Professional Documents

Culture Documents

Beam ExampleProblems

Uploaded by

April IngramCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Beam ExampleProblems

Uploaded by

April IngramCopyright:

Available Formats

Section Moment Capacity: Example Problem No.

1

What is the section moment capacity of 530UB92.4 Grade 300 beams about the major

principal axis (x)?

t

w

= 10.2 mm f

yw

= 320 MPa

t

f

= 15.6 mm f

yf

= 300 MPa

Section capacity (For the failure mode of local buckling and yielding)

Flange

e

= (b

f

- t

w

)/2t

f

)

250

f

y

= 6.37

250

300

= 6.98 <

ep

of 9. Compact flange

Web

e

= (d

1

/t

w

)

250

f

y

= 49.2

250

320

= 55.7 <

ep

of 82 Compact web

Section is therefore compact.

Z

ex

= Lesser of S

x

or 1.5Z

x

= Lesser of 2370 x 10

3

or 1.5 x 2080 x 10

3

= 2370 x 10

3

mm

3

| M

sx

= | f

y

Z

ex

= 0.9 x 300 x 2370 x 10

3

= 640 kNm

In this case of compact flange and web (compact section), the capacity is not affected by local

buckling, and is equal to the full plastic moment capacity M

p

.

Note: Since the web and flange thicknesses are different (15.6 and 10.2 mm), their yield

stresses are not the same (320 and 300 MPa) despite being the same steel grade of 300. In the

plate slenderness

e

calculations, a nominal yield stress value of 300 could have been used to

simplify the calculations, however, actual values of 300 and 320 have been used here. The use

of actual values makes very little difference to the final answers. For the section capacity

calculations, the minimum yield stress value of 300 MPa has been used (conservative).

Example Problem No.2

What is the section moment capacity of 200UC52.2 Grade 300 beams about the minor

principal axis (y)?

t

w

= 8 mm f

yw

= 320 MPa

t

f

= 12.5 mm f

yf

= 300 MPa

Section capacity (For the failure mode of local buckling and yielding)

Flange

e

= (b

f

- t

w

)/2t

f

)

250

f

y

= 7.84

250

300

= 8.59 <

ep

of 9. Compact flange

No need to check the web as it is on the neutral axis.

Section is therefore compact.

Z

ey

= Lesser of S

y

or 1.5Z

y

= Lesser of 264 x 10

3

or 1.5 x 174 x 10

3

= 261 x 10

3

mm

3

| M

sy

= | f

y

Z

ey

= 0.9 x 300 x 261 x 10

3

= 70.5 kNm

In this case of compact section, the capacity is not affected by local buckling, and is equal to

the full plastic moment capacity M

p

. Note that S

y

> 1.5Z

y

, so 1.5Z

y

is used.

Example Problem No.3

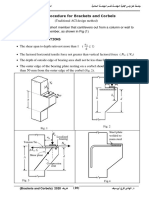

Figure 4.4 shows a lightly welded box-girder made of Grade 350 steel. What is its section

moment capacity about the major principal axis (x)?

t

w

= 10 mm f

yw

= 360 MPa

t

f

= 12 mm f

yf

= 360 MPa

Figure 4.4 Welded Box-girder in Example Problem No.3

Section capacity (For the failure mode of local buckling and yielding)

Flange

e

= (b

f

/t

f

)

250

f

y

= (360/12)

250

360

= 36 >

ep

of 30, but <

ey

of 40.

Non-compact flange

Web

e

= (d

1

/t

w

)

250

f

y

= [(400-2x12)/10]

250

360

= 45 <

ep

of 82 Compact web

Section is therefore non-compact.

Effective section modulus Z

e

will be between Z and Z

c

(Lesser of S or 1.5 Z )

Z

e

= Z +( Z

c

- Z )

ey e

ey ep

Elastic section modulus

Z = [2x10x(400-2x12)

3

/12 + 2x400x12(400/2-12/2)

2

]/200 = 2.250x10

6

mm

3

Plastic section modulus

S = 2x10x(400-2x12)

2

/4 + 2x400x12(400/2-12/2) = 2.569x10

6

mm

3

Z

c

= Lesser of S or 1.5 Z = 2.569x10

6

mm

3

Z

ex

= 2.250x10

6

+ (2.569-2.250)x10

6

x

) 30 40 (

) 36 40 (

= 2.377x10

6

mm

3

(Note that 2.250x10

6

corresponds to

ey

of 40 whereas 2.569x10

6

corresponds to the

ep

of 30)

Design section moment capacity

| M

sx

= | f

y

Z

ex

= 0.9 x 360 x 2.377 x 10

6

= 770 kNm

In this case of compact web and non-compact flange (non-compact section), the capacity is

affected by inelastic local buckling of the compression flange, and therefore will not reach

the full plastic moment capacity M

p

.

