Professional Documents

Culture Documents

ABB Traction Systems For Locomotives and High-Speed Applications - Low Res Web

Uploaded by

Ahmad ElsheemyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABB Traction Systems For Locomotives and High-Speed Applications - Low Res Web

Uploaded by

Ahmad ElsheemyCopyright:

Available Formats

Traction systems for locomotives and high-speed applications

ABB your partner of choice Unrivaled flexibility

Large series of trains and locomotives fitted with ABB traction equipment are in reliable and economic operation every day and in every climate. ABB is the expert for traction converters, motors, transformers, and complete traction chain solutions. In deep and trustful partnerships with vehicle builders, refurbishers, and rail operators, we supply state-of-the-art traction systems. Among traction specialists, ABB excels with the broadest traction portfolio and engineering capabilities for tailor-made solutions. We combine decades of rail experience and a world-leading position in areas such as traction transformers with a wealth of cross-industry know-how in power electronics, motion control and project management. ABB is not only the leader in industrial drives, but also the most innovative supplier of power semiconductors.

2 Traction systems for locomotives and high-speed applications

The following pages offer many ideas of how ABB could contribute to your next locomotive and high-speed project. We hope to inspire you as to what is possible today in the areas of power management and energy efficiency, hybrid and multi-system technology, compactness and energy-density, reliability and robustness, control and adaptability. One of the greatest strengths of ABB is our flexibility to create real value-adding innovations. Given a sound business opportunity, ABB is ready to quickly embark with you on a partnership for game-changing new solutions.

We care for every detail, because we know the impact on the lifetime of the traction system.

Complete product portfolio ABB traction solutions

BORDLINE traction converters and ABB traction solutions stand for comprehensive, flexible solutions with high performance and rewarding cost and energy savings over the life cycle. Traction chain partner As a major supplier of traction systems, ABB works with most of the leading rolling stock manufacturers. We also support transport operators throughout the whole life cycle of the trac tion chain, i.e. in the areas of service, maintenance, upgrades, and retrofit projects. Benefits of comprehensive traction chain responsibility Single partner for the entire traction chain Optimization of component dimensions and interfaces Fast commissioning and homologation TCMS integration and system optimization Higher total energy efficiency and reduced life cycle cost ABB traction solutions for all rail appliations Complete portfolio of traction chain solutions from a few 100 kW to more than 7 MW and for all types of locomotives (e.g. passenger, freight, shunting), power heads, and distributed propulsion systems.

Electric

AC DC MS DE/AC

Hybrid

DE/DC DE/MS

DieselElectric

Global presence ABB is present in more than 100 countries and can provide strong local support to your project. With a truly global organization, we are committed to local competence and local service.

4 5

1 2

7 8

Overview of ABBs traction offerings

[1] Traction transformer [2] Traction converter [3] Traction control [4] Train Control and Monitoring System [5] Traction motor [6] Diesel engine generator [7] Auxiliary converter [8] Battery charger [9] Energy storage

Traction systems for locomotives and high-speed applications 3

Proven traction components Transformers, motors, generators

ABB traction transformers World market leader with unrivaled experience Minimum line harmonics and optimum total efficiency of the traction system State-of-the-art production technology as well as design and simulation software Tailor-made configurations for under-floor or machine-room installation Highly flexible design for compactness and optimized winding topology, being critical for multi-system (MS) vehicles to respect vehicle weight/axle restrictions ABB traction motors Frameless induction traction motors designed to ensure reliable operation and high torque output Fully customizable motor concept to meet a broad range of requirements regarding e.g. output power, mounting arrangements and air duct position Broad design skills and experience to achieve a carefully calculated optimum solution for each application, whether tailor-made or based on a standard design

Examples of ABB traction components

ABB traction generators Synchronous brushless generators designed for highpowered diesel-electric locomotives Single bearing design for two couplings to be combined with the diesel engine crankshaft decreasing the size and weight of the gensets ABB UNITROL 1020 automatic voltage regulator generator, designed for reliable excitation control in traction applications Complete family of induction (asynchronous) generators suitable for medium power range applications Main advantages: simple, compact and reliable design

