Professional Documents

Culture Documents

STP Biochip Package Plant

Uploaded by

David LambertCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STP Biochip Package Plant

Uploaded by

David LambertCopyright:

Available Formats

Biochip Package Plant MODEL LS / MS / HS

Biochip Package Plant (BPP) is the latest innovative Sewage Treatment Plant (STP) system. It is designed specifically for fast implementation with minimum site construction work requirement. This system is an ideal approach for project sites where construction costs and time are critical. A complete process design (with all necessary features) from equalization, Biochip Moving Bed Biofilm Reactor (MBBR), Activated Sludge Process (ASP) and clarification can be designed and adopted in much shorter time than conventional systems. The utilization of proven Biochip MBBR has substantially reduced the overall biological treatment (both COD/BOD reduction and Nitrification) to less than 5 hours! The reduction of additional parameters (TN and P) can be incorporated into BPP with minor modifications. The clarification of activated sludge is performed in a separate biological clarifier. As single settling bottom cone with ideal slope is being designed, no dead zone and bio-fouling (typically found on lamellar plate clarification) will happen, thus, ideal liquid solid separation performance can be achieved. Our technologies offered have no moving parts and this simplifies installation, operation and maintenance. The endusers and contractors can easily install this factory-fabricated package plant by themselves with simple instructions. This allows the implementation cost can be further reduced. Other associated equipment that listed as options can easily be purchased and installed by others. The shown parameters are achievable by standard BPP. Higher concentration loading can be treated, simply by adding more biochip! Influent BOD (mg/l) COD (mg/l) TSS (mg/l) AN (mg/l) < 250 < 500 < 300 < 30 Effluent < 20 < 100 < 40 < 10

Standard Features

EQ Pumps (1d,1s) Tank MOC: FRP ISO MBBR Biochip SS304 air pipe Air Lift (PVC Material) SS304 Screen

BPP under construction

Applications

Hotel/School/University Camp/Mining/Construction Site Highway Rest Area/Airport Factory/Refinery Shopping Mall/Hypermarket Centralised Industrial Park Township/Hospital/Condominium

Options

Control Panel Air Blowers Static Screen SS304 Sump Pump (1d,1s) Bar Screen SS304

TN Removal by Biochip in Germany

GENERAL ARRANGEMENT DIAGRAM

MODEL LS / MS

MODEL HS

MODEL AND CAPACITY - LS / MS

Model 10 LS 20 30 50 MS 100 Q (m3/d) 10 20 30 50 100 PE 45 90 135 225 445 Qty (Tanks) 1+1 1+1 1+1 1+1 1+1 A B C D E (mm) (mm) (mm) (mm) (mm) 1500 2200 2200 2500 3000 2900 2500 3400 4200 5800 1500 2200 2200 3000 3500 1500 2200 2200 2500 3000 1600 1900 2300 2600 3400 Inlet (Dia) 50 80 100 100 100 Outlet (Dia) 50 80 100 100 100 EQ Pump EQ Blower Bio Blower Dry Wt (KW) (KW) (KW) (kg) 0.75 0.75 0.75 0.75 0.75 0.55 0.55 0.55 0.55 1.5 1.5 1.5 2.2 2.2 4.0 440 580 680 860 1200 Opt. Wt (kg) 7500 13500 18600 30000 59000

Note: The Population Equivalent (PE) as stated is calculated based on water consumption of 225 lit/PE.d Opt Wt. - Operating Weight.

MODEL AND CAPACITY - HS

Model 200 HS 300 500 Q (m3/d) 200 300 500 PE 900 1350 2250 Qty (Tanks) 1+2 2+3 3+5 F (mm) 12500 12500 15000 G (mm) 8200 12200 16300 H (mm) 3000 3000 3000 I (mm) 3400 3400 3400 Inlet (Dia) 150 200 250 Outlet EQ Pump EQ Blower Bio Blower Dry Wt (Dia) (KW) (KW) (KW) (kg) 150 200 250 1.5 1.5 3.7 1.5 1.5 2.2 7.5 11 15 2030 3200 5180 Opt. Wt (kg) 102000 140000 229000

Note: QtyTanks of 3+5 means 3 nos bioprocess tanks and 5 nos of clarifier. Bioprocess tank is a combination of EQ, MBBR and ASP. The details above is approximated and subjected to change without prior notice.

