Professional Documents

Culture Documents

AN17 Balancing

Uploaded by

ridzim4638Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AN17 Balancing

Uploaded by

ridzim4638Copyright:

Available Formats

Application

Field balancing under difficult conditions

Analyzing vibration causes Improving balance conditions Increasing system availability

Fig. 1 - Cover: Supply air fan of the central air system of an administration building

Field balancing under difficult conditions

Increased machine vibration is an undesirable phenomenon that is detrimental to product quality, places components under additional strain and reduces operational reliability. Imbalance is the most common cause of increased levels of vibration Imbalance is usually found in fans, blowers, belt pulleys and couplings. All possible causes of imbalance on fans are listed in Fig. 2. The purpose of balancing a machine under operating conditions is to reduce vibrations, strain, bearing forces and shaft deformation to acceptable levels. Using VIBXPERT , PRFTECHNIK service & diagnosis specialists are able to detect and quickly eliminate imbalance even under difficult conditions. The balancing results are automatically compared to the evaluation criteria for the balance condition of rotating, rigid bodies as stipulated in the DIN ISO 1940 standard. Examples of field balancing Fig. 3 shows the hammer shaft in a lignite power plant. The application of a 7 kg balance mass improved its balance quality and reduced vibration velocities (with a rotor weight of around 25 t). For service & diagnosis specialists, it is a matter of course that frequency spectra are analyzed for further irregularities as part of the field balancing procedure. After all, it only

Manufacturing defects

Difference in fit between the balancing and ventilator shafts Centrifugal force deformation Blade sag Blade cracks Improper paintwork or coating Strain from rotor disk weld

Imbalance from operation

Fouling on rotor disk Local corrosion Droplet erosion Heat deformation Wear from solids Stray imbalances Solid and fluid inclusions in hub shell

Installation errors

Faulty axial blade mounting Loose or tilted hub-to-shaft fit Bent shaft seat Imbalance on belt pulleys

Imbalance from repairs

Missing balancing masses Imbalance on coupling Improper paintwork or coating Detached coating

Fig. 2: Causes of imbalance

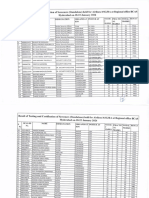

makes sense to continue balancing until the overall vibrations are reduced see Fig. 4. Fig. 5 depicts a typical balance report showing the balancing of a radial fan during operation. Vibrations of more than 30 mm/s were reduced to 1 mm/s by applying balance masses of around 155 g. Upon request, all results can be documented in separate measurement reports.

Fig. 5

How long does field balancing take? The measurement itself takes only a few minutes. The greatest portion of time is required to start up the machines, let them coast down, apply the balancing masses and attach and remove the cover panels. Specialists require four balancing runs at most.

Dominant rotational frequency calls for field balancing

Balancing report

Number of Meas. Values : 4 Unit: mm/s Date No. Mass A(g) 21.09.2006 0 0,00 21.09.2006 1 65,40 21.09.2006 2 49,00 21.09.2006 3 38,00

Balance Quality = 1,45 Speed = 2910 RpM Rotor Mass = 180 kg Radius = 150 mm

Pos. A() Amplitude A 0 32,87 0 19,99 342 8,31 21 1,16

Phase A() 106 99 138 295

< 7 kg balancing mass Fig. 3: Shaft of a hammer mill Fig. 4: Frequency spectrum of vibration velocity of two adjacent fans

Visit us at www.pruftechnik.com

Order number/technical data DIC 1.200 Field balancing and alignment service DIC 1.300 Mobile vibration diagnosis measurements PRFTECHNIK Condition Monitoring GmbH Oskar-Messter-Strae 19-21 85737 Ismaning, Germany www.pruftechnik.com Tel: +49 89 99616-342 Fax: +49 89 99616-300 eMail: diagnostic@pruftechnik.com

