Professional Documents

Culture Documents

Penetration and Perforation of Thick FRP Laminates

Uploaded by

Deepesh KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Penetration and Perforation of Thick FRP Laminates

Uploaded by

Deepesh KumarCopyright:

Available Formats

Penetration and perforation of thick FRP laminates

H.M. Wen*

Department of Mechanical, Aerospace and Manufacturing Engineering, UMIST, PO Box 88, Manchester M60 1QD, UK

Received 17 January 2001; accepted 13 February 2001

Abstract

Analytical equations are given for the prediction of the penetration and perforation of thick FRP laminates struck normally by

missiles over a wide range of impact velocities. The missiles have dierent nose shapes (i.e. truncated, conical, at, ogival and

hemispherical). The formulation is based on the assumption that the deformations are localized and that the mean pressure oered

by the FRP laminate targets to resist the missiles consists of two parts. One part is a cohesive quasi-static resistive pressure due to

the elastic-plastic deformation of the laminate materials. The other is a dynamic resistive pressure arising from velocity eects.

Analytical equations are derived for the depth of penetration (DOP) in the FRP laminate targets and the ballistic limits in the case

of perforation. It is shown that the theoretical predictions are in good correlation with available experimental data. # 2001 Pub-

lished by Elsevier Science Ltd. All rights reserved.

Keywords: FRP laminates; Missiles; Impact; Penetration; Perforation; Ballistic limit

1. Introduction

The penetration and perforation of targets by pro-

jectiles involve highly complex processes which have

been investigated experimentally for more than two cen-

turies and analytically largely during the last few dec-

ades. Accounts of this work can be found in the reviews

by Backman and Goldsmith [1], Zukas [2], Anderson

and Bodner [3] and Corbett et al. [4]. Depending on

impact velocity, the material and geometric properties

of both the projectile and the target, several theoretical

models (analytical and numerical) have been proposed

over the years to predict the level of the penetration in

thick targets or the impact conditions for the perfora-

tion of plates as can be seen from these reviews. However,

many of the analytical models are single-mechanism

models which have so far enjoyed limited applications.

Numerical simulations have been successful in predicting

the response of targets to projectile impact but, unfortu-

nately, they still require considerable resources in terms

of computing time (CPU) and manpower. On the other

hand, from the engineering point of view there is con-

siderable interest in the development of empirical or

semi-empirical laws for the penetration and perforation

of plates as noted in references [1,4,5].

Fibre-reinforced plastic laminates have been con-

sidered for armour applications [6,7], glass bres being

more popular than other types of bre such as Kevlar

because of their cost advantage. The mechanics of

deformation and failure of FRP laminates subjected to

local impact loads is understood only for a few cases of

simple geometrical form [6,7]. Static indentation of

thick composites with bres in the form of woven fab-

rics by conical indenters has been modelled by Ruther-

ford [8] (see [12]) who used an energy approach to relate

the force at a certain level of indentation to two strength

parameters representing the in-plane and through-thick-

ness strengths of the composites, respectively. A similar

problem was also examined by Zhao et al. [9] who

employed transversely isotropic elastic analysis and rigid,

perfectly-plastic material models. They showed that the

latter led to a formula depending only on the in-plane

strength of the material. This formula showed good

agreement with tests on Scotch-ply laminates.

The deformation mechanisms which occur during

dynamic penetration and perforation of laminates have

been examined by a number of authors [1019]. As

indicated in [12], Greaves [10,11] studied the deforma-

tion mechanisms during ballistic perforation of thick S-

2 glass/phenolic laminates by at-faced projectiles and

0266-3538/01/$ - see front matter # 2001 Published by Elsevier Science Ltd. All rights reserved.

PI I : S0266- 3538( 01) 00020- 3

Composites Science and Technology 61 (2001) 11631172

www.elsevier.com/locate/compscitech

* Tel.: +44-161-2363311, ext. 2403; fax: +44-161-228-7040.

E-mail address: h.m.wen@umist.ac.uk

found that the failure can be divided into two phases.

Phase 1 involves compression, shear, indentation and

expulsion of debris. In Phase 2, the formation of a cone

of delaminations, bre stretching and fracture occur

and the projectile exits the back face. It was noted that

the Phase 1 indentation mechanism, said to be domi-

nated by the through-thickness compressive resistance

of the material, absorbed most of the impact energy and

was therefore worthy of more detailed study. To this

end, an investigation into the impact force-indentation

characteristics of laminates at velocities of up to 200 m/s

has been carried out by Reid et al. [12].

Zhu et al. [13] investigated experimentally the pene-

tration of laminated Kevlar-29/polyester plates by con-

ical-nosed projectiles and proposed a range of models for

the various energy-absorbing mechanisms to estimate the

target resistance to the projectile motion [14]. The event of

ballistic impact was divided into three consecutive stages:

indentation, perforation and exit. The global structural

deformations were determined using laminated plate

theory. Dissipative mechanisms including indentation of

the projectile tip, bulging of the back surface of the

laminate, bre failure, delamination and friction were

described utilizing certain simplying assumptions. Good

agreement was obtained between the model predictions

and the experimental results.

Lee and Sun [15] carried out a combined experimental

and numerical study of the dynamic penetration of

clamped circular CFRP laminates by a 30 g, 14.5 mm

diameter at-ended projectile in the velocity range 24

91 m/s. The composite material examined was Hercules

AS4/3501-6 graphite-bre/epoxy and the stacking

sequence of all the laminates was based on a basic pat-

tern, namely [0/90/45/45]

s

. Three types of impact tests

were conducted on the graphite/epoxy laminates which

had two thicknesses (i.e. 2 and 4 mm) and the ballistic

limits were determined. The penetration process of

composite laminates by a at-ended missile consisted of

three stages: pre-delamination, post-delamination before

plugging and post-plugging. Based upon these three

stages, a nite-element model was established to simulate

the static punch process. The material was modelled using

eective moduli so that the details of the stacking

sequence were not included in the model. The simulated

static load/punch displacement curve was subsequently

employed in the dynamic penetration analysis, and the

displacements at certain specic checkpoints were adop-

ted as the penetration criteria. It was shown that the

computational results were in good agreement with the

limited experimental data.

Recently, Mines et al. [16] conducted an experimental

investigation into the high-velocity perforation beha-

viour of fully-clamped 200200 mm polymeric compo-

site laminates at impact velocities of up to 571 m/s.

