Professional Documents

Culture Documents

SSS Clutch Project

Uploaded by

Moustafa HelmyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SSS Clutch Project

Uploaded by

Moustafa HelmyCopyright:

Available Formats

ch ar M /A pr 00 20 il

Siemens on fast track to commission Santa Rita

Siemens on fast track to commission Santa Rita

A 1000 MW combined cycle with four single-shaft blocks is nearing completion in the Philippines. Through careful planning of the commissioning program on two fuels, Siemens are able to bring all four units into commercial operation within the space of a few days.

In the old days a steam plant with four 250 MW sets might at best have been brought into operation over the space of two years, with one unit being put into service every six months in accordance with the generation development plan of the utility concerned. Later, utilities faced with rapid growth in electricity demand were attracted to the combined cycle because a large multishaft block allowed the gas turbines to be commissioned quickly and run simple cycle for upwards of 12 months while the steam cycle was completed. The trend to install large singleshaft combined cycle blocks with, for the 60 Hz market, gas turbines of about 180 MW has been accompanied by a move to reduce the construction time by having a greater degree of factory assembly for what is effectively a standardised plant design. The electricity supply system in the Philippines is in a process of change. The National Power Corporation (NAPOCOR) is no longer in the business of building generating plant. That is left to IPPs either alone or in partnership with NAPOCOR, to build new plants or refurbish and repower existing stations. In effect the company, which is still in the public sector, will become the market place for electricity trade, with responsibility for the high-voltage grid and the HVDC links between the major island networks. Another factor which has brought the Santa Rita and other combined cycles into being is the discovery of the Malampaya gas field offshore southwest Luzon in 1990. Shell, as developer of the field saw that in the absence of any gas market in Manila and the other large cities, the only way to exploit this field would be through power generation. 3000 MW was seen as the size of market that would enable the development to go ahead. As development of the first combined cycle plants got under way, the country was seeing growth in demand

Figure 1. Santa Rita power station viewed from the fuel unloading jetty. Unit 10, the first to complete commissioning is at right of picture. The mobile crane at left is working on preparation of the San Lorenzo site

of 7.5% per year, then at the beginning of 1998, growth slowed down and is now effectively at zero. In this situation new construction is for plant replacement to benefit from improved efficiency and environmental quality of power generation. Basically three large combined cycle plants and a planned 300 MW CHP unit at the Caltex refinery in Batangas define the market that enables the development of the Malampaya field. The first of these, Santa Rita, with four single-shaft blocks of Siemens Model V84.3A, is nearing completion. A second plant, San Lorenzo, on the neighbouring site achieved financial closure February 15 It will have two of the same combined cycle units as Santa Rita and a number of shared facilities including the control room. These two plants account for half of the 3000 MW. About 40 km north along the coast, at Ilijan, site preparation is in progress, pending financial closure, for a 1200 MW combined cycle to be built for a joint venture of NAPOCOR and KEPCO (Korea Electric Power Corp). Mitsubishi is reportedly the prime contractor. The plant is expected to be completed just as the first gas arrives. It was because of the prospect of

developing gas infrastructure in the Philippines that British Gas holds 40% of First Gas Power Corporation, the owners of Santa Rita. The other partners are First Philippine Holdings, with 51%, and the Meralco Pension Fund with 9%. For San Lorenzo, the owners are a joint venture of First Philippine Holdings and British Gas alone. But Meralco, as the electricity distributor in Manila will buy the net output of both stations which must be wheeled over the NAPOCOR 230 kV grid. Indeed, Siemens turnkey contract for Santa Rita includes construction of a 35 km dual-circuit transmission line from the 230 kV switchyard on site to NAPOCORs Calaca substation, the capacity of which is more than will be the combined output of both plants when San Lorenzo comes into operation in the second quarter of 2002.

