Professional Documents

Culture Documents

Tab 6

Uploaded by

Gregory StewartOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tab 6

Uploaded by

Gregory StewartCopyright:

Available Formats

Motor Protection Devices

6-1

6

Section Overview

Current Relays

Bulletin 809 Instantaneous Trip Current Relays Page 6-2

Bulletin 809S Solid-State AC Current Relays Page 6-5

Bulletin 810 Inverse Time Current Relays Page 6-8

Bulletin 813S Solid-State Line Voltage

and Current Monitor Relays Page 6-11

Thermistor Protection Relay

Bulletin 817

For Critical Applications Page 6-14

Automatic, Manual and Remote Reset

SMM Smart Motor Manager

Bulletin 825

0.5630A Current Range Page 6-19

Arcing Ground Fault Detection System

Bulletin 1409

Adjustable Trip from 16A Page 6-30

Motor Winding Heater

Bulletin 1410

Automatic Operation Page 6-34

Solid-State Design

Control Circuit Transformers

Bulletin 1497

502000 VA Page 6-36

Bulletin 809

Instantaneous Trip Current Relays

6-2

6

Bulletin 809

Magnetically Operated

Adjustable Trip Point

Rated up to 320A

Available in IP30

(Type 1) Enclosures

TABLE OF CONTENTS

Description Page Description Page

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3 Approximate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Description

Bulletin 809 is a magnetically operated instantaneous trip current relay which can be

used with AC or DC motors. The relays are supplied with a N.O./N.C. automatic reset

contact. Tripping point is adjustable.

RESET POINT The Bulletin 809 relay resets between 70 and 85% of its trip setting

when used on AC, and between 62 and 82% of its setting when used on DC.

Your order must include:

Cat. No. of the current relay selected.

Full load current and tripping current.

Approvals:

CSA Certied

UL Listed

Bulletin 809

Instantaneous Trip Current Relays

6-3

Product Selection

Instantaneous Trip Current Relays

Contact Ratings

600V AC or DC Maximum B 25, 50, 60 Hz

Maximum

Continuous

Coil

Current (A)

Tripping Current

Adjustment Range (A) Open Type

Type 1

General Purpose

Enclosure

AC DC Cat. No. Cat. No.

2 1.13.1 0.952.8 809-A01E 809-B01E

3 1.64.5 1.44.3 809-A02E 809-B02E

4 2.16.1 1.95.7 809-A03E 809-B03E

6 3.29.1 2.88.5 809-A04E 809-B04E

9 4.813.6 4.212.8 809-A05E 809-B05E

12 6.318.1 5.717.0 809-A06E 809-B06E

16 8.524.0 7.622.7 809-A07E 809-B07E

20 10.530.0 9.428.3 809-A08E 809-B08E

28 1543 1340 809-A09E 809-B09E

40 2161 1957 809-A10E 809-B10E

48 2572 2368 809-A11E 809-B11E

56 3085 2780 809-A12E 809-B12E

60 38108 34102 809-A13E 809-B13E

72 38108 34102 809-A14E 809-B14E

87 46130 41123 809-A15E 809-B15E

100 53150 47141 809-A16E 809-B16E

108 57163 51153 809-A17E 809-B17E

120 68195 61184 809-A18E 809-B18E

120 76217 68205 809-A19E 809-B19E

130 68195 61184 809-A20E 809-B20E

144 76217 68204 809-A21E 809-B21E

162 85244 76229 809-A22E 809-B22E

185 98279 87262 809-A23E 809-B23E

210 114325 102305 809-A24E 809-B24E

216 114325 102305 809-A25E 809-B25E

259 136390 122367 809-A26E 809-B26E

320 171488 152458 809-A27E 809-B27E

320 227650 203612 809-A28E 809-B28E

320 340975 305920 809-A29E 809-B29E

AC DC

Maximum Contact Rating Per Pole

NEMA Rating Designation B600

Voltage

Range (V)

Ampere

Rating (A)

Max. AC

Voltage (V)

50/60 Hz

Amperes Continuous

Carrying

Current (A)

Volt Amperes

Make (A) Break (A) Make (VA) Break (VA)

120 30 3.00 5 3600 360

115125

230250

550600

0.40

0.20

0.10

240 15 1.50 5 3600 360

480 7.5 0.75 5 3600 360

600 6 0.60 5 3600 360

Prices Consult Sales Office or price list

Bulletin 809

Instantaneous Trip Current Relays

6-4

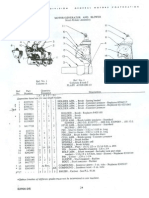

Approximate Dimensions

Dimensions are shown in millimeters (inches). Dimensions are not intended to be used for manufacturing purposes.

Max.

Amperes

(A)

Open Type

IP30 (Type 1) General Purpose

Enclosure

A

Wide

B

High

C

Deep

A

Wide

B

High

C

Deep D E

60

76.2

(3)

196.8

(7-3/4)

111.1

(4-3/8)

161.9

(6-3/8)

288.9

(11-3/8)

155.6

(6-1/8)

234.9

(9-1/4)

107.9

(4-1/4)

120

85.7

(3-3/8)

196.8

(7-3/4)

120.7

(4-3/4)

161.9

(6-3/8)

288.9

(11-3/8)

155.6

(6-1/8)

234.9

(9-1/4)

107.9

(4-1/4)

210

85.7

(3-3/8)

196.8

(7-3/4)

130.2

(5-1/8)

187.3

(7-3/8)

415.9

(16-3/8)

196.8

(7-3/4)

361.9

(14-1/4)

133.4

(5-1/4)

320

114.3

(4-1/2)

212.7

(8-3/8)

136.5

(5-3/8)

238.1

(9-3/8)

542.9

(21-3/8)

196.8

(7-3/4)

488.9

(19-1/4)

184.2

(7-1/4)

C

D

E

A

B

3/4

A C

B

Open Type Dimension B

allows for core removal

NEMA Type 1 (IP42) Enclosure

Bulletin 809S

Solid-State AC Current Relays

6-5

6

Bulletin 809S

Available in Two

Configurations:

Overcurrent and

Undercurrent

Incorporates the

Following Delay Modes

Into its Design:

Starting

Trip

Inhibit (Overcurrent

Relay Only)

TABLE OF CONTENTS

Description Page Description Page

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Approximate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Description

Bulletin 809S solid-state AC current relay is designed to sense AC current and

is available in two congurations: Overcurrent and Undercurrent. Each relay is

available in two current ratings, 5A and 12A. For higher current values, the 5A

relays are used with current transformers.

Optional features include a remote trip current potentiometer and a meter

calibrated in percent of trip current.

OVERCURRENT RELAY The Overcurrent relay is designed to operate a

sealed contact when the monitored current exceeds an adjustable trip level.

UNDERCURRENT RELAY The Undercurrent relay is designed to change the

state of an output relay when the current magnitude drops below an adjustable

trip level. This is dened as the tripped condition. The time response of the relay

is determined by the setting of the time delay adjustment.

Your order must include:

Cat. No. of the solid-state AC current

relay selected.

If required, Cat. No. of current

transformer.

If required, Cat. No. of any

accessories.

Approvals:

CSA Certied

UL Listed

Bulletin 809S

Solid-State AC Current Relays

6-6

Product Selection

AC Current Relays

Current Transformers

Use only with Cat. Nos. 809S-AB100A1, 809S-CB100A1, 809S-AB010A1, or 809S-CB010A1.

Output Contact Rating for AC Relays

Accessories

0 To order legend plate, refer to page 11-46 for Bulletin 800T and page 11-123 for Bulletin 800MR.

Automatic Reset B Adjustable Differential B 600V AC Maximum

Trip

Current

Range

30800 Hz

Continuous

AC

(A)

Maximum

Current

(A)

Open Type Without Enclosure

Overcurrent Relays

Normally Open

Output

Normally Closed

Output

(Electrically Held)

Continuous Inrush Cat. No. Cat. No.

0.425 7.5 35 809S-AB100A1 809S-AB010A1

112 18 84 809S-BB100A1 809S-BB010A1

Undercurrent Relays

Normally Open Normally Closed

0.425 7.5 35 809S-CB100A1 809S-CB010A1

112 18 84 809S-DB100A1 809S-DB010A1

Trip Current Range

30400 Hz

Continuous AC

Amperes

(5A Secondary

Winding)

Maximum Current

(A) Transformer Only

Continuous Inrush Cat. No.

4.250 75 350 809S-CT1

17200 300 1400 809S-CT2

42500 750 3500 809S-CT3

1001200 1800 8400 809S-CT4

Output Contact Ratings

NEMA B600 NEMA P300

Volts AC Make Break Volts DC Make/Break

120600 3600VA 360VA 125300 138VA

72120 30A 360VA 46125 138VA

572 30A 5A 546 3A

Description Cat. No.

Remote Trip Current

Potentiometers

Bulletin 800T 800T-U91 0

Bulletin 800MR 800MR-U91H 0

Percent Trip Current Meter 809S-N1

Prices Consult Sales Office or price list

Bulletin 809S

Solid-State AC Current Relays

6-7

Approximate Dimensions

Dimensions are shown in millimeters (inches). Dimensions are not intended to be used for manufacturing purposes.

