Professional Documents

Culture Documents

An Experimental Study of Flash Evaporation From Liquid Pools - GOPALA KRISHNA ET AL

Uploaded by

Samson RaphaelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Experimental Study of Flash Evaporation From Liquid Pools - GOPALA KRISHNA ET AL

Uploaded by

Samson RaphaelCopyright:

Available Formats

Desalination, 65 (1987) 139-151

Elsevier Science Publishers B. V., Amsterdam - Printed in The Netherlands

D EZPBRDIE1I'rAL S'l'ODY 0.. PLASH EVAPOUT:IO. PROM L:IQU:ID POOLS

S. GOPALAKRISHNA, V. M. PURUSHOTHAMAN, and N. LIOR.

Department of Mechanical Engineering and Applied Mechanics,

University of Pennsylvania,

Philadelphia. PA 19104-6315 (USA)

SUMMARY

139

The objective of this study is, based on experiments. to

improve the understanding of flash evaporation from pools, and to

develop empirical correlations of the total quantity of vapor

released and the rate of vapor generation (both in non-

dimensional form) as a function of the primary nondimensional

parameters which govern the process: the Jakob number (Ja ).

Prandtl number (Pr). a dimensionless hydrostatic head

the salt concentration (C). The work was done in the range of

parameters characteristic to desalination plants and to open-

cycle ocean-thermal energy conversion. Experiments were

performed with fresh water and with saline water (3.5% NaCI

concentration). for initial temperatures from 25

0

C - 80

0

C. flash-

down temperature differences from 0.5

0

C - 10

0

C, and pool depths

of 6.5" (165 mm), 12" (305 mm) and 18" (457 mm). The prediction

of flashed mass as a function of the nondimensional pa

2

ameters is

accurate to within 7.5%. A new time scale T = (where

a = surface tension. = thermal diffusivity of the liquid. and

= pressure between the liquid and the vapor space)

was employed. The expressions for the rate of flashed steam

using this time scale show a scatter of 68%. The asymptotic

value of the flashed mass increases with Jakob number, increases

slightly with pool ,depth, and decreases with increasing liquid

Prandtl number. The comparisons show very good agreement with

the experimental values. but underpredict the data obtained from

other experiments.

SYMBOLS

A

a

l

_

4

C

C

1

C

2

c

p

H

h

fg

Ja

k

m

m

..

free surface area of the liquid

correlation powers, eq. (7)

concentration of NaCI in the solution

correlation coefficient, eq. (7)

correlation coefficient. eq. (9)

specific heat

depth of the pool

latent heat of vaporization

Jakob number ( =

thermal conductivity

amount of vapor released

asymptotic value of vapor released, after a long time

140

iii

m

v

iii

p

Subscripts

o

e

1

P

sat

T

v

m/m

v

total mass of vapor eq. (5)

rate of flashing

initial rate of flashing

Prandtl number of the liquid

parameter in the least-squares curve fit

flash-down pressure difference

time

initial temperature of pool

final equilibrium temperature

overall superheat

bubble time scale

viscosity

density

initial

equilibrium

liquid

pressure, eq. (4)

saturation

thermal, eq. (3)

vapor

INTRODUCTION

Flash evaporation is widely used in distillation processes,

such as in water desalination, and in energy conversion and

storage processes for steam production. For example, the open-

cycle ocean-thermal energy conversion (OTEC) process (first

developed by Claude, ref. 1) employs flash evaporation of the

warmer surface layer of the ocean to generate steam for driving a

turbine; "steam accumulators" have been used for many years in

Rankine power plants to store heat in pressurized water when

demand is below the boiler capacity, and then to generate steam

by flash evaporation for power production when demand rises above

boiler capacity (ref. 2). Knowledge of the flash evaporation

rates, and their economical maximization, is necessary in the

design and application of all of these processes.

Flash evaporation is initiated by exposing the liquid to a

pressure lower than that corresponding to saturation at the

existing conditions. This causes at least some of the liquid to

141

violently undergo a transition to the vapor phase in the presence

of vigorous ebullition. As described by many researchers (refs.