Ultraspan Sdn. Bhd.

37, Jalan Salung 33/26, Seksyen 33, Shah Alam, 40400, Selangor, Malaysia Email: sales@ultraspan.com.my

Tel: +60351220319 Fax: +60351220036 www.ultraspan.com.my

You might also like

- ASBR PresentationDocument37 pagesASBR PresentationDileep C DileepNo ratings yet

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- Reinforced Concrete With Side PlateDocument1 pageReinforced Concrete With Side PlateHattori HanzoNo ratings yet

- Equalization Lec 7 Week 7 MSC 2021Document21 pagesEqualization Lec 7 Week 7 MSC 2021haseeb tahirNo ratings yet

- Characteristics and comparison of SBR, ASBR and SBBR systems for wastewater treatmentDocument10 pagesCharacteristics and comparison of SBR, ASBR and SBBR systems for wastewater treatmentThanh LanNo ratings yet

- Design of Grit Channels Controlled by Parshall FlumesDocument16 pagesDesign of Grit Channels Controlled by Parshall FlumesGarethNo ratings yet

- Custom Designed WWTP BrochureDocument16 pagesCustom Designed WWTP BrochureFaraz HaiderNo ratings yet

- ACO Passavant - Technical Handbook and Product CatalogueDocument24 pagesACO Passavant - Technical Handbook and Product CatalogueACO PassavantNo ratings yet

- British Plastics Federation: Search The Website..Document8 pagesBritish Plastics Federation: Search The Website..Yang LuNo ratings yet

- Hydrochloric acid Regeneration of Cation Exchange Resin 225 HDocument8 pagesHydrochloric acid Regeneration of Cation Exchange Resin 225 HPravin BoteNo ratings yet

- Aeration System in WWTPDocument10 pagesAeration System in WWTPashokNo ratings yet

- Design Manual For Small Wastewater Works 2009-2Document52 pagesDesign Manual For Small Wastewater Works 2009-2VichekaNo ratings yet

- M13 - L17 Grit ChamberDocument6 pagesM13 - L17 Grit ChamberBerliana Cahya Ningtias0% (1)

- CPI Oil Water SeparatorDocument2 pagesCPI Oil Water Separatormashonk okNo ratings yet

- EPA Lagoon Design Manual - Paul Krauft Utah State PDFDocument79 pagesEPA Lagoon Design Manual - Paul Krauft Utah State PDFNataliaKNo ratings yet

- DNIT Vol 2 Part 1Document196 pagesDNIT Vol 2 Part 1JitendraHatwarNo ratings yet

- ENVI Trickling FiltersDocument23 pagesENVI Trickling FiltersbaBy daBy AnNetTeNo ratings yet

- STP Presentation - SBRDocument51 pagesSTP Presentation - SBRNoriel LunaNo ratings yet

- Design of Dual Media Filters To Suit Existing Water Treatment Plants in IndiaDocument5 pagesDesign of Dual Media Filters To Suit Existing Water Treatment Plants in IndiareinpolyNo ratings yet

- UASB Reactor: How It Treats Sewage Without MediaDocument23 pagesUASB Reactor: How It Treats Sewage Without MediasasisNo ratings yet

- Environmental Engineering QuestionsDocument10 pagesEnvironmental Engineering QuestionsSuresh Raju0% (1)

- Full Design of Componets OF Sewage Tretment Plant (200 KLD)Document4 pagesFull Design of Componets OF Sewage Tretment Plant (200 KLD)rahul100% (1)

- Sewage Treatment WorksheetDocument18 pagesSewage Treatment WorksheetRemedanNo ratings yet

- Package Type STPDocument4 pagesPackage Type STPjeykumar.BalannairNo ratings yet

- Frosco Grease InterceptorDocument39 pagesFrosco Grease InterceptorSopi Labu100% (2)

- Grit Removal & Treatment for Sustainable Grit RecyclingDocument47 pagesGrit Removal & Treatment for Sustainable Grit RecyclingRavena RemaditaNo ratings yet

- Design of A Sedimentation BasinDocument8 pagesDesign of A Sedimentation BasinCOLLEN KGAODINo ratings yet