Current Relays

Note: Relays can be mounted directly on a panel, or installed on Bulletin 700 Mounting Strips (Cat. Nos. 700-M4, -M8, -M12, -M16,

-M32). The relay will occupy three mounting strip spaces. Special, longer screws are supplied with the relay to secure it to the

mounting strips.

Current Transformers

Percent Trip Current Meter Drilling Dimensions

A B C D E F G

154

(6-1/16)

89

(3-1/2)

111

(4-3/8)

114

(4-1/2)

20

(25/32)

79.5

(3-1/8)

4.8

(3/16)

Cat. No.

A

Min. B C D E F

809S-CT1 32

(1-1/4)

102

(4)

117

(4-5/8)

95.5

(3-3/4)

32

(1-1/4)

6.4

(1/4) 809S-CT2

809S-CT3

57

(2-1/4)

149

(5-7/8)

181

(7-1/8)

127

(5)

38

(1-1/2)

7.1

(9/32)

809S-CT4

95.5

(3-3/4)

171

(6-3/4)

198

(7-25/32)

165

(6-1/2)

41.5

(1-5/8)

7.1

(9/32)

Letter

Millimeters

(Inches) Letter

Millimeters

(Inches)

A

90.5

(3-9/16)

E

69

(2-23/32)

B

51.5

(2-1/32)

F

112

(4-13/32)

C

123

(4-27/32)

G

102

(4)

D

51

(2)

B F

G

A

E D

C

C

B

D

A

E

F Hole Dia.

610 (24) lead

F

G

B

A

D

C

E

4 Mounting Holes Dia. 4 (5/32)

Overall Depth 66.5 (2-5/8)

Bulletin 810

Inverse Time Current Relays

6-8

6

Bulletin 810

Adjustable Trip Current

Adjustable Trip Time

Minimum Trip Current

Does Not Change with

Ambient Temperature

Changes

2320A Ratings

TABLE OF CONTENTS

Description Page Description Page

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9 Approximate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Description

Bulletin 810 is a magnetically-operated overload relay which can be used in the

protection of AC or DC motors. Both the tripping current and tripping time are easily

adjustable. Unless otherwise specied, the relays are supplied with N.C. contacts

and an automatic reset. Like thermal overload relays, the Bulletin 810 has inverse

time tripping characteristics; unlike thermal relays, its minimum (or ultimate) tripping

current does not signicantly change with ambient temperature changes. This, along

with the adjustment feature, gives the Bulletin 810 overload relay special application.

Your order must include:

Cat. No. of the inverse time current

relay selected.

Full Load Current

Minimum Tripping Current.

Approvals:

CSA Certied

UL Listed

Bulletin 810

Inverse Time Current Relays

6-9

Product Selection

Contact Ratings 0

0 Continuous Operating To prevent relay damage, current through the relay coil should be interrupted after the relay trips. Relay can carry

the listed continuous currents in the non-tripped position only.

O High Voltage Relays Relays are available for use at 2500V maximum, with continuous current ratings of up to 100A. Refer to factory for

information.

O Pre-Set Time Setting Refer to Sales Office for pricing information.

O Hand Reset A N.C. (normally closed) hand reset contact block is available. Change the last letter in the listed Cat. No. from A to C. If a

N.O. (normally open) hand reset contact block is wanted, change the last letter in the listed Cat. No. from A to D.

O Normally Open Contacts Relays with N.O. contacts can be supplied. Change the last letter in the listed Cat. No. from A to B.

O Bifurcated Contacts Provide increased contact reliability where dust and foreign particles are apparent. Bifurcated contacts are factory

installed with a clear plastic transparent cover. Add the letter Z to the end of the listed Cat. No..

6 Dashpot Fluid Cat. No. 810-N9B (Blue Fluid) is included as standard. Cat. No. 810-N9C (Clear Fluid) can be substituted by adding R to

the end of the listed Cat. No. Fluid is included in the price of the relay.

600V AC or DC Maximum B 25, 50, 60 Hz B N.C. Contacts B Automatic Reset OO

Maximum

Continuous

Coil

Current (A)

Tripping Current

Adjustment Range (A)

Amperes Open Type OOO6

IP30 (Type 1)

General Purpose

Enclosure OOO6

AC DC Cat. No. Cat. No.

2 1.13.1 0.952.8 810-A01A 810-B01A

3 1.64.5 1.44.3 810-A02A 810-B02A

4 2.16.1 1.95.7 810-A03A 810-B03A

6 3.29.1 2.88.5 810-A04A 810-B04A

9 4.813.6 4.212.8 810-A05A 810-B05A

12 6.318.1 5.717.0 810-A06A 810-B06A

16 8.524.0 7.622.7 810-A07A 810-B07A

20 10.530.0 9.428.3 810-A08A 810-B08A

28 1543 1340 810-A09A 810-B09A

40 2161 1957 810-A10A 810-B10A

48 2572 2368 810-A11A 810-B11A

56 3085 2780 810-A12A 810-B12A

60 38108 34102 810-A13A 810-B13A

72 38108 34102 810-A14A 810-B14A

87 46130 41123 810-A15A 810-B15A

100 53150 47141 810-A16A 810-B16A

108 57163 51153 810-A17A 810-B17A

120 68195 61184 810-A18A 810-B18A

120 76217 68205 810-A19A 810-B19A

130 68195 61184 810-A20A 810-B20A

144 76217 68204 810-A21A 810-B21A

162 85244 76229 810-A22A 810-B22A

185 98279 87262 810-A23A 810-B23A

210 114325 102305 810-A24A 810-B24A

216 114325 102305 810-A25A 810-B25A

259 136390 122367 810-A26A 810-B26A

320 171488 152458 810-A27A 810-B27A

320 227650 203612 810-A28A 810-B28A

320 340975 305920 810-A29A 810-B29A

AC DC

Max. Contact Rating Per Pole

NEMA Rating Designation A600

Voltage

Range (V)

Ampere

Rating (A)

Max. AC

Voltage (V)

50/60 Hz Make (A) Break (A)

Continuous

Carrying

Current (A)

Volt Amperes

Make (VA) Break (VA)

120 60 6.00 10 7200 720

115125

230250

550600

0.4

0.2

0.1

240 30 3.00 10 7200 720

480 15 1.50 10 7200 720

600 12 1.20 10 7200 720

Prices Consult Sales Office or price list

Bulletin 810

Inverse Time Current Relays

6-10

Approximate Dimensions

Current Relays

Dimensions are shown in millimeters (inches). Dimensions are not intended to be used for manufacturing purposes.

Max.

Amperes (A)

Open Type IP30 (Type 1) General Purpose Enclosure

A

Wide

B

High

C

Deep

A

Wide

B

High

C

Deep D E

60

76.2

(3)

193.7

(7-5/8)

111.1

(4-3/8)

161.9

(6-3/8)

288.9

(11-3/8)

152.4

(6-1/8)

234.9

(9-1/4)

107.9

(4-1/4)

120

85.7

(3-3/8)

193.7

(7-5/8)

120.7

(4-3/4)

161.9

(6-3/8)

288.9

(11-3/8)

152.4

(6-1/8)

234.9

(9-1/4)

107.9

(4-1/4)

210

85.7

(3-3/8)

209.6

(8-1/4)

130.2

(5-1/8)

187.3

(7-3/8)

415.9

(16-3/8)

196.8

(7-3/4)

361.9

(14-1/4)

133.3

(5-1/4)

320

114.3

(4-1/2)

212.7

(8-3/8)

136.5

(5-3/8)

238.1

(9-3/8)

542.9

(21-3/8)

196.8

(7-3/4)

488.9

(19-1/4)

184.1

(7-1/4)

A C

B

A

B

C

D

E

3/4

Open Type Dimension B

allows for dashpot removal

IP30 (Type 1) Enclosure

Bulletin 813S

Solid-State Line Voltage and Current Monitor Relays

6-11

6

Bulletin 813S

Line Voltage Monitor

Detects Phase Failure,

Voltage Uunbalance,

Phase Reversal and

Undervoltage

Provides Pre-start and

Running Protection on the

Line Side of the Point of

Connection

Line Current Monitor

Detects Phase Failure,

Current Unbalance and

Phase Reversal

Provides Running

Protection on theLine and

Load Side of Point of

Connection When Used in

a Single Motor Branch

Circuit

TABLE OF CONTENTS

Description Page Description Page

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Approximate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Description

Line Voltage Monitor and Line Current Monitor are solid-state devices designed for

use in three phase systems to protect motors and other loads against abnormal

voltage/current conditions. In general, the Line Voltage Monitor is applied where

pre-start protection and line side protection are important, whereas the Line Current

Monitor is applied where line and load side protection is important.

Approvals:

Your order must include:

Cat. No. of the line voltage or current

monitor relay selected.

CSA Certied

UL Listed

Line Voltage Monitor

Cat. No. 813S-VOA

Line Current Monitor

Cat. No. 813S-COWEM

Bulletin 813S

Solid-State Line Voltage and Current Monitor Relays

6-12

Product Selection

0 For applications using Size 5 and larger starters, the current transformers supplied with the starter for the heater element circuits can also be

used for the Line Current Monitor input circuits.

O Output contact is rated 250V AC maximum for all devices, regardless of supply voltage.

