Professional Documents

Culture Documents

Free Electric Power Windmill

Uploaded by

Jim100%(4)100% found this document useful (4 votes)

2K views3 pagesThis article shows you how to make a windmill with a DC auto generator. Make a windmill and capture some free power.

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis article shows you how to make a windmill with a DC auto generator. Make a windmill and capture some free power.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

100%(4)100% found this document useful (4 votes)

2K views3 pagesFree Electric Power Windmill

Uploaded by

JimThis article shows you how to make a windmill with a DC auto generator. Make a windmill and capture some free power.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Free

Electric

Power

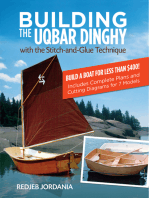

Here the 10-ft, impeller described below

has been mounted for belt drive. Note

position of jackshaft on the baseboard.

Y OUR vacation cottage or outlying farm

buildings can be lighted by electricity

even though you may be far from a power

pulsion from the suction on the lee side

of the sail. A roof in the path of a gale

is lifted up, not pushed down. Conse-

line. The wind will gladly do this job for quently, the blades of the impeller must

you—if you know how to harness it. The be so shaped that this suction force can aid

unit described will turn the trick for you them in turning.

with little manual effort and even less For the baseboard get a piece of oak or

monetary expense. similar hardwood, 5-1/2 in wide, 50 in long

Most people think of gales and hurri- and 1-1/4 in thick. Draw a centerline on the

canes when the wind is mentioned as a wide face of the board and do your layout

source of power. Nothing could be more from this guide. From a point 9 in. from

misleading, because there is vast energy the head and down to the end of the board

even from a gentle breeze. the sides are tapered down to a final width

Anyone with ordinary mechanical skill of 1-1/2 in.

can build this machine. And cutting the im- Drill a 3/4-in hole 26 in. from the tapered

peller blades will teach you more practical end and saw a 1/2-in slot to meet this hole.

aerodynamics than you could dig out of This slot is for the tail vane. For 'the gen-

an armful of books. (If the term "impeller" erator cradle a piece of wood 6 in. long

confuses you, a propeller driven by the and 1-1/4 in thick is fastened to the full end

wind becomes an impeller.) width of the baseboard. Shape the cradle

Without digging too deeply into theory, to match contour of generator used.

it is well to know a little about the giant The tail vane is a piece of exterior-grade

which we are about to harness. It is seldom plywood 30 in. long, 20 in. wide and 1/2 in.

realized that the force which the wind ex- thick with the leading edge rounded and

erts is composed of two distinct parts: a the trailing edge notched as shown.

pressure and a suction. Thus a sailboat The commutator (or collector rings) used

which seems to be pushed along by the to connect the swinging generator with feed

wind is actually deriving most of its pro- wires is essential [continued on next page]

Free Electric Power

for proper operation. To make it, get a piece 12 in. and so on. To make your task easier, cut

of 2-in. brass pipe 3 in. long, a piece of wood cardboard templates corresponding to degrees

with 2-in.-square and 4 in. long, and an 18 of slope that will fit the finished blades at the

in. length of 1 in. galvanized iron pipe threaded proper points. "

at one end. Trim the wooden block into a Cut the face of the blade first. This is a flat

cylinder that fits snugly into the brass pipe. surface but of continuously changing angle

Drill a 1-1/4-in. hole lengthwise through this with respect to the original face of the board.

cylinder true to the centerline. The trailing edge is always 1/16 in. thick. The

Soap the threaded end of the galvanized sloping face intersects the top of the board

pipe and drive it through the hole in the wood up to the 30 in. line and new leading edge is

until it extends far enough in the floor flange. cut along this distance.