3-12), this is a complex process, difficult to both analyze and

measure. The small temperature differences associated with water

desalination and with OTEC, make precise measurements even

harder. It is no surprise therefore that knowledge of the

process is still quite inadequate, and that process design is

based for the most part on empirical correlations with limited

ranges of validity and large scatter (cf. recent review by Lior,

ref. 12) ...

Mi ya take et al. (ref. 6) conducted experiments, somewhat

similar to the ones described in this paper, to investigate the

behavior of a pool of liquid in a tank subjected to a suddden

reduction in the pressure of the vapor space. They found two

exponential time decay processes - the initial with a higher

slope indicating vigorous ebullition, and the second with

relatively quiescent evaporation. They proposed dimensional-

parameter correlations to predict the flashed steam rate and the

nonequilibrium fraction. Nakamura et al. (ref. 7) studied the

dynamic behavior of flashing in vessels which are subjected to

reduction in pressure in the steam vent line. They found that

the narrowest diameter of the steam vent line, the initial water

depth, and the initial pressure, influenced the process. In

particular, the time constant of the pressure reduction was found

to be directly proportional to the initial water level and

inversely proportional to the 1.8

th

power of the nozzle throat

diameter. Some of the other studies on flashing flow in

multistage flash evaporators (refs. 8-10) have been aimed at the

design optimization of such uni ts. Sugeta and Toyama (ref. 8)

found experimentally that the nonequilibrium temperature

difference (which represents the degree of incompleteness of the

evaporation) increased with flow rate of the flashing liquid.

They proposed a chamber having a trapezoidal bottom to reduce

this temperature difference. Lior and Nishiyama (ref. 9) studied

the effect of noncondensables on the flash evaporation process.

The heat transfer characteristics and the approach to equilibrium

were found to improve with an increase of the concentration of

the noncondensable in the liquid, because the noncondensables

enhance bubble nucleation. They also proposed a correlation to

quantify this effect. Miyatake et al. (ref. 10) studied the

142

effect of flashing from superheated jets of water sprayed into a

low pressure chamber. An empirical equation for the prediction

of temperature of the jet with residence time was presented.

Peterson et al (ref. 13) examined the case of a postulated

pipe break in a nuclear reactor cooling system which could result

in flashing flow. The rate of pressure reduction imposed in the

experimental setup was of the order found in such situations, and

they found that the flashed steam rate was about 20 times that

due to evaporation alone. Correlations which predict these

for the range of parameters investigated were also given.

Clegg. and Papadakis (ref. L4) studied the evaporation rates of

Freon-l1 from storage tanks which hold the liquid under low gauge

pressures. The depressurization rates were taken to be linear,

and correlations for the boi'ling as well as the evaporation

regimes were obtained by experiments. Based on an analogy to the

surface evaporative processes, a heat transfer coefficient and

Nusselt number were proposed and expressed as a function of the

superheat. rt was found that beyond a supersaturation pressure

(Ap) of 5.5 kPa, a transition from the evaporative regime to the

boiling regime took place, resulting in increased fluxes. The

results were also used to predict the behavior of LNG tanks.

One of the applications of flash evaporation under

investigation at the University of Pennsylvania is that of steam

generation from a stratified thermal storage tank which is part

of a hybrid Rankine power cycle (ref. 15). In this cycle, solar

energy or other low level energy sources are used to heat water

in a storage tank, and by opening a valve which connects the tank

to the vapor space of the condenser, flash evaporation is

initiated, thus producing steam which is then superheated using

conventional fuel before entering the turbine. The advantages of

higher efficiency, better thermal source-sink matching,

and the elimination of a boiler in the conventional sense depend

upon the proper design and operation of the flash evaporator.

Experiments have been conducted on this system (with flash-tank

volume of about 20 m

3

), and preliminary design experience has

been gained (ref. 16). One of the aims of this study is to

develop expressions for flashing rates that can be used in that

system.