O The 120V device is typically connected to the secondary of potential transformers to monitor line voltages above 600V.

Specications

Line Voltage Monitor

Output Contact Ratings

Line Current Monitor

Output Contact Ratings

Line Voltage Monitor Relays B Automatic Reset Line Current Monitor Relays 0

Line

Volts (V)

3-Phase Hz

Open Type

IP30 (Type 1)

General Purpose

Enclosure

Supply

Volts (V)

O

Single

Phase

60 Hz Reset

Open Type

IP30 (Type 1)

General Purpose

Enclosure

Cat. No. Cat. No. Cat. No. Cat. No.

380 50 813S-VON 813S-VAN 120

Auto-

matic

813S-COWEA 813S-CAWEA

415 50 813S-VOI 813S-VAI 208 813S-COHA 813S-CAHA

440 50 813S-VOQ 813S-VAQ 240 813S-COAA 813S-CAAA

480 813S-COBA 813S-CABA

600 813S-COCA 813S-CACA

120 O 60 813S-VOWE 813S-VAWE 120

Manual

813S-COWEM 813S-CAWEM

208 60 813S-VOH 813S-VAH 208 813S-COHM 813S-CAHM

240 60 813S-VOA 813S-VAA 240 813S-COAM 813S-CAAM

480 60 813S-VOB 813S-VAB 480 813S-COBM 813S-CABM

600 60 813S-VOC 813S-VAC 600 813S-COCM 813S-CACM

Line Voltage

380V, 415V, 440V, +10%, 20%, 3-phase, 50 Hz, 1%;

120V, 208V, 240V, 480V, 600V, +10%, 20%, 3-phase, 60 Hz, 1%

Use device only at nameplate rating.

Temperature Range 20C+60C (4F+140F)

Volts

AC Make Break

Volts

DC Make/Break

170600

48170

148

4800VA

28.2A

28.2A

480VA

480VA

10A

128 10A

Continuous Carrying Current: 10A

Supply Voltage

120V, 208V, 240V, 480V, 600V,

+10%, 20%, single phase, 60 Hz.

Use only at voltages listed on relay nameplate.

Power requirement is 4.4VA.

Input Current 3 phase, 60 Hz, 1%

Normal operating range

Maximum continuous current

Maximum inrush current

Input impedance

05A

10A

35A for 5 seconds

0.005 ohm for each phase

Temperature Range 20C+60C (4F+140F)

Volts

AC Make Break

Volts

DC Make/Break

125250

1125

2200VA

17.6A

220VA

1.76A

130 3A

Continuous Carrying Current: 5A AC or DC

Prices Consult Sales Office or price list

Bulletin 813S

Solid-State Line Voltage and Current Monitor Relays

6-13

Specifications, Continued

Typical Wiring Diagrams

See Applicable Codes and Laws

Line Voltage Monitor Provides pre-start and running protection against abnormal voltage conditions on line side of voltage

monitor only.

Line Current Monitor Protects on line and load side of current transformers (CT) when used in single motor branch circuit.

Current unbalance protection is effective during motor running period only. Phase failure and reversal protection is provided during

both starting and running periods.

Approximate Dimensions

Dimensions are shown in millimeters (inches). Dimensions are not intended to be used for manufacturing purposes.

Open Type Dimensions above apply to both the voltage and current monitor versions. The devices can be installed in any position.

They can be installed directly on a panel, or installed on Bulletin 700 Type MP mounting strip. The relay will occupy three mounting

strip spaces.

L1 L2 L3

Disconnect

M

LOAD

A

B

C

1

CR

2 3

CR

4

STOP

START

M

M

O.L.s

Control Voltage

Line Voltage Monitor

Switch

(If Used)

L2 L1 L3

Control Voltage

STOP

START

(If Used)

Alarm

M

1 2 COM

Supply Voltage

L1

L2

Line Current Monitor

T3

E3

T2

E2

T1

E1

CT

CT

CT

M

LOAD

CR

(If Used)

O.L.s

(8-1/4)

(5/8)

(2-3/8)

Dia. Mounting Holes

(10-5/8)

(6-13/16) (5-17/32)

(7/32)

(3-1/8)

NEMA Type 1 Enclosure

Open Type Relay

(Can be mounted in any position.)

16

210

60.5

5.5

270

173 140

(3/16)

(25/32)

(4-1/2)

4 Mounting Slots

(3-1/2)

(6-1/16)

(4-3/8)

4.8

79.5

20

114

154

Use #8-32 Screws

89

111

Bulletin 817

Thermistor Protection Relay

6-14

6

Bulletin 817

Accurate Temperature

Monitoring for Critical

Applications

Automatic, Manual and

Remote Reset

Status Indicating LEDs

DIN Rail or Panel

Mounting

Guarded Terminals IP20

1 N.O. and 1 N.C. Output

Contacts as Standard

No Set-Up or

Adjustments Required

for Installation

TABLE OF CONTENTS

Description Page Description Page

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Approximate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Description

Bulletin 817 Thermistor Protection relays, utilized in conjunction with PTC thermistor

sensors, provide accurate temperature monitoring in critical applications and severe

environments such as widely varying temperatures and impeded ventilation and

cooling.

Conformity to Standards: Approvals:

IEC 255-8, IEC 292-1 SEV

IEC 255-4, IEC 69 NEMKO

SEV, SEN 36 1503 PTB

CSA C22.2 No. 14 FI

Your order must include:

Cat. No. of the relay selected with

Voltage Sufx Code.

UL 508 CSA Certied

UL Recognized

Bulletin 817

Thermistor Protection Relay

6-15

Product Overview

= Standard feature

= Cat. No. is incomplete. Refer to Product Selection below.

Product Selection

Voltage Sufx Code

Cat. No. as listed is incomplete. Select a Voltage Sufx Code from the table below to complete the Cat. No. Example: Cat. No. 817-A for 24V,

50 Hz becomes Cat. No. 817-AKD.

Model Cat. No. 817-A Cat. No. 817-M Cat. No. 817-U

Overtemperature protection

Short-circuit and open-circuit protection

for sensor measuring circuit

Trip indication (red LED)

Automatic reset

Manual reset

Remote reset (external button)

Storage of status in event of power failure

for more than 3 hours at +25C (77F)

unlimited (not temperature-dependent)

Test button

Power-on indication (green LED)

Description Cat. No.

Thermistor Protection relay 817-A

Thermistor Protection relay plus manual/remote reset 817-M

Thermistor Protection Relay plus manual/remote reset test function and

power indication LED

817-U

Voltage 24V 48V 110V 220V 240V 380V 415V 440V

50 Hz KD KH D A AJ KK I GB

60 Hz KD KH D A AJ KK I GB

DC Z24 Z48

Cat. No. 817-M Cat. No. 817-A Cat. No. 817-U

Specifications Page 6-16

Approximate Dimensions Page 6-18

Prices Consult Sales Office or price list

Bulletin 817

Thermistor Protection Relay

6-16

Specifications

0 Rated insulation voltage: 300V.

O American National Standards Institute.

O According to CSA, UL: pilot duty 240V (B 300).

O For more technical information, consult Allen-Bradley Sales Office.

O Bulletin 817 to motor; installation: up to 200m not shielded.

O For automatic reset: connect r1-r2.

Electrical

Rated Voltage

Acc. to IEC 255-8 440V According to AS, BS, VDE 0660 250V

Acc. to SEV 380V According to CSA, UL 0 240V

Test Voltage

Between separated circuits

Alternating current acc. to IEC 292-1 2.5 kV, 50/60 Hz, 1 min.

Surge voltage acc. to IEC 255-4 and SEN 36 1503 5 kV, 1.2/50 s

Interference voltage acc. to ANSI O C 37.90 a-

1974, IEC 255-6 and SEN 36 1503

2.5 kV, 1 MHz, 2 s

Supply

Rated supply voltage U

s

AC 110, 220, 240, 380, 415, 440V 50/60 Hz

AC

Special U

s

24, 48V 50/60 Hz

DC 24, 48V

Permissible Fluctuations

AC

0.81.1 U

s

50/60 Hz

DC

0.91.2 U

s

Power consumption AC 2.5VA (2.2W) DC 2.2W

Output Relay Contact Data Contacts (electrically isolated) 1 make and 1 break

Operating voltage O [V] 24 48 60 110 220 240 380 415 440

Continuous thermal current [A] 4 4 4 4 4 4 4 4 4

Rated operational current with AC AC-11 [A] 4 4 4 4 3 3 2 2 1.5

Rated operational current with DC DC-11

without protection circuit, L/R = 35 ms [A] 0.6 0.3 0.25 0.15 0.05 0.05

with protection circuit O, L/R = 100 ms [A] 0.6 0.6 0.5 0.5 0.5 0.5

Max. perm. make/break current [A] 44 44 44 44 33 33 22 22 16.5

Rated current of back-up fuse: Max. fast-acting 16A; slow-blow 10A

Mechanical

Vibration Resistance According to IEC 68 (10 150 Hz) 3g

Impact Resistance According to IEC 68-2-27 or DIN 40 046/7

30g, shock duration 18 ms, semi-sinusoidal in

the 3 directions x, y, and z

Measuring Line

mm

2

0.5 0.75 1 1.5 2.5

Minimum cross-section AWG 20 18 16 14 14

Maximum length O

m 200 300 400 600 1000

(ft) (656.2) (984.25) (1312.3) (1968.5) (3208.8)