To engage the two insulated collector rings, To cut the blades clamp the hub of the blade

cut two 1/2-in. sections from the brass pipe flat to your bench with the tip extending

and connect these to encompass the wooden straight out. Stand to the right of the blade

cylinder. Fill the space with Plastic Wood and and draw a sharp drawknife toward you until

trim flush. Drill holes through each brass ring the approximate contours are reached. Fasten

and the galvanized pipe to take the insulated the three blades to the hub plate with carriage

wires from the generator. Solder the ends of bolts using three for each blade.

these wires in the brass holes and file the out- For the impeller to run without vibration

side surface smooth. it must be carefully balanced and the jack-

The brush holder is fastened to the edge shaft (if it runs true and free) can be used

of the 1-1/4-in. galvanized floor flange. This as a balancing rig. Remove small shavings

floor flange is the top end of the 1-1/4-in. gal- from the heavy blade until the impeller comes

vanized pipe which serves as the mast. Its to rest at a different point each time it is given

upper surface should be ground smooth to a light spin.

ease the generator's swing into the wind. With the entire wind-electric generator as-

The auto generator, available at any auto sembled, including the impeller, find the

graveyard, should preferably be one from any center of balance of the baseboard and attach

of the large, older cars, since its output capa- the 1-in. floor flange above the commutator at

bilities will be higher and its price lower. this point. Center of balance is that point

The jackshaft assembly and its strap iron about which the entire unit balances itself

supports are now made. A bronze bearing is fore and aft.

soldered into each end of a 7-1/2-in. length of To protect all wooden parts against weather,

3/4-in. brass pipe. Align the bearings with the soak generously with linseed oil or coat with

shaft before soldering. The brass pipe acts as outdoor paint.

an oil reservoir and a small hole is drilled The 1-1/4-in. pipe should be well braced.

so that it may be filled. If guy wires are used, make sure that they

The hub plate to hold the three blades is an do not hinder the rotating blades.

11-in. circle of 1-3/4-in. exterior-grade ply- Mount the generator in place by slipping

wood, or maple. Center it accurately on the the 18-in. length of 1 in. pipe below the com-

end of the jackshaft and fasten securely with mutator into the mast. Brushes will then make

a flange and stove bolts. Cut a vee for a belt contact with rings of the commutator.

into the hub plate edge. Adjust the height of The feed wires to the unit are attached to

the jackshaft above the base to take a standard the two- spring brass brushes with the wiring

automobile fan belt connecting hub plate and exactly like that in your car. The cutout (to

generator pulley. disconnect the generator from the battery

The impeller of this generator is ten feet in when it is not charging) is the standard auto-

diameter and has three blades. It will make mobile type and may be left mounted on the

about 200 revolutions per minute in an eight- generator or may be placed near the battery.

mile-per-hour wind. You will also need an ammeter and a pro-

To assemble the impeller, obtain three tective fuse. Mount them on a plywood panel

pieces of straight, knot-free, well-seasoned 6x8 in. A small six or eight-volt radio panel

wood, each 60 in. long, 6 in. wide and 1-1/4 in. bulb will show at a glance when the generator

thick. Lay them on the bench side by side, is charging.

with grain running away from you and mark If you use a six-volt generator a standard

the top of each piece "face" and bottom automobile storage battery will be enough to

"back." Draw a squared line across each board store juice during calm periods. For higher

at six-inch intervals and mark each line with voltage systems several units of auto batteries

its distance from the preceding line, as 6 in., may be connected in series. [END]

You might also like

- Vintage Farm Impliment Plans 1950sDocument91 pagesVintage Farm Impliment Plans 1950sudivljini100% (3)

- Radio SimplifiedDocument94 pagesRadio SimplifiedJim100% (3)

- Pedalmatic 1951Document3 pagesPedalmatic 1951Jim100% (4)

- The Boy's Book of Crystal SetsDocument36 pagesThe Boy's Book of Crystal SetsJim100% (9)

- Maytag RoadsterDocument5 pagesMaytag RoadsterJim100% (3)

- Midgettractor PSMar 54Document7 pagesMidgettractor PSMar 54JimNo ratings yet

- Receive Short W A V E Onyour HomeradioDocument5 pagesReceive Short W A V E Onyour HomeradioJim100% (9)

- YardHorse ScooterDocument9 pagesYardHorse ScooterJim100% (5)

- Midget Tractor3 PlansDocument6 pagesMidget Tractor3 PlansDanilo RochaNo ratings yet

- Breeze Baby Sailboat PlansDocument5 pagesBreeze Baby Sailboat PlansJim100% (5)

- Breeze Baby Sailboat PlansDocument5 pagesBreeze Baby Sailboat PlansJim100% (5)

- Mineral Vegetable and Animal LifeDocument4 pagesMineral Vegetable and Animal LifeJim86% (7)

- Bull Frog Go KartDocument15 pagesBull Frog Go KartJim100% (3)