360 mm

400 mm

Example Problem No.4

Figure 4.5 shows a lightly welded I-section beam made of Grade 350 steel. What is its section

moment capacity about the major principal axis (x)?

t

w

= t

f

=10 mm f

y

= 360 MPa

Figure 4.5 Welded I-section in Example Problem No.4

Section capacity (For the failure mode of local buckling and yielding)

Flange

e

= (b

f

- t

w

)/2t

f

)

250

f

y

= [(400-10)/2x10]

250

360

= 23.4 >

ey

of 15. Slender flange

Web

e

= (d

1

/t

w

)

250

f

y

= [(400-2x10)/10]

250

360

= 45.6 <

ep

of 82 Compact web

Section is therefore slender.

Elastic section modulus

Z = [10x(400-2x10)

3

/12 + 2x400x10(400/2-10/2)

2

]/200 = 1.750x10

6

mm

3

Effective section modulus Z

e

= Z

ey

e

for flat plate element in uniform compression.

Z

ex

= 1.750x10

6

x 15/23.4 = 1.122x10

6

mm

3

Design section moment capacity

| M

sx

= | f

y

Z

ex

= 0.9 x 360 x 1.122 x 10

6

= 363.5 kNm

In the above method, the section modulus component of the web also gets reduced despite

being compact. Therefore a more accurate Z

ex

can be obtained as shown next if the reduction

is only applied to the section modulus component of the slender flange.

Z

ex

= [10x(400-2x10)

3

/12 + 2x400x10(400/2-10/2)

2

x(15/23.4)]/200 = 1.204x10

6

mm

3

| M

sx

= | f

y

Z

ex

= 0.9 x 360 x 1.204 x 10

6

= 390.1 kNm

This method gives about 7% more in bending capacity.

In this case of compact web and slender flange (slender section), the capacity is affected by

elastic local buckling of flanges, and therefore will not even reach the first yield moment

capacity M

y

.

400 mm

400 mm

Example Problem No.5

Figure 4.6 shows a lightly welded plate girder made of Grade 350 steel. What is its section

moment capacity about the major principal axis (x)?

t

w

= 10 mm f

yw

= 360 MPa

t

f

= 25 mm f

yf

= 340 MPa

Figure 4.6 Welded Plate Girder in Example Problem No.5

Section capacity (For the failure mode of local buckling and yielding)

Flange

e

= (b

f

- t

w

)/2t

f

)

250

f

y

= [(300-10)/2x25]

250

340

= 6.76 <

ep

of 8. Compact flange

Web

e

= (d

1

/t

w

)

250

f

y

= [(1500-2x 25)/10]

250

360

= 174 >

ey

of 115 Slender web.

Section is therefore slender, governed by web element, ie. Section slenderness

s

= 174

Ignoring the contribution of web to the section modulus

Z

ex

= [2x300x25x(1500/2-25/2)

2

]/750 = 10.878x10

6

mm

3

| M

sx

= | f

y

Z

ex

= 0.9 x 340 x 10.878x10

6

= 3329 kNm

The AS 4100 design rules do not address this case of slender web with both edges supported.

Instead it gives the following rule for flat plate element with maximum compression at

unsupported edge and tension at the other edge (including zero tension).

Effective section modulus Z

e

= Z (

ey

e

)

2

Applying this to the section modulus of the web only,

Z

ex

= [{10x(1500-2x25)

3

/12} x (115/174)

2

+ 2x300x25(1500/2-25/2)

2

]/750 =12.358x10

6

mm

3

WEB componet FLANGE component

Design section moment capacity

| M

sx

= | f

y

Z

ex

= 0.9 x 340 x 12.358 x 10

6

= 3780 kNm

This method gives about 13.5% more in capacity.

In this case of compact flange and slender web (slender section), the capacity is affected by

elastic local buckling of webs, and therefore will not even reach the first yield moment

capacity M

y

.

300 mm

1500 mm

Example Problem No.6

Figure 4.7 shows a welded plate girder made of Grade 350 steel. What is its section moment

capacity about the major principal axis (x)?

t

w

= 10 mm f

yw

= 360 MPa

t

f

= 15 mm f

yf

= 350 MPa

Figure 4.7 Welded Plate Girder in Example Problem No.6

Section capacity (For the failure mode of local buckling and yielding)

Flange

e

= (b

f

- t

w

)/2t

f

)

250

f

y

= [(450-10)/2x15]

250

350

= 17.4 >

ey

of 15.

