connected walls with the number of rods, which is essential for a correct design of the connection

system.

By looking at the distribution of contact stresses in Figure 12, the sliding force between the web

and flange walls can be evaluated. Since the vertical load is only applied on the web wall, the stress

at the flange base is the reaction to the combined compressive force and bending moment generated

by the horizontal force. The sliding force at the interface is thus given by

Figure 13. Definition of the geometry of the flange in the connected walls.

(11) F

s

= (0.85

.

f

d

- o

0

)

.

t

a

1

a

K

T

=

GA

w

GA

w

12EJ

T

1.2h

2

1

h

+ q r o

. .

(9)

[l

a

.

(l

p

+ t

a

)

2

- l

2

p

.

(l

a

- t

p

)]

2

- 4

.

l

a

.

l

p

.

(l

p

+ t

a

)

.

(l

a

- t

p

)

.

[(l

p

+ t

a

) - l

p

]

2

12

.

[l

a

.

(l

p

+ t

a

)- l

p

.

(l

a

- t

p

)]

J

T

=

NED UNIVERSITY JOURNAL OF RESEARCH, THEMATIC ISSUE ON EARTHQUAKES, 2012 71

The number of rods to be inserted to ensure that the connection resists until bending failure is then

given by

(12)

where R

T,1-2

is the connection tensile strength, according to one of the possible configurations, as

indicated in section 3. The total number of the rods to be applied is therefore equal to 4n, because

they are applied on both faces of the web wall and because they are inserted at 45.

5. CONCLUSIONS

The comparison of the performance of connected walls with that of adjacent walls (based on the

experiments carried out) indicated that a strength increase of

R

= 1.57 and displacement increase

of

d

= 3.2 was obtained. As a result, there is an increase in the capacity of about 60%, while ductility

increases by a factor of 3. Note that, beyond affecting the main resisting mechanisms, the proposed

strengthening technique provides both local and global ductility as this application can reverse the

hierarchy between failure mechanisms (shear and flexure), thus favouring the latter, which is more

ductile. Finally, it was ascertained that the developed equations are accurate in predicting both the

capacity and the stiffness of the strengthened wall system.

ACKNOWLEDGMENTS

The authors wish to thank the SACEN Company of Naples, Italy, for providing and applying the

NAILTEX AFRP rods.

NOTATION

fm = Mean compression strength

t

0

= Mean shear strength

K

e

= Stiffness of masonry wall

A

w

= Shear area of I-section

h = effective height of wall

l = Length of wall

o = Factor dependent of boundary condition (0.83 or 3.33 in case of cantilever)

t = Thickness of wall

o

0

= Mean normal tension on the total section area

H

0

= Point along the wall where the moment change sign

b = Factor depending of wall slenderness, and it can be take 1 Ob=h/l O1.5

f

yF

= Flexural capacity of wall

f

yV

= Diagonal shear capacity of wall

N

P

= Resultant of normal force on web section

N

a

= Resultant of normal force on flange section

e

p

= Eccentricity of Np

e

a

= Eccentricity of Na

K

I

= total stiffness of wall (I-shaped section)

J

T

= moment of inertia of T-shaped section

K

T

= total stiffness wall (T-shaped section)

F

S

= Sliding force at the interface web/flange

n = Number of rods

REFERENCES

[1] Ministry of Infrastructure and Transportation of Italy. Istruzioni per lapplicazione delle nuove

norme tecniche per le costruzioni di cui al decreto ministeriale 14 gennaio 2008. Supplemento

ordinario n. 27 alla Gazzetta Ufficiale, 2009.

[2] Ministry of Infrastructure and Transportation of Italy. Nuove Norme Tecniche per Le Costruzioni.

Gazzetta Ufficiale della Repubblica Italiana 2008.

[3] Tomazevic M. Earthquake resistant design of masonry buildings. Series on Innovation in

Structures and Construction., England, Imperial College Press London, 1981. p. 109-158.