Santa Rita

In December 1996, Siemens were awarded a turnkey contract by First Gas Power Corporation for the construction of a 1000 MW power plant. Preliminary access to site was granted in July 1997 and financial closure was achieved two months later on September 4. Official ground breaking to signify the start of works was performed two

4.8 bars, 235C

Turbine bypass 28.4 bars 540C 110 bars, 540C 250 MW Liquid fuel feed Direct cooling by the sea Fuel gas heater HP IP Booster pumps

Figure 2: Steam cycle of Santa Rita and San Lorenzo combined cycles in their final configuration with gas firing, which is expected to start in 3rd quarter of 2002. Until then Santa Rita will run on either gas condensate, naphtha, or a mixture of both.

months later on November 17. As originally planned the plant was to be two 500 MW blocks and this terminology has stuck even though the four units are considered separate and numbered 10, 20, 30 and 40. In any event the plan was to bring 10 and 20 to completion in 24 months and 30 and 40 after a further three months. Operational factors outside Siemens control have led to some delays so that the four units were due to be handed over in April, 2000. Each unit is similar in its basic configuration of the power train, and the steam cycle is similar to that of the 50 Hz single shaft units with Model V94.3A, as for instance at Otahuhu, New Zealand, (Jan/Feb 2000, p.34). The two gas turbines were developed as a common scaled design so that although the mass flow is less, the temperatures are the same. Operating examples of Model V84.3A in the United States exhibited the same humming at high loads that was observed on the larger Model V94.3A. This was due to a circumferential resonance being set up in the combustion chamber which, as in the larger 50 Hz machine was cured by fitting asymmetric collars to selected burners to dampen out any tendency to hum. The same modification has been applied to the 60 Hz machines in the field and subsequently on the production line. In the case of Model V84.3A sixteen of the 24 hybrid burners are fitted with these collars. Siemens standard steam cycle for both machines is tri-pressure reheat, with a 2-cylinder steam turbine exhausting to an axial condenser. Deaeration takes place in the condenser hot well so that the condensate extraction pump doubles as the LP boiler feed pump. There is a single preheater stage in which the conden-

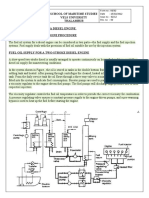

Figure 3: Units 1 and 2 of the first Block were simultaneously commissioned on diesel oil in mid February

all four sets are being commissioned on diesel fuel, after which commissioning will be carried out on whichever of the other liquid fuels is available. In commercial operation the plant will be started on distillate and switched to either naphtha or gas condensate, or a mixture of both. The original construction plan set a schedule to commission two 500 MW blocks three months apart. In practice the delays in the first block have brought the second block to the point that with careful planning commissioning of two units within the block can be performed at the same time.

Clutch aids testing

For this to be possible at all the generator has to be in the middle of the power train with an SSS clutch separating it from the steam turbine. Besides its normal uses to facilitate rapid start up, and to enable early access to the gas turbine at a maintenance outage, at Santa Rita it plays an important role in the commissioning of the combined cycle units. With the clutch open, the gas turbine can be run to clean the boiler which discharges steam through bypass valves to the condenser. The clutch has only to be closed to commission the steam turbine. On February 14, three of the four gas turbines had been synchronised and boiler cleaning was about to start on unit 40. In the first block, work was focusing on the commissioning of unit GT10 to full load, and the commissioning of ST20. For cleaning the boilers the gas turbines can be operated with their hybrid burners in diffusion mode. This is a high NOx mode of operation which is permissible during commissioning when the plant is exempt from prevailing environmental rules. In any case, in normal operation, premix mode would

sate passes through a heat exchanger, which is supplied by a steam bleed from the LP turbine. The main conceptual difference between this and Otahuhu is that it is directly cooled by sea water instead of having a hybrid cooling tower; and that since the gas turbine will, for the first three years, burn liquid fuel, it has water injection for NOx control. The initial fuel contracts for naphtha and gas condensate have been placed with Enron and the first shipment of 50 000 m of gas condensate was on site when Turbomachinery International visited on February 14. In the stations tank farm there are five 26 000 m tanks for storage of naphtha and gas condensate. In addition there are two for storage of diesel fuel, and a further two day tanks for the diesel fuel used for start-up and shut-down. The station will be operated on liquid fuel until Malampaya gas becomes available, which is expected to be in 2002. Shell are bringing it ashore at their Batangas refinery, from where First Gas Holdings will lay an 8 km pipe to the Santa Rita site. Meanwhile

Figure 4: Siemens standard single shaft combined cycle has centrally mounted generator and steam turbine exhausting to axial condenser as can be seen here in left background.

