Professional Documents

Culture Documents

Amm CH24

Uploaded by

Diego TorresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amm CH24

Uploaded by

Diego TorresCopyright:

Available Formats

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

D

Chapter Section Subject

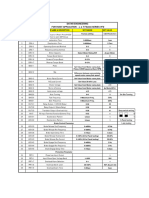

ELECTRICAL POWER LIST OF EFFECTIVE PAGES Chapter Section Subject

24 Effective Pages

Config

Page

1 2 3 4 * * *

Date

May 15/2008 May 15/2008 Aug 15/2007 May 15/2008 Oct 20/2004 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 DELETED May 28/2004 May 28/2004 May 28/2004 May 28/2004 Oct 20/2004 Oct 20/2004 May 28/2004 Dec 15/2007 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004

Config

Page

9 10 11 12 13 14 15

Date

May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004 Oct 20/2004 * * * * * * * * * * * * * * * * * * * * * * * May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 Oct 20/2005 Mar 15/2006 Oct 20/2005 Oct 20/2005

24 Contents

1 2 3 4 5 6 7 8 9 10 11 12 13 1 2 3 4 201 202 1 201 202 203 1 2 3 4 5 6 7 8

* * * * * * * * * * * *

242101

201 202 1 201 202 203 204 205 206 207 208 209 210 211 212 213 214 215 216 217 218 219 220 221 222 223 201 202 203 204

242102 242102

240000

240000

242000 242100

242101

242105

MASTER EFFECTIVITY: ALL

24Effective Pages

Page 1 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

D

Chapter Section Subject

Chapter Section Subject

242107

Config

Page

201 202 203 204 1 2 3 4 5 6 7 8 201 202 203 204 205 206 207 208 201 202 203 204 1 2 3 1 2 3 4 5 6 7 8 9 10 * * * * * * * *

Date

Oct 20/2005 Mar 15/2006 Oct 20/2005 Oct 20/2005 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 28/2004 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 May 15/2008 DELETED Jul 15/2006 Jul 15/2006 Jul 15/2006 Jul 15/2006 May 28/2004 May 28/2004 May 28/2004 Oct 20/2004 Oct 20/2004 Aug 15/2007 Oct 20/2004 Oct 20/2004 Oct 20/2004 Oct 20/2004 Oct 20/2004 Oct 20/2004 Oct 20/2004

Config

Page

11 12 13 14 15 16 17

Date

Oct 20/2004 Oct 20/2004 Oct 20/2004 Oct 20/2004 Oct 20/2004 Oct 20/2004 Oct 20/2004 Apr 15/2007 Apr 15/2007 Apr 15/2007 Aug 15/2007 Jun 20/2005 Jun 20/2005 Oct 20/2004 Oct 20/2005 Mar 15/2006 Oct 20/2005 Oct 20/2004 Oct 20/2004 Oct 20/2004 Oct 20/2004 Mar 15/2006 Mar 15/2006 Mar 15/2006 Mar 15/2006 Mar 15/2006 Mar 15/2006 Mar 15/2006 Mar 15/2006 Aug 15/2007 Aug 15/2007 Aug 15/2007

242201

243100

201 202 203 201 202 203 201 201 202 203 201 202 203 204 201 202 203 204 201 202 203 204 201 202 203

243101

242201

243102 243103

242203

243104

243000

243105

243100

243107

243108

MASTER EFFECTIVITY: ALL

24Effective Pages

Page 2 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

D

Chapter Section Subject

Chapter Section Subject

243201

Config

Page

1 2 3 4 5 201 202 203 204 205 206 207 1 2 3 201 202 1 2 3 4 201 202 1 2 3 201 202 1 2 3 4 5

Date

Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Oct 20/2004 Oct 20/2004 Oct 20/2004 Oct 20/2004 Oct 20/2004 Oct 20/2004 Oct 20/2004 Jul 27/2001 Jul 27/2001 Jul 27/2001

Config

Page

6 7 8 9 10

Date

Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 May 28/2004 May 28/2004 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Oct 20/2005 Mar 15/2006 Mar 15/2006 Mar 15/2006 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001

243201

244001

201 202 203 1 2 3 4 5 6 201 201 202 203 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

244901

243206

244901 243206 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 May 28/2004 May 28/2004 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Jul 27/2001 Oct 20/2004 Jul 27/2001 244903

243211

245001

243211

243216

243216

244001

MASTER EFFECTIVITY: ALL

24Effective Pages

Page 3 Aug 15/2007

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

D

Chapter Section Subject

Chapter Section Subject

245002

Config

Page

201 202 203 204 205 206 *

Date

May 15/2008 Oct 20/2005 Oct 20/2005 Oct 20/2005 Oct 20/2005 Oct 20/2005

Config

Page

Date

MASTER EFFECTIVITY: ALL

24Effective Pages

Page 4 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

ELECTRICAL POWER TABLE OF CONTENTS Chapter Section Subject 240000 1

Subject ELECTRICAL POWER GENERAL Description and Operation Description General Bus System Control Panels Circuit Breaker Panels Maintenance Practices Safety Precautions General Electrical/Electronic Safety Precautions Electrostatic Discharge Safety Precautions AC POWER GENERAL Description and Operation General AC VARIABLE FREQUENCY GENERATOR SYSTEM (MOD 8/0346 AND S.O.O. 8110) Maintenance Practices Removal/Installation Remove AC Generator Install AC Generator Adjustment/Test Initial Conditions Operational Test

Page

201

202 242000 1

242100 201

203

MASTER EFFECTIVITY: ALL

24Contents

Page 1 Oct 20/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

Subject AC VARIABLE FREQUENCY SYSTEM Description and Operation Description General Generator Generator Control Unit (GCU) AC Contactor Box Contactors Current Transformers AC Control AC Power Monitoring System Operation General Generator Operation Test AC Power Monitor System Abnormal Operation External Power Operation Maintenance Practices Removal/Installation Adjustment/Test Initial Conditions Operational Test AC CONTACTOR BOX Description and Operation Maintenance Practices Effectivity: ON A/C ALL General Removal/Installation of the AC Contactor Box Adjustment/Test Operational Test Of The External Power A. C. Bus Contactors and Associated Current Transformers

Chapter Section Subject 242101

Page

2 3

13

14 15 201

242102 1 201

206 216

MASTER EFFECTIVITY: ALL

24Contents

Page 2 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

Subject Procedure Operational Test Of The A. C. Bus Contactor and Associated Current Transformers Procedure Operational Test Of The External Power Protection Unit Procedure Operational Test Of The Remote Control Circuit Breaker (Pre Mod 8/2120) Producer Operational Test Of The K3 Relay (Post Mod 8/2120) Procedure Operational Test Of The A. C. Current Transformers Procedure Operational Test Of The Generator Control Units, Bus Contactors (GCU) and Associated Current Transformers AC SYSTEM CONTROL PANEL Maintenance Practices Effectivity: ON A/C ALL General Removal/Installation of the AC System Control Panel Adjustment/Test AC CONTROL PANEL Maintenance Practices Effectivity: ON A/C ALL General

Chapter Section Subject

Page 217

218

219

220

221 222

242105 201

204 242107 201

MASTER EFFECTIVITY: ALL

24Contents

Page 3 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

Subject Removal/Installation of the AC Control Panel Adjustment/Test AC 400 HZ SYSTEM Description and Operation Description General Static Inverters Paralleling Control Box Inverter Warning Control Box Autotransformers Caution Lights Inverter Control Power Monitoring Operation Normal Operation Test AC Power Monitor System Inverter Failure 26 Volt AC Bus Failure Maintenance Practices General Primary Inverter Removal/Installation Removal of the Primary Inverter Installation of the Primary Inverter Secondary Inverter Removal/Installation Removal of the Secondary Inverter Installation of the Secondary Inverter Auxiliary Inverter Removal/Installation Removal of the Auxiliary Inverter Installation of the Auxiliary Inverter Adjustment/Test

Chapter Section Subject

Page

204 242201 1

201

202

203

206

MASTER EFFECTIVITY: ALL

24Contents

Page 4 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

Subject Initial Conditions Operational Test 26 VAC AUTOTRANSFORMER Maintenance Practices Effectivity: ON A/C ALL General Removal of the Autotransformer Installation of the Autotransformer Operational Test of the Autotransformer DC POWER SYSTEM GENERAL Description and Operation Description General Bus System DC GENERATION SYSTEM Description and Operation Description General StarterGenerator Generator Control Unit Bus Bar Protection Unit Current Transformers DC Contactor Box DC Control DC Power Monitor System TransformerRectifier Units Operation General Generator Operation