Traction transformer LOT 1100 1.5 MW for 16 2/3 Hz high-speed double-deck trains

Traction transformer LOT 6500 / 6700 4.5 MW for 50 Hz AC locomotives

Traction transformer 4.8 MW for 16 2/3 Hz and 5.2 MW for 50 Hz highspeed trains

Traction motor 1.2 MW for cargo locomotives

Traction motor 600 kW for high power applications

Traction generator 2.65 MW for high power applications

4 Traction systems for locomotives and high-speed applications

Proven traction components BORDLINE CC Compact Converters

ABB traction converters BORDLINE CC Compact Converters: the heart and the brain of the traction system Two-level and three-level topologies for optimal energy efficiency, economic retrofit, and fast homologation Integrated auxiliary converters, battery chargers, and head-end power (HEP) converters fed from the DC link Large portfolio of optimized durable housing solutions: from lightweight all-aluminum machine room cabinets to stainless steel underframe constructions

Most compact and economic multi-system converters Tailor-made configurations for under-floor or machine-room installation Environmentally friendly and highly efficient water cooling Easy handling of low weight replacable power electronic modules

Examples of ABB traction components

Compact Converter 2.2 MW for multi-system power heads

Compact Converter 0.75 MW for hybrid shunting locomotives

Compact Converter 3.6 MW for 50 Hz AC locomotives

Compact Converter 1.8 MW for diesel-electric locomotives Traction systems for locomotives and high-speed applications 5

Proven traction components BORDLINE M Auxiliary converters

Auxiliary converter 180 kVA

Battery charger 10 kW

Auxiliary converter 130/260 kVA

Battery charger 15 kW

Auxiliary converters and battery chargers Complete portfolio of auxiliary converters, converting power from 2 kW up to 1 MW, ranging from converters for individual loads or batteries, to full onboard power supply for a train BORDLINE M: all stand-alone auxiliary converter types, battery chargers and head end power (HEP) converters BORDLINE CC: Compact Converters for the traction chain with integrated auxiliary converters (and battery chargers) connected to the DC link

6 Traction systems for locomotives and high-speed applications

Powerful converter modules Full flexibility for customized solutions

High-performance control module Key advantage of ABB traction solutions: the AC 800PEC control platform, probably the most powerful modular controller for high-speed performance on the market AC 800PEC control platform also used in ABB wind converters, high-power industrial drives, plant automation, high-power rectifiers and many other applications High volume and wide application diversity > high reliability Excellent range of control and communication functionality in cycle times extending from the sub-microsecond to the millisecond level Fast reaction times crucial to protect the traction system Complemented by a variety of input/output modules as well as engineering and service tools Tested under the most stringent environmental conditions Admired for the workmanship of the control wiring

Robust, reliable, service-friendly power modules All BORDLINE converters, offered in a multitude of configurations and designs, are built on a platform of a few optimized PEBBs (Power Electronic Building Blocks) with 1.7 kV, 3.3 kV, 4.5 kV, and 6.5 kV IGBTs (Insulated Gate Bipolar Transistor) High production quantity of standardized PEBBs: Excellent reliability and field experience Technical optimization (lifetime, switching behavior, power density) Multiple sources for all PEBB components High spare part availability at reasonable cost PEBBs also optimized for service aspects: easy to handle (small and lightweight) and to exchange Liquid-cooled PEBBs for high power converters (highest compactness and long lifetime) Air-cooled PEBBs for many types of auxiliary converters

Three-level power module

Two-level power module Traction systems for locomotives and high-speed applications 7