All the studies mentioned above develop expressions for

flashing that are valid only in limited ranges of the parameters,

143

and cannot usually be extended to cover related applications.

This study is aimed at the prediction of flash evaporative fluxes

primarily for the range of parameters of relevance in the

desalination industry and for open-cycle OTEC development, but it

has wider applicability than some of the earlier studies because

non-dimensional parameters are employed in the correlation. The

empirical correlation is also intended to reveal some of the

subtler aspects of the theory which can be used in the

formulation of theoretical models of the flash evaporation

process.

THE EXPERIMENTAL FACILITY

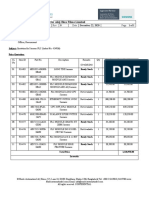

The experimental facility for pool flashing is shown in Fig.

1. It consists of a Pyrex cylinder of 6" (152 mm) internal

diameter and 24" (610 mm) height which serves as the evaporation

chamber. This evaporator is enclosed concentrically in a 12"

(305 mm) diameter acrylic cylinder, and the space between the two

cylinders is evacuated to reduce heat losses. The top of the

evaporator is connected to a 5 ft

3

(0.1416 m

3

) sealed tank by

means of a 2" (51 mm) copper tube. A quarter-turn 2" (51 mm)

ball valve is used in this line to produce the necessary pressure

drop in the evaporator vapor space. The reduction in pressure

Fig. 1 Schematic of the Pool Flashing Apparatus

144

necessary to cause flashing is obtained by pre-evacuating the

tank to the desired pressure, below the saturation pressure

corresponding to the initial temperature of the liquid. The

initial liquid temperature is brought to the desired value by

circulating the liquid to be flashed through a heat exchanger,

which is heated by oil coming from a temperature-regulated

circulator. The pyrex evaporator and the surrounding cylinder

are transparent, enabling good visual observation of the process.

The variables in this process which need precise measurement

include temperature and pressure distributions. The

temperatures were measured using a specially designed "thermistor

comb". It consists of a vertical probe on which 44 unevenly

spaced miniature thermocouples are mounted. The thermistors are

0.02" (0.508 mm) in diameter, and the entire assembly can be

o

moved up and down, and rotated about its axis by 360 (Fig. 1).

The probe is positioned such that the temperature profiles in the

vapor space as well as the liquid can be measured. Closer

spacing is provided at the free surface of the liquid where the

gradients are expected to be largest.

Absolute pressure in the vapor space of the flash tank, as

well as the differential pressure between the vapor space and the

vacuum tank, were measured. A parallel connection of electronic

pressure transmitters and mercury manometers was used. Liquid

level was measured using a cathetometer, and the salinity of the

liquid was measured using a conductivity monitor.

The experiment was started by filling the evaporator to the

required depth. The liquid was deaerated thoroughly by opening

the ball valve and exposing the liquid to a lower pressure for a

few trial runs. The liquid temperature was maintained constant

by pumping it through the heat exchanger. The ball valve was

then closed. and the vacuum tank depressurized to the desired

flash-down pressure by operating the vacuum pump. The actual run

was started by quick opening of the ball valve and consequent

exposure of the liquid to the lower pressure.

All the measurements were recorded using a computer-aided

Data Acquisition System (DAS). The DAS consists of a Hewlett

Packard (HP) 9845 desktop computer which controls an HP 3456

digital voltmeter and an HP 3497 digital scanner. The 24

channels used for measurement were monitored at the rate of 2.1

seconds per scan.

145

DATA ANALYSIS

The range of parameters cosidered in this study are: fresh

water and saline water with 3.5% NaCl concentration, initial

temperatures (TO) from 25

0

C - SOOC, flash-down temperature

difference (AT) from 0.5

0

C - 10

o

C, and pool depths (H) of 6.5"

(165 mm), 12" (305 mm) and IS" (457 mm).