Slender flange

Web

e

= (d

1

/t

w

)

250

f

y

= [(1500-2x15)/10]

250

360

= 176.4 >

ey

of 115

Slender web.

Section is therefore slender and its slenderness will be that of web as (176.4/115) >

(17.4/15). Section slenderness

s

= 176.4

Ignoring the contribution of web to the section modulus and allowing for the slender flange in

uniform compression, ie. Z

e

= Z

ey

e

for flat plate element in uniform compression;

Z

ex

= {[2x450x15x(1500/2-15/2)

2

]/750} x (15/17.4) = 8.555x10

6

mm

3

| M

sx

= | f

y

Z

ex

= 0.9 x 350 x 8.555x10

6

= 2695 kNm

The AS 4100 design rules do not address this case of slender web with both edges supported.

Instead it gives the following rule for flat plate element with maximum compression at

unsupported edge and tension at the other edge (including zero tension).

Effective section modulus Z

e

= Z (

ey

e

)

2

Applying this to the section modulus of the web only,

Z

ex

= [{10x(1500-2x15)

3

/12}x(115/176.4)

2

+{2x450x15x(1500/2-15/2)

2

}x(15/17.4)]/750

= 10.055x10

6

mm

3

WEB componet FLANGE component

450 mm

1500 mm

Design section moment capacity

| M

sx

= | f

y

Z

ex

= 0.9 x 350 x 10.055 x 10

6

= 3519 kNm

This method gives about 30.5% more in capacity.

In this case of slender web and flange (slender section), the capacity is affected by elastic

local buckling of both web and flange, and therefore will be much less than the first yield

moment capacity M

y

.

Example Problem No.7

How do you calculate the section moment capacity of an I-section beam about the minor

principal axis (y) if its flanges are slender?.

The AS 4100 design rules address this case of slender flanges with maximum compression at

unsupported edge and zero tension at the other edge.

Effective section modulus Z

e

= Z (

ey

e

)

2

Z

ey

= Z

flange

(

ey

e

)

2

where

ey

= 25 for hot-rolled sections.

The section modulus component of web, Z

web,

is negligible.

Example Problem No.8

What is the section moment capacity of a Grade 350 1500 x 10 CHS?

t = 10 mm f

yf

= 360 MPa d

o

= 1500 mm

Section capacity (For the failure mode of local buckling and yielding)

s

=

t

d

o

250

f

y

= (1500/10) x (360/250) = 216 >

ey

of 120.

Slender section

Z

e

= Lesser of Z\(

sy

/

s

) and Z(2

sy

/

s

)

2

= Lesser of Z x \(120/216) or Z x (2x120/216)

2

= Lesser of 0.745 Z or 1.235 Z = 0.745 Z

Z

e

= 0.745 [{t(1500

4

-1480

4

)/64}/750] = 12.903x10

6

mm

3

| M

s

= | f

y

Z

e

= 0.9 x 360 x 12.903x10

6

= 4181 kNm

Member Capacity: Example Problem No.1

Figure 4.14 shows the roof structure of a service station building. Determine the size of a

suitable UB section for the main beams B if the wind uplift pressure on the roof is 2.5 kPa.

Beam

B

2m

Column A

Elevation

1.5 m

Plan View

Figure 4.14. Service Station Building for Example Problem 1

Using the roofing and purlin manufacturers charts,

- The required roof sheeting: 0.42 mm Monoclad with an internal span of 1700 mm and

end spans of 1350 mm.

- the required C-section purlin to be used for the given wind uplift pressure is C300-30.

11 m 2 m

2 m

11 m

2 m

Column A

Purlins

Main Beams B

1.5 m

8 m

Metal sheeting Purlins

Load Evaluation for Beam Design

For each main beam, the uniformly distributed design load due to

wind uplift load = 2.5 x 5.5 x 15/15 = 13.75 kN/m

self-weight of sheeting = 4.28 kg/m

2

x (9.81/1000) x 5.5 = 0.231 kN/m

self-weight of 10 purlins = (12.72 kg/m x 5.5 x 10 / 15) x (9.81/1000) = 0.458 kN/m

Assume beam self-weight to be 80 kg/m = 0.78 kN/m

Total self-weight of roof allowing for connections = (0.231 + 0.458 + 0.78) 1.1 = 1.616 kN/m

w kN/m

Figure 4.15 Loading diagram for Main Beams B

Maximum bending moment M

max

= 7.5 w x 5.5 7.5 w x 3.75 = 13.125 w kNm

Wind Uplift Case (dead load plus wind load combination),

Design load w = 0.9 x (1.616) 13.75 = - 12.30 kN/m (net wind uplift)

Design moment M* = 13.125 x 12.30 = 161.4 kNm

Effective length factors:

Segment length is 11 m and its ends can be assumed to be fully restrained (F).