F

s

n = round

2

.

w

2

.

R

T,1-2

o p

NED UNIVERSITY JOURNAL OF RESEARCH, THEMATIC ISSUE ON EARTHQUAKES, 2012 72

M. Vailati and G. Monti

[4] Menegotto M, Monti G, Salvini S, Vailati M. Improvement of Transverse Connection of

Masonry Walls through AFRP Bars. In: Ye L, Yue Q, Peng F, Editors. Proceeding of 5th

International Conference on FRP Composites in Civil Engineering. Beijing, China: 2010.

p. 947-950.

[5] Anthoine A, Magonette G, Magenes G. Shear-compression Testing and Analysis of Brick

Masonry Walls. In: Proceedings of 10th European Conference on Earthquake Engineering.

Rotterdam, Netherlands: 1995.

[6] Magenes G, Calvi GM. Cyclic Behaviour of Brick Masonry Walls. In: Proceedings of 10th

World Conference on Earthquake Engineering. Rotterdam, Netherlands: 1992.

[7] Magenes G, Calvi GM. In-plane Seismic Response of Brick Masonry Walls. Earthq Eng Struc

Dyn 1997;26(11):1091-1112.

[8] Turnek V, Cacovic F. Some Experimental Results on the Strength of Brick Masonry Walls.

In: Proceedings of the 2nd International Brick Masonry Conference, Stoke-on-Trent, England:

1971. p. 149-156.

[9] Turnsek V, Sheppard P. The Shear and Flexural Resistance of Masonry Walls. In: Procedure

of the International Research Conference on Earthquake Engineering. Skopje, Macedonia:

1980. p. 517-573.

[10] Turco V, Secondin S, Morbin A, Valluzzi M.R, Modena C. Flexural and Shear Strengthening

of Un-reinforced Masonry with FRP Bars. Comp Sci Tech 2006;66(2):289-296.

[11] Tumialan G, Micelli F, Nanni A. Strengthening of Masonry Structures with FRP Composites.

In: Chang PC, Editor. Proceedings of the 2001 Structural Congress and Exposition. Washington

DC, USA: 2001. p. 1-8.

You might also like

- Validation Master PlanDocument27 pagesValidation Master PlanPrashansa Shrestha85% (13)

- Juan Martin Garcia System Dynamics ExercisesDocument294 pagesJuan Martin Garcia System Dynamics ExercisesxumucleNo ratings yet

- FP-XH PGRG eDocument936 pagesFP-XH PGRG ebvladimirov85No ratings yet

- CFRP-Retrofitted Concrete Shear Walls Pushover TestsDocument16 pagesCFRP-Retrofitted Concrete Shear Walls Pushover TestsАвирмэдийн ГэрэлболдNo ratings yet

- Panagiotou and Restrepo 7-Story DBD - Final Rev 11MAY-1Document42 pagesPanagiotou and Restrepo 7-Story DBD - Final Rev 11MAY-1Jorge Luis Garcia ZuñigaNo ratings yet

- 2010EQConf 000684Document10 pages2010EQConf 000684Khwopa CollegeNo ratings yet

- Tu et al. - 2022 - In-Plane Loading Tests and a Retrofitting TechniquDocument15 pagesTu et al. - 2022 - In-Plane Loading Tests and a Retrofitting TechniquJose Ignacio Fredes SiervoNo ratings yet

- WCEE2012 3403-ElwoodDocument10 pagesWCEE2012 3403-ElwoodjvixtorNo ratings yet

- Friction Coefficient Masonry Correlation Quality IndexDocument12 pagesFriction Coefficient Masonry Correlation Quality IndexPedro SilvaNo ratings yet

- Shear Capacity Prediction of Confined Masonry Walls Subjected To Cyclic Lateral LoadingDocument13 pagesShear Capacity Prediction of Confined Masonry Walls Subjected To Cyclic Lateral LoadingAdel AdelNo ratings yet