- Bull Frog Go KartDocument15 pagesBull Frog Go KartJim100% (3)

- Wren Minibike PlansDocument7 pagesWren Minibike PlansJim100% (5)

- Air Cooled Hot Air EngineDocument6 pagesAir Cooled Hot Air EngineJim50% (2)

- Air Cooled Hot Air EngineDocument6 pagesAir Cooled Hot Air EngineJim50% (2)

- Mini-Skat 6-Wheel Plans AssemblyDocument40 pagesMini-Skat 6-Wheel Plans AssemblyВладимир Батманов100% (3)

- Brush Buggy, Build An ExcitingDocument5 pagesBrush Buggy, Build An ExcitingJim88% (8)

- Homemade ATVDocument67 pagesHomemade ATVJim100% (7)

- Assembly Instructions For Strat and Tele Style PickupsDocument10 pagesAssembly Instructions For Strat and Tele Style PickupsLazyfingers61100% (2)

- Water Motor: Figure 105 Is A Perspective View of ADocument4 pagesWater Motor: Figure 105 Is A Perspective View of AHenry Pannell100% (1)

- Electric Scooter PlansDocument6 pagesElectric Scooter PlansJim88% (8)

- Electric Scooter PlansDocument6 pagesElectric Scooter PlansJim88% (8)

- Lathe Cross-Sli Olders.: " DuplexDocument3 pagesLathe Cross-Sli Olders.: " Duplexjohnboy183100% (1)

- Suitcase PowercycleV2Document13 pagesSuitcase PowercycleV2Jim67% (3)

- Model Hot Air EngineDocument4 pagesModel Hot Air EngineJim100% (4)

- Mini Dozer Info 1979Document6 pagesMini Dozer Info 1979Jim100% (3)

- PowerCycle With SideCarDocument7 pagesPowerCycle With SideCarJim100% (2)

- Candle Powered EngineDocument2 pagesCandle Powered EngineJimNo ratings yet

- Suburba ContestDocument4 pagesSuburba ContestJim100% (3)

- SMFeb 56 Roamabout Part 1Document17 pagesSMFeb 56 Roamabout Part 1Jim86% (7)

- Listening LoopsDocument2 pagesListening LoopsJim75% (4)

- Suburba Car, Chassis For ADocument7 pagesSuburba Car, Chassis For AJim100% (9)

- Station Wagon SkiffDocument8 pagesStation Wagon SkiffJim100% (3)

- King Midget ArticleDocument8 pagesKing Midget ArticleJim100% (10)

- Homebuilt Wood CarDocument26 pagesHomebuilt Wood Carsjdarkman1930100% (3)

- Building One Lung KartsDocument7 pagesBuilding One Lung KartsJim100% (5)

- Foxhole RadioDocument2 pagesFoxhole RadioJim89% (9)

- 1901 TruckDocument10 pages1901 TruckGary B. Watts100% (3)

- Six Wheeled ATV by Mechanix IllustratedDocument7 pagesSix Wheeled ATV by Mechanix IllustratedJim100% (6)

- Wartime ScooterDocument7 pagesWartime ScooterJim100% (5)

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityFrom EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNo ratings yet

- Mite Cycle by Mechanix IllustratedDocument7 pagesMite Cycle by Mechanix IllustratedJim100% (3)

- Yard-Dozer MidgetDocument5 pagesYard-Dozer MidgetOlin Stej80% (5)

- Super Scooter by Mechanix IllustratedDocument12 pagesSuper Scooter by Mechanix IllustratedJim100% (3)

- Relive the romance of early automobiles with a half-size 1901 Packard replicaDocument8 pagesRelive the romance of early automobiles with a half-size 1901 Packard replicaDillon Hartsyker100% (1)

- Plywood ScooterDocument7 pagesPlywood ScooterJim100% (4)

- Motor Canoe Boat PlansDocument4 pagesMotor Canoe Boat PlansJim100% (6)

- Micro TransportationDocument6 pagesMicro TransportationJim100% (3)

- Ge 1955 65T Usatc Operators Manual PDFDocument102 pagesGe 1955 65T Usatc Operators Manual PDFNancy100% (1)

- Saucy Skimmer AKA Saucy Shingle Hydroplane Boat PlansDocument8 pagesSaucy Skimmer AKA Saucy Shingle Hydroplane Boat PlansJim100% (6)