Reset

Cat. No. 817-A Automatic

Cat. No. 817-M Manual or automatic O

Cat. No. 817-U Manual or automatic O

Remote Reset with

Cat. No. 817-M, 817-U

External contact at r1-r2 Potential-free make contact

Max. line length for remote reset

Up to 300m (984.25 ft) shielded

Up to 1000m (3280.8 ft) shielded

Product Selection Page 6-15

Bulletin 817

Thermistor Protection Relay

6-17

Specifications, Continued

Typical Wiring Diagram

Terminal and block circuit diagram of Bulletin 817

0 For automatic reset available in Cat. No. 817-M and Cat. No. 817-U, connect r1-r2.

Environmental

Max. cold resistance of PTC sensor chain 1500

Max. number of series connected

PTC sensors acc. to IEC 34-11-2 6

Response level A = 25C (13F)+60C (140F) 3300 300

Reset level A = 25C (13F)+60C (140F) 1800 300

Response level with short circuit

in sensor circuit A = 25C (13F)+60C (140F) 15

Measuring voltage acc. to IEC 34-11-2 DC < 2.5V

Ambient Temperature

Normal operation 25C (13F)+60C (140F)

Storage (in dry rooms) 40C (40F)+60C (140F)

Climatic Classication

According to IEC 68-2-3 humid

heat

40C (104F), 92% rel. humidity, 56

days

PTC sensor characteristic

According to IEC-34-11-2 TNF: Rated response temperature

Trip memory

In event of power supply

failure (zero-voltage

safe-guard)

Storage Time

Cat. No. 817-M

At 25C (77F) > 3h

At 40C (104F) > 1h

At 60C (140F) > 15 min.

Cat. No. 817-U

Unlimited (not

temperature-dependent)

Construction

Terminals

Open Terminals Captive

Connection wire cross-sections

2 x 2.5 mm

2

(.0039 in

2

) single wire or

2 x 1.5 mm

2

(.0023 in

2

) with end

ferrule

Protection class according to

IEC 529

Device (less terminals) IP30 Terminals (acc. to VBG 4) IP20

Installation

Bulletin 817 Thermistor Protection relay is designed for surface

mounting with screw xing according to hole plan EN 50 002 or for

snap-on xing to a top hat rail EN 50 022'-35 x 7.5. Arrangement,

assignment and marking of terminals in accordance with EN 50 005.

The mounting position of the Bulletin 817 does not inuence its

function.

360 360

10

20

100

250

550

1330

4000

-20C TNF-20K

0C TNF- 5K

TNF+15K

TNF+ 5K

TNF

Thermal

Trip

Supply

Reset

Button

Output

13

14

21

22

Trip Memory for

Power Supply Failure

Supply

Indication

Test Button

Terminal and Block Circuit Diagram

T1

T2

A1(+)

A2()

r1

r2

Us

PTC Temperature Sensor

Remote Reset

Relay

Cat. No. 817-A , -M , -U

Cat. No. 817-M , -U

Cat. No. 817-U

0

Product Selection Page 6-15

Bulletin 817

Thermistor Protection Relay

6-18

Specifications/Approximate Dimensions

Application Example

Approximate Dimensions

Dimensions are shown in millimeters (inches). Dimensions are not intended for manufacturing purposes.

0 For Top Hat Rail 35mm to EN 50 022, Cat. No. 199-DR1.

Starter (Bulletin 100 and Bulletin 193) with additional Bulletin 817.

Legend

K1 Bulletin 100 contactor

F1 Bulletin 193 thermal overload relay

F2 Bulletin 817 Thermistor Protection relay

S1 ON button

S0 OFF button

S2 Remote button reset

U

s

Supply voltage

H1 Signal Lamp Contactor ON

H2 Signal Lamp Bulletin 817 tripped

B1 Thermistor in protected object

The contacts 1314 and 2122 of the output relay

are drawn in their power-off position A1A2.

L1

L2

L3

N

PE

F9

A1

A2

F1

M1 3

M

B1

T1 T2

F2

1 3 5

2 4 6

K1

6 4 2

Bulletin

+t

Main Circuit

Circuit Diagram

L1

F7 AC U

21

22

S0

13

S1

14

K1

13

14

S2

r1 r2 13 21 A1 )

F2

T2

A2

97 95

F1

98 96

H2 H1

B1

PTC

A1

K1

N

(L2/F8) A2

2

s

Control Circuit

Impulse Contact Control

14 22

Bulletin

817

817

Hole plan

35

6

0

5

0

4.8

not available

r1 and r2 are

of terminals

Position

45

T

2

T

1

2

1

1

3

A

1

(

+

)

(

)

A

2

r

2

r

1

2

2

1

4

7

0

95.5

7

(3/16)

(1-3/8)

(

1

-

3

1

/

3

2

)

(

2

-

2

3

/

6

4

)

(

2

-

3

/

4

)

(1-3/4)

3

5

(

1

-

3

/

8

)

5

(13/64)

(9/32)

(3-3/4)

95.5(3-3/4)

on Cat. No. 817-A

0

Product Selection Page 6-15

Bulletin 825

Smart Motor Manager

6-19

6

Bulletin 825

Modular Construction

Allows for Maximum Utilization

of Motor and Equipment

LCD Fault Diagnosis

Display of Real Data and

Statistical Data

Easy Programming, Either

Directly on the Unit or from a

PC via DeviceNet, Remote I/O,

Modbus, and PROFIBUS

Communication Options

0.5630A Current Range

Limited Starts per Hour

Emergency Start

Provides Motor Protection by

Detecting:

Thermal Overload

Phase Loss

Jam

Ground Fault

Short Circuit

Underload

TABLE OF CONTENTS

Description Page Description Page

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Approximate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Description

The Bulletin 825 Smart Motor Manager is a programmable, electronic motor overload

protection relay with communication capability. This enables the device to be

congured for specic motor applications to provide maximum motor protection. This

capability is achieved by utilizing the microprocessor of the Smart Motor Manager to

model the thermal conditions of the motor and to congure and monitor the desired

protective features of the device for motor protection. Protective features include:

thermal overload, phase loss, jam, ground (earth) fault, short circuit, over-

temperature and many other options. Control features include: emergency start,

warm starting, limited number of starts, two-speed and wye-delta starting. All this

makes it easy to customize the Smart Motor Manager to meet most motor protection

needs in many different applications.

Conformity to Standards: Approvals:

Your order must include:

Cat. No. of the Smart Motor Manager

selected with supply Voltage Sufx

Code.

Cat. No. of Converter Module selected.

If required, Cat. No. of any option cards

or accessories.

IEC 947-4 CE

CSA C22.2 No. 14 PTB

UL 508 CSA Certied

UL Listed

Smart Motor Manager

Cat. No. 825-M

Converter Module

Cat. No. 825-MCM180

Bulletin 825

Smart Motor Manager

6-20

Product Overview

Basic and Optional Features

Available

Possible Combinations of Option Cards with Basic Unit

0 The features and protective functions provided by each option card can be monitored through the communication network with any of the

communication cards.

O A single communication card (PROFIBUS, DeviceNet, Modbus or Remote I/O) can be used with any combination of option cards.

Available in shown combination

Features 0

Basic

Bulletin 825

Bulletin 825

Standard

Option

Cat. No. 825-MST

Bulletin 825

Low Voltage

Option

Cat. No. 825-MLV

Bulletin 825

Medium Voltage

Option

Cat. No. 825-MMV

Thermal Overload

Phase Imbalance (Asymmetry)

Jam (High Overload/Stalling)

Underload

Ground (Earth) Fault (Holmgreen)

Starting Time Monitor

Limited Starts Per Hour

Emergency Start

Short Circuit

Ground (Earth) Fault (Core Balance C.T.)

Stalling During Start

Thermistor Input (PTC)

Analog Output for Thermal Utilization

Wye-Delta (Star-Delta) Starting

Phase Reversal (Sequence)

Phase Failure

PT 100 Inputs #1#6

(Stator/Bearings)

PT 100 Input #7

(Ambient Temp.)

Basic

Bulletin 825-M

Option Cards O

Cat. No. 825-MST Cat. No. 825-MLV Cat. No. 825-MMV

Product Selection Page 6-21

Accessories Page 6-22

Specifications Page 6-24

Approximate Dimensions Page 6-29

Bulletin 825

Smart Motor Manager

6-21

Product Selection

Smart Motor Manager

Control Voltage Sufx Code

The Cat. No. as listed is incomplete. Select a control Voltage Suffix Code from the table below to complete the Cat. No. Example: Cat. No.

825-M for 120V power supply becomes Cat. No. 825-MD.

Converter Module

0 Up to 630A when using primary current transformers.

Description Cat. No.

Motor Manager

Programmable electronic motor overload

protection relay with communication capability

Thermal Overload

Phase Imbalance

Jam (High Overload)

Underload

Ground (Earth) Fault

Starting Time Monitor

Limited Starts per Hour

825-M

Voltage AC 24V 120-220V 220-240V 380-415V 440V Voltage DC 24-48V

50/60 Hz KD D AJ N GB Code Z48

Description Current Range (A) Cat. No.