The temperature, pressure and other data for each run was

used in carrying out a liquid-to-vapor heat balance to obtain the

flashed mass and other related quantities. An error analysis

indicated that the rms error in the mass of vapor

released ranged from 2.4 to 4.2%. Saturation conditions were

assumed at the bubble interface. Once the curve of flashed mass

versus time for each run was obtained, a least-squares curve fit

(using eqn. 1 below) was employed to get the parameters

corresponding to that particular run.

The data for the mass of flashed steam as a

function of time was found to be correlated very well by

(1 )

Hence, the mass flow rate due to flashing can be by

(2 )

A dimensional analysis of the variables in the system was

performed to identify the non-dimensional parameters that could

be used to get a universal correlation. The following numbers

were found to be representative of the nature of the process:

1) Ja = cpAT/h

fg

, the Jakob number, which represents the driving

force for evaporation (superheat)

2) Pr = cpU /k, the Prandtl number, which relates to the heat

transfer through the liquid to the evaporating interfaces

3) Ap/H, a term which relates the diving force for evaporation

(in terms of pressures) to the ebullition-supression hydrostatic

head (depth of liquid) H

4) l+C, to express the effect of NaCl concentration.

The def ini tion of Ja used above was modi f ied in two ways.

First, the ratio of liquid to vapor densities was included to get

(3)

146

since the pressure reduction top .is the primary driving force in

flashing unlike the bailing situation where the superheat AT

produced by wall heating is the important parameter. Using

Clapeyron's equation to relate top and AT. the modified

definition. Ja

p

is given as

(4)

The ranges of variables used in this study correspond to the

following ranges of these non-dimensional parameters:

12 < Ja

p

< 197

2.706 < Pr < 5.941

0.1116 < Ap/H < 2.615

1 < l+C < 1.035

~ was scaled by mv' the maximal amount of vapor that can be

liberated (i.e . for attainment of stable equilibrium).

(5)

The time t was scaled by a time characteristic to bubble growth

limited by heat transfer. T where:

(6)

in lieu of a better scale. We note that this scaling is probably

reasonable for the very early time when the vigor of the flashing

process is such that a bubble time scale governs the rate of

flashing. Beyond this time, the rate of pressure reduction in

the vapor space could be a significant factor controlling the

process, and this time scale may not be satisfactory.

The coefficients ~ and P2 from the least-squares

correlation of each experimental run were used as the data points

in a mul tiple linear regression (MLR) fit to generate a single

predictive correlation. The scaled ~ was taken to be a function

of the four non-dimensional parameters defined above:

(7)

In(m 1m )

.. v

In(C

1

) + a

1

In(Ja

p

) + a

2

In(Pr) + a

3

In(top/H) + a

4

In(1+C) (8)

147

The constants C

1

, a

1

, a

2

, a

3

and a

4

were obtained by the

regression analysis. A similar predictive pattern was tried for

the inverse time scale P2' but there was much more scatter in the

prediction. After a few trials using various combinations of the

variables, the final expression using MLR for P

2

was

(9)

or,

(10)

RESULTS AND DISCUSSION

The final form of the correlation and the numerical values

of the constants are m = m

w

{l - exp(-P

2

t)},

where m

w

P

2

with C

1

C

2

a

1

a

2

as

a

4

b

1

and b

2

0.8867

0.27

0.05

-0.05

-0.05

0.06

0.133,

-1.6.

( 11)

The curve-fit for the mass of flashed steam as a function of

time for a sample run (run # 15) is shown in Fig. 2. It can be

seen that the exponential fit is quite good. Such a correlation

was obtained for all of the other runs, with an overall standard

error of roughly 1.8 %.

~ .8375

Ul

Ul

~

C

~

Ul

5 .812S

..

. .

. ~ ~ ~ ~ ~ ~ ~ .

8 JB 28 30 ... 0 58 68

TIME (seconds:)

Fig. 2 Curve-fit of experimental data for Run #15 (TO

fl.T = 5.77

0

C, H = 12" (S05mm

63.5

0

C,

148

The results of MLR on the parameter are shown next in Fig. 3.