Figure 5: Centrifuge fuel treatment system by Westfalia Separator will handle diesel , naphtha and condensate fuels in the first two years of operation until natural gas arrives.

cut in at above the 80 MW output level needed to clean the boiler. With both boilers cleaned and the clutch of the Unit 20 closed its steam turbine can be tested up to full load and the control settings established with the gas turbine still firing in diffusion mode. While this is happening, the clutch of GT10 is open with the gas turbine commissioning, and the boiler dumping steam into the condenser. Commissioning tests entail taking the gas turbine output up to full load in stages and checking out hardware and control software to establish operating settings and eliminate any design anomalies. For this, the Teleperm controller has a software editing display which allows the commissioning engineer to view, and if necessary amend the section of the control program code corresponding to the particular condition of loading under which the gas turbine is testing. Using this facility, alarm signals can be verified and settings confirmed. With commissioning completed, the finalised control software of unit GT10 can now be transferred to the controller of GT20. Similarly, control software for ST20 can then be transferred to ST10. The file transfers can be carried out overnight after which a final check of GT20 and ST10 can proceed in

Figure 6. Without an SSS clutch in each unit simultaneous commissioning would not have been possible

parallel so that both units can be brought to completion of the entire block of two gas turbines, and a steam turbine in about four days. While this is going on the defined control software routines can be transferred to the other two units provided that cleaning of the boilers has been completed. Running on naphtha or gas condensate poses a problem of lubricity. This is not so severe in the Siemens

fuel system with an annular combustor arrangement as in some units with cannular combustors but it still means that without purging the system at shutdown there is a risk of sludge collecting in fuel lines and pumps. It is in India where naphtha firing has really taken off and Siemens have therefore carried out extensive tests on the Paguthan combined cycle with two Model V94.2 near Ahmedabad. With naphtha firing the gas turbine can be started on diesel fuel and switched to naphtha when full load has been reached. To shut down it is not necessary to switch back to diesel. The gas turbine is run down on naphtha and then the whole fuel system can be purged with demineralised water. This method has been found to be effective in Paguthan and will be applied also to the four units at Santa Rita. Commissioning on either naphtha or gas condensate followed commissioning on distillate, and using the same methods to bring all four units up to commercial operation together. At the same time, work has started in earnest on the construction of the two single shaft blocks for San Lorenzo. By the time that this station is completed natural gas may be available, and then Santa Rita will have to be taken out of service for commissioning on this fuel.

SSS Gears Limited Park Road, Sunbury-on-Thames Middlesex, TW16 5BL, England Telephone: +44 1932 780644 Fax: +44 1932 780018 SSS Reference 0300/2

SSS Clutch Company Inc 610 West Basin Road New Castle, DE 19720, USA Telephone: +1 302 322 8080 Fax: +1 302 322 8548

Printed in the United Kingdom

You might also like

- Turbomachinery: Blackstone: Flexible and Environmentally Friendly Power PlantDocument6 pagesTurbomachinery: Blackstone: Flexible and Environmentally Friendly Power PlantbastechNo ratings yet

- Kinney Piston Vacuum Pump BrochureDocument18 pagesKinney Piston Vacuum Pump BrochureVivek BelaNo ratings yet

- Fluid Coupling PDFDocument5 pagesFluid Coupling PDFRagvendra BistNo ratings yet

- Booster Kinney KMBD SeriesDocument24 pagesBooster Kinney KMBD SeriesHector ManuelNo ratings yet

- Blowers and Vacuum BoostersDocument6 pagesBlowers and Vacuum BoostersMara RusyadiNo ratings yet

- Cryostar CorporateDocument16 pagesCryostar CorporateNarayan MarndiNo ratings yet

- NEA U M Recip Compressors Pocket Brochure PRDocument5 pagesNEA U M Recip Compressors Pocket Brochure PRMadhana GopalNo ratings yet

- AC Induction Motor Specifications White Paper August 2003Document5 pagesAC Induction Motor Specifications White Paper August 2003clide_050793No ratings yet