Converter Module

Connection to the

Smart Motor Manager

is made by a cable

wire plug provided as

standard with the

converter module.

0.52.5 0 825-MCM2

2.520 0 825-MCM20

20180 825-MCM180

160630 825-MCM630

Cat. No. 825-MCM180

Cat. No. 825-MCM360

Product Overview Page 6-20

Accessories Page 6-22

Specifications Page 6-24

Approximate Dimensions Page 6-29

Prices Consult Sales Office or price list

Bulletin 825

Smart Motor Manager

6-22

Option Cards 0/Accessories

0 Option cards include a connector set.

O The standard option card is not included with the Basic Bulletin 825. The standard option must be ordered separately.

O Cat. Nos. 825-MLV and 825-MMV use the same slot, therefore only one of the option cards may be used at one time.

O Available from Prosoft Technology Inc. contact your local distributor.

O AT type computer or better required.

Description Cat. No.

Standard Card O Features

Short Circuit

Ground (Earth) Fault (Core Balance C.T.)

Stalling During Start

Thermistor Input (PTC)

Analog Output for Thermal Utilization

825-MST

Low Voltage Card O Features

Wye-Delta (Star-Delta) Starting

Phase Reversal (Sequence)

Phase Failure (Motor Supply)

825-MLV

Medium Voltage Card O Features

PT 100 Inputs #1#6 (Stator/Bearings)

PT 100 Input #7 (Ambient Temperature)

825-MMV

Communication Card

DeviceNet 825-MDN

Modbus O

PROFIBUS 825-MPB

Remote I/O O

PC Option Set Card with Software For use

with 825-MPB

Real Time Values via PROFIBUS

Parameter setting and monitoring

Storing, loading and transferring of the param-

eter setting tables between a unit and a moni-

toring station. O

825-MPC

Bus Bars for Cat. No. 825-MCM180 Features

Terminals: M8

4 x 16 x 100mm

Weight: 230 g

825-MVM

Thermal Utilization Meter 825-MTUM

Product Overview Page 6-20

Specifications Page 6-24

Approximate Dimensions Page 6-29

Prices Consult Sales Office or price list

Bulletin 825

Smart Motor Manager

6-23

Accessories

Control Voltage Sufx Code

The Cat. No. as listed is incomplete. Select a control Voltage Suffix Code from the table below to complete the Cat. No. Example: Cat. No.

825-MPS for 120V power supply becomes Cat. No. 825-MPSD.

0 Maximum Cable Lengths for Various Transmission Rates

Description Cat. No.

Panel Mounting Frame 825-FPM

Connector Sets

Provided as Standard

with option card

For use with Cat. No. 825-

M

MST

MMV

MLV

825-CSB

825-CSST

825-CSMV

825-CSLV

PROFIBUS Accessories

T-Piece Junction from Bus Cable to the 825-M 825-PTS

Stub Cable Connection between T-Piece

and 825-M

0.2 Meter

0.4 Meter

825-PTL2

825-PTL4

Bus Cable Segment

Ready Prepared Cable with Plugs 1 Meter 825-PCB1

Bus Termination

To avoid disturbances, both ends of the PROFIBUS

cable must be equipped with a bus termination. The

bus termination has to be plugged onto the T-Piece.

825-PCE

Bus Cable

For distances greater than 1 meter 825-BC 0

Connector for Bus Cable

9 Pin Connector 825-CBC9

Power Supply Module 825-MPS

Voltage AC 24V 120-220V 220-240V 380-415V 440V Voltage DC 24-48V

50/60 Hz KD D AJ N GB Code Z48

Transmission Rate (KBits/sec) 9.6 19.2 93.75 187.5 500

Max. Length m 1200 1200 1200 600 200

ft 3937.2 3937.2 3937.2 1968.6 656.2

Cat. No. 825-FPM

Cat. No. 825-PTS

Cat. No. 825-PTL4

Cat. No. 825-PCB1

Cat. No. 825-PCE

Cat. No. 825-MPS

Product Overview Page 6-20

Product Selection Page 6-21

Specifications Page 6-24

Approximate Dimensions Page 6-29

Prices Consult Sales Office or price list

Bulletin 825

Smart Motor Manager

6-24

Specifications

Operating Elements

Settings

The following parameters must be programmed for every application. The other parameters (e.g. High overload, Asymmetry)

have factory set values, which are correct for most of the applications.

Main Settings

0 If instead of the permissible locked-rotor time the maximum time starting is known, the approximate locked-rotor time is calculated as follows:

Locked-rotor time = starting time

1.4

Special Settings

' Values Selection of mode Test Test functions

(alarm, trip, trip time)

Actual indication of actual operational

data

Set setting mode

(set/vary, store parameters)

I Reset Reset trips

Recorded indication of statistical data

LCD Single line

(two lines of text are

displayed alternately)

^ Select Select function and enter/

change operating parameters

Settings Entry I Fault indicator LED

Change enable entry Flashing warning

Enter memorize entry Steady state trip

Setting Range Factory Setting

Rated motor current or operating current I

e

0.5630A 20A

Use of a primary current transformer Yes/No No

Current ratio of primary current transformer 1600 1

Locked-rotor current

2.512 I

e

6 I

e

Locked-rotor time 0 1600s 10 s

Setting Range Factory Setting

Connection of main relay (MR) Electrically held/non-fail-safe Electrically held

Reset of thermal trip Manual/auto Manual

Reset at % thermal utilization 10100% 70%

Reset PTC trip Manual/auto Manual

Cooling constant ratio motor on/off 15 2.5

Motor insulation class B/E/F B

Station number (Communication) 1122 2

DeviceNet Baud Rate (125/250/500k baud) 02 0 (125 kBd)

Remote I/O Baud Rate (57.6, 115.2, 230.4k baud) 023

4 (57.6 kBd, Inst rack,

starting mod group 1)

PROFIBUS Baud Rate (9.6; 19.2; 93.75; 187.5; 500 kBd) 04 4 (500 kBd)

Modbus Baud Rate

(0.3, 0.6, 1.2, 2.4, 4.8, 9.6, 19.2, 38.4 kBd)

0188

4 (4.8 kBd, RTU mode, one stop bit,

no parity)

'

^

I

Product Overview Page 6-20

Product Selection Page 6-21

Accessories Page 6-22

Approximate Dimensions Page 6-29

Bulletin 825

Smart Motor Manager

6-25

Specifications, Continued

Electrical

0 The measuring inputs for PT-100 and PTC, the 4 through 20 mA output and the RS 485 interface are not insulated from one another.

Construction

Cat. No.825-MCM2 Cat. No. 825-MCM20 Cat. No.825-MCM180, -MCM630

Nominal Rated Voltage U

e

Motor circuit

Per IEC, SEV, VBE 0660 400V AC 660V AC 1000V AC

Per CSA, UL 240V AC 600V AC 600V AC

Control circuits

Main relay (MR) 9598, supply A1, A2

Phase sequence protection L1, L2, L3

Per IEC 947 400V AC

Per SEV 380V AC

Per CSA, UL 240V AC

Alarm relay (AL) 13/14

Auxiliary relay #1, #4, #5

Per IEC 947 400V AC

Per SEV 250V AC

Per CSA, UL 240V AC

Auxiliary relay #2, #3 50V AC/30V DC

Control inputs #1, #2 24V AC/24V DC

Electrical Tests

Test Voltage

Motor circuit

Per IEC 947-1 U

imp

2.5 kV U

imp

6 kV U

imp

8 kV

Control circuit

U

imp

4 kV

Between control circuits and to all other circuits 0

Main relay (MR) 9598, supply A1, A2

Phase sequence protection L1, L2, L3

Alarm relay (AL), Auxiliary relay #1, #4, #5

Per IEC 947-1

Core balance c.t. k, I

U

imp

2.5 kV

Control inputs #1, #2

Auxiliary relay #2, #3

Per IEC 947-1

Mounting Position

22.5 22.5

22.5

90

Product Overview Page 6-20

Product Selection Page 6-21

Accessories Page 6-22

Approximate Dimensions Page 6-29 Continued on next page.

Bulletin 825

Smart Motor Manager

6-26

Specifications, Continued

Main Current Transformers for the Motor Circuit

Relays

0 Protection current transformer (P = Protection):

1% error at rated current (I

e

)

5% error at rated overcurrent (10 I

e

)

Rated thermal current = 120% I

e

With starting current 10 I

e

: class 5 P 20

The current transformer error adds up to the Bulletin 825 error.

O 2.5A with Cat. No. 825-MCM2, 20A with Cat. No. 825-MCM20.

O Max. rated current of fuse: rapid (D) 16A; slow (DT) 10A.