Chapter Section Subject

Page

242203 201

204 243000 1

243100 1

4 7

MASTER EFFECTIVITY: ALL

24Contents

Page 5 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

Subject TRU Operation External DC Power Test DC Power Monitor System Failure Conditions Maintenance Practices Removal/Installation StarterGenerator Inspection/Check StarterGenerator Brushes Adjustment/Test Operational Test Generators DC GENERATION SYSTEM Maintenance Practices General Removal/Installation Remove the current limiter Install the current limiter BUS BAR PROTECTION UNIT Maintenance Practices BUS BAR PROTECTION UNIT REMOVAL INSTALLATION Bus Bar Protection Unit Removal Remove the Bus Bar Protection Unit (BBPU) as follows: Bus Bar Protection Unit Installation Install the Bus Bar Protection Unit (BBPU) as follows: Close Out

Chapter Section Subject

Page 8

201

243101 201

243102 201

MASTER EFFECTIVITY: ALL

24Contents

Page 6 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

Subject DC GENERATOR CONTROL UNIT Maintenance Practices Effectivity: ON A/C ALL General Removal/Installation of DC Generator Control Unit Removal of DC Generator Control Unit (GCU) Installation of the DC Generator Control Unit TRANSFORMER RECTIFIER UNIT Maintenance Practices Renoval/Installation Remove Transformer Rectifier Unit (TRU) Install Transformer Rectifier Unit (TRU). Adjustment/Test Operational Test Transformer Rectifier Units (TRU) DC SYSTEM CONTROL PANEL Maintenance Practices Effectivity: ON A/C ALL General Removal/Installation of the DC System Control Panel Adjustment/Test DC CONTROL PANEL Maintenance Practices Effectivity: ON A/C ALL General Removal/Installation of the DC Control Panel Adjustment/Test

Chapter Section Subject 243103

Page

243104 201

243105 201

202 243107 201

202

MASTER EFFECTIVITY: ALL

24Contents

Page 7 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

Subject DC CURRENT SHUNTS Maintenance Practices General Equipment and Materials Removal of the DC Current Shunts Installation of the DC Current Shunts BATTERY SYSTEM Description and Operation Effectivity: ON A/C ALL Description General Battery Control Circuit Operation Maintenance Practices Effectivity: ON A/C ALL Removal/Installation General Remove Battery Install Battery Removal/Installation General Remove Battery Install Battery Adjustment/Test Initial Conditions Operational Test BATTERY VENTING SYSTEM Description and Operation Effectivity: ON A/C ALL General

Chapter Section Subject 243108

Page

243201 1

2 201

202

203 207

243206 1

MASTER EFFECTIVITY: ALL

24Contents

Page 8 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

Subject Maintenance Practices Effectivity: ON A/C ALL Removal/Installation Remove Battery Sump Jar Install Battery Sump Jar Inspection/Check Check Battery Venting System Cleaning/Painting Clean Battery Sump Jar BATTERY TEMPERATURE MONITOR SYSTEM Description and Operation Effectivity: ON A/C ALL Description Battery Temperature Monitor Temperature Sensors Overheat Lights Electrical Power Operation Self-Test Maintenance Practices Effectivity: ON A/C ALL Removal/Installation General Adjustment/Test Operational SelfTest BATTERY CHARGER SYSTEM (SOO 8095) Description and Operation Effectivity: ON A/C ALL Description General

Chapter Section Subject

Page 201

243211 1

201

243216 1

MASTER EFFECTIVITY: ALL

24Contents

Page 9 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

Subject Operation General Maintenance Practices Effectivity: ON A/C ALL Removal/Installation General Remove Isolation Diode (CR1) Install Isolation Diode (CR1) Remove Temperature Sensor Switches Install Temperature Sensor Switches Adjustment/Test Operational Test, Battery Charger System EXTERNAL POWER Description and Operation Effectivity: ON A/C ALL General External DC Power Description Operation External AC Power Description Operation Maintenance Practices Effectivity: ON A/C ALL Adjustment/Test Operational Test DC External Power Operational Test External Power, DC Through TRUs Operational Test AC External Power

Chapter Section Subject

Page

201

202

244001 1

8 9 201

202 203

MASTER EFFECTIVITY: ALL

24Contents

Page 10 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

Subject APU DC GENERATION Description and Operation Effectivity: ON A/C ALL Description Power Supplies and Grounds Operation General Normal Operation Power Monitoring Fault Indications Maintenance Practices Effectivity: ON A/C ALL Removal/Installation Adjustment/Test Operational Test APU DC GENERATOR CONTROL UNIT (GCU) Maintenance Practices Effectivity: ON A/C ALL General Removal/Installation of APU DC Generator Control Unit Removal of APU DC Generator Control Unit (GCU) Installation of the APU DC Generator Control Unit ELECTRICAL LOAD DISTRIBUTION Description and Operation Effectivity: ON A/C ALL General Circuit Breaker Panels

Chapter Section Subject 244901

Page

201

244903 201

202

245001 1

MASTER EFFECTIVITY: ALL

24Contents

Page 11 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

Subject Left DC Circuit Breaker Panel Right DC Circuit Breaker Panel 115V AC VARIABLE FREQUENCY Circuit Breaker Panel Avionics Circuit Breaker Panel STANDBY POWER UNIT, AC POWER CONTROL Maintenance Practices Effectivity: ON A/C 402, 404408, 410, 412, 414416, 420, 422423, 438, 442443, 451, 458, 462, 464, 466467, 474, 481, 483, 485, 487, 489, 491, 493, 495, 499, 503, 505, 508, 517, 519, 521, 523, 525, 527, 531535, 538539, 543546, 548549, 552557, 560565, 567571, 573578, 580592, 594605, 607611, 613625, 627636, 638645, 647648, 650654, 656660, 662663, 667672 General Removal/Installation of AC Power Control Unit For The SPU HYD. Removal of AC Power Control Unit Installation of AC Power Control Unit Removal/Installation of the Contactor Relay (2921K1) Removal of Contactor Relay Installation of Contactor Relay

Chapter Section Subject

Page

245002 201

202 204

MASTER EFFECTIVITY: ALL

24Contents

Page 12 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

ELECTRICAL POWER GENERAL 1. Description A. General Electrical Power Systems Electrical Power is provided by the following systems: (1) A directcurrent (dc) generation system which provides 28 volts, generated by two enginedriven dc startergenerators and from a variable frequency ac system through two transformerrectifier units. These power sources are supplemented by two nickelcadmium (Nicad) batteries, one of 40 amperehour capacity, the other of 15 amperehour capacity. (Two 40 amperehour batteries with SOO 8070 incorporated). Provisions are included to power the system from an external (ground) power source. (2) The ac variable frequency power system provides 115/200 volts, 3phase alternating current power from two enginedriven ac generators. Provisions are also included to power this system from an external (ground) power source. (3) An ac 400 Hz system provides 115 volts single phase power, generated by three solidstate inverters using 28 volts dc input. Two stepdown autotransformers with 115 volt input from the inverter system provide 26 volts 400 Hz single phase power. B. Bus System Electrical power is distributed by the following bus system: (1) L and R DC Essential buses. (2) L and R DC Main buses. (3) L and R DC Secondary buses. (4) L and R AC 115V, 400 Hz buses. (5) L and R AC 26V, 400 Hz buses. (6) L and R AC 115/200V Variable Frequency buses. For emergency purposes, certain equipment is connected directly to the main battery, which is one of the power sources for the dc bus systems. C. Control Panels The electrical power systems are controlled by switches on the DC CONTROL and AC CONTROL panels on the overhead console. Adjacent to the two control panels are two power monitoring panels labeled DC SYSTEM and AC SYSTEM respectively, which provide digital voltage and load readouts for the systems. D. Circuit Breaker Panels Circuit breaker consoles are installed beside the pilot and copilot seats, outboard side. The circuit breaker panels for the dc main, essential and secondary buses are mounted on the top surfaces; left buses on the pilot side, right buses on the copilot side. The consoles each contain three shelves which mount the 400 Hz inverters and other powerrelated equipment. The avionics circuit breaker panel is mounted above and behind the pilots circuit breaker console, on the rear flight compartment bulkhead at Station X 111.05. The 115 V ac variable frequency circuit breaker panel is mounted on the copilots side in

MASTER EFFECTIVITY:

240000

Page 1 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

a similar position on the rear flight compartment bulkhead. Refer to ELECTRICAL LOAD DISTRIBUTION for details.