Since purlins are located on the tension flange, they are considered not to provide any lateral

restraint to the main beam, hence the Full span segment has to be considered (ie. 11 m)

k

t

= 1; load applied on the sheeting, ie. on the tension flange, k

l

= 1; k

r

= 1

Effective length l

e

= 1 x 1 x 1 x 11 m = 11 m

Try 610UB101, Z

ex

= 2900 x 10

3

|M

sx

= 0.9 x 300 x 2900 x 10

3

= 783 kNm (M

sx

= 870 kNm)

For l

e

= 11 m, the reference buckling moment M

o

= 223 kNm from the table given at the end

of this problem. Alternatively, it can be calculated using appropriate section properties of

610UB101 and an effective length of 11 m in the buckling formula given earlier in this

section.

o

s

= 0.6 [ )

223

870

( 3 )

223

870

(

2

+ ] = 0.220

Moment distribution factor o

m

= 1.13 for a bending moment distribution due to a uniformly

distributed load on a simply supported beam (ignoring the effect due to overhangs).

|M

bx

= o

m

o

s

|M

sx

= 1.13 x 0.220 x 783 = 194.7 kNm > M* of 161.4 kNm

Hence the choice of 610UB101 is satisfactory.

Check the self-weight of beam 610UB101 = 101 kg/m = 0.99 kN/m

Revised self-weight of roof = (0.231 + 0.458 + 0.99) x 1.1 = 1.85 kN/m

Revised design moment = 13.125 x [0.9 x 1.85 13.75] = 158.6 kNm, OK.

11m 2 m 2 m

Now check for Gravity Load Case (Dead load plus live load combination)

For each main beam, the uniformly distributed design load due to

Live load Q = 0.25 kPa x 5.5 = 1.375 kN/m

Dead load G = 1.85 kN/m

Design load w = 1.2 x 1.85 + 1.5 x 1.375 = 4.28 kN/m

Design moment M* = 13.125 x 4.28 = 56.2 kNm

Effective length factors:

In this case purlins are fixed to the compression flange of the beams and hence will improve

its buckling strength. They will also divide the main span into many small segments.

Segment length l is equal to purlin spacing = 1.7 m and its ends can be assumed to be fully

restrained (F) see AISC publication.

k

t

= 1;

load is applied on the sheeting, ie. on the compression flange, so usually k

l

could have been

1.4, but the load is transferred via the purlin at the segment end, so k

l

= 1.0

k

r

= 1

Effective length l

e

= 1 x 1 x 1 x 1.7 = 1.7 m

For l

e

= 1.7 m, the reference buckling moment M

o

= 6338 kNm

o

s

= 0.6 [ )

6338

870

( 3 )

6338

870

(

2

+ ] = 0.960

Moment distribution factor o

m

can be taken as 1 for a short segment of length 1.7 m.

|M

bx

= o

m

o

s

|M

sx

= 1 x 0.960 x 783 = 752 kNm > M* of 56.2 kNm

Hence the choice of 610UB101 is satisfactory, but over-design; the section is too big.

This is not an economical design; reduce effective length for wind uplift case by providing

fly braces at every purlin (spaced at 1.7 m).

Effective length l

e

= 1 x 1 x 1 x 1.7 m = 1.7 m

Moment distribution factor o

m

can be taken as 1 for a short segment of length 1.7 m.

Using ASI design capacity tables, required section is 310UB46.2.

Its design capacity is o

m

x 176 = 176 kNm > M* of 158.6 kNm OK

For gravity loads, effective length l

e

= 1 x 1.0 x 1 x 1.7 m = 1.7 m

As before, o

m

= 1, |M

bx

= 176 kNm for the chosen 310UB46.2. This is > M* of 56.2 kNm.

OK

Use 310UB46.2

Example Problem No. 2

Design the beam ABCD shown in Figure 2. The loads shown include load factors. The

connection and support conditions at A, B and C are as per the AISC publication (Types 1, 11

and 8, respectively).