Productive maintenance technology

Copyright 2007 PRFTECHNIK AG Printed in Germany VIB 9.110-17

You might also like

- Caracteristici Otel BetonDocument2 pagesCaracteristici Otel Betonridzim4638No ratings yet

- T.S. Golosinski and A. TytkoDocument10 pagesT.S. Golosinski and A. Tytkoridzim4638No ratings yet

- 1Document4 pages1ridzim4638No ratings yet

- SatelitDocument1 pageSatelitridzim4638No ratings yet

- Safe Overload: 150% F.S. Ultimate Overload: 200% F.S.Document5 pagesSafe Overload: 150% F.S. Ultimate Overload: 200% F.S.ridzim4638No ratings yet

- Beginning Vibration Analysis PDFDocument96 pagesBeginning Vibration Analysis PDFromadhinhoNo ratings yet

- 5962 7276eDocument88 pages5962 7276eridzim4638No ratings yet

- L1Document1 pageL1ridzim4638No ratings yet

- Watermarked Fa 3 Mini Chrome TransmitterDocument1 pageWatermarked Fa 3 Mini Chrome Transmitterridzim4638No ratings yet

- CDocument123 pagesCridzim4638No ratings yet

- Finepix s2980 Manual enDocument144 pagesFinepix s2980 Manual enaya mikageNo ratings yet

- ReadmeDocument2 pagesReadmeridzim4638No ratings yet

- Diction AreDocument1 pageDiction Areridzim4638No ratings yet

- AS4324.1-1995 Standard For Design of Bulk Materials Handling MachinesDocument8 pagesAS4324.1-1995 Standard For Design of Bulk Materials Handling Machinesridzim4638100% (1)

- NTN Bearing Bpfo&BpfiDocument61 pagesNTN Bearing Bpfo&BpfishantanusamajdarNo ratings yet

- Two Plane Bal ReadmeDocument1 pageTwo Plane Bal Readmeridzim4638No ratings yet

- 3 2 ISO TC 16 Committee Draft QualVal March 2011v2Document12 pages3 2 ISO TC 16 Committee Draft QualVal March 2011v2ridzim4638No ratings yet

- ReadmeDocument1 pageReadmeridzim4638No ratings yet

- Guide For The Validation ISO 11095Document92 pagesGuide For The Validation ISO 11095ridzim4638No ratings yet

- Max7426 Max7427Document12 pagesMax7426 Max7427ridzim4638100% (1)

- LicenseDocument6 pagesLicensemerrysun22No ratings yet

- Charge Amplifiers: Instruction ManualDocument19 pagesCharge Amplifiers: Instruction Manualridzim4638No ratings yet

- Comparative Study of Fatigue Damage Models Using Different Number of Classes Combined With The Rainflow MethodDocument6 pagesComparative Study of Fatigue Damage Models Using Different Number of Classes Combined With The Rainflow MethodjeanpremierNo ratings yet

- 2 Plane BalanceDocument6 pages2 Plane BalanceitaryNo ratings yet

- FourPointBalance WophaseDocument1 pageFourPointBalance WophaseMark FrascaNo ratings yet

- NouDocument12 pagesNouridzim4638No ratings yet

- A Multipurpose VibDocument10 pagesA Multipurpose Vibridzim4638No ratings yet

- 53 Bevel Gear Support DrawDocument1 page53 Bevel Gear Support DrawFelipe KnorstNo ratings yet

- BeanDevice AX 3DDocument7 pagesBeanDevice AX 3Dridzim4638No ratings yet

- Cosmosm ManualDocument596 pagesCosmosm Manualpeter_prabhatNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Innova M3 New: 3. InstallationDocument8 pagesInnova M3 New: 3. InstallationAndreea DanielaNo ratings yet

- Chapter 9 Audit SamplingDocument47 pagesChapter 9 Audit SamplingYenelyn Apistar CambarijanNo ratings yet

- Project Guidelines (Issued by CBSE) : CA. (DR.) G.S. GrewalDocument51 pagesProject Guidelines (Issued by CBSE) : CA. (DR.) G.S. GrewalShruti Yadav0% (1)