MASTER EFFECTIVITY:

240000

Page 2 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

ELECTRICAL POWER COMPONENT LOCATION Figure 1 (Sheet 1 of 2)

MASTER EFFECTIVITY:

240000

Page 3 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

ELECTRICAL POWER COMPONENT LOCATION Figure 1 (Sheet 2 of 2)

MASTER EFFECTIVITY:

240000

Page 4 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

See Effective TR

ELECTRICAL POWER MAINTENANCE PRACTICES 1. Safety Precautions A. General Unless detailed on applicable maintenance practices, removal and installation procedures for electrical equipment are considered selfevident. Equipment grounding and bonding surfaces must be cleaned to ensure good conductivity, and after installation any bared surfaces must be refinished. B. Electrical/Electronic Safety Precautions WARNING: FAILURE TO OBSERVE SAFETY PRECAUTIONS BEFORE CARRYING OUT MAINTENANCE PRACTICES ON OR NEAR ELECTRICALLY CONTROLLED OR OPERATED EQUIPMENT COULD RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT. The following safety precautions must be observed before removal or installation of electrical equipment, or unless otherwise detailed, when carrying out maintenance practices on electrically controlled or operated equipment in the aircraft. (1) Obey all local safety regulations during electrical system maintenance. (2) Make sure that the aircraft is correctly grounded. Connect a static ground to the aircraft at the grounding point on one of the two main landing gear drag strut crossbeams. (3) Make sure that the BATTERY MASTER, MAIN BATT, AUX BATT, and EXT PWR switches on the DC CONTROL panel and AC CONTROL panel are set to the OFF position. (4) Tag each switch that is in the OFF position as follows:

WARNING: DO NOT MOVE THIS SWITCH FROM THE OFF POSITION UNTIL THE MAINTENANCE TASK IS COMPLETED. (5) Open all applicable system circuit breakers necessary to do the maintenance task and put in clips to prevent pushtoreset, or disconnect the left and right batteries. (6) Tag each open circuit breaker as follows: WARNING: DO NOT CLOSE THIS CIRCUIT BREAKER UNTIL THE MAINTENANCE TASK IS COMPLETED. (7) If the units that are removed are not to be immediately replaced, make sure that the connector ends are capped and stowed, and all loose wires are insulated and stowed. (8) Do not use electrical test equipment that can cause sparks in areas where explosive gases can occur. (9) Make sure to align the electrical connector plug and connector pins before installation. This will prevent damage to the connector and pins. WARNING: MAKE SURE THAT ALL PERSONS IN THE AREA OF THE AIRCRAFT ARE TOLD BEFORE THE ELECTRICAL SYSTEM IS ENERGIZED. IF YOU DO NOT DO THIS, YOU CAN CAUSE INJURIES TO PERSONS OR DAMAGE TO EQUIPMENT. (10) After installation, reconnect batteries and external power source as applicable, remove the clips and close the circuit breakers. Do the operational test if necessary

MASTER EFFECTIVITY:

240000

Page 201 Oct 20/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

on the unit. (11) When a circuit breaker opens without sufficient cause, do the tasks that follow: (a) Do not close the circuit breaker until the source of the problem is identified and corrected. (b) If the open circuit breaker protects a threephase circuit breaker, open the other two circuit breakers. (c) Only close the circuit breaker after the source of the problem is identified and corrected. C. Electrostatic Discharge Safety Precautions WARNING: OBEY ALL THE SAFETY PRECAUTIONS WHEN YOU DO MAINTENANCE ON OR NEAR THE ELECTRICAL/ELECTRONIC EQUIPMENT. IF YOU DO NOT DO THIS, YOU CAN CAUSE INJURIES TO PERSONS AND/OR DAMAGE TO THE EQUIPMENT. (1) Obey all local safety regulations during maintenance procedures on electronic components that contain electrostaticsensitive devices. (2) Before maintenance is done on electrostaticsensitive discharge devices, make sure that all persons are correctly grounded. (3) Before maintenance is done on an electrostaticsensitive device, make sure that all persons read, fully know and understand the maintenance practices that follow. To keep the risk of damage to equipment to a minimum, carefully and accurately obey the practices that follow: (a) Remove all power, signal sources and electrical loads used with the unit. (b) Place the unit on a work surface that is grounded and can conduct electricity. (c) Ground the maintenance person through a conductorcontained wrist strap or other device. To prevent injury, the device must contain a 470 ohm series resistor. (d) Ground all tools that will touch the unit. A tool that touches your hand is sufficiently grounded, since it is electrically isolated. (e) Do not touch electrostatic sensitive devices and do not remove them from their packages until they are required.

MASTER EFFECTIVITY:

240000

Page 202 Oct 20/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

ACPOWER GENERAL 1. General Alternating current power is provided from two sources, a fixed frequency source (400 Hz) for instruments, navigation and communication equipment, and a variable frequency source for propeller deicing, auxiliary fuel pumps, standby hydraulic pumps, windshield heat and stall warning transducer heaters. The fixed frequency source is provided by static inverters, which convert dc power to 400 Hz ac. The variable frequency source is provided by two enginedriven ac generators.

MASTER EFFECTIVITY:

242000

Page 1 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY GENERATOR SYSTEM MAINTENANCE PRACTICES (MOD 8/0346 AND S.O.O. 8110). 1. Removal/Installation Refer to Figure 201. A. Remove AC Generator (1) Disconnect AC Generator electrical connectors 2421P1 and 2421P2. (2) Temporally secure AC Generator electrical connectors 2421P1 and 2421P2 away from AC Generator. (3) Remove AC Generator four securing nuts (12) and washers (11). (4) Separate AC Generator from generator mounting flange (4). (5) Remove and secure oil transfer tube (2 & 3), and O ring seals (5& 6) from generator mounting flange oil ports . (6) Remove splined drive shaft O ring seal from drive shaft. (7) Lift and remove AC Generator away from engine B. Install AC Generator CAUTION: MAKE SURE AC GENERATOR PRESSURE OIL TUBE ASSEMBLY IS INSTALLED AND SECURED TO THE AC GENERATOR DRIVEPAD. REFER TO ENGINE MAINTENANCE MANUAL. (1) Make sure that the AC generator strainer is clean (Refer to Chapter 055036). (2) Remove packing grease from generator splined drive. (3) Lubricate both O ring seals (5) with engine oil and install in the groove of the oil transfer tube (2) see Figure 201. (4) Lubricate both O ring seal (6) with engine oil and install in the groove of the oil transfer tube (3) see Figure 201. (5) Lubricate splined drive shaft and O ring seal (7) with engine oil. Install O ring seal (7) in the groove of the generator drive shaft, see Figure 201. (6) Lubricate O ring seal (8) with engine oil. Install O ring seal (8) in the groove of the AC generator see Figure 201. (7) Align generator with drive pad with electrical receptacles positioned at the top of the engine. Engaging oil transfer tube with oil transfer ports of the generator and mounting flange, Push generator toward the mounting flange (4), until generator meets mounting flange. (8) Secure generator with washers (11) and nut (12). Torque nuts to 130 to 150 poundinches see Figure 201. (9) Connect and tighten AC generator electrical connectors 2421P1 and 2421P2.

MASTER EFFECTIVITY:

242100

Page 201 Dec 15/2007

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC GENERATOR PRESSURE OIL TUBE ASSEMBLY

6

3

AC GENERATOR REMOVAL AND INSTALLATION (MOD 8/0346 AND SOO 8110) Figure 201

MASTER EFFECTIVITY:

242100

Page 202 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

2.

Adjustment/Test A. Initial Conditions (1) On left dc circuit breaker panel, ensure the following circuit breakers are closed: PWR MONITOR DC (H9) PWR MONITOR AC (J9) AC GEN CONT 1 (K9) (2) On right dc circuit breaker panel, ensure the following circuit breakers are closed: PWR MONITOR DC (H9) PWR MONITOR AC (J9) AC GEN CONT 2 (K9) CAUT LTS 1 (M1) CAUT LTS 2 (N1) (3) On 115V AC VARIABLE FREQUENCY panel, ensure the following circuit breakers are closed: LEFT AC VOLTMETER PH A, PH B, PH C RIGHT AC VOLTMETER PH A, PH B, PH C Open L TRU and R TRU breakers on this panel. (4) At the AC CONTROL panel, select all switches OFF. (5) Ensure all systems using 115V variable frequency power are switched OFF. (6) Observe all normal operating precautions and start engines (refer to Chapter 71). Run engines with propeller speed of 900 rpm. (7) Apply generator power to primary dc bus system (refer to Chapter 12, SERVICING GENERAL). Operate switches on DC SYSTEM power monitor panel to ensure that all dc buses are powered. B. Operational Test (1) Perform Initial Conditions as detailed in para 2.A. (2) Check that #1 AC GEN and #2 AC GEN caution lights are on. (3) At the AC CONTROL panel, select GEN 1 switch on. Check that #1 AC GEN caution light goes off. (4) At the AC SYSTEM power monitor panel select phases A, B and C on the left and right buses. Check that each phase reads 115V + or 3.0 (112118) volts. (5) At the AC CONTROL panel, select GEN 1 switch OFF and GEN 2 on. Check that #1 AC GEN caution light comes on, and #2 AC GEN caution light goes off. (6) Repeat step (4). (7) At the AC CONTROL panel select GEN 1 switch on. Check that #1 and #2 AC GEN caution lights are off, and that correct voltage is indicated on left and right buses. (8) At 115V AC VARIABLE FREQUENCY panel, close L TRU and R TRU circuit breakers. At AC SYSTEM panel, check that indicated voltage is 115V as in step (4) and LOAD reading indicates current is being drawn by the TRUs. (9) Shut down engines (refer to Chapter 71).