- NP Pumps BlackmerDocument4 pagesNP Pumps BlackmerrasottoNo ratings yet

- KMBD BP(国外罗茨泵ROOTS)Document2 pagesKMBD BP(国外罗茨泵ROOTS)tutuli1990No ratings yet

- CHP02 CDocument2 pagesCHP02 Cyahia108No ratings yet

- Pure Dynamism - Cryostar Magazine5Document12 pagesPure Dynamism - Cryostar Magazine5Narayan MarndiNo ratings yet

- NR1000 2 Size 74T Clutch For Gas Turbine Starting DrivesDocument1 pageNR1000 2 Size 74T Clutch For Gas Turbine Starting DrivesJJNo ratings yet

- Oerlikon Leybold Roots Blower Vacuum Pump CatalogDocument40 pagesOerlikon Leybold Roots Blower Vacuum Pump CatalogYasir Ali100% (1)

- Marktinfo - 17. Auflage - 2020-03-06 - InTDocument875 pagesMarktinfo - 17. Auflage - 2020-03-06 - InTOliver FrereNo ratings yet

- Fluitec Boost VR 1310Document2 pagesFluitec Boost VR 1310api-221802169No ratings yet

- Pumps in Range - Cryostar Magazine4Document12 pagesPumps in Range - Cryostar Magazine4Narayan MarndiNo ratings yet

- Titration of Total Base Number TBN DIN ISO 3771 ASTM 2896Document10 pagesTitration of Total Base Number TBN DIN ISO 3771 ASTM 2896vektron6No ratings yet

- Svedala RV Eng GerardDocument6 pagesSvedala RV Eng GerardPaseandoPorlaVidaNo ratings yet

- Instructions for fitting SSS clutchDocument4 pagesInstructions for fitting SSS clutchferayiNo ratings yet

- Simulated Distillation Analysis Middle Distillates PDFDocument8 pagesSimulated Distillation Analysis Middle Distillates PDFgraciela areinamoNo ratings yet

- Steam Sealing CondensersDocument2 pagesSteam Sealing Condensersbadrul1981No ratings yet

- 7970 1 en 0509 PDFDocument94 pages7970 1 en 0509 PDFOlusegun OlugbadeNo ratings yet

- Accessories HydraulicsDocument47 pagesAccessories HydraulicsawfahaddadinNo ratings yet

- Dry Vacuum Pump Cobra Busch enDocument2 pagesDry Vacuum Pump Cobra Busch enJessica ChandlerNo ratings yet

- Teikoku Canned Motor Pumps: Sealless Design for Zero LeakageDocument16 pagesTeikoku Canned Motor Pumps: Sealless Design for Zero LeakageHideyoshi Ardi ToyotomiNo ratings yet

- Steam Amonia TurbineDocument21 pagesSteam Amonia TurbineLuis Alexandre MachadoNo ratings yet

- Blackmer GX-X200926143331824Document2 pagesBlackmer GX-X200926143331824JonathanNo ratings yet

- Specific Heat Ratios For HydrocarbonsDocument3 pagesSpecific Heat Ratios For HydrocarbonsChristian CândidoNo ratings yet

- Stepless Clearance Pocket: Oil & GasDocument4 pagesStepless Clearance Pocket: Oil & Gasshank100No ratings yet

- Mechanical Pumps For Vacuum ProcessingDocument10 pagesMechanical Pumps For Vacuum Processinghwang2No ratings yet

- Brochure BHGEDocument44 pagesBrochure BHGEbederinadmlNo ratings yet

- Donk in Turbo CompressorsDocument16 pagesDonk in Turbo CompressorsLeon SanchezNo ratings yet

- Adhesive and Tape Solutions Design Guide - LR PDFDocument100 pagesAdhesive and Tape Solutions Design Guide - LR PDFjohanNo ratings yet

- Centrifugal Pumps Bearings - Part 1Document23 pagesCentrifugal Pumps Bearings - Part 1visitabhinav80% (5)

- PlasticsEurope Eco-Profile VCM PVCDocument48 pagesPlasticsEurope Eco-Profile VCM PVCABC100% (1)

- Tuthill Blower Spec - 02Document8 pagesTuthill Blower Spec - 02Kari ConwayNo ratings yet

- Flender Fluid CouplingsDocument38 pagesFlender Fluid CouplingsTraian SerbanNo ratings yet