When Cat. No. 825-M is used as secondary relay with

Cat. No. 825-MCM2/825-MCM20

Recommended c.t. in the phase

Min. nominal service voltage Nominal service voltage of motor

Min. rated primary current I

th

Nominal service current of motor

Rated secondary current 1A or 5A

Class and nominal overcurrent factor 5 P 10 ext. 120% 0

Power rating According to power consumption in leads and measuring circuits

Rated frequency (Hz) 50/60

Burden: Cat. No. 825-M + 825-MCM2 Cat. No. 825-M + 825-MCM20

Power consumption at max. rated current O 0.1 VA/phase 0.4 VA/phase

Thermal limit current cont. (A) 3 24

Thermal limit current 1 s (A) 250 600

Frequency of input current (Hz) 50/60 50/60

General notes on Bulletin 825

No-load Secondary no-load permitted, as burden is mounted in detection module

Contact data of output relays

Main relay (MR) 95...96

Contacts tted 1 N.C. and 1 N.O. galv. separated

Service voltage [V] 24 48 60 110 220/230 240 380 415 440

Per CSA, UL: pilot duty 240V

Continuous thermal current [A] 4 4 4 4 4 4 4 4 4

Rated service current AC [A] 4 4 4 4 3 3 2 2 1.5

Rated service current DC

Without prot. network, L/R = 35 ms [A] 0.6 0.3 0.25 0.15 0.05 0.05

With prot. network O, L/R = 100 ms [A] 0.6 0.6 0.5 0.5 0.5 0.5

Max. permissible switching current [A] 44 44 44 44 33 33 22 22 16.5

Alarm relay (AL), Auxiliary relay #1, #4, #5

Contacts tted 1 N.O. each

Continuous thermal current (A) 4

Max. permissible switching voltage 400V AC/125V DC

Nominal service current

cos = 1 4A at 250V AC or 30V DC

cos = 0.4, L/R = 7 ms 2A at 250V AC or 30V DC

Max. switching power

cos = 1 1250 VA/150W

cos = 0.4, L/R = 7 ms 500 VA/60W

Per CSA/UL 240V; 1A pilot duty

Auxiliary relay #2, #3

Contacts tted 1 N.O. each

Continuous thermal current (A) 4

Max. permissible switching voltage 50V AC/30V DC

Max. switching power (W)

cos = 1 150

cos = 0.4, L/R = 7 ms 60

Product Overview Page 6-20

Product Selection Page 6-21

Accessories Page 6-22

Approximate Dimensions Page 6-29

Bulletin 825

Smart Motor Manager

6-27

Specifications, Continued

Supply

Core Balance Current Transformer

Environmental

Ambient Conditions

Terminals

Nominal supply voltage U

s

50/60 Hz; 110V, 220240V, 380415V, 440V

2448V DC

Permissible voltage uctuation

AC 0.851.1 U

s

DC 0.801.1 U

s

Power consumption

AC 13 VA

DC 10W max.

Short-circuit protection

appropriate conductor cross-section of cable

the supply module is self-protected against short circuits

Recommended data for core balance current transformer

Burden: Measuring circuit Bulletin 825-M

Power consumption at rated current (0.5A) 0.4 VA

Limiting thermal current, continuous 0.5 VA

Limiting thermal current for 1 s (A) 25

Frequency of input current (Hz) 50/60

Temperature

Operation 5+60C (+23+140F)

Storage 40+60C (40+140F)

Transport 40+60C (40140F)

Climatic sensitivity

Damp heat IEC 68-2-3 40C (104F), 92% rel. humidity, 56 days

Climatic cycling IEC 68-2-30 25/40 C (77/140F), 21 cycles

Degree of protection

Cat. No. 825-M, enclosed in panel IP65

Terminals IP20

Resistance to vibration

Per IEC 68-2-6 10150 Hz, 3g

Resistance to shock

Per IEC 68-2-27 30g, shock duration 18 ms, semisinusoidal in x-, y-, z- directions

Bulletin 825 plug-in terminals Range of cross-section:

0.52.5 mm

2

, single wire (20 AWG14 AWG)

0.51.5 mm

2

, double wire (20 AWG14 AWG)

Per UL 2014 AWG

Per VDE

Nominal 1.5mm

2

(.0023 in

2

)

Main circuit

Cat. No. 825-MCM2/825-MCM20 Terminals:

2 x 2.5mm

2

/1 x 4 mm

2

(2 x .0039 in

2

/1 x .006 in

2

)

2 x AWG 2014/1 x AWG 2012

Cat. No. 825-MCM180

Insertion opening: max. 19mm (25/32in.) or current bars 20 x 4mm

(51/64 x 5/32in.)

Cat. No. 825-MCM630 Current bars 25 x 8mm (63/64 x 21/64 in)

Nominal ratio K

n

=

minimum detectable ground (earth) fault

pickup current of ground (earth) fault prot. Cat. No. 825-M

Product Overview Page 6-20

Product Selection Page 6-21

Accessories Page 6-22

Approximate Dimensions Page 6-29 Continued on next page.

Bulletin 825

Smart Motor Manager

6-28

Specifications, Continued

Adjustable Setting Characteristic

Power Supply Module Cat. No. 825-MPS

Identication Instrument Cat. No. 825-MTUM for Thermal Utilization

The degree of inertia can be set to

match the properties of the motor. A

suitable reference value, among others,

is the admissible locked-rotor time of

the cold motor in conjunction with the

associated current. This makes it

possible to protect motors which are

thermally very rapid or very slow.

The thermal capacity of the iron is

particularly important at small

overloads. Allowance for it in the

thermal image enables the overload

reserves of the motor to be utilized

without risking a premature trip.

Time/current characteristics of the

electronic motor protection system Cat.

No. 825-M (from the cold state)

t

A

Tripping time in s

I

e

Rated service current of the motor

= I

eF

a Lock-Rotor current; setting range

I

A

= 2.5...12I

e

b Inertia: Setting range with

appropriate set locked-rotor

current t

IA

= 1600 sec

Note: The setting of I

A

/t

IA

must be

outside the range b (e.g.

when I

A

= 6 x Ie, t

IA

must

be 100 s)

Technical Data AC and DC Power Supply Modules

Admissible voltage uctuation

AC 0.851.1 U

s

DC 0.801.1 U

s

Power consumption

AC 13 VA

DC 10 max.

Short circuit protection The power supply module is short circuit proof

Front 96 x 96mm (3-25/32 x 3-25/32 in.)

Panel cutout

91.5 x 91.5mm (0mm/+ 0.5mm)

(3-39/64 x 3-39/64 in.) (0/+ 1/64 in.)

Mounting depth 55mm (2-11/64 in.)

Product Overview Page 6-20

Product Selection Page 6-21

Accessories Page 6-22

Approximate Dimensions Page 6-29

Bulletin 825

Smart Motor Manager

6-29

Approximate Dimensions

Flush Mounting (or Panel Mounting Frame)

0 For DIN rail mounting EN 50022 35 x 15, order 35 x 7.5.

O Cat. No. 825-MCM180 with busbars or 19mm (3/4 in.) openings for looping the conductors.

O See page 6-22 for Cat. No. 825-MCM180 bus bars.

Approximate Shipping Weight

Dimensions are shown in millimeters

(inches).

The Cat. No. 825-M is suited for ush

mounting as well as for surface mounting.

Surface Mounting

For surface mounting, the Cat. No. 825-M

may be mounted into the panel mounting

frame Cat. No. 825-FPM. The Cat. No.

825-FPM is equipped with a hinge, allowing

to swing it out by 90. The terminals are

accessible and it is not necessary to

dismount the unit.

Cat. No. A B C D E F G H J K L

825-MCM2

120

(4-45/64)

85

(3-23/64)

102

(4-1/64)

66

(2-39/64)

5.3

(7/32)

5.3

(7/32)

100

(3-15/16)

55

(2-11/64)

1x4mm

2

(1 x 5/32)

38.5

(1-33/64)

825-MCM20

120

(4-45/64)

85

(3-23/64)

102

(4-1/64)

66

(2-39/64)

5.3

(7/32)

5.3

(7/32)

100

(3-15/16)

55

(2-11/64)

1x4mm

2

(1 x 5/32)

38.5

(1-33/64)

825-MCM180

120

(4-45/64)

100

(3-7/8)

102

(4-1/64)

72

(2-27/32)

5.3

(7/32)

5.3

(7/32)

100

(3-15/16)

55

(2-11/64)

O O

38.5

(1-33/64)

825-MCM630

155

(6-7/64)

145

(5-11/16)

156

(6-9/64)

118

(4-21/32)

6.3

(1/4)

6.3

(1/4)

135

(5-21/64)

88

(3-15/32)

11

(7/16)

M10

48

(1-57/64)

Cat. No. kg (lbs) Cat. No. kg (lbs)

825-MCM2 0.570 (1.27) 825-PTL2 0.04 (0.09)

825-MCM20 0.570 (1.27) 825-PTL4 0.045 (0.1)

825-MCM180 0.860 (1.9) 825-PCB1 0.095 (0.2)

825-MCM630 3.12 (6.88) 825-PCE 0.02 (0.04)

825-MVM 0.230 (0.51) 825-CBC 0.015 (0.03)

825-PTS 0.075 (0.17)

138

(5-7/16)

144

(5-43/64)

144

(5-43/64)

170

(6-11/16)

6.5

(1/4)

150

(5-29/32)

170

(6-11/16)

185

(6-1/2)

138

(5-3/16)

170

(6-11/16)

Mounting Depth

137

(5-25/64)

149

(5-55/64)

139

(5-15/32)

10

(25/64)

E

J

F

L L

G

A

HBB

I

C

D

A

G

L L

F

E

J

HB

K

D

C

Cat. No.