Woven roving, z-stitched and through-thickness z-stit-

ched glass polyester laminates for a number of laminate

thicknesses (6, 12, 24 ply), three types of impactors (i.e.

at, hemispherical and conical), and two missile masses

(6 and 12 g) were examined. The results were presented

in terms of static and impact perforation energies and

energy absorption mechanisms during high-velocity per-

foration were also discussed with a view to identifying

Nomenclature

a missile radius

a

T

radius of truncated part

A instant cross-sectional area of a missile

A

o

cross-sectional area of missile shank

(A

o

a

2

)

A

T

cross-sectional area of truncated part

(A

T

a

2

T

)

D missile diameter

E

k

impact energy of a missile

F mean resistive force

G missile mass

T thickness of monolithic FRP laminates

L missile shank length

L

N

missile nose length

L

T

length of truncated part

P depth of penetration

S dened in Fig. 1(a)

V

i

impact velocity of a missile

V

b

Critical impact velocity; ballistic limit

[ constant, dened in Eq. (2)

j constant, evaluated by Eq. (20d)

cone angle of a conical-nosed projectile

,

p

missile density

,

e

p

equivalent missile density

,

t

density of FRP laminates

o mean resistive pressure of FRP laminates

o

cone

mean pressure of FRP laminates to resist a

conical-nosed missile

o

d

dynamic resistive pressure of FRP laminates

o

e

elastic limit of FRP laminates in through-

thickness compression

o

flat

mean pressure of FRP laminates to resist a

at-ended missile

o

ogive

mean pressure of FRP laminates to resist an

ogival-nosed missile

o

s

quasi-static resistive pressure of FRP laminates

dened in Fig. 1(a)

o

dened by Eq. (11c)

T

dened by Eq. (11d)

[ calibre-radius-head, [ S,2a

1164 H.M. Wen / Composites Science and Technology 61 (2001) 11631172

improved combinations of materials. It was found that

all types of construction behave in a similar manner.

Wen et al. [1719] carried out a comprehensive study

on the penetration and perforation of FRP laminates

and sandwich panels with such laminates as skins and

with foam cores in the context of oshore applications

as part of the UK collaborative research programme on

the Cost Eective Use of Fibre-Reinforced Composites

Oshore. The results of penetration and perforation

tests performed on composite laminates and sandwich

panels using at-faced, hemispherical-ended and conical-

nosed indenters/missiles under quasi-static, drop-weight

and ballistic impact conditions with impact velocities up

to 305 m/s were reported. Load-displacement character-

istics under quasi-static loading were presented and the

energies corresponding to dierent degrees of damage

were calculated. Fracture patterns observed in sandwich

panels loaded dynamically were compared with those

observed in identical panels under quasi-static loading.

Ballistic limits and perforation energies were determined

and a classication of the responses was deduced from

the test data. Experimental evidence shows that pro-

jectile/ballistic impact on FRP laminates and sandwich

panels with such laminates as skins and with foam cores

can be categorized into low velocity impact (global) and

wave-dominated (localized) responses.

Simple analytical analyses using multiple-spring mod-

els were developed [17] to predict the quasi-static top skin

failure load and the energy absorbed for sandwich panels.

Failure maps were constructed for sandwich panels loa-

ded quasi-statically by at-faced punches. Empirical for-

mulae that predict the penetration and perforation

energies of FRP laminates and sandwich panels under

quasi-static and dynamic loading conditions were derived

for at-faced and hemispherical-ended indenters/pro-

jectiles [1719]. It was shown that the model predictions

are in good correlation with the available experimental

data. It was also shown that, to a rst approximation, the

empirical formula obtained for hemispherical-ended

missiles is also applicable to conical-nosed projectiles.

The objective of this paper is to derive analytical

equations for predicting the penetration and perforation

of FRP laminates struck at normal incidence by missiles

over a wide range of impact velocity. The missiles have

dierent nose shapes, i.e. truncated, conical, at, ogival

and hemispherical. The formulation is based on the

assumption that the deformations are localized and that

the average pressure provided by the FRP target materi-

als to resist the projectiles can be decomposed into two

parts. One part is the cohesive quasi-static resistive pres-

sure applied normally to the projectile surface due to the

elastic-plastic deformations of the laminate materials

and the other is the dynamic resistive pressure arising

from velocity eects. This latter is simply expressed as a

velocity-dependent enhancement factor applied to the

static pressure term. Correlation between the equations

and the available experimental data is presented and

discussed.

2. Formulation of the problem

2.1. Assumption about the resistive pressure

It is assumed that the mean pressure, o, applied nor-

mally to the surface of the missile provided by an FRP

laminate material to resist penetration and perforation

by a missile consist of two parts, one part is the cohesive

quasi-static resistive pressure, o

s

, as a result of the elastic-

plastic deformations of the laminate material and the

other is the dynamic resistive pressure, o

d

, arising from

velocity eects. Thus

o o

s

o

d

1

If it is further assumed that the cohesive quasi-static

resistive pressure is equal to the quasi-static linear elas-

tic limit, o

e

, in through-thickness compression of the

FRP laminates [6,15], i.e. o

s

o

e

and that the dynamic

resistive pressure, o

d

, is a function of the parameter,

,

t

,o

e

1,2

V

i

and is taken to be o

d

[ ,

t

,o

e

1,2

V

i

o

e

, then

Eq. (1) can be rewritten as

o 1 [

,

t

o

e

_

V

i

_ _

o

e

2

Here, ,

t

and V

i

are the density of the FRP laminates

and the initial impact velocity of the projectile respec-

tively. [ is a constant which are determined empirically.

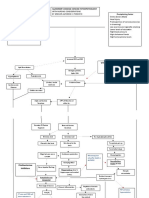

Fig. 1. Projectile geometries: (a) truncated-ogive-nose and (b) trun-

cated-cone-nose.

H.M. Wen / Composites Science and Technology 61 (2001) 11631172 1165

The resistive pressure is generally expected to be a func-

tion (usually a polynomial function) of the penetration

velocity, as noted in [1,20]. In Eq. (2), the mean pressure

provided by the FRP target material to resist the pro-

jectile is simply taken as a linear function of the initial

impact velocity. For bre-reinforced plastics it has been

observed in the static indentation tests [15] that the rst

term in Eq. (2) is related to the static strengths of FRP

laminates in compression in the two principal direc-

tions, through the thickness and in-plane.