Cutting-edge control technology High-performance control software

State-of-the-art adhesion control Key for the quantitative performance of the locomotive or the train and for reducing maintenance cost due to less mechanical wear Superior determination of actual vehicle speed and perfect wheel-slip/slide control for all types of driven axle configurations (single axle or bogie control) Exceptional adhesion performance, see references on pages 12 and 14 Reduced mechanical wear of the vehicle Reduced wear of motors, gears, wheels, and the bogies Minimization of harmonics in the motor current for all speed-torque regimes Reduced vibrational oscillations Suppression of torsional oscillations of the driven axles in a bogie Optimized line voltage impact Minimization of line harmonics Faster homologation Stabilization of the line voltage by active damping under weak line conditions, resulting in higher availability of vehicles with ABB traction Examples ofother innovative ABB software functions Various system control functions for reducing energy consumption in cooling, auxiliaries, and diesel engines Converter emergency operation mode to clear track even when TCMS is fault De-icing function for the catenary Integration of energy storage control

Traction diagram

Effort [kN] 500 450 400 350 300 250 200 150 100 50 0 10 20 30 40 50 60 70 80 Speed [km/h] 90 100 110 120 130 Running resistance 22 15 0 Tractive effort

8 Traction systems for locomotives and high-speed applications

Cutting-edge control technology Excellence in software development

Control code consistency and traceability Simple, transparent and intuitive code, programmed in a modular and visual function block language Used consistently from the design phase through to detailed implementation, in real-time simulation tests and finally during fine-tuning under commissioning and homologation Perfect traceability of requirements and specifications to the operative version of the traction system software Speeding up of commissioning and homologation Fast commissioning and homologation due to: Quality and transparency of the software development Simple adjustment of parameters during commissioning and homologation Minimization of line harmonics Rigorous and automated testing of the control software in a real-time simulation environment Reduced lead time between commissioning and first roll-out Faster project delivery and substantial cost savings as a result of shortened vehicle commissioning and homologation Safe testing of non-standard operational modes Real-time simulator extending the software validation to situations inaccessible on the test track (e.g. speed limitations, very unlikely system failures) Faster project delivery Flexible adaptation of the control software Control software change requests facilitated by leadingedge software development environment Sustainable quality of traction system control over the lifetime of the vehicle

Traction systems for locomotives and high-speed applications 9

Retrofit and modernizations Cooperation with operators

Project example for energy savings through retrofit Old traction chain

Energy input 167 % 10.3 % 18.1 % 18.2 % 7.6 % 12.4 %

New traction chain

Energy input 143 %

Transformer Converter Motor and gearbox Vehicle parking Power head auxiliary systems

15 % lower losses

7.5 % 4.7 % 12.2 % 8.4 %* 9.9 %

Transformer Converter Motor and gearbox Vehicle parking Power head auxiliary systems

Energy at wheel 100 %

Energy at wheel 100 %

* Higher percentage value due to substantially reduced absolute losses

Energy losses in the traction chain of high-speed trains before and after retrofit with new IGBT converters

Interesting business cases for retrofit Need to replace converters or other traction chain components while the major part of the locomotive or high-speed train are fit for another 20 years of operation: Availability and cost of spare parts Unsatisfactory reliability and performance Additional benefits (mid life crisis as a chance): Energy savings Easy maintenance concepts Lifetime extension for retained components, e.g. motors Reduced heat and noise generation Higher compactness and lower weight of new traction chain components Optional change of fleet mission, e.g. hybrid or multisystem operation, higher speed or tractive effort, higher on-board power Return on investment scales with the size of the modernized fleet

ABB support for assessment Which traction chain components to keep, to upgrade or to replace Performance potential of the complete traction chain for new duty profiles RAMS (reliability, availability, maintainability, safety) potential Demanding tailor-made engineering Traction chain retrofit engineering for an existing vehicle by far more challenging than for new designs ABB with a wealth of experience in engineering and project management Deep partnership with the customer Flexible to utilize the customers workshop capacities for the retrofit project Training and empowerment of the customers operations and maintenance staff

Assessment

Re-engineering

Re-cycling

Re-building

Re-homologation

REVENUE

10 Traction systems for locomotives and high-speed applications

Service and support New era of industry partnership

Field Service and Repairs Remote Support and Diagnostics Training and Consultancy