The residuals resulting from the linear regression were found to

be quite small (with an overall standard error of the estimate of

7.5% which was considered satisfactory). As a measure of the

goodness of the fit, a plot of calculated versus

experimentally observed is shown in Fig. 4. The closer the

pOints are to the 45

0

line, the better the fit is.

seen that the prediction is quite accurate.

Standardized Residuals vSx lnOii)

* ..

x "i!

-1

-2

-3

-4

-5", ..

IS)

Fig. 3 Linear regression on m

.2

..

.15

.,

"

E

"C

.1

?' I)

..

,'"

0

'"

,05

Il

/

c

IL

0

(21 .05 .1

/

--

.15

Experimental mass ( Kg )

,,/

.2

Fig. 4 Comparison of correlation with experiment

It can be

Next, the results of the regression analysis on the exponent

P2 are shown in Fig. 5. The large scatter in the prediction,

which amounts to about 60% (1.8 standard residuals) was

attributed to the inadequacy of the measurements to determine the

fast transients which occur during the initial second of the

149

5 Standardized Residuals vs InCP2T)

e

-1

-2

-3

-.

-5

j'

.

XX

III ~

II

'tI: 'k

m

I

x".- "'"

on

I

'"

I

Fig. 5 Linear regression on P2T

process, and possibjy to other phenomena, not taken into

consideration by the definition of the nondimensional parameters

used here, such as, for example, the rate of pressure reduction

which may be an important factor in the early stages of the

process. We also tried other forms of correlation such as

nonlinear regression and the use of other time scales with

limited success. Within a period of 30 seconds from the start,

the above-described scatter in the value of P

2

amounts to a

scatter of 68% in the flash evaporation rate m. It is

noteworthy that no correlations for this purpose seem to exist at

this time which have smaller scatter.

The a v a ~ l a b l e data in the literature on pool flashing is

either in the form of rate expressions (which must be integrated

over time to compare with the total flashed mass data in our

experiment), or they were obtained for parameters outside the

range of this study. The data obtained by Miyatake et al. (ref.

6) was used for comparison with the expressions found in our

study. In their experiments, the flashed mass flux was expressed

as a function of the equilibrium temperature at the end of

flashing and the overall superheat. The range of non-dimensional

numbers corresponding to their variables was found to be within

our range of parameters, and hence a comparison could be made.

The results are shown in Fig. 6. The observed differences may be

attributed to the more accurate technique (by maybe an order of

magnitude, because of the use of thermistors instead of

thermocouples) used in the measurement of temperature in the

150

... Ref. (6)

"

: ';1.1

:L :

c

"0 D

Gl

.

" .

ffl

U.

Present Study

6p/R = 1. 0

.. '"

4.0 ..... 6p/R

'. '. ... 1.0

..... .................. .

.9L0 .... ........ .... ....

Jakob Number

Fig. 6 Comparison with correlations of Ref. (6)

study reported in this paper. Furthermore, the trends observed

in this study (Fig. 6) appear to be physically more plausible

than those observed in ref. 6, esspecially in the low Ja region.

CONCLUSIONS

In summary, this study resulted in a general expression for

the evaluation of flashed mass in a pool flash evaporator. The

experiments were carried out in the range of operation of

desalination and OTEC plants, but the conclusions reached may

possibly be valid for other applications because of the non-

dimensional nature of the correlation.

ACKNOWLEDGMENT

This study was supported in part by the Solar Energy

Research Institute through a Westinghouse Electric Company

subcontract to the University of Pennsylvania, and by the Solar

Heat Technologies Division, Office of Conservation and Solar

Applications of the U. S. Department of Energy. We would also

like to express our thanks to the International Desalination

Association for the award of the K. C. Channabasappa scholarship

to one of the authors (SG).

151

REFERENCES

1 G. Claude, power from the Tropical Seas, Mechanical

Engineering 52 (1930) 1039-1044.