- Gfts Tank Model 140 17.5 Ø42.69 M, Nominal Volume 6170 M : ConfidentialDocument3 pagesGfts Tank Model 140 17.5 Ø42.69 M, Nominal Volume 6170 M : ConfidentialFathurrachman RachmanNo ratings yet

- Hospital Waste Water TreatmentDocument5 pagesHospital Waste Water TreatmentNP100% (1)

- 04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFDocument8 pages04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFVic KeyNo ratings yet

- Design of Sewage Treatment PlantDocument7 pagesDesign of Sewage Treatment PlantBill Harley VinsmokeNo ratings yet

- 500 LPH UF Plant BOQDocument6 pages500 LPH UF Plant BOQSimbu ArasanNo ratings yet

- Course Material Week 10 Biological Process Technology Environmental Engineering Dept. Institut Teknologi BandungDocument50 pagesCourse Material Week 10 Biological Process Technology Environmental Engineering Dept. Institut Teknologi BandungAnnisa MaulinaNo ratings yet

- 3-KY Tshai Et Al SDHDocument8 pages3-KY Tshai Et Al SDHAnonymous P8Bt46mk5INo ratings yet

- o & M Instruction Manual (Rapid Gravity Filter)Document68 pageso & M Instruction Manual (Rapid Gravity Filter)ahmed salam100% (1)

- Removal of Chromium From Tannery Solid WasteDocument7 pagesRemoval of Chromium From Tannery Solid WasteLuis Paz Soldán G100% (1)

- Flocculator Eng PDFDocument2 pagesFlocculator Eng PDFAbdul LatifNo ratings yet

- Optimization of A2O BNR Processes Using PDFDocument16 pagesOptimization of A2O BNR Processes Using PDFPhạm LinhNo ratings yet

- Liquid Containment Shells ReviewDocument13 pagesLiquid Containment Shells ReviewpouyaNo ratings yet

- Deliverable-1.10 Guideline Design Granular Sludge ReactorDocument19 pagesDeliverable-1.10 Guideline Design Granular Sludge ReactorCatalina Nicoleta RoscaNo ratings yet

- Efficiency Comparison of Sewage Treatment Plants in BangaloreDocument36 pagesEfficiency Comparison of Sewage Treatment Plants in BangalorePRETTY MARY100% (1)

- Reed Bed System FINALDocument12 pagesReed Bed System FINALHardik Kashyap VepariNo ratings yet

- Water Treatment Plant SpecsDocument131 pagesWater Treatment Plant SpecsDhaval ParmarNo ratings yet

- Buckling of Thin-Walled Conical Shells Under Uniform External PressureDocument14 pagesBuckling of Thin-Walled Conical Shells Under Uniform External PressureAnonymous wWOWz9UnWNo ratings yet

- Crystalline Waterproofing ConcreteDocument2 pagesCrystalline Waterproofing ConcreteBalasubramanian AnanthNo ratings yet

- SBRDocument44 pagesSBRNavneet Singh67% (3)

- Tank Bottom Scraper Zickert - enDocument22 pagesTank Bottom Scraper Zickert - enzxc007No ratings yet

- Municipal Wastewater Treatment: Evaluating Improvements in National Water QualityFrom EverandMunicipal Wastewater Treatment: Evaluating Improvements in National Water QualityNo ratings yet

- Trickling Filters: Biological Wastewater Treatment Using Porous MediaDocument7 pagesTrickling Filters: Biological Wastewater Treatment Using Porous MediaTasirmistNo ratings yet

- Memcor UF Product Data Sheet CPII MemRackDocument2 pagesMemcor UF Product Data Sheet CPII MemRackDio MiNo ratings yet

- ZENON MBR Tech (Chris Jeffery)Document70 pagesZENON MBR Tech (Chris Jeffery)Srinivas DiviNo ratings yet

- Sewage Treatment Plant Revamping ReportDocument4 pagesSewage Treatment Plant Revamping Reportjeykumar.BalannairNo ratings yet

- Sewerage and Sewage Treatment of Panvel, Maharashtra (Presentation) PDFDocument38 pagesSewerage and Sewage Treatment of Panvel, Maharashtra (Presentation) PDFDhruv MudgalNo ratings yet