MASTER EFFECTIVITY:

242100

Page 203 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY SYSTEM DESCRIPTION AND OPERATION 1. Description Refer to Figure 1. A. General The ac variable frequency generating system provides 115/220 volts threephase power for ac systems that are not frequencysensitive, such as deicing, fuel auxiliary pumps, and electric motordriven standby hydraulic pumps. It also supplies power to the transformerrectifier units, which are part of the dc generation system. Two generators are installed, one on each engine, supplying power independently to left and right bus systems. An ac external power receptacle and control circuitry are provided to enable the system to be powered from an external source while the aircraft is on the ground. Facilities are provided to automatically tie the bus systems in event of either generator failure, or the aircraft being operated on external ac power. The system consists of two generators, two generatorcontrol units (GCU), ac contactors, current transformers, control circuits and caution lights. Digital voltage and load monitoring systems are installed for monitoring system conditions and operation. The generators are connected to the variable ac buses by bus contactors in the ac contactor boxes located in the engine nacelles. The bus loads are distributed from the ac contactor boxes to the left and right variable frequency ac buses circuit breaker panel located in the flight compartment. Each ac generator is driven through its propeller gear box. The speed, and hence the output frequency of each generator, varies directly with propeller speed, but the output voltage remains constant over a wide range of propeller speed, being controlled by its individual generator control unit (GCU). Each GCU automatically controls operation of the associated generator by monitoring output voltage, current, and speed. These monitored signals are in turn used by internal circuits of the GCU to vary the excitation field current of the generator and to control operation of the bus contactor. In the event of a generator failure, logic switching in the GCU operates the bus contactor to a crosstie position, switching the feeder lines to the other generator. Current information is supplied to the GCU from current transformers within the generators as well as externally on each output phase. Separate transformers supply current information to the power monitor system. When external power is applied and selected, each bus contactor is automatically selected to the crosstie position by its associated GCU, and external power contactors connect the external power to both left and right bus systems. Generator operation is inhibited while external power is selected. B. Generator The generator is fitted to, and driven by the propeller gear box on each engine. The output power is 115/200 volts, threephase, variable frequency, with normal capacity of 20 KVA and overload capacity of 30 KVA. It is a twostage brushless, twobearing design, with stationary and rotary excitation. On the rotary shaft is the first stage generator, excited by the stationary field. This generates an ac current which is rectified by diodes mounted on the shaft to supply current to the main field for excitation of the second, or main stage stator output

MASTER EFFECTIVITY:

242101

Page 1 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

C.

D.

windings. A magnetic speed sensor and current transformers are also mounted in the generator housing. An overtemperature switch is installed in the generator. The switch contacts close when the stator windings reach a temperature of 210 degrees C, to operate the AC GEN HOT lights on the caution panel. It will automatically reset when the temperature returns to a safe level. The output frequency of the generator varies with propeller speed, and ranges from 333 Hz at 10,000 rpm, to 528 Hz at 15,850 rpm, but the output voltage is controlled by the GCU. Lubrication and cooling of the generator is provided by internal oil circulation. Oil supplied from the engine enters an inlet port at the flange (mounting) end under pressure. The oil is ducted to and through the hollow rotor shaft of the generator, exiting through eight spray nozzles which direct the flow onto the rotor and stator windings. Bearing lubrication is provided by a controlled leakage device within the rotor shaft. The oil flows through a screen to a collector sump in the bottom of the generator and is returned to the engine through the outlet port by action of the oil scavenge pump. Generator Control Unit (GCU) The generator control unit is all solid state, with the exception of two control relays which are hermetically sealed. The components and printed circuit boards are encased in a singlepiece aluminum cover on which is mounted a multipin connector. One unit is located in an ac contactor box in each engine nacelle. The GCU contains the voltage regulator and control circuits for the generator, protection circuits, and bus contactor control. Contactor control includes the automatic switchover function of the feeders and buses in the event of generator failure. With both generators selected ON, each GCU monitors the following functions for control of the generator and contactor: (1) Generator output voltage on each phase measured at the bus contactors, and supplied to pins F, E and D through circuit breakers CB3, 5 and 7 (left) and CB4, 6 and 8 (right) located in the ac contactor boxes. (2) Feeder current in each phase, developed in transformers T1 and T4, supplied to pins M, N and P for differential current sensing (refer to Figure 1). (3) Internal generator current, developed from current transformers within the generators, supplied to pins R, S and T. (4) Generator speed (rpm) developed from the magnetic speed sensor within the generator, and supplied to pins U and V. (5) Operational status information from the other GCU. This information is provided by direct interconnections between the GCUs on pins m, t, n, b, s, i, j and r. The GCU circuitry uses the above information to control the generator output by adjusting the amount of current flowing in the exciter field winding, or by switching it off as required. Time delay circuits prevent nuisance tripping due to normal switching transients or line noise, and enable the GCU to verify a fault before taking corrective action. AC Contactor Box There are two ac contactor boxes, one mounted in each engine nacelle, containing most of the components for the left and right ac systems. Each box contains a bus contactor, an external power contactor, a generator control unit, current transformers, output feeder

MASTER EFFECTIVITY:

242101

Page 2 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

E.

F.

G.

H.

fuses, and control circuit breakers for the associated side (left or right). Also contained in each box is the remote control circuit breaker for the left or right standby hydraulic pump. The right ac contactor box holds the external power protection unit and fuses. All electrical connections are via multipin connectors mounted on two sides of the box assemblies. The output feeders consist of three No. 12 wires, routed from each contactor box to the left and right ac variable frequency buses circuit breaker panel in the flight compartment. Contactors Refer to Figure 1. Two bus contactors (left and right) switch the threephase feeders between their own generator or the opposite generator (crosstie position). The crosstie position is also used when external power is selected. The left and right bus contactors are hermetically sealed, three position centeroff type, with a threepole double throw (3PDT) contact arrangement. Separate coil windings, designated X and Y, are used to energize the contact arm to either of the two closed positions. Heavy threaded studs provide electrical connections to external circuits. The external power contactors are conventional twoposition contactors, hermetically sealed, with a 3PDT contact arrangement actuated by a single coil. The deenergized position provides the crosstie connection for the bus contactors. When energized, external power is supplied to the bus contactors. Current Transformers Six current transformers are installed in the system, labeled T1 thru T6. Transformers T5 and T6 measure total generator output current for the ac power monitor system. Transformers T1 and T4 measure total current flow in the main and crosstie feeders. The sensed output is used in the GCU differential current sensing circuits. Transformers T2 and T3 measure crosstie current. They sense current flow only when the bus contactors are in the crosstie position. Their output is summed with the output of the opposite T1 or T4 for differential current sensing within the GCU. Each current transformer assembly consists of three single phase toroidal current transformers, installed in a light weight aluminum housing. Each line of the 3phase system to be monitored is passed through its toroid. Electrical connections to the toroids are via a multipin connector. The mounting holes for the assembly are asymmetrical to avoid improper installation. AC Control Refer to Figure 2. Manual control of the ac variable frequency system is provided by switches on the AC CONTROL panel, located on the overhead console. The panel contains two toggle switches for generators onoff control, labeled GEN 1 and GEN 2 with the OFF position centrally marked. These also serve to reset the GCU trip circuits as is explained in Para. 2. A toggle switch for selection of external power, marked EXT POWER/OFF, and an external power indicator lamp are also located on the control panel. There are three additional toggle switches for control of the 400 Hz inverters (see AC 400 Hz SYSTEM). AC Power Monitoring System Refer to Figure 2 and 3. The ac power monitor panel labeled AC SYSTEM is located adjacent to the ac control panel. The right half of the panel is labeled VARIABLE FREQUENCY, with two digital

MASTER EFFECTIVITY:

242101

Page 3 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

readout windows labeled VOLTS and LOAD, and a 6position rotary selector switch. The digital readouts indicate voltage and current readings on the selected left or right phase. The LOAD display window monitors load currents expressed as a percentage factor of the rated circuit load. For example, a readout of 1.00 indicates full load (87 amps per phase), .50 indicates half load; and a reading of 1.20 indicates a twenty percent overload. An overload condition is advised by a flashing positive sign (+) preceding the readout. The TEST pushbutton tests the monitor display and circuit operation when pressed. Voltage readings are from individual circuit breakers on each phase of the left and right power buses; current indications are obtained from transformer T5 on the left generator output and T6 on the right generator output (refer to Figure 1).