BORDLINE Service

Obsolescence Management Spare Parts and Logistics Field Data Monitor

Empowering the customer Pragmatic maintenance concept for efficient adoption of on-site maintenance by customers service personnel: Customized trainings Strong diagnostic tools Modular repair Commissioning support Product maintenance Upgrades Commitment to customer support with flexible ABB service contracts spanning multi-year periods: Clever spare part logistics Repairs, on-site service Field operating statistics and analysis Support line and expert support The BORDLINE Service philosophy: Deep partnership with the customers service organization, providing focused services in areas of the industrial partners expertise Smooth commissioning and early operation phase Guaranteeing high converter availability after the warranty period and through the entire life cycle

Reinventing spare parts logistics No more stocking of obsolete spare parts, no more waiting for spares BORDLINE Service concept: The right spare parts at the right site at the required time Containerized consignment stocks with automatic replenishment, optimized to suit the fleet requirements Service program for motors, generators, and transformers Please refer to service brochures TransForLife Solutions and motor/generator service Unique service network Global network of skilled experts and service sites for converters, motors, generators, and transformers

Traction systems for locomotives and high-speed applications 11

Selected references Locomotives

BORDLINE CC1500 AC | LOT 6500 / 6700 | BORDLINE M130 / 260

BORDLINE CC1500 DE | Traction motor | Traction generator

Locomotives WAG 9 / WAP 7 / WAP 5, Indian Railways Customer need Replacement of GTO (Gate Turn-Off thyristor) converters without any modification to mechanical loco design, interfaces, control, transformer, and traction motor Design suitable for old as well as new locomotives Resistent to high temperatures Service-friendly solution ABB solution Design of new tailor-made IGBT-based (Insulated Gate Bipolar Transistor) converters High energy efficiency by reducing losses in the transformer and motors New generation adhesion control embedded in converter control Conversion from bogie control to single axle control Customer benefits IGBT converters fully interchangeable with GTO converter series Significantly improved tractive effort under all conditions Haulage increased by 9% to 5500 tons Better energy-efficiency and less heat generation Higher redundancy in case of motor failure Easy maintenance and reduction of operating cost Reliable long-term supply for traction transformers

Diesel-electric locomotive EUROLIGHT, Vossloh Customer need Reliable traction chain partner Minimum weight of traction chain for diesel-electric propulsion ABB solution Optimized system of generator, compact converters, and traction motors New traction chain platform, configurable for Bo-Bo locomotive with head end power / Co-Co locomotive Customer benefits High adhesion coefficient utilization reducing sand consumption and mechanical wear significantly The EUROLIGHT is currently the only diesel-electric locomotive available on the market that combines a low axle-load (< 20 t) with a high power rating, resulting in high operational flexibility and low operating cost

12 Traction systems for locomotives and high-speed applications

Selected references High-speed trains

LOT 1100 | BORDLINE CC1500 AC | BORDLINE M10

BORDLINE CC1500 AC

High-speed double-deck train KISS, Stadler Rail Customer need Highest reliability and availability, based on proven technologies High acceleration Minimum weight and space for traction equipment ABB solution Further optimization of well-proven low-voltage IGBT compact converter platform Robust all-aluminum cabinet Optimized transformer Customer benefits Very high reliability High energy-efficiency due to high switching frequency More comfort and space for passengers Traction converter with highest power density (1.5 MW/t) on the market

Retrofit of ICE 1 high-speed power head, Deutsche Bahn Customer need Replacement of old thyristor converters without any modification to mechanical power head design, interfaces, control, transformer, and traction motors Significant increase in energy efficiency and availability ABB solution Development and production of new IGBT-based propulsion converter for 4.8 MW power head within 13 months Innovative three-level converter technology Service concept for easy maintenance Reliable delivery of one power head retrofit kit per week Customer benefits Reliable partnership for quick refurbishment of 38 power heads in the workshop of DB Energy consumption cut by at least 15 % Massive reduction in operating cost Massive gain in reliability and availability