- Comparing Effects of Openings in Concrete Shear WallsDocument10 pagesComparing Effects of Openings in Concrete Shear WallsIrshadAhmedNo ratings yet

- Earthquake Performance of High-Strength Concrete Structural Walls With Boundary ElementsDocument18 pagesEarthquake Performance of High-Strength Concrete Structural Walls With Boundary ElementsAbi Ilamvazhuthi100% (1)

- 21 Seismic Behaviour of Confined Masonry WallsDocument13 pages21 Seismic Behaviour of Confined Masonry WallsFouad KehilaNo ratings yet

- Strength and Stiffness of Masonry Shear Walls With OpeningsDocument12 pagesStrength and Stiffness of Masonry Shear Walls With OpeningsAhmad NaqiNo ratings yet

- Analytical and Experimental Study of The In-Plane Shear Behavior of Reinforced Masonry WallsDocument12 pagesAnalytical and Experimental Study of The In-Plane Shear Behavior of Reinforced Masonry Wallsjiliang liuNo ratings yet

- Non-Linear Behaviour of Welded Stitch Plate Connections in Jointed Precast Building CoresDocument9 pagesNon-Linear Behaviour of Welded Stitch Plate Connections in Jointed Precast Building Coresrui yangruixiNo ratings yet

- Greifenhagen Lestuzzi Eng Struct 2005Document28 pagesGreifenhagen Lestuzzi Eng Struct 2005Killian WismanNo ratings yet

- Published Paper - 2i-0002Document9 pagesPublished Paper - 2i-0002Qingzhi LiuNo ratings yet

- Seismic Performance of Precast Polystyrene RC Walls: Ari WibowoDocument8 pagesSeismic Performance of Precast Polystyrene RC Walls: Ari Wibowoc4ppuc1n0No ratings yet

- Cyclic Behavior of Masonry Walls Strengthened by Tie RodsDocument14 pagesCyclic Behavior of Masonry Walls Strengthened by Tie RodsSCHLEUNYNo ratings yet

- Evaluate Performance of Precast Concrete Wall To Wall ConnectionDocument6 pagesEvaluate Performance of Precast Concrete Wall To Wall ConnectionRohan ReddyNo ratings yet

- Literature ReviewDocument3 pagesLiterature Reviewharshithak.cee21No ratings yet

- Kazaz - Deformation Limits For Structural Walls With Confined Boundaries PDFDocument28 pagesKazaz - Deformation Limits For Structural Walls With Confined Boundaries PDFKamirã Barbosa RibeiroNo ratings yet

- RC Masonry Shear Wall DuctilityDocument8 pagesRC Masonry Shear Wall DuctilityArieska HermastiadiNo ratings yet

- Behavior o Welded Plate Connections in Precast Concrete Panels Under Simulated Seismic LoadsDocument13 pagesBehavior o Welded Plate Connections in Precast Concrete Panels Under Simulated Seismic Loadslil_starNo ratings yet

- Behnam Et Al-2017-The Structural Design of Tall and Special BuildingsDocument17 pagesBehnam Et Al-2017-The Structural Design of Tall and Special BuildingsKepian Hussein DraboNo ratings yet

- Shake-Table Tests of Partially Grouted Reinforced Masonry BuildingsDocument12 pagesShake-Table Tests of Partially Grouted Reinforced Masonry BuildingstonyNo ratings yet

- Shear Capacity Prediction of Confined Masonry Walls Subjected To Cyclic Lateral LoadingDocument14 pagesShear Capacity Prediction of Confined Masonry Walls Subjected To Cyclic Lateral LoadingJalal KeNo ratings yet

- Finite Element Analysis of Cantilever and Counterfort Retaining Wall BehaviorDocument15 pagesFinite Element Analysis of Cantilever and Counterfort Retaining Wall BehaviorKhalid AljanabiNo ratings yet