MASTER EFFECTIVITY:

242101

Page 4 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY POWER SYSTEM SCHEMATIC Figure 1 (Sheet 1 of 6)

MASTER EFFECTIVITY:

242101

Page 5 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY POWER SYSTEM SCHEMATIC Figure 1 (Sheet 2 of 6)

MASTER EFFECTIVITY:

242101

Page 6 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY POWER SYSTEM SCHEMATIC Figure 1 (Sheet 3 of 6)

MASTER EFFECTIVITY:

242101

Page 7 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY POWER SYSTEM SCHEMATIC Figure 1 (Sheet 4 of 6)

MASTER EFFECTIVITY:

242101

Page 8 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY POWER SYSTEM SCHEMATIC Figure 1 (Sheet 5 of 6)

MASTER EFFECTIVITY:

242101

Page 9 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY POWER SYSTEM SCHEMATIC Figure 1 (Sheet 6 of 6)

MASTER EFFECTIVITY:

242101

Page 10 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC CONTROL PANEL Figure 2

MASTER EFFECTIVITY:

242101

Page 11 May 28/2004

dam03_2421010_007.dc, 12/03/02

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC SYSTEM POWER MONITOR PANEL Figure 3

MASTER EFFECTIVITY:

242101

Page 12 May 28/2004

dam03_2421010_008.dc, 12/03/02

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

2.

Operation A. General With the aircraft engines running with no external ac power connected, and the AC CONTROL panel switches GEN 1 and GEN 2 selected on, the generators are brought on line for normal operation and disconnected as required automatically by the associated GCU. The two systems are essentially identical and normally operate independently. They are however, crosstied during singlegenerator operation by the logic switching function of the GCU. The generator output lines are connected to one side of the twoposition bus contactors K1 (left) and K2 (right). The other side of the contactors are connected to the normallyclosed contacts of the crosstie/external power contactors K3 and K4 for opposite generator feed or for external power feed, when they are in the energized position. The variable frequency buses are connected through limiters F7, F9 and F11 (left) or F8, F10 and F12 (right) to the arm of the contactors, which select one of the two power sources. Operation of the bus contactors is controlled automatically by the GCU. The GCU continuously monitors several different parameters for its control function. Voltage and load information is supplied to the AC SYSTEM panel for monitoring by the flight crew. B. Generator Operation Assuming initial engine startup (the right engine is normally started first), with the ac generators selected on, the GCUs hold all contactors in the open condition. As right generator speed increases to approximately 5000 rpm, the right GCU energizes contactor K2 by applying a ground to terminal X2. This action connects the generator output to the right variable frequency buses. Simultaneously, an [ldquo]on line[rdquo] signal is sent from the right GCU pin b to the left GCU pin j, causing it to energize its contactor K1 in the crosstie position by energizing coil terminals Y1/Y2. The right generator is then supplying both variable frequency buses through normallyclosed contacts, A, B and C of K3. At this speed, output voltage is low, approximately 41 to 42 volts per phase, with a frequency of approximately 150 Hz. When the generator reaches its normal operating speed of 10,000 to 15,850 rpm, the output voltage is regulated to 115 volts + or 2.8V per phase by the GCU, which varies the current flow through the exciter field winding. Within the normal operating speed range of the generator the output frequency varies between 333 and 528 Hz. Operation of the opposite generator is identical. When it reaches its [ldquo]on line[rdquo] speed, the GCU operates the contacts of K1 by removing the ground return from coil Y2 and applying it to coil X2, connecting the left feeders to the left generator. The left and right buses are then fed independently as the second generator increases to its normal operating speed. The GCU voltage regulator senses the average of the three phase voltages applied to pins D, E and F for primary regulation, and also senses phase overvoltage or undervoltage conditions. Overvoltage protection is preset to shut down the generator if output voltage exceeds 125 volts, and automatically transfers the feeder buses to the opposite generator by switching the bus contactor. The undervoltage circuit operates on sensing a low bus voltage (below 90 volts), providing bus fault protection. It operates a

MASTER EFFECTIVITY:

242101

Page 13 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

C.

D.

latching relay (BCCR1) within the GCU to remove energizing voltage from pin B, preventing either coil of the bus contactor from operating, thus isolating the faulty bus from any power source until the fault has been cleared. NOTE: If the latching relay is actuated, the GCU must be manually reset by selecting the appropriate GEN switch on the AC CONTROL panel to OFF, then on. The OFF position provides a reset to the GCU circuits and the latched relay. Currents flowing through the generator output windings and the external current transformers are normally identical. These currents are monitored by the GCU differential current sensing circuits through pins R, S, T connected to the generator internal current transformers, and M, N, P connected to T1 (left) or T4 (right). A change within the main or crosstie feeders producing a difference in these values, triggers the GCU circuits to transfer the load to the other generator. The output of the generator current transformer is also used by the GCU for overcurrent protection of the generator. During crosstie operation, the transferred bus supply is routed through a separate current transformer (T2 on the left, and T3 on the right) the output windings of which are paralleled and summed with the bus supply current from the operational system. Separate current transformers T5 (left) and T6 (right) provide generator output current indications to the ac power monitor panel. The speed sensor input to pins U and V of the GCU provides additional control under high and low speed operation of the generator, and disconnects the load bus (deenergizes the bus contactor) below a predetermined frequency of 150 Hz. On high frequency output the GCU maintains voltage regulation, but on low frequency output below 325 Hz the output voltage is permitted to sag to a voltage/frequency ratio limit, until the preset limit of 42V/150 Hz (approximately) is reached. There are four interconnecting circuits between the GCU that provide added functions. One (m to s) ensures that 28 volts control power is available for bus contactor operation, independent of the other system. The second (b to j) provides a logic signal indicating that the generator is [ldquo]on line[rdquo] supplying its own bus. The undervoltage signal (t to i) and bus fault time delay (n to r) enable logic circuits to determine if, and when, a load bus should be transferred to the other generator or locked out due to a fault. Test AC Power Monitor System To operate the internal test circuits of the AC SYSTEM power monitor panel, the TEST pushbutton is pressed and held. Pressing the button causes all segments of both VOLTS and LOAD digital display characters to light. When held longer than approximately two seconds, the internal test circuits simulate VOLTS of 150 + or 3 and LOADS of 1.05 + or .03, which is displayed on both sections of the panel. Abnormal Operation (1) Generator Hot Indicator The overtemperature sensor in each generator closes a circuit if the temperature exceeds a preset limit. The sensor is connected to pins A (grounded) and B of generator connector P2. Upon closing, a ground path is provided to pin B, lighting the AC GEN HOT (NO. 1 or NO. 2) lamp on the caution panel. An overheat condition will not automatically take the generator off the line. The generator must be manually shut off by selection of the GEN OFF switches. If the generator cools to a safe level, the caution light goes off.

MASTER EFFECTIVITY:

242101

Page 14 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

E.

(2) Generator Failure Loss of output voltage is sensed by the GCU pins F, E and D, connected to the generator output at terminals A1, B1 and C1 of the bus contactor. The GCU control circuits remove the ground from bus contactor terminal X2, and apply a ground to terminal Y2, transferring the contactor to the crosstie position. The GCU also shuts down the generator by removing the exciter field current from the generator pins K and J. Simultaneously, a voltage is supplied by the GCU from pin e, lighting the AC GEN (No. 1 or No. 2) caution light. (3) Bus Bar/Feeder Failure An overload or short circuit in the bus or feeder system is detected by the GCU by voltage or current monitoring. (a) If the voltage at the point of regulation falls below 90 volts, the GCU will remove the energizing voltage supply to the bus contactor coil (pin B on GCU) by operating an internal latching relay (BCCR1). The appropriate bus fault caution light (L AC BUS or R AC BUS) is switched on by GCU relay contacts BCCR2 providing a ground return on pin d. When the fault is cleared, the latching relay must be manually reset by selecting the appropriate GEN switch on the AC CONTROL panel to OFF, then on to return the generator to the line. (b) Currents flowing within the generator and the feeder current transformers are compared in the GCU differential current sensing circuits. Any difference in these values causes the GCU to transfer the load to the other generator by operation of the bus contactor. Time delay circuits within the GCU provide allowance for normal transients caused by onoff switching of various loads, and these will not cause any GCU switching action. External Power Operation With ac external power connected to the aircraft, voltage is supplied to the external power bus through fuses F1, F3, F5 (left side) and F2, F4, F6 (right side). The external power control switch on the AC CONTROL panel is interlocked with the external power protection relay 2442K1, which monitors the external power source for proper voltage, frequency and phase rotation. With the external power protection relay energized, selection of the EXT POWER switch to on energizes left and right external power contactors K3 and K4, powered from the 28 V dc essential buses (or the ground power unit if equipped with dc output). The green EXT PWR advisory light on the ac control panel is also operated by the external power switch. Simultaneously, 28 V dc is supplied to the GCUs through pin f applying power for the left (K1) and right (K2) bus contactors terminals Y1/Y2, which operate to the crosstie position. The left and right ac power buses are then parallelconnected to the external power source. NOTE: Both GCUs must be installed and operational for external power to be applied. Refer to EXTERNAL POWER DESCRIPTION AND OPERATION (AC) for details.