Type 11

A 3 m B 3 m C 3 m D

Type 1 Type 8

Figure 4.16. Beam ABCD for Example Problem 2

Reaction at A: 6R = 400 x 3 100 x 3 R = 150 kN

Design moments M* at B = 450 kNm, at C = 300 kNm

Assuming an o

m

value of 1.5, M* for AISC design capacity tables = 450/1.5 = 300 kNm

Effective length = 3 m, Required beam = 610UB101

|M

s

of 610UB101 = 782 kNm

Segment

AB BC CD

End Restraints PF FF FU

Length l (m) 3 3 3

k

t

1+

3

)

6 . 10 2

8 . 14

(

3000

572

x

= 1.065

1 1

k

l

1 1 2

k

r

1 1 1

l

e

(m) 3 x 1.065 = 3.2 3 x 1 = 3 3 x 2 = 6

M

o

(kNm) 1792 1993 570

o

s

0.788 0.810 0.470

o

m

1.75 |

m

=300/450 = 0.67,

so o

m

= 2.5

1.25

|M

b

= o

m

o

s

|M

s

1079>|M

s

of 782

so 782

1584>|M

s

of 782

so 782

459

M* (kNm) 450 450 300

Conclusion OK, but overdesign OK, but overdesign OK, but overdesign

400 kN

100 kN

Bending moment

You might also like

- RC 3Document4 pagesRC 3Jade David FranciscoNo ratings yet

- CE Review - Steel Design Problems SolvedDocument3 pagesCE Review - Steel Design Problems SolvedLemuel TeopeNo ratings yet

- Design of Plate GirderDocument9 pagesDesign of Plate GirdermunnaiitrNo ratings yet

- Modes of Failure of A Bolted/ Riveted ConnectionDocument4 pagesModes of Failure of A Bolted/ Riveted ConnectionNajib A. CasanNo ratings yet

- Reinforced ConcreteDocument12 pagesReinforced ConcreteluckywaysNo ratings yet

- PDF Sample Problems in Pre Stressed Concretepdf DD - PDFDocument25 pagesPDF Sample Problems in Pre Stressed Concretepdf DD - PDFKeith GarridoNo ratings yet

- Module 4. Lesson 3 - Example For Earthquake Load Combination - Strength DesignDocument5 pagesModule 4. Lesson 3 - Example For Earthquake Load Combination - Strength DesignRich Lenard L. MagbooNo ratings yet

- 343 400Document58 pages343 400MakaraSoyNo ratings yet

- Nov 2021 CoachingDocument71 pagesNov 2021 CoachingKenny CaluzaNo ratings yet

- Design and Analysis of Tension MemberDocument29 pagesDesign and Analysis of Tension MemberJhianne Dulpina RoqueNo ratings yet

- 05 04 Chap GereDocument12 pages05 04 Chap GereDipNdra SharmaNo ratings yet

- Moren - MODULE 3 - Beams-ColumnDocument18 pagesMoren - MODULE 3 - Beams-ColumnJoshua Espanto MorenNo ratings yet

- Sagging: Compression Compres SionDocument45 pagesSagging: Compression Compres SionramsundarNo ratings yet

- Tension Members SampleDocument6 pagesTension Members SampleTachooNo ratings yet

- Review Module: Steel Design - Plastic Analysis and The Collapse MechanismDocument3 pagesReview Module: Steel Design - Plastic Analysis and The Collapse MechanismDJ GRNo ratings yet

- RCD Assignment 1Document5 pagesRCD Assignment 1Camille Semilla100% (1)

- 8d. Hibbeler - 8th - Conjugate BeamDocument8 pages8d. Hibbeler - 8th - Conjugate BeamMuhammad KaisarNo ratings yet

- RC Example ES-EN Code-1Document17 pagesRC Example ES-EN Code-1Firomsa EntertainmentNo ratings yet

- Module 2 Analysis of Prestressed Concrete Beams Using Combined Load ApproachDocument48 pagesModule 2 Analysis of Prestressed Concrete Beams Using Combined Load ApproachVann AlfredNo ratings yet

- Design and analysis of laterally supported steel beamsDocument9 pagesDesign and analysis of laterally supported steel beamsCristan RetuermaNo ratings yet

- 4.2.3 Design of Eccentric Welded Connections (IIIDocument10 pages4.2.3 Design of Eccentric Welded Connections (IIIyadoleNo ratings yet

- 3331 ST7008 Prestressed Concrete QBDocument11 pages3331 ST7008 Prestressed Concrete QBsundar100% (1)

- 02 - Design of Steel Tension MembersDocument15 pages02 - Design of Steel Tension MembersMayur PatelNo ratings yet

- Design An Interior Rib of A Concrete Joist Floor System With TheDocument4 pagesDesign An Interior Rib of A Concrete Joist Floor System With TheChea VannaiNo ratings yet

- Assignment Solution 1Document3 pagesAssignment Solution 1nzb1234No ratings yet

- Pre Stressed Concrete 18Cv641: Topic: Magnels MethodDocument14 pagesPre Stressed Concrete 18Cv641: Topic: Magnels MethodShobhaNo ratings yet