Traction systems for locomotives and high-speed applications 13

Selected references Locomotives

BORDLINE CC750 MS

BORDLINE CC750 DC

Hybrid shunting locomotive Eem 923, Stadler Rail Customer need Hybrid system: 11/15/25 kVAC and diesel-electric for last mile operation High energy-efficiency ABB solution Very compact and lightweight tailor-made traction transformer and two independent traction converters Superb adhesion control system Low noise emission Customer benefits CO2 emissions will be reduced by more than 4000 tons per year with a first order of 30 shunters for SBB Cargo Significant reduction of operating costs

Rack and adhesion locomotive, Stadler Rail Customer need High-power 3kVDC traction equipment controlling individually six motors 5 MW locomotive power Recuperation at full load (downhill) Easy maintenance ABB solution Highly redundant traction system (six converters per locomotive) Well proven three-level medium voltage technology Customer benefits Massive energy savings due to energy recuperation capability 780 kN tractive effort on ramps up to 104 Remote diagnosis system for easier service

Photo SBB

14 Traction systems for locomotives and high-speed applications

Partnering with ABB Major benefits

High flexibility and innovation to realize your project vision Large global corporation and technology leader with a long-term strategic commitment to the rail industry

ABB as a pure traction chain and electrical partner for train builders and operators Competent local service and support wherever your project is

Traction systems for locomotives and high-speed applications 15

Contact us

ABB Switzerland Ltd Traction Converters Austrasse CH-5300 Turgi, Switzerland Phone: +41 58 585 00 00 E-Mail: traction.converters@ch.abb.com www.abb.com/railway

We reserve all rights in this document and in the subject matter and illustrations contained therein. Any reproduction, disclosure to third parties or utilization of its contents - in whole or in parts - is forbidden without prior written consent of ABB AG. Copyright 2012 ABB All rights reserved.

3BHS340077 ZAB E09

Note: We reserve the right to make technical changes or modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. ABB Ltd does not accept any responsibility whatsoever for potential errors or possible lack of information in this document.

You might also like

- TLE003 111114015808 F13 16 Non-Sparking Tools ENDocument22 pagesTLE003 111114015808 F13 16 Non-Sparking Tools ENAhmad ElsheemyNo ratings yet

- Maxtor M3 Portable - User Manual-EN - E01 - 19 05 2016 PDFDocument22 pagesMaxtor M3 Portable - User Manual-EN - E01 - 19 05 2016 PDFAhmad ElsheemyNo ratings yet

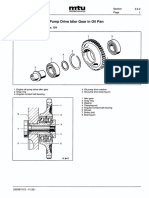

- T - Eng - Engine Oil Pump Idler Gear in Oil Pan - 01 - 160323Document11 pagesT - Eng - Engine Oil Pump Idler Gear in Oil Pan - 01 - 160323Ahmad ElsheemyNo ratings yet

- Technical Guidebook 1 10 en RevfDocument446 pagesTechnical Guidebook 1 10 en RevfTfelx CflexNo ratings yet

- High-efficiency PAR 56 lamp for clubs and discosDocument3 pagesHigh-efficiency PAR 56 lamp for clubs and discosAhmad ElsheemyNo ratings yet

- DOE Fundamentals Handbook, Mechanical Science, Volume 1 of 2Document122 pagesDOE Fundamentals Handbook, Mechanical Science, Volume 1 of 2Bob VinesNo ratings yet

- C00341ED 2vol Aug1980 Extracted Page 141Document1 pageC00341ED 2vol Aug1980 Extracted Page 141Ahmad ElsheemyNo ratings yet

- T - Eng - Valve Set Lubrication - 01 - 160323 PDFDocument10 pagesT - Eng - Valve Set Lubrication - 01 - 160323 PDFAhmad ElsheemyNo ratings yet