- Static and Dynamic Analysis of Shear Wall Subjected To Lateral LoadsDocument7 pagesStatic and Dynamic Analysis of Shear Wall Subjected To Lateral LoadsVivek PatvaNo ratings yet

- Laura N. Lowes, Dawn E. Lehman, and Carson BakerDocument23 pagesLaura N. Lowes, Dawn E. Lehman, and Carson BakerCarsonBakerNo ratings yet

- Seismic Performance of Masonry Infill Walls Retrofitted With CFRP SheetsDocument14 pagesSeismic Performance of Masonry Infill Walls Retrofitted With CFRP SheetsamaliaconstantinNo ratings yet

- An Experimental Study of Confined Masonry Walls With Varying Aspect RatioDocument39 pagesAn Experimental Study of Confined Masonry Walls With Varying Aspect RatioCarlos NBNo ratings yet

- SigmundDocument35 pagesSigmundTariqul IslamNo ratings yet

- Testing Joints Between Walls Made of AAC Masonry Units: ArticleDocument21 pagesTesting Joints Between Walls Made of AAC Masonry Units: ArticleJalal KeNo ratings yet

- Seismic Retrofitting of Unreinforced Masonry Walls by Cable SystemDocument15 pagesSeismic Retrofitting of Unreinforced Masonry Walls by Cable SystemDamit SuranaNo ratings yet

- Seismic Upgrade of Beam-Column Joints With FRP ReinforcementDocument17 pagesSeismic Upgrade of Beam-Column Joints With FRP Reinforcementodhie79No ratings yet

- Seismic Strengthening and Repair of RC Shear Walls PDFDocument8 pagesSeismic Strengthening and Repair of RC Shear Walls PDFSri LathaNo ratings yet

- 13194-Article Text For Production-67096-1-10-20210813Document12 pages13194-Article Text For Production-67096-1-10-20210813AbigailNo ratings yet

- Seismic Resistance of Precast Concrete Shear WallsDocument17 pagesSeismic Resistance of Precast Concrete Shear WallsDavid LopezNo ratings yet

- Thin-Walled Structures: Full Length ArticleDocument17 pagesThin-Walled Structures: Full Length ArticleSeban ACNo ratings yet

- Energy Aspect of Coupled Shear Walls Behaviour in An EarthquakeDocument2 pagesEnergy Aspect of Coupled Shear Walls Behaviour in An EarthquakeMohammed ZakariaNo ratings yet

- Design of High-Rise Core-Wall Buildings PerspectiveDocument8 pagesDesign of High-Rise Core-Wall Buildings Perspectivefoush bashaNo ratings yet

- Rat Trap Bond StructuresDocument8 pagesRat Trap Bond Structuresprozoam21No ratings yet

- Hysteretic Behavior of RC Shear Walls Strengthened With CFRP StripsDocument9 pagesHysteretic Behavior of RC Shear Walls Strengthened With CFRP StripstoilfulboyNo ratings yet

- Comparing Effects of Openings in Concrete Shear Walls Under Near-Fault Ground MotionsDocument10 pagesComparing Effects of Openings in Concrete Shear Walls Under Near-Fault Ground MotionsBajrang GuptaNo ratings yet

- Construction and Building Materials: Giulio Castori, Marco Corradi, Emanuela SperaziniDocument15 pagesConstruction and Building Materials: Giulio Castori, Marco Corradi, Emanuela SperazinivadaleNo ratings yet

- Construction and Building Materials: Giulio Castori, Marco Corradi, Emanuela SperaziniDocument4 pagesConstruction and Building Materials: Giulio Castori, Marco Corradi, Emanuela SperaziniisaacNo ratings yet

- 1 s2.0 S1350630713002768 MainDocument17 pages1 s2.0 S1350630713002768 MainJithin PayyanurNo ratings yet