- Dynamic Reaction Inside Co-Rotating Twin Screw Extruder. II. Waste Ground Rubber Tire Powder - Polypropylene BlendsDocument11 pagesDynamic Reaction Inside Co-Rotating Twin Screw Extruder. II. Waste Ground Rubber Tire Powder - Polypropylene Blendspickpocket27No ratings yet

- Oiece0302 1122Document52 pagesOiece0302 1122Hüseyin SuzukNo ratings yet

- LRVP PowerDocument28 pagesLRVP Powermnbvcx213323No ratings yet

- INW Roots Blowers Operating Instructions 2020Document20 pagesINW Roots Blowers Operating Instructions 2020cristobal pascuaNo ratings yet

- SSS Clutch PrincipleDocument2 pagesSSS Clutch PrincipleSyed Safiur RahmanNo ratings yet

- Multi-Stage Steam Turbines: Proven Reliability and EfficiencyDocument8 pagesMulti-Stage Steam Turbines: Proven Reliability and EfficiencyAlfredo Velasquez100% (1)

- HXL BlackmerDocument2 pagesHXL BlackmerrasottoNo ratings yet

- Siemens Combined Cycle Reference Power Plant SCC5-4000F 1S: Answers For EnergyDocument12 pagesSiemens Combined Cycle Reference Power Plant SCC5-4000F 1S: Answers For EnergySandra CooperNo ratings yet

- Centrifugal Damper CatDocument8 pagesCentrifugal Damper CatAdil Shahzad100% (2)

- Gas SealsDocument38 pagesGas SealskbogeshwaranNo ratings yet

- Datum Compressor Cut PDFDocument1 pageDatum Compressor Cut PDFJ.SIVIRANo ratings yet

- File 61 PDFDocument40 pagesFile 61 PDFNguyenHuanNo ratings yet

- Hermetic CompressorsDocument102 pagesHermetic CompressorsMalau Arief100% (1)

- Centrifugal AxialcompressorsDocument28 pagesCentrifugal Axialcompressorsultrasonic81100% (1)

- Alstom - BoA 2&3 + WTA - 2008Document8 pagesAlstom - BoA 2&3 + WTA - 2008fransdaunNo ratings yet

- Variety of Steam Turbines in Svartsengi & Reykjanes Geothermal Power PlantDocument6 pagesVariety of Steam Turbines in Svartsengi & Reykjanes Geothermal Power PlantErnesto Sánchez GómezNo ratings yet

- The Durgapur PR-WPS OfficeDocument33 pagesThe Durgapur PR-WPS OfficeSuraj SharmaNo ratings yet

- Steam Turbine UpgradesDocument3 pagesSteam Turbine UpgradesYugandhara Chakravarthy Kancherla100% (1)

- Doosan Wins French Biomass Deal From EDocument4 pagesDoosan Wins French Biomass Deal From Ejackdawn21No ratings yet

- 660 MW Power PlantDocument6 pages660 MW Power Plantnestor0259No ratings yet

- Thermal Power Plant BathindaDocument58 pagesThermal Power Plant Bathindadeepzsohl100% (1)

- 500MW San Lorenzo CCGT Power PlantDocument3 pages500MW San Lorenzo CCGT Power PlantChristian Denric CosinasNo ratings yet

- General Marine Loading Arm MaintenanceDocument1 pageGeneral Marine Loading Arm MaintenanceMoustafa HelmyNo ratings yet

- Kao Corporation, S.A.: SK Fert FA80TSDocument1 pageKao Corporation, S.A.: SK Fert FA80TSMoustafa HelmyNo ratings yet

- March 2017 - August 2018: API SIRE Exam Publications Effectivity Sheet - ForDocument2 pagesMarch 2017 - August 2018: API SIRE Exam Publications Effectivity Sheet - ForSlbcar LoogingNo ratings yet

- System AnalysisDocument2 pagesSystem AnalysismustafaNo ratings yet

- Potassium Silicate SDSDocument9 pagesPotassium Silicate SDSMoustafa HelmyNo ratings yet

- Machinery Lubricantion Fundamentls Course OutlineDocument1 pageMachinery Lubricantion Fundamentls Course OutlineMoustafa HelmyNo ratings yet