- Build a Tesla coil that produces spectacular electrical fireworksDocument5 pagesBuild a Tesla coil that produces spectacular electrical fireworksmad10000No ratings yet

- Space Age Crystal SetDocument3 pagesSpace Age Crystal SetJim100% (3)

- Magnetic BaseDocument3 pagesMagnetic BaseJim100% (2)

- Power HackSawDocument6 pagesPower HackSawMike Nichlos100% (2)

- Polliwog Sailboat PlansDocument6 pagesPolliwog Sailboat PlansJim100% (4)

- PHY G10 Q2 W10 D3 RevDocument9 pagesPHY G10 Q2 W10 D3 RevVictorino Victorino Butron100% (1)

- A Crystal Set For The Boy BuilderDocument3 pagesA Crystal Set For The Boy BuilderJim100% (4)

- Crystal Radio LampDocument4 pagesCrystal Radio LampJim100% (2)

- Crystal Radio LampDocument4 pagesCrystal Radio LampJim100% (2)

- Vintage Transistor RadioDocument4 pagesVintage Transistor RadioJim100% (1)

- Vintage Transistor RadioDocument4 pagesVintage Transistor RadioJim100% (1)

- Electrical Machines by Abhijit Chakrabarti Sudipta DebnathDocument1,238 pagesElectrical Machines by Abhijit Chakrabarti Sudipta DebnathSubodhKumar0% (1)

- Stiletto BoatDocument7 pagesStiletto BoatJim100% (5)

- ELECTRICAL QUESTIONS AND ANSWERS-MCQ-8-ETO - Electro Technical OfficerDocument11 pagesELECTRICAL QUESTIONS AND ANSWERS-MCQ-8-ETO - Electro Technical Officeramit100% (3)

- Star Lite SailboatDocument13 pagesStar Lite SailboatJim100% (8)

- Electric MotorDocument30 pagesElectric MotorBob100% (1)

- Build A Scintillometer Uranium Detector For ProspectingDocument11 pagesBuild A Scintillometer Uranium Detector For ProspectingJim80% (5)

- P-503 (П-503) Airborne Recorder: Maintenance Schedule СЫ1.740.015 РОDocument24 pagesP-503 (П-503) Airborne Recorder: Maintenance Schedule СЫ1.740.015 РОhaileNo ratings yet

- Flashlight RadioDocument5 pagesFlashlight RadioJim67% (3)

- Magnetic Current PamphletDocument9 pagesMagnetic Current PamphletJim100% (2)

- War Toys For BoysDocument48 pagesWar Toys For BoysJim100% (2)

- Pudgy A 12 Foot Canvas Runabout Boat PlansDocument5 pagesPudgy A 12 Foot Canvas Runabout Boat PlansJim100% (5)

- Miller, T.J.E. - SPEED's Electric MotorsDocument307 pagesMiller, T.J.E. - SPEED's Electric Motorsmiculurs100% (13)

- Singer Sewing Machine Parts Price List for Family Model 99-13Document45 pagesSinger Sewing Machine Parts Price List for Family Model 99-13korina3No ratings yet

- 3 Wheel Dune BuggyDocument5 pages3 Wheel Dune BuggyyukitadaNo ratings yet

- Unsinkable UniboatDocument6 pagesUnsinkable UniboatJim100% (4)

- NSS 2010 US Parts Price ListDocument144 pagesNSS 2010 US Parts Price ListNestor Marquez-DiazNo ratings yet

- 40 Meters VerticalDocument10 pages40 Meters Verticalعرفان عرفانNo ratings yet

- Simple Boat-Building - Rowing Flattie, V-Bottom Sailing Dinghy, Moulded Pram, Hull for OutboardFrom EverandSimple Boat-Building - Rowing Flattie, V-Bottom Sailing Dinghy, Moulded Pram, Hull for OutboardNo ratings yet

- Electrical Machine Design - Lecture NotesDocument39 pagesElectrical Machine Design - Lecture NotesAnuraj Gupta100% (1)

- Service Manual En: OPUS OSE120, OSE120PDocument240 pagesService Manual En: OPUS OSE120, OSE120PWagner Dalla BernardinaNo ratings yet