2 W. Goldstern, Steam Storage Installations, Pergamon, Oxford,

1963.

3 F. W. Gilbert, C. M. Coogan, and D. A. Fisher, Experimental

investigation of flashing seawater in open rectangular

channel flow, AS ME Paper 70-FE-39 (1970).

4 G. Coury, J. Deronzier, and J. Huyghe, Etude du mechanisme de

la detente en geometrie complex, Desalination, 12 (1973) 295-

313.

5 N. Lior and R. Greif, Some basic observations on heat

transfer and evaporation in the horizontal flash evaporator,

Desa1ination, 33 (1980) 269-286.

6 O. Miyatake, K. Murakami, Y. Kawata and T. Fujii,

Fundamentalexperiments with flash evaporation, Heat Transfer-

Japanes Research, 2(4) (1973) 89-100.

7 S. Nakamura, T. Matushima and S. Anzai, Transient

characteristics of flashing phenomena of saturated water in

vessels and their method of analysis, Heat Transfer Japanese

Research, 13(4) (1984) 1-18.

8 T. Sugeta and S. Toyama, An experimental study of Flash

evaporation phenomena at high liquid flow rates, Heat

Transfer-Japanese Research, 7(2) (1978) 65-73.

9 N. Lior and E. Nishiyama, The Effect of Gas Bubbles on Flash

Evaporation, Desalination, 45 (1983) 231-240.

10 O. Miyatake, T. Tomimura, Y. Ide and T. Fujii, An

Experimental Study of Spray Flash Evaporation, Desalination,

36 (1981) 113-128.

11 D. Bharathan, F. Kreith, D. Schlepp and W.L. Owens, heat and

mass transfer in open-cycle OTEC systems, heat transfer

Engineering, 5(1) (1984) 17-30.

12 N. Lior, Formulas for calculating the approach to equilibrium

in open channel flash evaporators for saline water,

Desalination, 60 (1986) 223-249.

13 R.J. Peterson, S.S. Grewal and M.M. El-Wakil, Investigation

of Liquid Flashing and Evaporation due to Sudden

Depressurization, Int Journal of Heat Mass Transfer,

27 (1984) 301-310.

14 G.T. Clegg and G. Papadakis, Rates of Evaporation

Accompanying the Depressurization of a Pool of Saturated

Freon-II, Chem. Engg. Sci., 41(12) (1986) 3037-3043.

15 N. Lior and K. Koai, Solar-powered/fuel-assisted Rankine

cycle power and cooling system: simulation method and

seasonal performance, Journal of Solar Energy Engineering,

106(4) (1984) 447-456.

16 A. Girbal-Puig and N. Lior, The Solar-Powered/Fuel-Assisted

Hybrid Rankine Cycle ("SSPRE"): The thermal storage/flash

evaporation steam generator ("steam accumulator")

experimental facility, Report SAN/ET/20110-16 to the

U.S.D.O.E., August 1986.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ChatGPT & EducationDocument47 pagesChatGPT & EducationAn Lê Trường88% (8)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Rsi r2 Super Rsi FaqDocument14 pagesRsi r2 Super Rsi FaqChandrasekar Chandramohan100% (1)

- 12 Step Worksheet With QuestionsDocument26 pages12 Step Worksheet With QuestionsKristinDaigleNo ratings yet

- Selection of Materials For Use in Desalination Plants: A Corrosion Literature Review PaperDocument8 pagesSelection of Materials For Use in Desalination Plants: A Corrosion Literature Review PaperSamson RaphaelNo ratings yet

- P3 Past Papers Model AnswersDocument211 pagesP3 Past Papers Model AnswersEyad UsamaNo ratings yet

- WeldingofStainlesssSteelandotherJoiningMethods 9002Document0 pagesWeldingofStainlesssSteelandotherJoiningMethods 9002jvs11021102No ratings yet

- How To Write A ThesisDocument33 pagesHow To Write A ThesisA Roy100% (27)