MASTER EFFECTIVITY:

242101

Page 15 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY GENERATOR SYSTEM MAINTENANCE PRACTICES 1. Removal/Installation A. For removal and installation of the AC Generator, refer to the Power Plant BuildUp Manual, PSM 18310. Adjustment/Test A. Initial Conditions (1) On left dc circuit breaker panel, ensure the following circuit breakers are closed: PWR MONITOR DC (H9) PWR MONITOR DC (H9) AC GEN CONT 1 (K9) (2) On right dc circuit breaker panel, ensure the following circuit breakers are closed: PWR MONITOR DC (H9) PWR MONITOR AC (J9) AC GEN CONT 2 (K9) CAUT LTS 1 (M1) CAUT LTS 2 (N1) (3) On 115V AC VARIABLE FREQUENCY panel, ensure the following circuit breakers are closed: LEFT AC VOLTMETER PH A, PH B, PH C RIGHT AC VOLTMETER PH A, PH B, PH C Open L TRU and R TRU breakers on this panel. (4) At the AC CONTROL panel, select all switches OFF. (5) Ensure all systems using 115V variable frequency power are switched OFF. (6) Observe all normal operating precautions and start engines (refer to Chapter 71). Run engines with propeller speed of 900 rpm. (7) Apply generator power to primary dc bus system (refer to Chapter 12, SERVICING GENERAL). Operate switches on DC SYSTEM power monitor panel to ensure that all dc buses are powered. B. Operational Test (1) Perform Initial Conditions as detailed in para 2.A. (2) Check that #1 AC GEN and #2 AC GEN caution lights are on. (3) At the AC CONTROL panel, select GEN 1 switch on. Check that #1 AC GEN caution light goes off. (4) At the AC SYSTEM power monitor panel select phases A, B and C on the left and right buses. Check that each phase reads 115V + or 3.0 (112118) volts. (5) At the AC CONTROL panel, select GEN 1 switch OFF and GEN 2 on. Check that #1 AC GEN caution light comes on, and #2 AC GEN caution light goes off. (6) Repeat step (4). (7) At the AC CONTROL panel select GEN 1 switch on. Check that #1 and #2 AC GEN caution lights are off, and that correct voltage is indicated on left and right buses.

2.

MASTER EFFECTIVITY:

242101

Page 201 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

(8) At 115V AC VARIABLE FREQUENCY panel, close L TRU and R TRU circuit breakers. At AC SYSTEM panel, check that indicated voltage is 115V as in step (4) and LOAD reading indicates current is being drawn by the TRUs. (9) Shut down engines (refer to Chapter 71).

MASTER EFFECTIVITY:

242101

Page 202 May 28/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC CONTACTOR BOX DESCRIPTION AND OPERATION

MASTER EFFECTIVITY:

242102

Page 1 Oct 20/2004

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

**ON A/C ALL AC CONTACTOR BOX MAINTENANCE PRACTICES 1. General A. The maintenance procedure that follow is for the removal, installation and adjustment/test of the AC Contactor Box. There are two AC Contactor Boxes one in each nacelle. AC Contactor Box contain most of the components for the left and right AC Variable Frequency Power System. Each AC Contactor Box contain bus contactors, external power contactors, a generator contactor, a generator control units, current transformers, external power protection unit, output feeder fuses and control circuit breakers for associated sides. B. The No. 1 AC Contactor Box is located on the left side forward of the landing gear wheel well in the left engine nacelle. C. The No. 2 AC Contactor Box is located on the left side forward of the wheel well in the right engine nacelle, aft of the External AC receptacle. The No. 2 AC Contactor Box is identical to the No. 1 AC Contactor Box except for the Voltage Sensor Module and the Current Limiter Module mounted externally on the underside of the box. Removal/Installation of the AC Contactor Box A. Removal of the AC Contactor Box REMOVE ALL ELECTRICAL POWER FROM THE AIRCRAFT BEFORE YOU DO MAINTENANCE. PUT WARNING PLACARDS AT THE CIRCUIT BREAKERS OR EXTERNAL POWER. IF YOU DO NOT DO THIS YOU CAN CAUSE INJURIES TO PERSONS OR DAMAGE TO THE EQUIPMENT. WARNING: OBEY ALL THE SAFETY PRECAUTIONS WHEN YOU DO MAINTENANCE ON OR NEAR THE ELECTRICAL/ELECTRONIC EQUIPMENT. IF YOU DO NOT DO THIS, YOU CAN CAUSE INJURIES TO PERSONS AND/OR DAMAGE TO THE EQUIPMENT. WARNING: FAILURE TO OBSERVE SAFETY PRECAUTIONS BEFORE CARRYING OUT MAINTENANCE PRACTICES ON OR NEAR ELECTRICALLY CONTROLLED OR OPERATED EQUIPMENT COULD RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT. BEFORE SWITCHING THE ELECTRICAL SYSTEM POWER ON, CAUTION: MAKE SURE THAT ALL CONNECTIONS AND INSTALLATIONS ARE COMPLETE AND SECURE. (1) Obey all the electrical/electronic safety precautions (Refer to Chapter 240000). (2) Obey all electrostatic discharge safety precautions (Refer to Chapter 240000). (3) Make sure external dc power is removed from aircraft (Refer to Chapter 120005). (4) Make sure that the external ac power is removed from the aircraft (Refer to Chapter 120005). (5) For the No. 1 AC Contactor Box, open and tag the circuit breakers that follow: WARNING:

2.

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 201 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

B.

On the 28 VDC left essential bus circuit breaker panel: AC GEN CONT 1 (K9) PWR MONITOR AC (J9) (6) For the No. 2 AC Contactor Box, open and tag the circuit breakers that follow: On the 28 VDC right essential bus circuit breaker panel: AC GEN CONT 2 (K9) PWR MONITOR AC (J9) EXT PWR LOGIC (F8) (7) Remove the No. 1 AC Contactor Box as follows: Refer to Figure 201. (a) Disconnect the six electrical connectors (1) from the AC Contactor Box (4). (b) Loosen the six securing studs (3) on the AC Contactor Box cover (2). (c) Remove the AC Contactor Box cover (2). (d) Remove the four securing screws (5) and washers (6) from AC Contactor Box (4). (e) Remove the AC Contactor Box (4) from the aircraft. (8) Remove the No. 2 AC Contactor Box as follows: Refer to Figure 202. (a) Disconnect the seven electrical connectors (2) from the AC Contactor Box (4). (b) Loosen the six securing studs (3) on the AC Contactor Box cover (1). (c) Remove the AC Contactor Box cover (1). (d) Remove the four securing screws (5) and washers (6) from AC Contactor Box (4). (e) Remove the AC Contactor Box (4) from the aircraft. Installation of the AC Contactor Box (1) Make sure that the aircraft is in the same configuration as in the removal task. (2) Install the No. 1 AC Contactor Box as follows: Refer to Figure 202. (a) Install the AC Contactor Box (4) with the four washers (6) and screws (5). (b) Install the AC Contactor Box cover (2) with the six studs (3) on the AC Contactor Box (4). (c) Connect the six electrical connectors (1) to the AC Contactor Box (4). (3) Install the No. 2 AC Contactor Box as follows: Refer to Figure 202. (a) Install the AC Contactor Box (4) with the four securing washers (6) and screws (5). (b) Install the AC Contactor Box cover (1) with the seven studs (3) on the AC Contactor Box (4). (c) Connect the seven electrical connectors (2) to the AC Contactor Box (4).

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 202 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

(4) Remove all the tools, equipment and unwanted materials from the work area. (5) Do an operational test of the AC Contactor Box (Refer to Para 3.).

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 203 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

6 5

1 1

LEGEND 1. Electrical connector. 2. AC contactor box cover. 3. Stud. 4. AC contactor box. 5. Screw. 6. Washer.

NOTE

1

Contents of AC contactor box vary therefore only the attaching hardware is shown.

NO. 1 AC CONTACTOR BOX REMOVAL/INSTALLATION Figure 201

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 204 May 15/2008

dam03_2421022_001.dg, kg, dec27/2007

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

3 4 6 5

2 2 2

LEGEND 1. AC contactor box cover. 2. Electrical connector. 3. Stud. 4. AC contactor box. 5. Screw. 6. Washer.

NOTE Contents of AC contactor box vary therefore only the attaching hardware is shown.

NO. 2 AC CONTACTOR BOX REMOVAL/INSTALLATION Figure 202

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 205 May 15/2008

dam03_2421022_002.dg, kg, dec27/2007

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

3.