- BrasdaDocument3 pagesBrasdaJayson Brylle MojaresNo ratings yet

- Brackets and Corbels ACI 318 L # 1Document7 pagesBrackets and Corbels ACI 318 L # 1soran azizNo ratings yet

- Chapter 4 Flexural Design - (Part 5)Document35 pagesChapter 4 Flexural Design - (Part 5)Raja AliNo ratings yet

- Steps in Vertical Stirrup DesignDocument7 pagesSteps in Vertical Stirrup DesignJayvee EcayNo ratings yet

- Two Way Slab (First Slab Level Slabs)Document15 pagesTwo Way Slab (First Slab Level Slabs)Anjali DudhyalNo ratings yet

- CE Board Nov 2020 Strength of Materials Set 1Document2 pagesCE Board Nov 2020 Strength of Materials Set 1Eugenio Genesis AbadNo ratings yet

- MASTERY TEST SOLUTIONSDocument6 pagesMASTERY TEST SOLUTIONSU-line Anne Roque VillafloresNo ratings yet

- Design of Beams Miscellaneous Topics (Shear, Deflection, Etc.)Document37 pagesDesign of Beams Miscellaneous Topics (Shear, Deflection, Etc.)Morad AJNo ratings yet

- Final ExamDocument4 pagesFinal ExamEzekiel SantosNo ratings yet

- RC Beam and Slab Design PrinciplesDocument21 pagesRC Beam and Slab Design PrinciplesKrishna DhageNo ratings yet

- Torsion Design of Prestressed ConcreteDocument20 pagesTorsion Design of Prestressed ConcreteDr. M.V.Krishna RaoNo ratings yet

- Slab DesignDocument13 pagesSlab DesignLimwell AquinoNo ratings yet

- Bolted and Riveted Connections Strength CalculationDocument1 pageBolted and Riveted Connections Strength CalculationJoshua TesoroNo ratings yet

- Moment of Resistance For Doubly Reinforced SectionsDocument32 pagesMoment of Resistance For Doubly Reinforced SectionsWanda Beasley100% (3)

- ECCENTRIC CONNECTION DESIGNDocument13 pagesECCENTRIC CONNECTION DESIGNJoshua Espanto MorenNo ratings yet

- Principles of Reinforced Concrete Design: Arlegui, Quiapo, ManilaDocument10 pagesPrinciples of Reinforced Concrete Design: Arlegui, Quiapo, ManilaMary Scarlette CenaNo ratings yet

- RC Practice Set 2 2016 SolutionsDocument5 pagesRC Practice Set 2 2016 SolutionsSayed YusufNo ratings yet

- Review Module - Structural Engineering (Bolted and Welded Connections) Concentrically Loaded ConnectionsDocument2 pagesReview Module - Structural Engineering (Bolted and Welded Connections) Concentrically Loaded ConnectionsJoseph LantoNo ratings yet

- Approximate Analysis of Statically Indeterminate StructuresDocument36 pagesApproximate Analysis of Statically Indeterminate StructuresRommel BaesaNo ratings yet

- 7 - Analysis and Design of T-BeamsDocument16 pages7 - Analysis and Design of T-BeamsgarhgelhNo ratings yet

- 11 - Design of One-Way Slabs PDFDocument23 pages11 - Design of One-Way Slabs PDFAndrea Sochayseng SolijonNo ratings yet

- CALCULATION OF ONE-WAY SLAB PARAMETERSDocument2 pagesCALCULATION OF ONE-WAY SLAB PARAMETERSRal GLNo ratings yet

- Ce Reviewer DesignDocument18 pagesCe Reviewer Designeleonor0% (1)

- Plate No.6 - Autor, Joy LauriaDocument12 pagesPlate No.6 - Autor, Joy LauriaJoy lauriaNo ratings yet

- CIVIL ENGINEERING BOARD EXAMDocument7 pagesCIVIL ENGINEERING BOARD EXAMConan EdogawaNo ratings yet

- Shear StrengthDocument17 pagesShear StrengthVon San Jose100% (1)

- Plate GirderDocument11 pagesPlate GirderAfia S HameedNo ratings yet

- Tutorial 1 - Properties and Section ClassificationDocument20 pagesTutorial 1 - Properties and Section ClassificationCyrus Hong100% (1)

- Base Plate DesignDocument9 pagesBase Plate DesignprashantkothariNo ratings yet

- ZND332 - A-Base & Top Plate & Anchors-REV-E (Repaired)Document15 pagesZND332 - A-Base & Top Plate & Anchors-REV-E (Repaired)redflex9001889No ratings yet

- Tension Member Design-1Document39 pagesTension Member Design-1Arfan Haider100% (2)