- History of Phosphoric Acid Technology (Evolution and Future Perspectives)Document7 pagesHistory of Phosphoric Acid Technology (Evolution and Future Perspectives)Fajar Zona67% (3)

- Hex Bucket InspectionDocument1 pageHex Bucket InspectionSixto Guarniz AnticonaNo ratings yet

- Sop Urilyzer 100Document4 pagesSop Urilyzer 100misriyantiNo ratings yet

- Release ACOS 4.1.4-GR1-P10 IssuesDocument241 pagesRelease ACOS 4.1.4-GR1-P10 IssuesdanielatellaNo ratings yet

- Civpro RevDocument102 pagesCivpro RevJocelyn Baliwag-Alicmas Banganan BayubayNo ratings yet

- Q3 Week 1 Homeroom Guidance JGRDocument9 pagesQ3 Week 1 Homeroom Guidance JGRJasmin Goot Rayos50% (4)

- Order 49Document14 pagesOrder 49NURADRIANA OMAR BAHSIRNo ratings yet

- ShinojDocument4 pagesShinojArish BallanaNo ratings yet

- WTO & MFA AnalysisDocument17 pagesWTO & MFA Analysisarun1974No ratings yet

- University of Nottingham Department of Architecture and Built EnvironmentDocument43 pagesUniversity of Nottingham Department of Architecture and Built EnvironmentDaniahNo ratings yet

- 13 - Conclusion and SuggestionsDocument4 pages13 - Conclusion and SuggestionsjothiNo ratings yet

- Basic Details: Government Eprocurement SystemDocument4 pagesBasic Details: Government Eprocurement SystemNhai VijayawadaNo ratings yet

- San Francisco Chinese Christian Union, Et Al. v. City and County of San Francisco, Et Al. ComplaintDocument25 pagesSan Francisco Chinese Christian Union, Et Al. v. City and County of San Francisco, Et Al. ComplaintFindLawNo ratings yet

- A Comprehensive Review On Renewable and Sustainable Heating Systems For Poultry FarmingDocument22 pagesA Comprehensive Review On Renewable and Sustainable Heating Systems For Poultry FarmingPl TorrNo ratings yet

- Top Ten Helicopter Checkride TipsDocument35 pagesTop Ten Helicopter Checkride TipsAbhiraj Singh SandhuNo ratings yet

- Orthopanton Villa System MedicalDocument61 pagesOrthopanton Villa System MedicalOscarOcañaHernándezNo ratings yet

- Autoclave 2Document52 pagesAutoclave 2SILVANA ELIZABETH ROMO ALBUJANo ratings yet

- Indian Handmade Carpets EnglishDocument16 pagesIndian Handmade Carpets EnglishVasim AnsariNo ratings yet

- Airport Demand ModelDocument26 pagesAirport Demand ModelbsvseyNo ratings yet

- Guide To Networking Essentials Fifth Edition: Making Networks WorkDocument33 pagesGuide To Networking Essentials Fifth Edition: Making Networks WorkKhamis SeifNo ratings yet

- Application Letters To Apply For A Job - OdtDocument2 pagesApplication Letters To Apply For A Job - OdtRita NourNo ratings yet

- Shear Wall Design PDFDocument9 pagesShear Wall Design PDFjk.dasgupta100% (2)

- Assignment 03 Investments in Debt SecuritiesDocument4 pagesAssignment 03 Investments in Debt SecuritiesJella Mae YcalinaNo ratings yet

- Module 2 Lesson 2 Communication and TechnologyDocument7 pagesModule 2 Lesson 2 Communication and TechnologyClarence EscopeteNo ratings yet

- Vivado Power Analysis OptimizationDocument120 pagesVivado Power Analysis OptimizationBad BoyNo ratings yet

- 02Document257 pages02shaney navoaNo ratings yet

- HyderabadDocument3 pagesHyderabadChristoNo ratings yet