Adjustment/Test A. Initial Conditions (1) Make sure that the main battery and the auxiliary battery are installed and connected (Refer to Chapter 120006). (2) Do the inservice engines starting checkout (Refer to Chapter 710000). (3) On the left dc circuit breaker panel, close the circuit breakers that follow: PWR MONITOR DC (H9) PWR MONITOR AC (J9) AC GEN CONT 1 (K9) (4) On the right dc circuit breaker panel, close the circuit breakers that follow: PWR MONITOR DC (H9) PWR MONITOR AC (J9) AC GEN CONT 1 (K9) CAUS LTS 1 (M1) CAUS LTS 2 (N1) (5) On the 115 AC variable frequency panel, close the circuit breakers that follow: LEFT AC VOLTMETER (PH A) LEFT AC VOLTMETER (PH B) LEFT AC VOLTMETER (PH C) RIGHT AC VOLTMETER (PH A) RIGHT AC VOLTMETER (PH B) RIGHT AC VOLTMETER (PH C) B. Operational Test Refer to Figure 203 and Figure 204. (1) Run both engines with the propeller speed at 900 RPM minimum (Refer to Chapter 710000). (2) On the overhead DC CONTROL panel, set the No. 1 and No. 2 dc generator switches to the GEN 1 and GEN 2 positions. (3) On the caution light panel, make sure that the No. 1 AC GEN and No. 2 AC GEN caution lights are on. (4) On the overhead AC CONTROL panel, set the No. 1 ac generator switch to the "GEN 1" position. (5) On the caution lights panel, make sure that the No. 1 AC GEN caution light goes off. (6) On the AC SYSTEM monitor panel, set phases A, B and C on the left and right buses and make sure that each phase reads 1153.0 volts ac. (7) On the AC CONTROL panel, set the GEN 1 switch to the "OFF" position and the No. 2 ac generator switch to the "GEN 2" position. (8) On the caution lights panel, make sure that the No. 1 AC GEN caution light comes on and the No. 2 AC GEN caution light goes off.

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 206 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

(9) On the AC SYSTEM monitor panel, set phases A, B and C on the left and right buses and make sure that each phase reads 1153.0 volts ac. (10) On the AC CONTROL panel, set the GEN 1 switch to the on position. (11) On the caution lights panel, make sure that the No. 1 AC GEN and the No. 2 AC GEN caution lights are off. (12) On the AC SYSTEM monitor panel, set the phases A, B and C on the left and right buses and make sure that each phase reads 1153.0 volts ac. (13) Set the GEN 1 and GEN 2 switches to the "OFF" position. (14) Shut down both engines (Refer to Chapter 710000).

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 207 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

DC CONTROL PANEL Figure 203

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 208 May 15/2008

dam03_2431010_001.dc, 20/03/02

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC CONTROL PANEL Figure 204

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 209 May 15/2008

dam03_2421010_007.dc, 12/03/02

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY POWER SYSTEM SCHEMATIC Figure 205 (Sheet 1 of 6)

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 210 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY POWER SYSTEM SCHEMATIC Figure 205 (Sheet 2 of 6)

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 211 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY POWER SYSTEM SCHEMATIC Figure 205 (Sheet 3 of 6)

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 212 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY POWER SYSTEM SCHEMATIC Figure 205 (Sheet 4 of 6)

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 213 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY POWER SYSTEM SCHEMATIC Figure 205 (Sheet 5 of 6)

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 214 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

AC VARIABLE FREQUENCY POWER SYSTEM SCHEMATIC Figure 205 (Sheet 6 of 6)

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 215 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

4.

Operational Test Of The External Power A. C. Bus Contactors and Associated Current Transformers WARNING: OBEY ALL THE SAFETY PRECAUTIONS WHEN YOU DO MAINTENANCE ON OR NEAR THE ELECTRICAL/ELECTRONIC EQUIPMENT. IF YOU DO NOT DO THIS, YOU CAN CAUSE INJURIES TO PERSONS AND/OR DAMAGE TO THE EQUIPMENT. WARNING: FAILURE TO OBSERVE SAFETY PRECAUTIONS BEFORE CARRYING OUT MAINTENANCE PRACTICES ON OR NEAR ELECTRICALLY CONTROLLED OR OPERATED EQUIPMENT COULD RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT. CAUTION: BEFORE SWITCHING THE ELECTRICAL SYSTEM POWER ON, MAKE SURE THAT ALL CONNECTIONS AND INSTALLATIONS ARE COMPLETE AND SECURE. NOTE: Both GCUs must be installed and Operational. DC External is required. All operational systems circuit breakers should be closed.

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 216 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

A.

5.

Procedure Refer to Figure 205. 1. There are two external power ac bus contactors, K3 and K4. 2. Make sure main battery and Aux. battery are installed and connected. 3. Make sure all installation and connections are complete and secured. 4. Make sure all operational circuit breaker are in. 5. Make sure all switches are off or in normal position. 6. Connect DC External power. 7. Select DC External power ON in cockpit overhead DC panel. Make sure power is on all buses. 8. Connect AC External power to the aircraft at right nacelle. 9. Select AC External power ON in the cockpit overhead AC panel. 10. Make sure power is on all buses, verify on AC panel by selecting rotatory knob on the left and right buses make sure all buses. 11. AC External power unit scenes voltage, frequency and phase rotations on all three phases. If correct than selecting AC External power switch "ON" AC External power panel. Power is supplied to external power buses and through fuses F1, F3 and F5 on left buses and through F2, F4 and F6 on right buses. 12. The external power control switch on the AC CONTROL panel is interlocked with the External Power Protection Unit, which monitors the external power source for proper voltage, frequency and phase rotation. 13. With the external power protection relay energizes left and right external power contactors K3 and K4, powered from 28V dc essential buses through bus contactors power buses. 14. The EXT. PWR. advisory light on the ac control is also operated by external power switch. Simultaneously, 28 V dc is supplied to the GCUs through pin "f" applying power for the left and right K1 and K2 bus contactors terminal Y1/Y2, which operate to the crosstie position. The left and right ac power buses are then parallel connected to the external power through bus tie contactors. 15. Select Variable Frequency Rotatory Switch on AC System panel to all six position that is Left A, B and C phases shows voltages on all position. 16. Above operational test, give operation test of External Power AC bus contactors and associate current transformers. Operational Test Of The A. C. Bus Contactor and Associated Current Transformers WARNING: OBEY ALL THE SAFETY PRECAUTIONS WHEN YOU DO MAINTENANCE ON OR NEAR THE ELECTRICAL/ELECTRONIC EQUIPMENT. IF YOU DO NOT DO THIS, YOU CAN CAUSE INJURIES TO PERSONS AND/OR DAMAGE TO THE EQUIPMENT.

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 217 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

6.

FAILURE TO OBSERVE SAFETY PRECAUTIONS BEFORE CARRYING OUT MAINTENANCE PRACTICES ON OR NEAR ELECTRICALLY CONTROLLED OR OPERATED EQUIPMENT COULD RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT. CAUTION: BEFORE SWITCHING THE ELECTRICAL SYSTEM POWER ON, MAKE SURE THAT ALL CONNECTIONS AND INSTALLATIONS ARE COMPLETE AND SECURE. NOTE: Both GCUs must be installed and Operational. DC External is required. All operational systems circuit breakers should be closed. A. Procedure 1. There are two A. C. Bus Contactors, K1 and K2. 2. Connect A. C. External Power to the aircraft at right nacelle. 3. Select A.C. External power Switch "ON" in cockpit overhead panel. 4. Make sure power is on all buses, verify on A. C. panel by rotatory knob on left and right buses. 5. External power protection unit scenes voltage, frequency and phase rotation on all three phases. If all correct than by selecting A. C External power switch "ON" A. C. External power panel. Power is supplied to external power buses and through fuses F1, F3 and F5 on left buses and through F2, F4 and F6 on right buses. 6. The external power control switch on the AC CONTROL panel is interlocked with the External Power Protection Unit, which monitors the external power source for proper voltage, frequency and phase rotation. 7. With the external power protection relay energizes left and right external power contactors K3 and K4, powered from 28V dc essential buses through bus contactors power buses. 8. The EXT. PWR. advisory light on the ac control is also operated by external power switch. Simultaneously, 28 V dc is supplied to the GCUs through pin "f" applying power for the left and right K1 and K2 bus contactors terminal Y1/Y2, which operate to the crosstie position. The left and right ac power buses are then parallel connected to the external power through bus tie contactors. 9. The EXT. PWR. advisory light on the ac control is also operated by external power switch. Simultaneously, 28 V dc is supplied to the GCUs through pin "f" applying power for the left and right K1 and K2 bus contactors terminal Y1/Y2, which operate to the crosstie position. The left and right ac power buses are then parallel connected to the external power through bus tie contactors. 10. Select Variable Frequency Rotatory Switch on AC System panel to all six position that is Left A, B and C phases shows voltages on all position. 11. Above Operational Test Of The A. C. Bus Contactor and Associated Current Transformers. Operational Test Of The External Power Protection Unit WARNING: OBEY ALL THE SAFETY PRECAUTIONS WHEN YOU DO MAINTENANCE ON OR NEAR THE ELECTRICAL/ELECTRONIC EQUIPMENT. IF YOU DO NOT DO THIS, YOU CAN CAUSE INJURIES TO PERSONS AND/OR DAMAGE TO THE EQUIPMENT.