- Tutorial 7 - Connections - Part ADocument28 pagesTutorial 7 - Connections - Part ACyrus HongNo ratings yet

- C4.tension Member Compatibility ModeDocument45 pagesC4.tension Member Compatibility ModejojomarbunNo ratings yet

- Slide Share BDocument42 pagesSlide Share BShakeel WaseemNo ratings yet

- MTech SMFE Rev12032019Document78 pagesMTech SMFE Rev12032019Mr.Bhaskar WabhitkarNo ratings yet

- 189ufrep prelims-GS PDFDocument45 pages189ufrep prelims-GS PDFRavi SNo ratings yet

- About Civil Engg. DeptDocument17 pagesAbout Civil Engg. DeptMitaNo ratings yet

- CE GATE 2021 Postal ChecklistDocument3 pagesCE GATE 2021 Postal ChecklistApril IngramNo ratings yet

- 189ufrep prelims-GS PDFDocument45 pages189ufrep prelims-GS PDFRavi SNo ratings yet

- Btech Syll Civil r2013-14 PDFDocument256 pagesBtech Syll Civil r2013-14 PDFdhiliban1989No ratings yet

- Course Details - Master of Infrastructure Engineering and Management (Online Study)Document7 pagesCourse Details - Master of Infrastructure Engineering and Management (Online Study)April IngramNo ratings yet

- Calculus Self Taught Well Summarized Lecture Notes With Relevant Examples For BetterDocument31 pagesCalculus Self Taught Well Summarized Lecture Notes With Relevant Examples For BetterApril IngramNo ratings yet

- Lecture 11Document6 pagesLecture 11April IngramNo ratings yet

- 1904Document24 pages1904Palani KumarNo ratings yet

- Advanced Concrete Technology MSC (Eng) - PGDip - Advanced Concrete Technology MSC (Eng) - PGDip - School of Civil Engineering - University of LeedsDocument2 pagesAdvanced Concrete Technology MSC (Eng) - PGDip - Advanced Concrete Technology MSC (Eng) - PGDip - School of Civil Engineering - University of LeedsApril IngramNo ratings yet

- Indian Standard: Code of Practice For Determination of Breaking Capacity of Shallow Foundations (Document20 pagesIndian Standard: Code of Practice For Determination of Breaking Capacity of Shallow Foundations (api-19754583100% (1)

- Amity M.tech. - Structural EngineeringDocument2 pagesAmity M.tech. - Structural EngineeringApril Ingram100% (1)

- Check List 2019Document1 pageCheck List 2019April IngramNo ratings yet

- Indian Standard: Code of Practice For Determination of Breaking Capacity of Shallow Foundations (Document20 pagesIndian Standard: Code of Practice For Determination of Breaking Capacity of Shallow Foundations (api-19754583100% (1)

- Opencut ExampleDocument2 pagesOpencut ExampleApril IngramNo ratings yet

- M.E.ft Construction Engg. Managment 2015Document29 pagesM.E.ft Construction Engg. Managment 2015April IngramNo ratings yet

- School of Civil and Environmental Engineering: Project CVEN04Document3 pagesSchool of Civil and Environmental Engineering: Project CVEN04April IngramNo ratings yet

- Infrastructure 2011+Document5 pagesInfrastructure 2011+April IngramNo ratings yet

- 1904Document24 pages1904Palani KumarNo ratings yet

- Btech Are 2010Document73 pagesBtech Are 2010April IngramNo ratings yet

- Class Routine (19 & 21 Jan 2015) : AdviceDocument1 pageClass Routine (19 & 21 Jan 2015) : AdviceApril IngramNo ratings yet

- Class Routine (13 & 14 Dec 2014) : All Classes Are Suspended Due To Semester ExamDocument1 pageClass Routine (13 & 14 Dec 2014) : All Classes Are Suspended Due To Semester ExamApril IngramNo ratings yet

- BH ECN CurrentDocument2 pagesBH ECN CurrentApril IngramNo ratings yet

- Class Routine (22 & 23 Nov 2014) : AdviceDocument1 pageClass Routine (22 & 23 Nov 2014) : AdviceApril IngramNo ratings yet

- Syllabuses CivE 14 15 4YDocument19 pagesSyllabuses CivE 14 15 4YApril IngramNo ratings yet

- Class Routine (17 & 18 Jan 2015) : AdviceDocument1 pageClass Routine (17 & 18 Jan 2015) : AdviceApril IngramNo ratings yet

- Struc Constr IllustrationsDocument1 pageStruc Constr IllustrationsApril IngramNo ratings yet

- Humidification Load Calculation Armstrong PDFDocument3 pagesHumidification Load Calculation Armstrong PDFsyedNo ratings yet