- Engineering Structures: Chuanlin Wang, John P. Forth, Nikolaos Nikitas, Vasilis SarhosisDocument13 pagesEngineering Structures: Chuanlin Wang, John P. Forth, Nikolaos Nikitas, Vasilis Sarhosisحيدر الهنداويNo ratings yet

- Engineering Structures: Francesca Da Porto, Flavio Mosele, Claudio ModenaDocument11 pagesEngineering Structures: Francesca Da Porto, Flavio Mosele, Claudio ModenavijayiitbbsNo ratings yet

- Bashar and EanDocument12 pagesBashar and EanBashar SamiNo ratings yet

- Shear Wall Research PapersaDocument11 pagesShear Wall Research PapersaPrakhar BoyalNo ratings yet

- Cyclic lateral load behavior of squat reinforced concrete wallsDocument14 pagesCyclic lateral load behavior of squat reinforced concrete wallsMilton Alexander Rivera TorresNo ratings yet

- Seismic Performance of Fabricated Shear Wall StrucDocument14 pagesSeismic Performance of Fabricated Shear Wall StrucJDNo ratings yet

- Evaluation of Behavior of Reinforced Concrete Shear Walls Through Finite Element AnalysisDocument28 pagesEvaluation of Behavior of Reinforced Concrete Shear Walls Through Finite Element AnalysisEuNo ratings yet

- Lateral Load Resistance of Cross-Laminated Timber Shear WallsDocument11 pagesLateral Load Resistance of Cross-Laminated Timber Shear WallskirubaNo ratings yet

- Kaloper - Zivalj - Medic - Experimental and Numerical Assessment of Reinforced Concrete Column Under Cyclic Loading - CroCEEDocument8 pagesKaloper - Zivalj - Medic - Experimental and Numerical Assessment of Reinforced Concrete Column Under Cyclic Loading - CroCEEsenad medicNo ratings yet

- Study of Composite Steel-Concrete Shear Wall Subjected to Lateral LoadsDocument9 pagesStudy of Composite Steel-Concrete Shear Wall Subjected to Lateral LoadsBoopathi YoganathanNo ratings yet

- An Improved Tie Force Method For Progressive Collapse Resistance of Precast Concrete Cross Wall StructuresDocument9 pagesAn Improved Tie Force Method For Progressive Collapse Resistance of Precast Concrete Cross Wall StructuresCristina VlaicuNo ratings yet

- Habusadeh, Journal Manager, 182-187Document6 pagesHabusadeh, Journal Manager, 182-187Bhagirathi DengiNo ratings yet

- Tall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966From EverandTall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966A. CoullRating: 5 out of 5 stars5/5 (1)

- Development of Seismic Vulnerability Assessment Methodologies Over The Past 30 YearsDocument6 pagesDevelopment of Seismic Vulnerability Assessment Methodologies Over The Past 30 YearsrashidkingNo ratings yet

- 160901-TC21 Tor R07Document4 pages160901-TC21 Tor R07rashidkingNo ratings yet

- Karachi To Kotri - The First Railways in PakistanDocument14 pagesKarachi To Kotri - The First Railways in PakistanrashidkingNo ratings yet

- SHSCP 11 ArchDocument1 pageSHSCP 11 ArchrashidkingNo ratings yet

- Tructural Ealth Onitoring: M. Mayur S.I.E.T.K PutturDocument37 pagesTructural Ealth Onitoring: M. Mayur S.I.E.T.K PutturrashidkingNo ratings yet

- Seismic Analysis - Conc Build - D ValueDocument18 pagesSeismic Analysis - Conc Build - D ValuerashidkingNo ratings yet

- Guidebook On Technologies For Disaster Preparedness and Mitigation ISRO Satyabrata SahuDocument102 pagesGuidebook On Technologies For Disaster Preparedness and Mitigation ISRO Satyabrata SahuS.Alec KnowleNo ratings yet