2.2. Penetration of semi-innite FRP laminates

Fig. 1(a) and (b) shows the geometries of rigid missiles

with truncated-ogive-nose and truncated-cone-nose,

respectively. The missiles are assumed to have density ,

p

and mass G with shank diameter D (or radius a). L, L

N

,

L

T

and a

T

are the lengths of the shank, the total nose,

the truncated part and the radius of the truncated part for

truncated-ogive-nose and truncated-cone-nose missiles,

respectively, as shown in Fig. 1(a) and (b). Fig. 1(a) shows

the ogive prole as the arc of a circle that is tangent to the

projectile shank. It is also common to dene the ogive in

terms of calibre-radius-head, viz. CRH S,2a, where S

and a are the radii of the ogive and the shank of the mis-

sile respectively, as dened in Fig. 1(a). If a rigid trun-

cated-nose projectile has a complex conguration (for

example, it is hollow or has a sabot system) then the

projectile still can be described as one of those depicted

in Fig. 1 but with an eective density (,

e

p

) which is taken

to be the ratio of the projectile mass to the volume of

the basic conguration as shown in Fig. 1.

Fig. 2 shows the impact of a truncated-cone-nose mis-

sile on an FRP laminate target at normal incidence with

an initial impact velocity V

i

. Two situations may arise

depending upon the initial kinetic energy of the missile, as

shown in Fig. 2. One scenario is that the nal depth of

penetration has not reached the shoulder of the missile

when its kinetic energy has been dissipated and the other is

that the nal depth of penetration is larger than the nose

length. Similar situations may occur for a truncated-ogive-

nose missile transversely impacting an FRP laminate tar-

get. Equations are derived in the following sections for

the depth of penetration into the FRP laminate targets

by rigid missiles with truncated-cone/ogive-noses.

2.2.1. Truncated-cone-nose missiles

2.2.1.1. Case I, P4L

N

L

T

. For a rigid truncated-

cone-nose missile, the motion and the nal depth of

penetration can be calculated if the resistive forces are

known. The resistive force of a truncated-cone-nose

missile penetrating an FRP laminate target at normal

incidence as shown in Fig. 2(I) can be written as

F o

flat

A

T

o

cone

A A

T

3

where F is the resistive force and o

flat

and o

cone

are the

respective mean resistive pressures of the truncated part

and the conical nose provided by the target material and

dened by Eq. (2) with [ 2 (for at-face) and

2sin ,2 (for conical-nose), respectively. is the cone

angle of the missile, as shown in Fig. 2. A

T

L

2

T

tan

2

,2 is the area of the truncated part and A

P L

T

2

tan

2

,2 is the instant cross-sectional area

and can be determined from the geometrical congura-

tion depicted in Fig. 2(I). P is the depth of penetration.

Substituting A

T

L

2

T

tan

2

,2 and A P L

T

2

tan

2

,2 into Eq. (3) gives

F o

flat

L

2

T

tan

2

2

o

cone

P

2

tan

2

2

2PL

T

tan

2

2

_ _

4

From energy conservation, one obtains

E

k

_

p

0

FdP 5

where E

k

is the initial kinetic energy of the missile.

Substituting Eq. (4) into the above equation and rear-

ranging yields

E

k

o

flat

L

2

T

Ptan

2

3

o

cone

P

3

tan

2

2

o

cone

P

2

L

T

tan

2

2

6

Substituting E

k

1,2 GV

2

i

into Eq. (6) and rearrang-

ing gives

Fig. 2. Schematic diagrams of a conical-nosed projectile impacting on

semi-innite FRP laminate targets. (I) P4L

N

L

T

; (II) P > L

N

L

T

.

1166 H.M. Wen / Composites Science and Technology 61 (2001) 11631172

P

L

L

N

3

1

L

T

L

N

_ _

3

_ _

,

p

,

t

_ _

,

t

V

2

i

2o

cone

1

1

3

P

L

N

_ _

2

P

L

N

_ _

L

T

L

N

_ _

L

T

L

N

_ _

2

o

flat

o

cone

_ _

7

after using G ,

p

L L

N

,3 1 L

T

,L

N

3

_ _ _ _

L

2

N

tan

2

,2 .

2.2.1.2. Case II, P > L

N

L

T

. As shown in Fig. 2(II),

the penetration process can be divided into two stages.

The rst stage when P4L

N

L

T

has been described in

the previous section. For the second stage when

P > L

N

L

T

, the resistive force (F) can be written as

F o

flat

A

T

o

cone

A

o

A

T

8

From energy consideration, one obtains

E

k

_

L

N

L

T

o

FdP

_

p

L

N

L

T

FdP 9a

Substituting Eqs. (6) and (10) into Eq. (11a) and

rearranging yields

E

k

o

cone

L

2

N

tan

2

2

_

1

L

T

L

N

_ _

2

o

flat

o

cone

1

_ _

_ _

1

L

T

L

N

_ _

2

_ _

2L

N

3

L

T

3

_ _

_ 9b

Substituting E

k

1,2 GV

2

i

into the above equation

and using G ,

p

L L

N

,3 1 L

T

,L

N

3

_ _ _ _

L

2

N

tan

2

,2 gives the nal depth of the penetration

P

L

L

N

3

1

L

T

L

N

_ _

3

_ _

,

p

,

t

_ _

,

t

V

2

i

o

cone

1

2 1

L

T

L

N

_ _

2

o

flat

o

cone

1

_ _

_ _

2 1

L

T

L

N

_ _

2

_ _

1

1

2

L

T

L

N

_ _ _ _

3

L

L

N

_ _

1

L

T

L

N

_ _

3

_ _

10

2.2.2. Truncated-ogive-nose missiles

Similarly, Eqs. (11) and (12) can be obtained for the

nal depth of penetration into an FRP laminate target

by a rigid truncated-ogive-nose missile.

2.2.2.1. Case I, P4L

N

L

T

.

,

p

L 8[

3

j

T

a

_ _

V

2

i

16[

3

ao

ogive

__

-cos

1

3

cos

3

1

2

sin2

_ _

sin

o

sin

2

o

cos

o

2

sin

o

j

T

o

flat

o

ogive

1

_ _

sin

T

sin

o

2

cos

T

cos g

11a

P

4[1

_

2[cos

_ _

a L

T

11b

in which is dened in Fig. 1(a) and the mean resistive

pressure o

ogive

is determined by Eq. (2) with [

3, 4[ .

o

.

T

and j

T

are evaluated by the following

equations

o

sin

1

2[1

2[

_ _

11c

L

T

2[a cos

o

cos

T

11d

j

T

2

sin

o

cos

T

1

3

cos3

T

T

1

2

sin2

T

_ _

sin

o

sin

2

o

cos

T

11e

2.2.2.2. Case II, P > L

N

L

T

.