- Tab IndexDocument21 pagesTab IndexAhmad ElsheemyNo ratings yet

- T - Eng - Pressure Relief Valve - 01 - 160323 PDFDocument9 pagesT - Eng - Pressure Relief Valve - 01 - 160323 PDFAhmad ElsheemyNo ratings yet

- Logic DesignDocument364 pagesLogic DesignAhmad ElsheemyNo ratings yet

- تقنية تشغيلDocument217 pagesتقنية تشغيلHeraiz RachidNo ratings yet

- Indian Institute of Technology, Delhi: Department of Mechanical EnggDocument0 pagesIndian Institute of Technology, Delhi: Department of Mechanical EnggGeorge KaridisNo ratings yet

- Termodinamika Vol 1Document138 pagesTermodinamika Vol 1Moh Rusli BahtiarNo ratings yet

- The Design of Electrical Machines Using ANSYS Maxwell July 16th 2013Document48 pagesThe Design of Electrical Machines Using ANSYS Maxwell July 16th 2013Ahmad Elsheemy100% (3)

- Catia V5 Bending Torsion Tension Shear TutorialDocument18 pagesCatia V5 Bending Torsion Tension Shear Tutorialrankx001No ratings yet

- Electric DrivesDocument49 pagesElectric DrivessureshNo ratings yet

- AutoCAD 3D Course ManualDocument166 pagesAutoCAD 3D Course ManualJed Tedor98% (47)

- Industrial Decision Making Analysis The Implementation of The Theory of ConstraintsDocument57 pagesIndustrial Decision Making Analysis The Implementation of The Theory of ConstraintsAhmad ElsheemyNo ratings yet

- Industrial Decision Making Analysis The Implementation of The Theory of ConstraintsDocument57 pagesIndustrial Decision Making Analysis The Implementation of The Theory of ConstraintsAhmad ElsheemyNo ratings yet

- CNC Machines GuideDocument36 pagesCNC Machines GuideAhmad ElsheemyNo ratings yet

- Weixiukun104476 Self 201202 6Document10 pagesWeixiukun104476 Self 201202 6Ahmad ElsheemyNo ratings yet

- Combustion Control of Diesel Engines Using Injection TimingDocument12 pagesCombustion Control of Diesel Engines Using Injection TimingAhmad ElsheemyNo ratings yet

- 2012 ECOSM Lamara Et AlDocument8 pages2012 ECOSM Lamara Et AlAhmad ElsheemyNo ratings yet

- Electrical Transient PDFDocument6 pagesElectrical Transient PDFalexwoodwickNo ratings yet

- Computer Simulation Study of Exhaust GasDocument3 pagesComputer Simulation Study of Exhaust GasAhmad ElsheemyNo ratings yet

- ERR RET Optimisation11 2columnsDocument7 pagesERR RET Optimisation11 2columnsAhmad ElsheemyNo ratings yet

- A Fuzzy PID Controller For Exhaust Gas Recirculation SystemDocument7 pagesA Fuzzy PID Controller For Exhaust Gas Recirculation SystemAhmad ElsheemyNo ratings yet

- Computer Simulation Study of Exhaust GasDocument3 pagesComputer Simulation Study of Exhaust GasAhmad ElsheemyNo ratings yet

- Egr PDFDocument30 pagesEgr PDFAhmad Elsheemy50% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tubo de RX ToshibaDocument22 pagesTubo de RX ToshibaDeulin Natalia Tonguino TacanNo ratings yet

- NV 2001-01 Using Voltage Reference and Temperature Sensor ICs Parts 1-3Document12 pagesNV 2001-01 Using Voltage Reference and Temperature Sensor ICs Parts 1-3Dylan KomichekNo ratings yet

- RANGER 305g LincolnDocument6 pagesRANGER 305g LincolnWilfredoNo ratings yet

- EM - 1110!2!3006-HEPP Electric DesignDocument118 pagesEM - 1110!2!3006-HEPP Electric DesignekaamfNo ratings yet