- Maintaining Ohio Package Treatment PlantsDocument25 pagesMaintaining Ohio Package Treatment PlantsHendra SusantoNo ratings yet

- Lecture 4 SedimentationDocument6 pagesLecture 4 Sedimentationth3-encyclopediaNo ratings yet

- Water Treatment CalculatorDocument3 pagesWater Treatment CalculatorgrabettyNo ratings yet

- Clarifier Gear Drive Torque ValuesDocument4 pagesClarifier Gear Drive Torque ValuesDavid Lambert100% (4)

- Cyclone DesignDocument1 pageCyclone DesignDavid LambertNo ratings yet

- DAFDocument1 pageDAFDavid LambertNo ratings yet

- Booster Pump RequiredDocument6 pagesBooster Pump RequiredDavid LambertNo ratings yet

- Process Produksi WOOD PELLLETDocument3 pagesProcess Produksi WOOD PELLLETDavid LambertNo ratings yet

- Grease Trap SizingDocument9 pagesGrease Trap SizingEngFaisal Alrai100% (2)

- Venting DesignDocument1 pageVenting DesignDavid LambertNo ratings yet

- Pekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDocument34 pagesPekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDavid LambertNo ratings yet

- Pekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDocument34 pagesPekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDavid LambertNo ratings yet

- Pressure Drop CalculationDocument8 pagesPressure Drop CalculationDavid Lambert100% (1)

- Booster Pump RequiredDocument6 pagesBooster Pump RequiredDavid LambertNo ratings yet

- DAFDocument1 pageDAFDavid LambertNo ratings yet

- Commissioning Procedure Air Pre HeaterDocument15 pagesCommissioning Procedure Air Pre HeaterDavid LambertNo ratings yet

- Selecting of Booster Pump For BuildingDocument7 pagesSelecting of Booster Pump For BuildingDavid LambertNo ratings yet

- Gambar ProsesDocument1 pageGambar ProsesDavid LambertNo ratings yet

- Matchday Hari IniDocument2 pagesMatchday Hari IniDavid LambertNo ratings yet

- Price List With Breakdown & Unit PriceDocument1 pagePrice List With Breakdown & Unit PriceDavid LambertNo ratings yet

- PyrolysisDocument1 pagePyrolysisDavid LambertNo ratings yet

- Load FactorDocument4 pagesLoad FactorDavid LambertNo ratings yet

- PFD WTP PDFDocument1 pagePFD WTP PDFDavid LambertNo ratings yet

- Perhitungan Natural DraftDocument2 pagesPerhitungan Natural DraftDavid LambertNo ratings yet

- Sizing ScrubberDocument62 pagesSizing ScrubberindahazhrNo ratings yet

- Bleaching Tank PT. Gurita Mandala No. Deskripsi KeteranganDocument1 pageBleaching Tank PT. Gurita Mandala No. Deskripsi KeteranganDavid LambertNo ratings yet

- Load FactorDocument4 pagesLoad FactorDavid LambertNo ratings yet

- Local Control Panel Sheet-5Document1 pageLocal Control Panel Sheet-5David LambertNo ratings yet

- Wiring Diagram DC IIDocument2 pagesWiring Diagram DC IIDavid LambertNo ratings yet

- Konversi Besi Tulangan Ke Wire MeshDocument1 pageKonversi Besi Tulangan Ke Wire MeshDavid LambertNo ratings yet

- MBBR OM Manual-250Document42 pagesMBBR OM Manual-250senthil2002100% (3)

- Layout Line Checking Part (Front View) Revisi-1Document1 pageLayout Line Checking Part (Front View) Revisi-1David LambertNo ratings yet

- Technical Form WWTPDocument35 pagesTechnical Form WWTPDavid LambertNo ratings yet

- CFS50 motor feedback installation instructionsDocument1 pageCFS50 motor feedback installation instructionsJavier AlzateNo ratings yet

- VDP08 Technical CatalogueDocument47 pagesVDP08 Technical CatalogueAdal VeraNo ratings yet