P

L 8[

3

j

T

a

,

p

,

t

_ _

,

t

V

2

i

2o

ogive

1 4[

2

o

flat

o

ogive

1

_ _

sin

T

sin

o

2

_ _

4[ 1

p

a 8[

3

a j

T

o

flat

o

ogive

1

_ _

sin

T

sin

o

2

cos

T

_ _

L 8[

3

j

T

a 1 4[

2

o

flat

o

ogive

1

_ _

sin

T

sin

o

2

_ _

12

2.3. Perforation of nite FRP laminates

The ballistic limit condition for an FRP laminates

with nite thickness struck transversely by a rigid pro-

jectile with dierent noses can be estimated by the

energy balance method. There are three phases of pene-

tration for a rigid projectile with truncated-cone-nose

(12)

H.M. Wen / Composites Science and Technology 61 (2001) 11631172 1167

impacting on a nite plate. First, the nose enters the

plate, second, the nose is fully embedded and nally, the

nose exits the plate. The same arguments can also apply

to the rigid projectile with truncated-ogive-nose. From

energy consideration, it is easy to show that

E

k

a

2

To

cone

1

o

flat

o

cone

1

_ _

a

T

a

_ _

2

_ _

13a

for truncated-cone-nose missiles and

E

k

a

2

To

ogive

1

o

flat

o

ogive

1

_ _

a

T

a

_ _

2

_ _

13b

for truncated-ogive-nose missiles. Substituting E

k

1,2 GV

2

b

into the above equations and rearranging

yields an approximate value for the ballistic limit

V

b

2a

2

To

cone

G

_

1

o

flat

o

cone

1

_ _

a

T

a

_ _

2

_ _1

2

14a

for truncated-cone-nose missiles and

V

b

2a

2

To

ogive

G

_

1

o

flat

o

ogive

1

_ _

a

T

a

_ _

2

_ _1

2

14b

for truncated-ogive-nose missiles. V

b

is the critical

impact velocity or ballistic limit.

3. Correlation with experimental data and discussion

The equations derived in Section 2 can be compared

with available experimental data for the penetration and

perforation of FRP laminate targets by rigid missiles

which have dierent nose shapes.

3.1. Conical-nosed missiles

Aconical-nosed missile can be seen as the special case of

a truncated-cone-nose missile with L

T

0. Hence, the

corresponding Eqs. (7), (10) and (14a) can be written as

3.1.1. Case I, P4L

N

P

L

L

N

3

,

p

,

t

_ _

,

t

V

2

i

o

e

1

2

3

1 [

,

t

o

e

_

V

i

_ _

P

L

N

_ _

2

15

3.1.2. Case II, P > L

N

P

L

L

N

3

,

p

,

t

_ _

,

t

V

2

i

o

e

1

2 1 [

,

t

o

e

_

V

i

_ _

2

3

L

L

N

_ _

1

16

3.1.3. Ballistic limit

V

b

sin

2

_ _

,

t

o

e

p

D

2

T

2G

1

1

2G

sin

2

2

_ _

,

t

D

2

T

_

_

_

_

_

_

_

_

17

Fig. 3 shows comparison of the model predictions

with the experimental data for GRP (S-2 glass/phenolic)

laminates impacted by a 7.5 mm diameter conical-nosed

missile with a mass of 47 g which was examined in Ref.

[12]. In the theoretical calculation, ,

t

2200 kg/m

3

,

o

e

755 MPa and 90

. The broken and solid lines

in Fig. 3 are the theoretical predictions by Eqs. (15) and

(16), respectively. It is seen from Fig. 3 that the model

predictions [Eqs. (15) and (16)] are in correlation agree-

ment with the experimental data in terms of the nal

depth of penetration.

Fig. 4 shows comparison between the theoretically

predicted ballistic limits and the experimental observa-

tions for GRP (E-glass/polyester) laminates struck

transversely by a 10.5 mm diameter conical-nosed mis-

sile with a mass of 18.7 g [17]. In the theoretical calcu-

Fig. 3. Comparison of the theoretical predictions with the experi-

mental data for the penetration of thick GRP (S2-glass/phenolic)

laminates struck normally by a 7.5 mm diameter conical-nosed pro-

jectile. , Eq. (15); , Eq. (16); ~, experiments [12].

1168 H.M. Wen / Composites Science and Technology 61 (2001) 11631172

lation, ,

t

1650 kg/m

3

, o

e

225 MPa and 90

. It

is clear from Fig. 4 that the model predictions by Eq.

(17) are in good agreement with the experimental data.

Fig. 5 shows comparison between the model predic-

tions [Eq. (17)] and the experimental data for the per-

foration of GRP (E-glass/polyester) laminates struck

transversely by 7.6 mm diameter conical-nosed missiles

with masses of 6 and 12 g [16]. In the theoretical calcu-

lation, ,

t

1650 kg/m

3

, o

e

225 MPa and 90

. It

is evident from Fig. 5 that the theoretically predicted

ballistic limits [Eq. (17)] are in good agreement with the

experimental data.

Fig. 6 shows the comparison between Eq. (17) and the

test results for the perforation of KFRP (Kevlar 29/

polyester) laminates impacted normally by a 12.7 mm

diameter conical projectile with a mass of 28.9 g [13]. In

the theoretical calculation, ,

t

1231 kg/m

3

, o

e

145

MPa and 60

. It is seen from Fig. 6 that Eq. (17) is

in good agreement with the experimental results.

3.2. Flat-faced projectiles

A at-faced projectile may be seen as the special case

of a conical-nosed missile with 180

. Hence, Eqs.

(16) and (17) can be rewritten as

P

L

,

p

,

t

_ _

,

t

V

2

i

o

e

1

2 1 2

,

t

o

e

_

V

i

_ _ 18

and

V

b

,

t

o

e

p

D

2

T

2G

1

1

2G

,

t

D

2

T

_ _ _

19

after using sin ,2 sin90

1.

Fig. 7 shows comparison between the theoretically

predicted ballistic limits and the experimental observa-

tions for GRP (E-glass/polyester) laminates struck

transversely by a 10.5 mm diameter at-faced projectile

Fig. 4. Comparison of the theoretical predictions with the experi-

mental data for the perforation of GRP (E-glass/polyester) laminates

struck transversely by a 18.7 g, 10.5 mm diameter conical-nosed

missile. , Eq. (17); *, experiments [17].

Fig. 5. Comparison of the theoretical predictions with the experi-

mental data for the perforation of GRP (E-glass/polyester) laminates

struck transversely by a 7.6 mm diameter conical-nosed missile

[16]. , Eq. (17); (a) G 6 g and (b) G 12 g.

Fig. 6. Comparison of the theoretical predictions with the experi-

mental data for the perforation of KFRP (Kevlar 29/polyester) lami-

nates struck transversely by a 28.9 g, 12.7 mm diameter conical-nosed

missile. , Eq. (17); *experiments [13].