- Seismo-Tectonic Routes of PakistanDocument9 pagesSeismo-Tectonic Routes of PakistanrashidkingNo ratings yet

- Heavy Monsoon Downpour Lashes KarachiDocument9 pagesHeavy Monsoon Downpour Lashes KarachirashidkingNo ratings yet

- Self Assessment Manual PDFDocument45 pagesSelf Assessment Manual PDFrashidkingNo ratings yet

- 14 S07-013Document8 pages14 S07-013rashidkingNo ratings yet

- Heidarzadeh Et Al 2008 OE Historical Tsunami in Makran Subduction ZoneDocument13 pagesHeidarzadeh Et Al 2008 OE Historical Tsunami in Makran Subduction ZonerashidkingNo ratings yet

- First General StatutesDocument6 pagesFirst General StatutesrashidkingNo ratings yet

- Brrda: FCGKJ Xzkeh.K Ifk Fodkl, TsalhDocument2 pagesBrrda: FCGKJ Xzkeh.K Ifk Fodkl, TsalhrashidkingNo ratings yet

- May 12th Evening JournalDocument1 pageMay 12th Evening JournalrashidkingNo ratings yet

- 1.3153330 HAZUS Second ImportantDocument12 pages1.3153330 HAZUS Second ImportantrashidkingNo ratings yet

- 3rd Eastern SF Bay Earthquake ConferenceDocument1 page3rd Eastern SF Bay Earthquake ConferencerashidkingNo ratings yet

- A1 Example Fire Safety Maintenance ChecklistDocument30 pagesA1 Example Fire Safety Maintenance ChecklistrashidkingNo ratings yet

- Environment and Urbanization 2003 Ahmed 33 42Document10 pagesEnvironment and Urbanization 2003 Ahmed 33 42rashidkingNo ratings yet

- KW&SB Bid Evaluation Report for COD Filter Plant Silt RemovalDocument6 pagesKW&SB Bid Evaluation Report for COD Filter Plant Silt RemovalrashidkingNo ratings yet

- Aashto Pedestrian Bridge CatalogueDocument5 pagesAashto Pedestrian Bridge CataloguerashidkingNo ratings yet

- DPR Historic Structure Assessment FormDocument6 pagesDPR Historic Structure Assessment FormrashidkingNo ratings yet

- BOE Is Structural 3.2Document28 pagesBOE Is Structural 3.2aomareltayebNo ratings yet

- Hydrological and Hydraulic Study of Bridges / Culverts: N K, S A, S A A S, M E S, N ADocument5 pagesHydrological and Hydraulic Study of Bridges / Culverts: N K, S A, S A A S, M E S, N ArashidkingNo ratings yet

- Scanned CardsDocument1 pageScanned CardsrashidkingNo ratings yet

- HazusicgmanualDocument22 pagesHazusicgmanualrashidkingNo ratings yet

- 1.3153330 HAZUS Second ImportantDocument12 pages1.3153330 HAZUS Second ImportantrashidkingNo ratings yet

- Addresses 1Document5 pagesAddresses 1rashidkingNo ratings yet

- Collaborative Simulation Interface For Planning Disaster MeasuresDocument6 pagesCollaborative Simulation Interface For Planning Disaster MeasuresrashidkingNo ratings yet

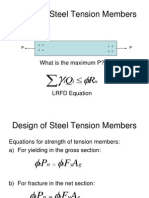

- 02 - Design of Steel Tension MembersDocument15 pages02 - Design of Steel Tension MembersMayur PatelNo ratings yet

- Xii Neet Chemistry Mcqs PDFDocument30 pagesXii Neet Chemistry Mcqs PDFMarcus Rashford100% (3)

- Are Hypomineralized Primary Molars and Canines Associated With Molar-Incisor HypomineralizationDocument5 pagesAre Hypomineralized Primary Molars and Canines Associated With Molar-Incisor HypomineralizationDr Chevyndra100% (1)