- Engineering MaterialsDocument197 pagesEngineering MaterialsSidiq BudhyNo ratings yet

- Engineering MaterialsDocument197 pagesEngineering MaterialsSidiq BudhyNo ratings yet

- Handbook CPWD NoPWDocument498 pagesHandbook CPWD NoPWAijaz Zende100% (6)

- Topic: Grammatical Issues: What Are Parts of Speech?Document122 pagesTopic: Grammatical Issues: What Are Parts of Speech?AK AKASHNo ratings yet

- FLOWTITE Pipe Systems: For Subaqueous InstallationsDocument12 pagesFLOWTITE Pipe Systems: For Subaqueous InstallationsRusu CatalinNo ratings yet

- PDS DeltaV SimulateDocument9 pagesPDS DeltaV SimulateJesus JuarezNo ratings yet

- Jerusalem-Archaeology History Apologetic ProofDocument260 pagesJerusalem-Archaeology History Apologetic ProofSamson Raphael100% (2)

- Seismic Resistance of Pressure Equipment and Its Supports: Practice NoteDocument134 pagesSeismic Resistance of Pressure Equipment and Its Supports: Practice NoteSamson RaphaelNo ratings yet

- Scrum Exam SampleDocument8 pagesScrum Exam SampleUdhayaNo ratings yet

- ANSYS Command Reference PDFDocument1,614 pagesANSYS Command Reference PDFSamson RaphaelNo ratings yet

- IndianOil Lubes Product SheetDocument97 pagesIndianOil Lubes Product SheetHellz Girish100% (1)

- Vibrational Analysis of Shell and Tube Heat Exchanger PDFDocument6 pagesVibrational Analysis of Shell and Tube Heat Exchanger PDFSamson RaphaelNo ratings yet

- QTR Ch8 - Waste Heat Recovery TA Feb-13-2015Document27 pagesQTR Ch8 - Waste Heat Recovery TA Feb-13-2015Samson RaphaelNo ratings yet

- 1 s2.0 S1364032113004140 Main PDFDocument16 pages1 s2.0 S1364032113004140 Main PDFSamson RaphaelNo ratings yet

- Thermodynamic Porperties of Molten Nitrate Salts CordaroDocument8 pagesThermodynamic Porperties of Molten Nitrate Salts CordaroSamson RaphaelNo ratings yet

- Large-Scale Vacuum Vessel Design and Finite Element AnalysisDocument9 pagesLarge-Scale Vacuum Vessel Design and Finite Element AnalysisSamson RaphaelNo ratings yet

- Concentrating Solar Power - State of The Art, Cost Analysis and Pre-Feasibility Study For The Implementation in China PDFDocument115 pagesConcentrating Solar Power - State of The Art, Cost Analysis and Pre-Feasibility Study For The Implementation in China PDFSamson RaphaelNo ratings yet

- CorrossionDocument7 pagesCorrossionSamson RaphaelNo ratings yet

- X Steam For MatlabDocument5 pagesX Steam For Matlabshane5ul100% (1)

- Zarza DSG Overview PDFDocument22 pagesZarza DSG Overview PDFSamson RaphaelNo ratings yet

- Children Education AllowanceDocument3 pagesChildren Education AllowanceSamson RaphaelNo ratings yet

- Thermal Analysis of A Fireplace Using ANSYSDocument58 pagesThermal Analysis of A Fireplace Using ANSYSSamson RaphaelNo ratings yet

- Steam TablesDocument15 pagesSteam TablesSamson RaphaelNo ratings yet

- PDFDocument19 pagesPDFSamson RaphaelNo ratings yet

- Ocean Thermal Vol 2Document67 pagesOcean Thermal Vol 2Mohammad MujtabaNo ratings yet

- Steam TablesDocument15 pagesSteam TablesSamson RaphaelNo ratings yet

- Horizontal Vessel FEA2 PDFDocument7 pagesHorizontal Vessel FEA2 PDFpouya_msNo ratings yet