H.M. Wen / Composites Science and Technology 61 (2001) 11631172 1169

with a mass of 20.4 g [1719]. In the theoretical calcu-

lation, ,

t

1650 kg/m

3

, o

e

225 MPa. It is seen from

Fig. 7 that Eq. (19) is in good agreement with the

experimental data.

Fig. 8 shows comparison between the model predic-

tions [Eq. (19)] and the experimental data for the per-

foration of GRP (E-glass/polyester) laminates struck

transversely by 7.6 mm diameter at-faced missiles with

masses of 6 and 12 g [16]. In the theoretical calculation,

,

t

1650 kg/m

3

, o

e

225 MPa. It is evident from Fig. 8

that the theoretically predicted ballistic limits [Eq. (19)]

are in good agreement with the experimental data.

3.3. Ogival-nosed missiles

An ogival-nosed missile can be seen as the special case

of a truncated-ogive-nose missile with L

N

0. Hence,

the corresponding Eqs. (11), (12) and (14b) can be

written as

3.3.1. Case I, P4L

N

,

p

L 8[

3

ja

_ _

V

2

i

16[

3

ao

_

cos

1

3

cos

3

1

2

sin2

_ _

sin

o

sin

2

o

cos

o

2

sin

o

j

_

20a

P

4[1

_

2[cos

_ _

a 20b

o

sin

1

2[1

2[

_ _

20c

j

2

sin

o

cos

o

1

3

cos

3

o

o

1

2

sin2

o

_ _

sin

o

sin

2

o

cos

o

20d

3.3.2. Case II, P > L

N

P

L 8[

3

ja

,

p

,

t

_ _

,

t

V

2

i

o

e

1

2 1 [

,

t

o

e

_

V

i

_ _

4[1

p

8[

3

j

_ _

a

L 8[

3

ja

21

3.3.3. Ballistic limit

V

b

3

,

t

o

e

p

D

2

T

16[G

1

1

128[

2

G

9,

t

D

2

T

_

_

_

_

_

22

Fig. 9 shows comparison between the theoretical pre-

dictions and the experimental data for the perforation

of GRP (E-glass/phenonic) laminates struck normally

by a 6 mm diameter ogival-nosed AP projectile with a

mass of 5 g [21]. In the theoretical calculation, ,

t

2200

kg/m

3

, o

e

755 MPa and [ 2. It is seen from Fig. 9

Fig. 7. Comparison of the theoretical predictions with the experimental

data for the perforation of GRP (E-glass/polyester) laminates struck

transversely by a 20.4 g, 10.5 mm diameter at-faced missile. ,

Eq. (19); *, experiments [1719].

Fig. 8. Comparison of the theoretical predictions with the experi-

mental data for the perforation of GRP (E-glass/polyester) laminates

struck transversely by a 7.6 mm diameter at-faced missile [16]. ,

Eq. (19); (a) G 6 g and (b) G 12 g.

1170 H.M. Wen / Composites Science and Technology 61 (2001) 11631172

that Eq. (22) is in good agreement with the experimental

data which were reported in Ref [21].

3.4. Hemispherical-ended projectiles

A hemispherical-ended projectile can be seen as the spe-

cial case of an ogival-nosed missile with [ 0.5. Hence,

the corresponding equations can be rewritten as follows:

3.4.1. Case I, P4a

P

L

2

3

a

,

p

,

t

_ _

,

t

V

2

i

o

e

1

2 1 1.5

,

t

o

e

_

V

i

_ _

P

a

1

3

P

a

_ _

2

_ _

23

3.4.2. Case II, P > a

P

L

2

3

a

,

p

,

t

_ _

,

t

V

2

i

o

e

1

2 1 1.5

,

t

o

e

_

V

i

_ _

1

3

L

a

_ _

2

24

3.4.3. Ballistic limit

V

b

3

,

t

o

e

p

D

2

T

8G

1

1

32G

9,

t

D

2

T

_ _ _

25

after using [ 3, 4[ 1.5.

Fig. 10 shows comparison between the theoretically

predicted ballistic limits [Eq. (21)] and the experimental

data for the perforation of GRP (E-glass/polyester)

laminates struck transversely by a 10.5 mm diameter

hemispherical-ended projectile with a mass of 17.9 g

Fig. 9. Comparison of the theoretical predictions with the experi-

mental data for the perforation of GRP (E-glass/phenonic) laminates

struck transversely by a 5 g, 6 mm diameter ogival-nosed AP pro-

jectile. , Eq. (22); ~, experiments [21].

Fig. 10. Comparison of the theoretical predictions with the experi-

mental data for the perforation of GRP (E-glass/polyester) laminates

struck transversely by a 17.9 g, 10.5 mm diameter hemispherical-ended

missile. , Eq. (25); *, experiments [1719].

Fig. 11. Comparison of the theoretical predictions with the experi-

mental data for the perforation of GRP (E-glass/polyester) laminates

struck transversely by hemispherical-ended missiles [16]. , Eq. (25);

(a) D 10 mm, G 6 g and (b) D 7.6 mm, G 12 g.

H.M. Wen / Composites Science and Technology 61 (2001) 11631172 1171

[1719]. In the theoretical calculation, ,

t

1650 kg/m

3

,

o

e

225 MPa. It is clear from Fig. 10 that Eq. (25) is in

good agreement with the experimental observations.

Fig. 11 shows comparison between the model predic-

tions [Eq. (25)] and the experimental data for the per-

foration of GRP (E-glass/polyester) laminates struck

transversely by hemispherical-ended projectiles with

diameters of 10 and 7.6 mm and masses of 6 and 12 g

[16]. In the theoretical calculation, ,

t

1650 kg/m

3

,

o

e

225 MPa. It is evident from Fig. 11 that the theo-

retically predicted ballistic limits [Eq. (25)] are in good

agreement with the experimental data.

4. Concluding remarks

Analytical equations have been derived in this paper

for the penetration and perforation of thick FRP lami-

nates struck transversely by rigid missiles over a wide

range of impact velocity. The missiles have dierent nose

shapes (i.e. truncated, conical, at, ogival and hemi-

spherical). The approach is based upon the assumption

that the deformation is localized (i.e. wave-dominated

response) and the mean pressure provided by FRP lami-

nate targets to resist the projectiles can be decomposed

into two parts. One part is the cohesive quasi-static

resistive pressure as a result of elastic-plastic deforma-

tion of the target materials, the other is the dynamic

resistive pressure arising from the velocity eects.

Equations have been obtained for the depth of penetra-

tion and the ballistic limits in case of perforation.