825-MCM2825-MCM180

Cat. No. 825-MCM630

0

O

Product Overview Page 6-20

Product Selection Page 6-21

Accessories Page 6-22

Specifications Page 6-24

Bulletin 1409

Arcing Ground Fault Detection System

6-30

6

Bulletin 1409

Adjustable Trip From

16A for Maximum

Sensitivity Without

Nuisance Tripping

Output Form C Contact

(Single-Pole

Double-Throw) for

Application Flexibility

Time Delay of 50 ms

Nominal to Minimize

Nuisance Tripping and

Allow Time for High

Current Inhibit

Test Circuit is Built In to

Test System for Proper

Specifications

TABLE OF CONTENTS

Description Page Description Page

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

Approximate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-33

Description

Low level (arcing) ground faults are below the fuse or circuit breaker rating and

therefore go undetected until a much larger problem develops. The Allen-Bradley

Arcing Ground Fault Detection System is designed to sense these low level faults

and either drop out the motor controller or operate a shunt-trip circuit breaker to clear

the fault.

The Bulletin 1409 Arcing Ground Fault Detection Systems are intended for equipment

protection only. These systems are not Ground-Fault Circuit-Interrupters for

personnel protection as dened in Article 100 of the U.S. National Electric Code.

The Bulletin 1409 is available in two designs, Class I and Class II. The Class I Arcing

Ground Fault Detection Systems are intended for use with shunt-trip circuit breakers

or medium voltage controllers. These Class I systems do not contain a high current

inhibit circuit.

The Class II Arcing Ground Fault Detection Systems are designed for use with motor

starters or contactors (controllers) to interrupt low level ground faults. These detection

systems incorporate a high current inhibit circuit which guards against the controller

opening when the fault current exceeds the controller interrupting capacity. Ground

fault currents exceeding the interrupting rating of the controllers are designed to be

cleared by the short circuit protection device (fuse or circuit breaker).

Both Class I and Class II Arcing Ground Fault Detection Systems consist of two

parts a relay and a sensor. The Arcing Ground Fault Relay contains all the

detection, adjustment and output circuitry. The Arching Ground Fault Sensor is a

special two-winding current transformer. Operation of the ground fault detection

system is indicated by the relay toggle.

Approvals:

Your order must include:

Cat. No. of the arching ground fault

relays and sensor selected.

CSA Certied

UL Listed

Arcing Ground Fault Relay

Cat. No. 1409-DOBD

Arcing Ground Fault Sensor

Cat. No. 1409-N2

Bulletin 1409

Arcing Ground Fault Detection System

6-31

Product Selection

Arcing Ground Fault Relays Class II with High Current Inhibit Feature

Arcing Ground Fault Sensors

0 For a 3-phase system with one cable per phase except as indicated.

O 8000V cable select sensor to have a window diameter greater than 2.5 times the cable diameter.

Arcing Ground Fault Relays Class I without High Current Inhibit Feature

Note: Interrupting capacity is determined by starter or circuit breaker selection.

NEMA

Starter

Size

Maximum

Voltage (V)

AC

Maximum

HP

Full Load

Current

(A)

High Current

Inhibit (A)

Cat No. Min. Max.

1

200230 7.5 27 114 144 1409-BOAD

460 10 14 63 79 1409-BOBD

575 10 11 50 62 1409-BOCD

2

200230 15 45 189 239 1409-COAD

460 25 34 153 193 1409-COBD

575 25 27 122 153 1409-COCD

3

200230 30 90 360 456 1409-DOAD

460 50 65 293 370 1409-DOBD

575 50 52 234 296 1409-DOCD

4

200230 50 135 585 741 1409-EOAD

460 100 124 558 706 1409-EOBD

575 100 99 446 564 1409-EOCD

5

200230 100 270 1116 1413 1409-FOAD

460 200 240 1080 1368 1409-FOBD

575 200 192 864 1094 1409-FOCD

6

200230 200 540 2160 2736 1409-GOAD

460 400 465 2147 2718 1409-GOBD

575 400 372 1719 2177 1409-GOCD

NEMA

Starter

Size

Maximum Recommended

Cable Size 0

Window

Diameter Cat. No.

12 2 AWG @ 600V AC 1-9/16 1409-N1

34

250 MCM @ 600V AC

2-1/2 1409-N2 4/0 @ 5000V AC

4/0 @ 8000V AC O

5

500 MCM @ 600V AC

3-1/4 1409-N3 350 MCM @ 5000V AC

350 MCM @ 8000V AC O

6

2-500 MCM @ 600V AC

4-1/4 1409-N4 500 MCM @ 5000V AC

500 MCM @ 8000V AC O

Application Max. Line Voltage (V) Cat. No.

Shunt-Trip

Circuit Breaker

600

1409-MV

Medium Voltage

Controller

7200

Prices Consult Sales Office or price list

Bulletin 1409

Arcing Ground Fault Detection System

6-32

Specifications

Technical Data

Typical Wiring Diagrams

(See Applicable Codes and Laws)

0 Wiring diagrams are shown in the tripped condition.

Response Time 50 milliseconds nominal plus the controller drop-out time

Supply Voltage 120V AC, 60 Hz

Power Input 3VA

Temperature Range

The operating ambient temperature range for the sensor is 40C+85C (40F+184F) and for

the relay is 0C+65C (+32F+149F)

Output Contact Rating Make 30A; Break 3A; Continuous carrying current 5A at 120V

M

N0

NC

C

L1

L2

CT4

CT3

GND

CT2

CT1

Internal

Printed Circuit

Ground Fault Relay

Internal Circuit

Breaker

Load

On Off

Line

N0

NC

C

Test

Winding

Operate

Winding

Motor

CT1

CT2

CT3

CT4

Ground

Fault

Sensor

Pilot

Device

Ind.

Light

OL s

To

Source of

120V, 60Hz

Control

Voltage

OL's

To Disconnect &

Source of Power

L1 L2 L3

M M M

Sensor

Fault

Ground

CT4

CT3

CT2

CT1

Motor

Winding

Operate

Winding

Test

C

NC

N0

Line

Off On

Load

Breaker

Internal Circuit

Ground Fault Relay

Printed Circuit

Internal

CT1

CT2

GND

CT3

CT4

L2

L1

C

NC

N0

To

120V,

60Hz

Shunt

Trip

Power

Source

Motor

Controller

Contacts

Circuit

Breaker

Source

of

Power

Internal

Coil Clearing

Contact

Typical when used with

shunt trip circuit breaker

Class II with High Current Inhibit Circuit 0

Class I without High Current Inhibit Circuit 0

Bulletin 1409

Arcing Ground Fault Detection System

6-33

Approximate Dimensions

Dimensions are shown in millimeters (inches). Dimensions are not intended to be used for manufacturing purposes.

Arcing Ground Fault Relay

Arcing Ground Fault Sensors

Cat. No. A B C D E F G H J K

1409-N1

92.6

(3-21/32)

88.9

(3-1/2)

104

(4-3/32)

74

(2-15/16)

67.3

(2-21/32)

56.4

(2-7/32)

92.9

(3-21/32)

39.6

(1-9/16)

1409-N2

91.4

(3-19/32)

115.8

(4-9/16)

131.8

(5-3/16)

77

(3-1/32)

88.9

(3-1/2)

88.9

(3-1/2)

120.6

(4-3/4)

63.5

(2-1/2)

69.8

(2-3/4)

54.9

(2-5/32)

1409-N3

73.2

(2-7/8)

144

(5-11/16)

157.2

(6-3/16)

54.9

(2-5/32)

96.8

(3-13/16)

119.4

(4-23/32)

146.1

(5-3/4)

82.6

(3-1/4)

1409-N4

77.2

(3-1/32)

169.9

(6-11/16)

182.6

(7-3/16)

59.5

(2-11/32)

123.7

(4-7/8)

138.2

(5-7/16)

171.5

(6-3/4)

108

(4-1/4)

154 (6-1/16)

114 (4-1/2)

111(4-3/8)

Use (4) #832 Screws for Mounting

89 (3-/12)

79.5 (3-1/8)

4.8 (3/16)

20 (25/32)

F

C

G

E B

A

D

J

K

H Dia.

4 Open Slots

4 Closed

Slots 12.7 (1/2) x

(1409N2 Only)

5.6(7/32) Dia.

Cat. No. 1409-N1: 12.7 (1/2) x 7.1 dia. (9/32)

Cat. No. 1409-N2: 12.7 (1/2) x 11.1 dia. (7/16)

F

F

C

G

H Dia.

B E

D

A

4 Holes

(13/32) Dia.

10.3

4 Open Slots

11.9 (15/32)

X

5.6 (7/32)

For

#10 Screws

Cat. No. 1409-N3

Cat. No. 1409-N4

Bulletin 1410

Motor Winding Heater

6-34

6

Bulletin 1410

Solid-State Design

Automatic Operation

No Adjustments

Required

TABLE OF CONTENTS

Description Page Description Page

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Approximate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-35

Description

Bulletin 1410 Motor Winding Heater is intended for use with 3-phase AC motors to

guard against damage caused by condensation build-up on motor windings, which

can occur in high humidity environments during motor off times. This device is not

intended to be used to dry out damp motors.