- Auditing Effect On Firm Performance-Final GheatyDocument50 pagesAuditing Effect On Firm Performance-Final GheatyMoustafa HelmyNo ratings yet

- Valve SpecificationsDocument2 pagesValve SpecificationsMoustafa HelmyNo ratings yet

- Project Report Lecico FinalDocument52 pagesProject Report Lecico FinalMoustafa HelmyNo ratings yet

- Offer letter for Position of Job Title at Company NameDocument1 pageOffer letter for Position of Job Title at Company NameMoustafa HelmyNo ratings yet

- T24117 127Document12 pagesT24117 127Moustafa HelmyNo ratings yet

- Potassium SilicateDocument1 pagePotassium SilicateMoustafa HelmyNo ratings yet

- Pipe Sch 40 SMAW Assumptions and Correction FactorsDocument1 pagePipe Sch 40 SMAW Assumptions and Correction FactorsMoustafa HelmyNo ratings yet

- Corporate GovernanceDocument12 pagesCorporate GovernanceMoustafa HelmyNo ratings yet

- Gift LetterDocument1 pageGift LetterMoustafa HelmyNo ratings yet

- Nitric Acid 60 PR - Product Data SheetDocument1 pageNitric Acid 60 PR - Product Data SheetMoustafa HelmyNo ratings yet

- Storage of Hot Ammonium Nitrate Solutions (BPE)Document48 pagesStorage of Hot Ammonium Nitrate Solutions (BPE)Vanjared OcampoNo ratings yet

- Starbucks Company TimelineDocument5 pagesStarbucks Company TimelineMoustafa HelmyNo ratings yet

- Statistics Traning ExamDocument6 pagesStatistics Traning ExamMoustafa Helmy100% (2)

- Corporate Governance and AuditDocument12 pagesCorporate Governance and AuditMoustafa HelmyNo ratings yet

- Jungtec - Prospekt - EnglischDocument44 pagesJungtec - Prospekt - EnglischMoustafa HelmyNo ratings yet

- KaolinDocument1 pageKaolinMoustafa HelmyNo ratings yet

- Asset Maintenance ManagementDocument37 pagesAsset Maintenance ManagementMoustafa Helmy100% (1)

- Mcdonald Final 2 140409005910 Phpapp02Document21 pagesMcdonald Final 2 140409005910 Phpapp02Moustafa HelmyNo ratings yet

- VIB Booklet ENDocument36 pagesVIB Booklet ENPetra HeutsNo ratings yet

- Vibxpert-II Brochure Lit.53.400.EnDocument4 pagesVibxpert-II Brochure Lit.53.400.EnMoustafa HelmyNo ratings yet

- M0743-109000 Barrierta L55 2Document4 pagesM0743-109000 Barrierta L55 2Moustafa HelmyNo ratings yet

- Performance Curve For Firefighting PumpDocument1 pagePerformance Curve For Firefighting PumpMoustafa HelmyNo ratings yet

- Delayed Intermittent ControlDocument2 pagesDelayed Intermittent ControlMoustafa HelmyNo ratings yet

- Pumps - IntroductionDocument31 pagesPumps - IntroductionSuresh Thangarajan100% (1)

- Industrial Caterpillar Engine Specifications: V12, 4-Stroke-Cycle DieselDocument5 pagesIndustrial Caterpillar Engine Specifications: V12, 4-Stroke-Cycle DieselLuis Eduardo Albarracin RugelesNo ratings yet

- MondeoDocument3 pagesMondeorodrigo maranonNo ratings yet

- Effect of Weighting Materials on Mud PropertiesDocument5 pagesEffect of Weighting Materials on Mud PropertiesKhairil IkramNo ratings yet

- Liquid FuelsDocument12 pagesLiquid FuelsCharles MayoNo ratings yet

- 1 - Catalog 2019 PDFDocument33 pages1 - Catalog 2019 PDFAndres VargasNo ratings yet

- Global Service Learning: D11T Track-Type TractorDocument17 pagesGlobal Service Learning: D11T Track-Type Tractorluishvanegas67% (3)

- Weight Management: Aviation Operational Measures For Fuel and Emissions Reduction WorkshopDocument12 pagesWeight Management: Aviation Operational Measures For Fuel and Emissions Reduction WorkshopalkhaldyNo ratings yet