It has been shown that the theoretical predictions are

in good agreement with experimental observations for

FRP laminates struck normally by rigid missiles in

terms of penetration depth and ballistic limits.

References

[1] Backman ME, Goldsmith W. The mechanics of penetration of

projectiles into targets. Int J Eng Sci 1978;16:199.

[2] Zukus JA. Penetration and perforation of solids. In: Zukus JA et

al, editors. Impact dynamics. New York: John Wiley, 1982. p.

155214.

[3] Anderson Jr CE, Bodner SR. Ballistic impact: the status of ana-

lytical and numerical modelling. Int J Impact Eng 1988;7:935.

[4] Corbett GG, Reid SR, Johnson W. Impact loading of plates and

shells by free-ying projectiles: a review. Int J Impact Eng

1996;18(2):141230.

[5] Wen HM, Jones N. Semi-empirical equations for the perforation

of plates struck by a mass. In Bulson PS, editor. Structures under

shock and impact II. Southampton and Boston and Thomas

Telford, London: Computational Mechanics Publications, 1992.

p. 69380.

[6] Abrate S. Impact on laminated composite materials. Appl Mech

Rev 1991;44(4):15590.

[7] Abrate S. Impact on laminated composites: recent advances.

Appl Mech Rev 1994;47(11):51743.

[8] Rutherford KL, Indentation and penetration resistance of com-

posite materials to pointed projectiles. Unpublished UK DRA

report, 1992.

[9] Zhao Y, Pang SS, Grin SA. Force-indentation study of trans-

versely isotropic composite materials using a conical-tip indenter.

Composites Engineering 1991;1(6):393402.

[10] Greaves LJ. Failure mechanisms in GFRP armour. Unpublished

UK DRA report, 1992.

[11] Greaves LJ. Progress in modelling the perforation of GFRP by

ballistic projectiles. Unpublished UK DRA report, 1994.

[12] Reid SR, Reddy TY, Ho HM, Crouch IG, Greaves LJ. Dynamic

indentation of thick bre-reinforced composites. In: Rajapakse

YDS, Vinson JR, editors. High rate eects on polymer, metal and

ceramic matrix composites and other advanced materials. ASME,

AD-Vol. 48, 1995. p. 7179.

[13] Zhu G, Goldsmith W, Dharan CKH. Penetration of laminated

Kevlar by projectiles I. Experimental investigation. Int J

Solids and Structures 1992;29(4):399420.

[14] Zhu G, Goldsmith W, Dharan CKH. Penetration of laminated

Kevlar by projectiles II. Analytical model. Int J Solids and

Structures 1992;29(4):42136.

[15] Lee S-WR, Sun CT. Dynamic penetration of graphite/epoxy

laminates impacted by a blunt-ended projectile. Composites

Science and Technology 1993;49:36980.

[16] Mines RAW, Roach AM, Jones N. High velocity perforation

behaviour of polymer composite laminates. Int J Impact Eng

1999;22:56188.

[17] Wen HM, Reddy TY, Reid SR, Soden PD. Indentation penetra-

tion and perforation of composite laminates and sandwich panels

under quasi-static and projectile loading. Key Engineering Mate-

rials 1998;141-143:50152.

[18] Reddy TY, Wen HM, Reid SR, Soden PD. Penetration and per-

foration of composite sandwich panels by hemispherical and con-

ical projectiles. Trans ASME, J Pres Ves Technol 1998;120:18694.

[19] Reid SR, Wen HM, Soden PD, Reddy TY. Response of single

skin laminates and sandwich panels to projectile impact. In Wang

SS, Williams JJ, Lo KH, editors. Composite materials for oshore

operation 2. American Bureau of Shipping, 1999. p. 593617.

[20] Wen HM. Penetration and perforation of targets subjected to

projectile impact. In preparation.

[21] Siva Kumar K, Balakrishna Bhat T. Response of composite

laminates on impact of high velocity projectiles. Key Engineering

Materials 1998;141143:33748.

1172 H.M. Wen / Composites Science and Technology 61 (2001) 11631172

You might also like

- Predicting The Penetration and Perforation of FRP Laminates Struck Normally by Projectiles With Different Nose ShapesDocument9 pagesPredicting The Penetration and Perforation of FRP Laminates Struck Normally by Projectiles With Different Nose ShapesDeepesh Kumar100% (1)

- Numerical Simulation of Progressive Damage in Laminated Composites Due To Ballistic ImpactDocument8 pagesNumerical Simulation of Progressive Damage in Laminated Composites Due To Ballistic ImpactBAswaniKumarNo ratings yet

- A Teaching Essay on Residual Stresses and EigenstrainsFrom EverandA Teaching Essay on Residual Stresses and EigenstrainsNo ratings yet

- Fracture and Fatigue: Elasto-Plasticity, Thin Sheet and Micromechanisms ProblemsFrom EverandFracture and Fatigue: Elasto-Plasticity, Thin Sheet and Micromechanisms ProblemsJ. C. RadonNo ratings yet

- Ballistic Impact Into Fabric and Compliant Composite LaminatesDocument13 pagesBallistic Impact Into Fabric and Compliant Composite LaminatesSantiago VicenteNo ratings yet

- A021833 TERMINAL BALLISTICSDocument232 pagesA021833 TERMINAL BALLISTICSMoltKee50% (2)

- Materials and Design: X.F. Zhang, Y.C. LiDocument8 pagesMaterials and Design: X.F. Zhang, Y.C. LivenkatesanjsNo ratings yet

- Ballistic Resistance of High Hardness Armor Steels Against 7.62mm Armor Piercing AmmunitionDocument15 pagesBallistic Resistance of High Hardness Armor Steels Against 7.62mm Armor Piercing AmmunitionWasimullah KhanNo ratings yet

- Numerical Modeling of Physical Process of Far Field Underwater ExplosionsDocument11 pagesNumerical Modeling of Physical Process of Far Field Underwater ExplosionsKristjan TabriNo ratings yet

- Ballistic Impact of Dry Woven Fabric Composites: A Review: Ala Tabiei Gaurav NilakantanDocument13 pagesBallistic Impact of Dry Woven Fabric Composites: A Review: Ala Tabiei Gaurav NilakantanBhasker RamagiriNo ratings yet

- MD Nastran Demonstration Problems 2010Document1,347 pagesMD Nastran Demonstration Problems 2010Dan WolfNo ratings yet

- Coupling ANSYS Workbench With ModeFRONTIERDocument10 pagesCoupling ANSYS Workbench With ModeFRONTIERkristeen780% (1)