- 46 - The Thermal Efficiency Improvement of A Steam Rankine Cycle by Innovative Design of A Hybrid Cooling Tower and A Solar Chimney ConceptDocument1 page46 - The Thermal Efficiency Improvement of A Steam Rankine Cycle by Innovative Design of A Hybrid Cooling Tower and A Solar Chimney ConceptNachiket LohkareNo ratings yet

- Plano Hidraulico M313CDocument2 pagesPlano Hidraulico M313CKrippy KushNo ratings yet

- Modeling & Analysis Lab Manual - 15ael77: Vii SemesterDocument27 pagesModeling & Analysis Lab Manual - 15ael77: Vii SemesterJason JeevanNo ratings yet

- IPE, HE, UC steel section dimensionsDocument152 pagesIPE, HE, UC steel section dimensionsAshishNo ratings yet

- HX NotesDocument17 pagesHX Notesjuwel KabirNo ratings yet

- ACMV - Return Air SystemsDocument4 pagesACMV - Return Air SystemsBOYNo ratings yet

- Helicopteros 00mDocument17 pagesHelicopteros 00mpfylNo ratings yet

- HMT - 2 Marks PDFDocument29 pagesHMT - 2 Marks PDFFaiyu MechNo ratings yet

- White Paper Droplet Based Microfluidics Elveflow MicrofluidicsDocument28 pagesWhite Paper Droplet Based Microfluidics Elveflow MicrofluidicsSandeep KumarNo ratings yet

- Chapter 9: Agitation and Aeration Agitation: Che 514A: Biochemical EngineeringDocument9 pagesChapter 9: Agitation and Aeration Agitation: Che 514A: Biochemical EngineeringEzekielNo ratings yet

- Illustration 29 07 2017 PDFDocument3 pagesIllustration 29 07 2017 PDFGlenn D. KleinNo ratings yet

- Concrete BasementsDocument184 pagesConcrete BasementsMohan BhalmeNo ratings yet

- Offshore Hydro MechanicsDocument570 pagesOffshore Hydro MechanicsAsier DCNo ratings yet

- Radiation Heat Transfer FundamentalsDocument15 pagesRadiation Heat Transfer FundamentalsJade Carlo AntonioNo ratings yet

- Gold Tailings Liquefaction Under Critical State Soil MechanicsDocument5 pagesGold Tailings Liquefaction Under Critical State Soil MechanicsZhenhe SongNo ratings yet

- CLA-VAL Sizing ReportDocument6 pagesCLA-VAL Sizing ReportunnicyriacNo ratings yet

- Chapter 2Document33 pagesChapter 2ser hasbulaNo ratings yet

- 4.seismic-Wave-Based Testing in GeotechnicalDocument25 pages4.seismic-Wave-Based Testing in GeotechnicalBukhari RamliNo ratings yet

- Ejector vs Eductor - What's the DifferenceDocument2 pagesEjector vs Eductor - What's the DifferencePierre NorrisNo ratings yet

- L&T Construction, Chennai G-O20002: Subarnarekha - Main Bridge SubstrcutureDocument7 pagesL&T Construction, Chennai G-O20002: Subarnarekha - Main Bridge SubstrcutureGopu RNo ratings yet

- 2 - 2020-01 - Specification - Rev I - ENDocument33 pages2 - 2020-01 - Specification - Rev I - ENiyakushev1101No ratings yet

- Non Newtonian FluidDocument45 pagesNon Newtonian FluidThiyagu Sundaram100% (3)

- Understanding Bernoulli's Principle Through Simulations PDFDocument4 pagesUnderstanding Bernoulli's Principle Through Simulations PDFIoannis GaroufalidisNo ratings yet

- By: Engr. Gs RoblesDocument152 pagesBy: Engr. Gs Roblesetong saturninaNo ratings yet

- Fluid Mechanics Theory and DesignDocument158 pagesFluid Mechanics Theory and DesignWONG TSNo ratings yet

- Sana Jafar PDFDocument6 pagesSana Jafar PDFPrateek NegiNo ratings yet

- DIRECT SHEAR TEST TITLEDocument19 pagesDIRECT SHEAR TEST TITLESaid-Mansour MohamedNo ratings yet

- Mirpur University of Science & Technology (Must), Mirpur Azad Jammu & Kashmir Department of Civil EngineeringDocument3 pagesMirpur University of Science & Technology (Must), Mirpur Azad Jammu & Kashmir Department of Civil EngineeringAsadNo ratings yet

- Energy Loss in PipesDocument8 pagesEnergy Loss in Pipeskelechi2475% (8)