- Pistons and Connecting Rods - InstallDocument3 pagesPistons and Connecting Rods - Installsergio blandon lNo ratings yet

- LNGC Golar Frost - IMO 9253284 - Machinery Operating ManualDocument421 pagesLNGC Golar Frost - IMO 9253284 - Machinery Operating Manualseawolf50No ratings yet

- Book 11Document662 pagesBook 11SOG1806100% (1)

- New Holland b110 b115 en Service Manual 12n17446Document20 pagesNew Holland b110 b115 en Service Manual 12n17446james100% (51)

- BD 50Document4 pagesBD 50Pankaj TiwariNo ratings yet

- 4200 Wet Sump - Engine OverhaulDocument0 pages4200 Wet Sump - Engine Overhaulaiigee100% (8)

- High Temp Materials: Nickel SuperalloysDocument2 pagesHigh Temp Materials: Nickel Superalloysmadream7No ratings yet

- Dominar 400 Abs Non Abs SPCDocument82 pagesDominar 400 Abs Non Abs SPCAlex Philip0% (1)

- Promotion Policy at Indian Oil Corporation LTDDocument43 pagesPromotion Policy at Indian Oil Corporation LTDShweta Pankhania100% (1)

- sm-K1017314E DX210W LowResDocument1,184 pagessm-K1017314E DX210W LowResDavid Apaza Hurtado100% (1)

- Electrical Materials Sizing CalculationDocument3 pagesElectrical Materials Sizing CalculationTayebASherifNo ratings yet

- Description and Operation: Engine - 2.5L Duratec-ST (VI5) - EngineDocument13 pagesDescription and Operation: Engine - 2.5L Duratec-ST (VI5) - EngineAlejandro BrionesNo ratings yet

- Bio-Batteries: An Eco-Friendly Energy AlternativeDocument25 pagesBio-Batteries: An Eco-Friendly Energy AlternativeShahid FarooqiNo ratings yet

- School of Maritime Studies Vels University Thalambur The Fuel Oil System For A Diesel Engine Internal Combustion Engine ProcedureDocument2 pagesSchool of Maritime Studies Vels University Thalambur The Fuel Oil System For A Diesel Engine Internal Combustion Engine ProcedureAayush Agrawal100% (2)

- Grupo ElectrogenoDocument3 pagesGrupo ElectrogenoAnonymous 19s9qfNo ratings yet

- Diesel Locomotive RosterDocument11 pagesDiesel Locomotive RosterAgnivesh SharmaNo ratings yet

- Boiler Mountings and AccessoriesDocument17 pagesBoiler Mountings and AccessoriesYogesh ChaudhariNo ratings yet

- HCDP Using GCDocument11 pagesHCDP Using GCkhurram szdNo ratings yet

- As Pe High Rise Plumbing DesignDocument92 pagesAs Pe High Rise Plumbing Designalmira lhee cadores100% (1)

- Model ESC QPDocument2 pagesModel ESC QPGowda KadurNo ratings yet

- Engine RemovalDocument4 pagesEngine RemovalKiddNo ratings yet

- Hypersonic Air Breathing Propulsion CourseDocument2 pagesHypersonic Air Breathing Propulsion CourseloguhietNo ratings yet

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesFrom EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo ratings yet

- Black Gold Stranglehold: The Myth of Scarcity and the Politics of OilFrom EverandBlack Gold Stranglehold: The Myth of Scarcity and the Politics of OilNo ratings yet

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationFrom EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationRating: 4.5 out of 5 stars4.5/5 (2)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsFrom EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsRating: 5 out of 5 stars5/5 (1)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsFrom EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsNo ratings yet

- Subsea Valves and Actuators for the Oil and Gas IndustryFrom EverandSubsea Valves and Actuators for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (1)

- Petroleum Rock Mechanics: Drilling Operations and Well DesignFrom EverandPetroleum Rock Mechanics: Drilling Operations and Well DesignRating: 5 out of 5 stars5/5 (1)

- Compression Machinery for Oil and GasFrom EverandCompression Machinery for Oil and GasKlaus BrunRating: 4 out of 5 stars4/5 (4)