- Biaxial cyclic deformation behaviour of steelsDocument14 pagesBiaxial cyclic deformation behaviour of steelsDavid C Houser100% (1)

- Analysis of Failure in Fiber Polymer Laminates The Theory of Alfred Puck by Martin Knops Dr.-Ing. (Auth.)Document208 pagesAnalysis of Failure in Fiber Polymer Laminates The Theory of Alfred Puck by Martin Knops Dr.-Ing. (Auth.)Rafael M. ParaguassuNo ratings yet

- Bolted Joints in Composite Aircraft StructuresDocument4 pagesBolted Joints in Composite Aircraft StructuresZiggy Gregory100% (2)

- Neuber Method For FatigueDocument12 pagesNeuber Method For FatigueKuan Tek SeangNo ratings yet

- Primer On The Craig-Bampton MethodDocument54 pagesPrimer On The Craig-Bampton MethodtobecarbonNo ratings yet

- Development and Ballistic Testing of A Functionally Gradient Ceramic Metal AppliqueDocument12 pagesDevelopment and Ballistic Testing of A Functionally Gradient Ceramic Metal Appliquegrindormh53No ratings yet

- Failure Behavior of Honeycomb Sandwich Corner Joints and InsertsDocument14 pagesFailure Behavior of Honeycomb Sandwich Corner Joints and InsertsConstantinescu MateiNo ratings yet

- Ijsetr Vol 3 Issue 10 2868 2872Document5 pagesIjsetr Vol 3 Issue 10 2868 2872Deva IsmayaNo ratings yet

- Rolling Contact Fatigue Resistance of Hard Coatings On Bearing SteelsDocument24 pagesRolling Contact Fatigue Resistance of Hard Coatings On Bearing Steelsmans2014No ratings yet

- Structural Behaviour of Composite Sandwich PanelsDocument16 pagesStructural Behaviour of Composite Sandwich PanelsvasfidNo ratings yet

- MSC Fastener Modeling For Joining Composite Parts 06-SpiritAero - BoshersDocument22 pagesMSC Fastener Modeling For Joining Composite Parts 06-SpiritAero - BoshersSergey Fedorinov100% (1)

- 7175 PDFDocument19 pages7175 PDF孙俊磊No ratings yet

- Kevlar: What Is It Properties UsesDocument7 pagesKevlar: What Is It Properties UsesShukla PalitNo ratings yet

- BRL-MR-3733 - Aero Char of 7.62mm Match BulletsDocument73 pagesBRL-MR-3733 - Aero Char of 7.62mm Match BulletsRick GainesNo ratings yet

- Liners For Shaped Charges by Manfred Held (2001) PDFDocument1 pageLiners For Shaped Charges by Manfred Held (2001) PDFMalikHodzicNo ratings yet

- MSC Patran Making A Composite ModelDocument19 pagesMSC Patran Making A Composite Modeldulaijan100% (1)

- Progressive Failure Analysis of Composite Materials Using The PucDocument87 pagesProgressive Failure Analysis of Composite Materials Using The PucMansingh YadavNo ratings yet

- On Fracture MechanicsDocument81 pagesOn Fracture MechanicsDEEPAK100% (1)

- ASTM D671 - Plastic FatigueDocument1 pageASTM D671 - Plastic FatiguesamNo ratings yet

- CAEA v15 ANSYS Composite DamageDocument24 pagesCAEA v15 ANSYS Composite DamageDavid MartinsNo ratings yet

- NASA Space Vehicle Design Criteria for Buckling of Thin-Walled CylindersDocument56 pagesNASA Space Vehicle Design Criteria for Buckling of Thin-Walled CylindersSJLeemansNo ratings yet

- Accuracy of First - and Second-Order Tetrahedral ElementsDocument8 pagesAccuracy of First - and Second-Order Tetrahedral ElementsKillgusNo ratings yet

- The Effect of Fiber Architecture On The Mechanical Properties of Carbon-Carbon Fiber CompositesDocument13 pagesThe Effect of Fiber Architecture On The Mechanical Properties of Carbon-Carbon Fiber CompositesBolaji SuberuNo ratings yet

- Imp-Thoupal 2009-Mechanics of Mechanically Fastened Joints in Polymer-Matrix Composite Structures - A Review PDFDocument29 pagesImp-Thoupal 2009-Mechanics of Mechanically Fastened Joints in Polymer-Matrix Composite Structures - A Review PDFJamalDilferozNo ratings yet

- Fatigue Testing Under Variable Amplitude Loading PDFDocument10 pagesFatigue Testing Under Variable Amplitude Loading PDFPradeep Kundu100% (1)

- NASA CR-112237 Hart-Smith Scarf & Stepped-LapDocument115 pagesNASA CR-112237 Hart-Smith Scarf & Stepped-LapGregory A KressNo ratings yet

- The Optimisation of Shot Peen Forming ProcessesDocument5 pagesThe Optimisation of Shot Peen Forming ProcessesbkhmohamedNo ratings yet

- Analytical Models For Penetration MechanicsDocument24 pagesAnalytical Models For Penetration MechanicsWahyu SetiadiNo ratings yet

- 1994 Morandi PHDDocument296 pages1994 Morandi PHDnelyy7No ratings yet

- Measuring Strain with Electrical and Optical DevicesDocument10 pagesMeasuring Strain with Electrical and Optical DevicesvigneshwarimahamuniNo ratings yet

- Post BucklingDocument14 pagesPost BucklingthaoNo ratings yet

- Robert M. Jones (Auth.), I. H. Marshall (Eds.) - Composite Structures-Springer Netherlands (1981)Document736 pagesRobert M. Jones (Auth.), I. H. Marshall (Eds.) - Composite Structures-Springer Netherlands (1981)Abualtayef KhalilNo ratings yet

- Afwal TR-81-3041 Vol1Document158 pagesAfwal TR-81-3041 Vol1sqc150100% (1)

- Nonlinear Total vs Linear StrainDocument32 pagesNonlinear Total vs Linear StrainDasaka BrahmendraNo ratings yet

- Shape Memory AlloysDocument16 pagesShape Memory AlloysIvan HernandezNo ratings yet

- Fracture Specimen Stree AnalysisDocument15 pagesFracture Specimen Stree AnalysisGaurav PundirNo ratings yet

- HOneycomb Core Materials 14 04731 v2Document20 pagesHOneycomb Core Materials 14 04731 v2Senthil KumarNo ratings yet

- Serge Abrate-Impact On Composite Structures (1998) PDFDocument301 pagesSerge Abrate-Impact On Composite Structures (1998) PDFShree Biradar0% (1)