Bulletin 1410 Motor Winding Heater is designed for use with 3-phase AC squirrel

cage motors controlled by automatic full voltage starters. For applications involving

reduced voltage starters, multi-speed starters, synchronous motors, or the use of

power factor correction capacitors, consult your Allen-Bradley Distributor or Sales

Ofce representative.

Approvals:

Your order must include:

Cat. No. of the motor winding heater

selected.

CSA Certied

UL Listed

Motor Winding Heater

Bulletin 1410

Motor Winding Heater

6-35

Product Selection 0

0 For applications requiring different horsepower, kilowatt and voltage ranges than those listed, consult Allen-Bradley Sales Office.

Approximate Dimensions

Dimensions are shown in millimeters (inches). Dimensions are not intended to be used for manufacturing purposes.

Motor Voltage (V)

+10%, 15%

3-Phase, 60 Hz Motor HP Range Cat. No.

230

460

575

1550

25100

25100

1410-EOA47

1410-EOB50

1410-EOC50

230

460

575

50100

100200

100200

1410-FOA50

1410-FOB54

1410-FOC54

230

460

575

100200

200400

200400

1410-GOA54

1410-GOB59

1410-GOC59

230

460

575

200300

400600

400600

1410-HOA57

1410-HOB62

1410-HOC62

Specications Connection Diagram

(See Applicable Codes and Laws)

Output Voltage Regulation

Voltage applied to motor winding will

vary 5% maximum for line voltage

variations of +10%, 15%.

Ambient Temperature Range

Operating:

Storage:

+0C+50C (+32F+122F)

25C+85C (13F+184F)

Additional SCR Protection

Metal oxide varistor protects against

voltage surges. RC snubber circuit

limits rate of change of circuit

voltage.

True RMS Output Current

Approximately 15% of full load

current.

Power Delivered to the Motor Approximately 1 to 3 watts/HP.

Cat. No. A B C

1410-EOA47

1410-EOB50

1410-EOC50

146.1

(5-3/4)

88.9

(3-1/2)

114.3

(4-1/2)

1410-FOA50

1410-FOB54

1410-FOC54

204.8

(8-1/16)

108

(4-1/4)

177.8

(7)

1410-GOA54

1410-GOB59

1410-GOC59

238.1

(9-3/8)

146.1

(5-3/4)

206.4

(8-1/8)

1410-HOA57

1410-HOB62

1410-HOC62

279.4

(11)

244.5

(9-5/8)

207.2

(8-5/32)

FC1 LT2

L3

FU2

FU1

LT3

L2

Fuse

Condition

Indicator

(Optional)

L2

To To To To

Motor

Starter

Contacts

L3

"LT2 "LT3

Motor

To

L3 LT3

T3

L2 LT2

T2

M

T1

OL's

LT1 L1

Protection

Circuit

Branch

Motor

Motor Winding Heater

A

B

C

Prices Consult Sales Office or price list

Bulletin 1497

Control Circuit Transformers

6-36

6

Bulletin 1497

Available

From 502000 VA

TABLE OF CONTENTS

Description Page Description Page

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37 Approximate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-38

Description

Control transformers are used to provide reduced voltage for control circuits in

control panels.

Transformers for use with Bulletin 100 products from 50 through 500 VA are

supplied with an attached primary and secondary fuse block which also includes

a secondary fuse.

Transformers for use with Bulletin 500 products from 50 through 500 VA are supplied

with an attached secondary fuse block which also includes a secondary fuse.

Your order must include:

Cat. No. of the control circuit

transformer selected.

Cat. No. 1497-N2P

75 VA Transformer

For Use With Bulletin 100 IEC Products

Cat. No. 1497-N12

350 VA Transformer

For Use With Bulletin 500 NEMA Products

Bulletin 1497

Control Circuit Transformers

6-37

Product Selection

Control Circuit Transformers Used with Bulletin 100 IEC Products

Provided with a primary and secondary fuse block

Control Circuit Transformers Used with Bulletin 500 NEMA Products

Provided with a secondary fuse block

Regulation Data

0 Also rated 220/440V Primary, 110V Secondary 50/60 Hz.

O Also rated 550V Primary, 110V Secondary 50/60 Hz.

O This fuse block only mounts to Allen-Bradley 1497-N__ transformers of 750VA and below.

O Dimensions of laminations comprising stack in inches.

Continuous VA

Cat. Nos.

Primary

208V 60 Hz

Primary

240/480V 60 Hz

Primary

600V 60 Hz

Secondary

120V 60 Hz

Secondary

24V 60 Hz

Secondary

120V 60 Hz 0

Secondary

24V 60 Hz

Secondary

120V 60 Hz O

Secondary

24V 60 Hz

50

75

130

200

250

350

500

1497-N28P

1497-N1P

1497-N15P

1497-N4P

1497-N7P

1497-N10P

1497-N18P

1497-N45P

1497-N48P

1497-N51P

1497-N54P

1497-N57P

1497-N60P

1497-N63P

1497-N27P

1497-N2P

1497-N16P

1497-N5P

1497-N8P

1497-N11P

1497-N19P

1497-N46P

1497-N49P

1497-N52P

1497-N55P

1497-N58P

1497-N61P

1497-N64P

1497-N29P

1497-N3P

1497-N17P

1497-N6P

1497-N9P

1497-N12P

1497-N20P

1497-N47P

1497-N50P

1497-N53P

1497-N56P

1497-N59P

1497-N62P

1497-N65P

Continuous VA

Secondary

24V 60 Hz Cat. Nos.

Primary

208V 60 Hz

Primary

240/480V 60 Hz

Primary

600V 60 Hz

Secondary

120V 60 Hz

Secondary

24V 60 Hz

Secondary

120V 60 Hz

Secondary

24V 60 Hz

Secondary

120V 60 Hz

Secondary

24V 60 Hz

50

75

130

200

250

350

500

750

1000

1500

2000

1497-N28

1497-N1

1497-N15

1497-N4

1497-N7

1497-N10

1497-N18

1497-N33

1497-N36

1497-N39

1497-N42

1497-N45

1497-N48

1497-N51

1497-N54

1497-N57

1497-N60

1497-N63

1497-N27 0

1497-N2 0

1497-N16 0

1497-N5 0

1497-N8 0

1497-N11 0

1497-N19 0

1497-N34 0

1497-N37

1497-N40

1497-N43

1497-N46

1497-N49

1497-N52

1497-N55

1497-N58

1497-N61

1497-N64

1497-N29 O

1497-N3 O

1497-N17 O

1497-N6 O

1497-N9 O

1497-N12 O

1497-N20 O

1497-N35 O

1497-N38

1497-N41

1497-N44

1497-N47

1497-N50

1497-N53

1497-N56

1497-N59

1497-N62

1497-N65

Primary Fuse Block

Panel Mount Only

2-Pole (30A/600V)

1491-R162

Secondary Fuse Block

Panel Mounting Only

2-Pole (30A/600V)

1491-N162

Secondary Fuse Block O

Transformer Mounting Only

1-Pole (30A/250V)

1491-N100

Inrush VA at 40% Power Factor Power Factor Adjustments

Rated VA Hz Stack O Cat. No. 85% 90% 95% Power Factor Multiply By

50 50 1.000 1497-N27, -N27P 347 289 216 100% .64

75 50 1.375 1497-N2, -N2P 338 290 229 90% .67

130 50 2.000 1497-N16, -N16P 907 745 541 80% .71

200 50 1.625 1497-N5, -N5P 1267 1039 754 70% .78

250 50 2.188 1497-N8, -N8P 1394 1116 781 60% .82

350 50 3.000 1497-N11, -N11P 2870 2298 1584 50% .91

500 50 2.625 1497-N19, -N19P 3786 3013 2065 40% 1.00

750 50 4.375 1497-N34 7360 5763 3786 30% 1.11

1000 60 3.250 1497-N37 8837 6785 4329 20% 1.29

1500 60 3.625 1497-N40 14921 11328 7070 10% 1.50

2000 60 1497-N43

Prices Consult Sales Office or price list

Bulletin 1497

Control Circuit Transformers

6-38

Approximate Dimensions and Shipping Weights

Control Circuit Transformers Used with IEC Products

Dimensions are in millimeters (inches). Dimensions are not intended for manufacturing purposes.

0 Electrical clearance required to top of fuse block.

Cont. V.A.

Dimensions in mm (inches) Approximate

Shipping

Wt. kg (lbs.) A B C D E F G H 0

50

92.07

(3-5/8)

57.15

(2-1/4)

79.38

(3-1/8)

95.25

(3-3/4)

5.56

(7/32)

11.11

(7/16)

85.72

(3-3/8)

116.72

(4-19/32)

1.8

(3.9)

75

104.78

(4-1/8)

60.33

(2-3/8)

71.44

(2-13/16)

85.72

(3-3/8)

5.56

(7/32)

7.94

(5/16)

73.03

(2-7/8)

104.03

(4-3/32)

1.9

(4.2)

130

117.47

(4-5/8)

82.55

(3-1/4)

79.38

(3-1/8)

95.25

(3-3/4)

5.56

(7/32)

11.11

(7/16)

84.14

(3-5/16)

115.14

(4-17/32)