WARNING:

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 218 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

7.

8.

FAILURE TO OBSERVE SAFETY PRECAUTIONS BEFORE CARRYING OUT MAINTENANCE PRACTICES ON OR NEAR ELECTRICALLY CONTROLLED OR OPERATED EQUIPMENT COULD RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT. CAUTION: BEFORE SWITCHING THE ELECTRICAL SYSTEM POWER ON, MAKE SURE THAT ALL CONNECTIONS AND INSTALLATIONS ARE COMPLETE AND SECURE. NOTE: Both GCUs must be installed and Operational. DC External is required. All operational systems circuit breakers should be closed. A. Procedure 1. Connect A. C. External Power to the aircraft at right nacelle. 2. Select A.C. External power Switch "ON" in cockpit overhead panel. 3. Make sure power is on all buses, verify on A. C. panel by rotatory knob on left and right buses. 4. External power protection unit scenes voltage, frequency and phase rotation on all three phases. If all correct than by selecting A. C External power switch "ON" A. C. External power panel. Power is supplied to external power buses and through fuses F1, F3 and F5 on left buses and through F2, F4 and F6 on right buses. 5. The external power control switch on the AC CONTROL panel is interlocked with the External Power Protection Unit, which monitors the external power source for proper voltage, frequency and phase rotation. 6. With the external power protection relay energizes left and right external power contactors K3 and K4, powered from 28V dc essential buses through bus contactors power buses. 7. The EXT. PWR. advisory light on the ac control is also operated by external power switch. Simultaneously, 28 V dc is supplied to the GCUs through pin "f" applying power for the left and right K1 and K2 bus contactors terminal Y1/Y2, which operate to the crosstie position. The left and right ac power buses are then parallel connected to the external power through bus tie contactors. 8. Select Variable Frequency Rotatory Switch on AC System panel to all six position that is Left A, B and C phases shows voltages on all position. 9. Make sure approximately 115 Volts A C on both buses and on all phases. 10. Above test conclude Operational Test Of The External Power Protection Unit. Operational Test Of The Remote Control Circuit Breaker (Pre Mod 8/2120) NOTE: Before starting this operational test, Ref. to "Operational test of Standby Power Unit Oh. 291117. Producer WARNING: WITH HYDRAULIC POWER FROM STANDBY HYDRAULIC POWER UNIT APPLIED, DO NOT OPERATE PSEU BITE SYSTEM TEST SWITCH. (REFER TO CHAPTER 32, 326150). WARNING: MAIN GEAR REAR AND CENTER DOORS WILL CLOSE AT ENGINE START ON APPLICATION OF EXTERNAL HYDRAULIC POWER, OR SELECTION OF A STANDBY PUMP FOR GROUND OPERATION, WITH MAIN GEAR DOOR LOCK PIN REMOVED.

WARNING:

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 219 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

OBEY ALL THE SAFETY PRECAUTIONS WHEN YOU DO MAINTENANCE ON OR NEAR THE ELECTRICAL/ELECTRONIC EQUIPMENT. IF YOU DO NOT DO THIS, YOU CAN CAUSE INJURIES TO PERSONS AND/OR DAMAGE TO THE EQUIPMENT. WARNING: FAILURE TO OBSERVE SAFETY PRECAUTIONS BEFORE CARRYING OUT MAINTENANCE PRACTICES ON OR NEAR ELECTRICALLY CONTROLLED OR OPERATED EQUIPMENT COULD RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT. CAUTION: BEFORE SWITCHING THE ELECTRICAL SYSTEM POWER ON, MAKE SURE THAT ALL CONNECTIONS AND INSTALLATIONS ARE COMPLETE AND SECURE. NOTE: Both GCUs must be installed and Operational. DC External is required. All operational systems circuit breakers should be closed. 1. There are two remote control circuit breakers on each nacelle. 2. The SPUs can operate directly from switches on copilots instrument panel labeled STBY HYD PRESS, with switch selections 1 and 2 or NORM. 3. Set the #1 and #2 STBY HYD PRESS switches to the NORM position. 4. Make sure all post jobset up conditions exist. 5. With Mod 8/1983 incorporated, no. 2 SPU is energized automatically when no. 2 hydraulic system pressure decreases, when aircraft is in airborne mode. ( Ref. 291000 Main Systems) 6. With flaps selected to 0 on the lever quadrant in the flight compartment and STBY HYD PRESS switches set to NORM, make it sure the standby power are not in operation. 7. Select #1 SPU switch from normal to on position. 8. Make sure #1 SPU operates, providing hydraulic to #1 system. 9. Move switch back to normal position, SPU should stopped running. 10. Repeat last four steps for #2 SPU operation. 11. When flaps are selected to 5 or greater on flap quadrant, the STBY HYD PRESS switches are by passed by flap quadrant actuated switches and power is supply to both SPU pumps, pumps are running continuously. This is to ensure that during take off and landing, hydraulic power from both SPUs are continuously available to supplement the two main hydraulic systems. 12. Repeat steps (2) to (11) for #2 SPU. 9. Operational Test Of The K3 Relay (Post Mod 8/2120) NOTE: Before starting this operational test, Ref. to "Operational test of Standby Power Unit Oh. 291117. 10. Procedure WARNING: WITH HYDRAULIC POWER FROM STANDBY HYDRAULIC POWER UNIT APPLIED, DO NOT OPERATE PSEU BITE SYSTEM TEST SWITCH. (REFER TO CHAPTER 32, 326150).

WARNING:

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 220 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL

MAIN GEAR REAR AND CENTER DOORS WILL CLOSE AT ENGINE START ON APPLICATION OF EXTERNAL HYDRAULIC POWER, OR SELECTION OF A STANDBY PUMP FOR GROUND OPERATION, WITH MAIN GEAR DOOR LOCK PIN REMOVED. WARNING: OBEY ALL THE SAFETY PRECAUTIONS WHEN YOU DO MAINTENANCE ON OR NEAR THE ELECTRICAL/ELECTRONIC EQUIPMENT. IF YOU DO NOT DO THIS, YOU CAN CAUSE INJURIES TO PERSONS AND/OR DAMAGE TO THE EQUIPMENT. WARNING: FAILURE TO OBSERVE SAFETY PRECAUTIONS BEFORE CARRYING OUT MAINTENANCE PRACTICES ON OR NEAR ELECTRICALLY CONTROLLED OR OPERATED EQUIPMENT COULD RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT. CAUTION: BEFORE SWITCHING THE ELECTRICAL SYSTEM POWER ON, MAKE SURE THAT ALL CONNECTIONS AND INSTALLATIONS ARE COMPLETE AND SECURE. NOTE: Both GCUs must be installed and Operational. DC External is required. All operational systems circuit breakers should be closed. 1. There are two remote control circuit breakers on each nacelle. 2. The SPUs can operate directly from switches on copilots instrument panel labeled STBY HYD PRESS, with switch selections 1 and 2 or NORM. 3. Set the #1 and #2 STBY HYD PRESS switches to the NORM position. 4. Make sure all post jobset up conditions exist. 5. With Mod 8/1983 incorporated, no. 2 SPU is energized automatically when no. 2 hydraulic system pressure decreases, when aircraft is in airborne mode. ( Ref. 291000 Main Systems) 6. With flaps selected to 0 on the lever quadrant in the flight compartment and STBY HYD PRESS switches set to NORM, make it sure the standby power are not in operation. 7. Select #1 SPU switch from normal to on position. 8. Make sure #1 SPU operates, providing hydraulic to #1 system. 9. Move switch back to normal position, SPU should stopped running. 10. Repeat last four steps for #2 SPU operation. 11. When flaps are selected to 5 or greater on flap quadrant, the STBY HYD PRESS switches are by passed by flap quadrant actuated switches and power is supply to both SPU pumps, pumps are running continuously. This is to ensure that during take off and landing, hydraulic power from both SPUs are continuously available to supplement the two main hydraulic systems. 12. Repeat steps (2) to (11) for #2 SPU. 11. Operational Test Of The A. C. Current Transformers WARNING: OBEY ALL THE SAFETY PRECAUTIONS WHEN YOU DO MAINTENANCE ON OR NEAR THE ELECTRICAL/ELECTRONIC EQUIPMENT. IF YOU DO NOT DO THIS, YOU CAN CAUSE INJURIES TO PERSONS AND/OR DAMAGE TO THE EQUIPMENT.

WARNING:

MASTER EFFECTIVITY: See Pageblock 242102 page 201

242102

Page 221 May 15/2008

SERIES 300

AIRCRAFT MAINTENANCE MANUAL