- Flash ADCDocument3 pagesFlash ADCKiran SomayajiNo ratings yet

- Unit 4 - Software Engineering - WWW - Rgpvnotes.inDocument12 pagesUnit 4 - Software Engineering - WWW - Rgpvnotes.inNazma QureshiNo ratings yet

- Dimensions of Physical Quantities DensityDocument100 pagesDimensions of Physical Quantities DensityGerman Rincon UrregoNo ratings yet

- 8 Ways To Achieve Efficient Combustion in Marine EnginesDocument10 pages8 Ways To Achieve Efficient Combustion in Marine EnginestomNo ratings yet

- SBBR - Star Rnav Obdog 2b Rwy 29l - 29r - Star - 20220811Document1 pageSBBR - Star Rnav Obdog 2b Rwy 29l - 29r - Star - 20220811vitor marianoNo ratings yet

- Sap MM LSMWDocument18 pagesSap MM LSMWMani balan100% (1)

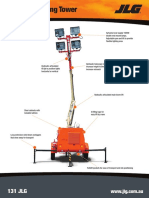

- JLG Lighting Tower 6308AN Series II 20150907Document2 pagesJLG Lighting Tower 6308AN Series II 20150907DwiSulistyo09No ratings yet

- Strength and Insulating Properties of Building Blocks Made From Waste MaterialsDocument7 pagesStrength and Insulating Properties of Building Blocks Made From Waste Materialsmjrobust05No ratings yet

- Schneider LV Switchboard Inspection GuideDocument59 pagesSchneider LV Switchboard Inspection GuideAlp Arslan Ok100% (1)

- 49 CFR Ch. I (10-1-11 Edition) 173.318Document5 pages49 CFR Ch. I (10-1-11 Edition) 173.318MauricioNo ratings yet

- XZX ZX ZXDocument4 pagesXZX ZX ZXWong VoonyeeNo ratings yet

- Fajs FSXDocument8 pagesFajs FSXJunhy Bandeira CassandraNo ratings yet

- ReleDocument3 pagesRelevitor4santos_6No ratings yet

- CAD1 AssignmentDocument11 pagesCAD1 AssignmentJohn2jNo ratings yet

- Method Statement For Architecture Work (Drywall) : No. Work Sequence Good Practices Picture Tools RemarksDocument16 pagesMethod Statement For Architecture Work (Drywall) : No. Work Sequence Good Practices Picture Tools RemarksAn-an ChanNo ratings yet

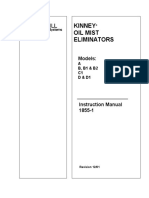

- 1855OME - Instruction Manual - Kinney Oil Mist EliminatorsDocument15 pages1855OME - Instruction Manual - Kinney Oil Mist EliminatorsahmedNo ratings yet

- Steam System DesignDocument74 pagesSteam System DesignIshan RanganathNo ratings yet

- Method StatementDocument2 pagesMethod StatementKumar Jbs100% (1)

- 050, 051Document28 pages050, 051kefaja67% (3)

- Switching Theory and Logic Design PDFDocument159 pagesSwitching Theory and Logic Design PDFSai TejaswiniNo ratings yet

- The Sperry Bombsight: A Pioneering Rival to NordenDocument6 pagesThe Sperry Bombsight: A Pioneering Rival to NordenPaul DupontNo ratings yet

- GRI 20RS-12-B Data SheetDocument6 pagesGRI 20RS-12-B Data SheetJMAC SupplyNo ratings yet

- VGS 8.1.2 Rev.20 - UTDocument29 pagesVGS 8.1.2 Rev.20 - UTPaul-Petrus MogosNo ratings yet

- Node diagnostics report for RBS6601WDocument9 pagesNode diagnostics report for RBS6601WWilson DiazNo ratings yet

- NTP35N15 Power MOSFET Features and SpecificationsDocument7 pagesNTP35N15 Power MOSFET Features and SpecificationsChristine GomezNo ratings yet

- CUCM Intracluster Port Usage GuideDocument3 pagesCUCM Intracluster Port Usage GuideAbhinayMylavarapuNo ratings yet

- Customer Targeted E-CommerceDocument4 pagesCustomer Targeted E-CommercepriyaNo ratings yet

- Ceramic Terminal BlocksDocument1 pageCeramic Terminal BlockselijbbNo ratings yet