- Thesis Patnode06Document271 pagesThesis Patnode06Syed Haider AliNo ratings yet

- Pressure Loss in Vacuum Lines With Water Vapour: The Diagram in Fig. 1, Is Calculat-Ed From The FormulaDocument2 pagesPressure Loss in Vacuum Lines With Water Vapour: The Diagram in Fig. 1, Is Calculat-Ed From The FormulaEsther Valladares NuñezNo ratings yet

- Engineering Ethics in Practice ShorterDocument79 pagesEngineering Ethics in Practice ShorterPrashanta NaikNo ratings yet

- SievesDocument3 pagesSievesVann AnthonyNo ratings yet

- Chakir Sara 2019Document25 pagesChakir Sara 2019hiba toubaliNo ratings yet

- Installation Instructions INI Luma Gen2Document21 pagesInstallation Instructions INI Luma Gen2John Kim CarandangNo ratings yet

- Community Profile and Baseline DataDocument7 pagesCommunity Profile and Baseline DataEJ RaveloNo ratings yet

- 2.0. Design, Protection and Sizing of Low Voltage Electrical Installations (Wiring) To IEE Wiring Regulations BS 7671 MS IEC (IEC) 60364 - 16&17.12.15Document2 pages2.0. Design, Protection and Sizing of Low Voltage Electrical Installations (Wiring) To IEE Wiring Regulations BS 7671 MS IEC (IEC) 60364 - 16&17.12.15Edison LimNo ratings yet

- Design ProjectDocument60 pagesDesign Projectmahesh warNo ratings yet

- Banking Ombudsman 58Document4 pagesBanking Ombudsman 58Sahil GauravNo ratings yet

- Rankine-Froude Model: Blade Element Momentum Theory Is A Theory That Combines BothDocument111 pagesRankine-Froude Model: Blade Element Momentum Theory Is A Theory That Combines BothphysicsNo ratings yet

- Meta100 AP Brochure WebDocument15 pagesMeta100 AP Brochure WebFirman RamdhaniNo ratings yet

- Naval TV SystemDocument24 pagesNaval TV Systemsharmasandeep0010No ratings yet

- TPDocument10 pagesTPfaisal gaziNo ratings yet

- Jurnal Job DescriptionDocument13 pagesJurnal Job DescriptionAji Mulia PrasNo ratings yet

- Wine TourismDocument9 pagesWine Tourismyarashovanilufar1999No ratings yet

- Poster-Shading PaperDocument1 pagePoster-Shading PaperOsama AljenabiNo ratings yet

- Point and Figure ChartsDocument5 pagesPoint and Figure ChartsShakti ShivaNo ratings yet

- 7 - Monte-Carlo-Simulation With XL STAT - English GuidelineDocument8 pages7 - Monte-Carlo-Simulation With XL STAT - English GuidelineGauravShelkeNo ratings yet

- 4. Nguyễn Thị Minh Khai, Sóc TrăngDocument15 pages4. Nguyễn Thị Minh Khai, Sóc TrăngK60 TRẦN MINH QUANGNo ratings yet

- Statistical Process Control and Process Capability PPT EXPLANATIONDocument2 pagesStatistical Process Control and Process Capability PPT EXPLANATIONJohn Carlo SantiagoNo ratings yet

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Document2 pagesLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulNo ratings yet

- Multiple Choice Practice Questions For Online/Omr AITT-2020 Instrument MechanicDocument58 pagesMultiple Choice Practice Questions For Online/Omr AITT-2020 Instrument Mechanicمصطفى شاكر محمودNo ratings yet

- The University of The West Indies: Application For First Degree, Associate Degree, Diploma and Certificate ProgrammesDocument5 pagesThe University of The West Indies: Application For First Degree, Associate Degree, Diploma and Certificate ProgrammesDavid Adeyinka RamgobinNo ratings yet

- Aditya Academy Syllabus-II 2020Document7 pagesAditya Academy Syllabus-II 2020Tarun MajumdarNo ratings yet