- A6 2018 D Validation Qualification Appendix6 QAS16 673rev1 22022018Document12 pagesA6 2018 D Validation Qualification Appendix6 QAS16 673rev1 22022018Oula HatahetNo ratings yet

- ADDRESSABLE 51.HI 60854 G Contoller GuideDocument76 pagesADDRESSABLE 51.HI 60854 G Contoller Guidemohinfo88No ratings yet

- Progibb LV Plus PGR - Low Voc FormulationDocument2 pagesProgibb LV Plus PGR - Low Voc FormulationDodik Novie PurwantoNo ratings yet

- AI Model Sentiment AnalysisDocument6 pagesAI Model Sentiment AnalysisNeeraja RanjithNo ratings yet

- BCP-8000 User's ManualDocument36 pagesBCP-8000 User's ManualAsad PatelNo ratings yet

- Lightwave Maya 3D TutorialsDocument8 pagesLightwave Maya 3D TutorialsrandfranNo ratings yet

- Background of The Study Statement of ObjectivesDocument4 pagesBackground of The Study Statement of ObjectivesEudelyn MelchorNo ratings yet

- Essentials For Professionals: Road Surveys Using SmartphonesDocument25 pagesEssentials For Professionals: Road Surveys Using SmartphonesDoly ManurungNo ratings yet

- Ultrasonic Weld Examination ProcedureDocument16 pagesUltrasonic Weld Examination ProcedureramalingamNo ratings yet

- Chapter 10 AP GP PDFDocument3 pagesChapter 10 AP GP PDFGeorge ChooNo ratings yet

- Tetracyclines: Dr. Md. Rageeb Md. Usman Associate Professor Department of PharmacognosyDocument21 pagesTetracyclines: Dr. Md. Rageeb Md. Usman Associate Professor Department of PharmacognosyAnonymous TCbZigVqNo ratings yet

- Project Binder 2Document23 pagesProject Binder 2Singh DhirendraNo ratings yet

- 2 - Elements of Interior DesignDocument4 pages2 - Elements of Interior DesignYathaarth RastogiNo ratings yet

- VivsayamDocument87 pagesVivsayamvalarumsakthi100% (2)

- 24.postpartum Period-Physiological Changes in The MotherDocument16 pages24.postpartum Period-Physiological Changes in The MotherHem KumariNo ratings yet

- Sibuyan Island ResiliencyDocument12 pagesSibuyan Island ResiliencyEndangeredSpeciesNo ratings yet

- Detection and Attribution Methodologies Overview: Appendix CDocument9 pagesDetection and Attribution Methodologies Overview: Appendix CDinesh GaikwadNo ratings yet

- Clean Milk ProductionDocument19 pagesClean Milk ProductionMohammad Ashraf Paul100% (3)

- 3D Area Clearance Strategies for Roughing ComponentsDocument6 pages3D Area Clearance Strategies for Roughing ComponentsMohamedHassanNo ratings yet

- Who will buy electric vehicles Segmenting the young Indian buyers using cluster analysisDocument12 pagesWho will buy electric vehicles Segmenting the young Indian buyers using cluster analysisbhasker sharmaNo ratings yet

- Library Dissertation in Community DentistryDocument9 pagesLibrary Dissertation in Community DentistryPayForPaperCanada100% (1)

- Accomplishment Report Yes-O NDCMC 2013Document9 pagesAccomplishment Report Yes-O NDCMC 2013Jerro Dumaya CatipayNo ratings yet

- Philippines' Legal Basis for Claims in South China SeaDocument38 pagesPhilippines' Legal Basis for Claims in South China SeaGeeNo ratings yet

- Caterpillar Ep15krtDocument37 pagesCaterpillar Ep15krtIvan MajikNo ratings yet

- Baseline Program Rev 3A Presentation 25 July 2020Document24 pagesBaseline Program Rev 3A Presentation 25 July 2020Shakti Sourava RautrayaNo ratings yet