- Journal Jpe 14-2 1420244966Document11 pagesJournal Jpe 14-2 1420244966Hua Hidari YangNo ratings yet

- Em I & A.C.Document20 pagesEm I & A.C.mitakar7868No ratings yet

- AGC-4 Installation Instructions 4189340687-F PDFDocument69 pagesAGC-4 Installation Instructions 4189340687-F PDFhs421No ratings yet

- Science 9 Quarter 4 LASDocument27 pagesScience 9 Quarter 4 LASFerd Reddick LeponNo ratings yet

- Bladeless WindmillDocument13 pagesBladeless WindmillNaseefNo ratings yet

- Laporan Reliability PLTD Suppa - Februari 2021Document125 pagesLaporan Reliability PLTD Suppa - Februari 2021Safriadi KadirNo ratings yet

- 0 All 1)Document125 pages0 All 1)RAMITHPNo ratings yet

- ATA 24 Electrical Power R04Document121 pagesATA 24 Electrical Power R04srtrtyrtNo ratings yet

- Sample Paper - ACST - Two Year Medical-2019Document10 pagesSample Paper - ACST - Two Year Medical-2019RibhavNo ratings yet

- Specsheet 3516 1825 kVA PrimeDocument6 pagesSpecsheet 3516 1825 kVA PrimeYusman EkaNo ratings yet

- Harmonics ReportDocument57 pagesHarmonics ReportNitesh Mehta100% (1)

- Asian Welding Set 1 QuestionsDocument11 pagesAsian Welding Set 1 Questionsjishnu k muraliNo ratings yet

- Test all electrosurgical devices with the Rigel Uni-ThermDocument4 pagesTest all electrosurgical devices with the Rigel Uni-ThermLeo AranibarNo ratings yet

- Led Light Home Power 73Document150 pagesLed Light Home Power 73Mohamed HareeshNo ratings yet

- EEE20005 Week 6 7Document96 pagesEEE20005 Week 6 7ShelbyNo ratings yet

- LT3-N Single Phase Generator PresentationDocument75 pagesLT3-N Single Phase Generator Presentationubaldo caraballo100% (1)

- Powermate by Pramac ENG 2015Document12 pagesPowermate by Pramac ENG 2015prasannaaaslNo ratings yet

- Wiring Color CodeDocument1 pageWiring Color CodeDamir ŠafaričNo ratings yet

- Battery Energy Storage System For Power Conditioning of Renewable Energy SourcesDocument6 pagesBattery Energy Storage System For Power Conditioning of Renewable Energy Sourcesapi-3826450No ratings yet

- Model: 15.5EOZD 13efozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 15.5EOZD 13efozd: 60 HZ 50 HZ 1-Phase Dieselabduallah muhammadNo ratings yet

- Polytechnic of Namibia Electrical Protection Exam Protection Scheme DesignDocument3 pagesPolytechnic of Namibia Electrical Protection Exam Protection Scheme Designmoses kakwenaNo ratings yet

- 190 e Cr302 en Servomotors-For-steam-turbinesDocument10 pages190 e Cr302 en Servomotors-For-steam-turbinesscribdkhatnNo ratings yet

- Course Specs Electro II CHEDDocument12 pagesCourse Specs Electro II CHEDReymarr HijaraNo ratings yet

- Qis 1250 MD Me: Technical SpecificationsDocument9 pagesQis 1250 MD Me: Technical Specificationskole_bgNo ratings yet

- SSLC Science Exam Prep: Key Questions on ElectricityDocument80 pagesSSLC Science Exam Prep: Key Questions on ElectricitySriNo ratings yet

- Republic of The Philippines Pablo Borbon Main II, Alangilan, Batangas City WWW - Batstate-U.edu - PH Tel. No. (043) 425-0139 Loc. 118Document6 pagesRepublic of The Philippines Pablo Borbon Main II, Alangilan, Batangas City WWW - Batstate-U.edu - PH Tel. No. (043) 425-0139 Loc. 118Harold De ChavezNo ratings yet