- Abstract - Fatigue Behavior in Strain Cycling in The Low and Intermediate Cycle RangeDocument55 pagesAbstract - Fatigue Behavior in Strain Cycling in The Low and Intermediate Cycle RangeZarra FaktNo ratings yet

- Torsion Spring Design InfoDocument3 pagesTorsion Spring Design Infoashish19851No ratings yet

- Buckling - EquationsDocument66 pagesBuckling - EquationsricardoborNo ratings yet

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- Modern Practice in Stress and Vibration Analysis: Proceedings of the Conference Held at the University of Liverpool, 3–5 April 1989From EverandModern Practice in Stress and Vibration Analysis: Proceedings of the Conference Held at the University of Liverpool, 3–5 April 1989J. E. MottersheadNo ratings yet

- Crack Control: Using Fracture Theory to Create Tough New MaterialsFrom EverandCrack Control: Using Fracture Theory to Create Tough New MaterialsNo ratings yet

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- UploadDocument1 pageUploadDeepesh KumarNo ratings yet

- ContentDocument2 pagesContentDeepesh KumarNo ratings yet

- BEAMDocument40 pagesBEAMDeepesh KumarNo ratings yet

- Energy Absorption Ef Ciency of Carbon Ber Reinforced Polymer LaminatesDocument9 pagesEnergy Absorption Ef Ciency of Carbon Ber Reinforced Polymer LaminatesDeepesh KumarNo ratings yet

- Predicting The Penetration and PerforationDocument37 pagesPredicting The Penetration and PerforationDeepesh KumarNo ratings yet

- Major TT July Dec2013 08nov 11AMDocument8 pagesMajor TT July Dec2013 08nov 11AMDeepesh KumarNo ratings yet

- InTech-Progressive Failure Analysis of Glass Epoxy Composites at Low TemperaturesDocument28 pagesInTech-Progressive Failure Analysis of Glass Epoxy Composites at Low TemperaturesDeepesh KumarNo ratings yet

- Sa Tally Education BrochureDocument6 pagesSa Tally Education BrochurePoojaMittalNo ratings yet

- Essay 2Document4 pagesEssay 2api-708904378No ratings yet

- Roy FloydDocument2 pagesRoy FloydDaniela Florina LucaNo ratings yet

- The Rolle of Surgery in Oncology: Surgery Departement Medical Faculty Ukrida UniversityDocument25 pagesThe Rolle of Surgery in Oncology: Surgery Departement Medical Faculty Ukrida UniversityGian Alodia RisamasuNo ratings yet

- Math 226 Differential Equation: Edgar B. Manubag, Ce, PHDDocument18 pagesMath 226 Differential Equation: Edgar B. Manubag, Ce, PHDJosh T CONLUNo ratings yet

- Communication Process Quiz AnswersDocument3 pagesCommunication Process Quiz AnswersAbigail CullaNo ratings yet

- Forbidden TextsDocument179 pagesForbidden TextsThalles FerreiraNo ratings yet

- How To Think Like Da Vinci PDFDocument48 pagesHow To Think Like Da Vinci PDFTushar Walia100% (5)

- Amdocs FSDocument4 pagesAmdocs FSlionrudrams81No ratings yet

- Algebra - QuestionsDocument13 pagesAlgebra - Questionsdhruvbhardwaj100% (1)

- Remedial 2 Syllabus 2019Document11 pagesRemedial 2 Syllabus 2019Drew DalapuNo ratings yet

- Mania: Caring For A Person ExperiencingDocument6 pagesMania: Caring For A Person ExperiencingGutsy JewelNo ratings yet

- Comparative Constitutional Law IsDocument7 pagesComparative Constitutional Law IsНикита РудницкийNo ratings yet

- TPADocument9 pagesTPAAli ShahNo ratings yet

- 300 Signs and Symptoms of Celiac DiseaseDocument7 pages300 Signs and Symptoms of Celiac DiseaseIon Logofătu AlbertNo ratings yet

- Virl 1655 Sandbox July v1Document16 pagesVirl 1655 Sandbox July v1PrasannaNo ratings yet

- Lista de Canciones de Los 80Document38 pagesLista de Canciones de Los 80Maria Luisa GutierrezNo ratings yet

- TASSEOGRAPHY - Your Future in A Coffee CupDocument5 pagesTASSEOGRAPHY - Your Future in A Coffee Cupcharles walkerNo ratings yet

- Pathophysiology of Alzheimer's Disease With Nursing ConsiderationsDocument10 pagesPathophysiology of Alzheimer's Disease With Nursing ConsiderationsTiger Knee100% (1)

- Application of Leadership TheoriesDocument24 pagesApplication of Leadership TheoriesTine WojiNo ratings yet

- THE PHILIPPINE JUDICIAL SYSTEM: PRE-SPANISH AND SPANISH PERIODDocument17 pagesTHE PHILIPPINE JUDICIAL SYSTEM: PRE-SPANISH AND SPANISH PERIODFranchesca Revello100% (1)

- Quiz Template: © WWW - Teachitscience.co - Uk 2017 28644 1Document49 pagesQuiz Template: © WWW - Teachitscience.co - Uk 2017 28644 1Paul MurrayNo ratings yet

- Photobiomodulation With Near Infrared Light Helmet in A Pilot Placebo Controlled Clinical Trial in Dementia Patients Testing MemorDocument8 pagesPhotobiomodulation With Near Infrared Light Helmet in A Pilot Placebo Controlled Clinical Trial in Dementia Patients Testing MemorarexixNo ratings yet

- CSR & Corporate FraudDocument18 pagesCSR & Corporate FraudManojNo ratings yet

- Challenges of Quality Worklife and Job Satisfaction for Food Delivery EmployeesDocument15 pagesChallenges of Quality Worklife and Job Satisfaction for Food Delivery EmployeesStephani shethaNo ratings yet

- Cultural Diversity and Relativism in SociologyDocument9 pagesCultural Diversity and Relativism in SociologyEllah Gutierrez100% (1)

- Docu53897 Data Domain Operating System Version 5.4.3.0 Release Notes Directed AvailabilityDocument80 pagesDocu53897 Data Domain Operating System Version 5.4.3.0 Release Notes Directed Availabilityechoicmp50% (2)

- Worksheets Section 1: Develop Quality Customer Service PracticesDocument3 pagesWorksheets Section 1: Develop Quality Customer Service PracticesTender Kitchen0% (1)

- Anaphylactic ShockDocument19 pagesAnaphylactic ShockrutiranNo ratings yet

- MEASURING HORIZONTAL DISTANCESDocument11 pagesMEASURING HORIZONTAL DISTANCESJosiah M. TubagaNo ratings yet