- Aircarflighttesting: by Angus LaidlawDocument3 pagesAircarflighttesting: by Angus LaidlawJimNo ratings yet

- Antena Movil HFDocument10 pagesAntena Movil HF10sd156100% (1)

- The Record Hound - A Free-Flight Model Airplane (Fuel Engine) (Convert To R/C?)Document8 pagesThe Record Hound - A Free-Flight Model Airplane (Fuel Engine) (Convert To R/C?)Bob KowalskiNo ratings yet

- How To Make Electrical Machines Containing Full Directions For Making Electrical Machines Induction Coils Dynamos and Many Novel Toys To Be Worked by Electricity 2Document101 pagesHow To Make Electrical Machines Containing Full Directions For Making Electrical Machines Induction Coils Dynamos and Many Novel Toys To Be Worked by Electricity 2GACEM ABDELKRIMNo ratings yet

- VDG Instruction PagesDocument12 pagesVDG Instruction PagesMarty cNo ratings yet

- Vertical Rev HDocument10 pagesVertical Rev HMiguel OyarzabalNo ratings yet

- Horizontal Slide-Valve EngineDocument19 pagesHorizontal Slide-Valve EngineDarius BooyensNo ratings yet

- How To Make Low Pressure TransformersDocument36 pagesHow To Make Low Pressure TransformersRoberto BernerNo ratings yet

- The Pacemaker - A Free-Flight Model Airplane (Fuel Engine) (Convert To R/C?)Document11 pagesThe Pacemaker - A Free-Flight Model Airplane (Fuel Engine) (Convert To R/C?)Bob KowalskiNo ratings yet

- 12thpak InstrutionsDocument5 pages12thpak InstrutionsJavier Rodriguez PaezNo ratings yet

- Dorothy 24 Foot Sailing CruiserDocument11 pagesDorothy 24 Foot Sailing CruiserJim92% (12)

- O Livro de Ouro Dos Experimentos Químicos (RARIDADE)Document114 pagesO Livro de Ouro Dos Experimentos Químicos (RARIDADE)Davidson De Oliveira Lima100% (1)

- Observer-Based Sensorless Control of a Five-Phase BLDC MotorDocument29 pagesObserver-Based Sensorless Control of a Five-Phase BLDC MotorSamhita Vishnu0% (2)

- DC MotorDocument3 pagesDC MotorAhmad AzizudinNo ratings yet

- Description: 1997 Ford Pickup F150 1997 Ford Pickup F150Document9 pagesDescription: 1997 Ford Pickup F150 1997 Ford Pickup F150s.e. e.p.No ratings yet

- 2Document6 pages2Sairam SaiNo ratings yet

- SUNBEAM S7 and S8 Tech InfoDocument74 pagesSUNBEAM S7 and S8 Tech InfoP JNo ratings yet

- CH-1 - DC Generator Q.bank PDFDocument2 pagesCH-1 - DC Generator Q.bank PDFjaythakar8887No ratings yet

- Load Test On Scharge MotorDocument4 pagesLoad Test On Scharge MotorRamakrishna SagarNo ratings yet

- Agility 125 Section 16 Starting System PDFDocument8 pagesAgility 125 Section 16 Starting System PDFdabura1986No ratings yet

- 420KW ELECTRICAL MACHINE DESIGNDocument5 pages420KW ELECTRICAL MACHINE DESIGNMiguel LigutanNo ratings yet

- Motor, Hoist and Pulldown: Rev:7 SheetDocument3 pagesMotor, Hoist and Pulldown: Rev:7 SheetFrancisco GonzalezNo ratings yet

- Demolition Hammer HM1304 Specs & ManualDocument8 pagesDemolition Hammer HM1304 Specs & ManualRadhakrishnan PaulNo ratings yet

- zxr400 H 15Document37 pageszxr400 H 15hugo_bikerNo ratings yet

- Magnetism: Magnetic Fingerprinting Allows Fingerprints To Be Seen On SurfacesDocument52 pagesMagnetism: Magnetic Fingerprinting Allows Fingerprints To Be Seen On SurfacesPRADITYO PUTRA PURNOMO ,No ratings yet

- The Schrage MotorDocument89 pagesThe Schrage MotorNoel Dunn67% (3)

- Shenzhen Green Electricity Kang Technology Co., LTDDocument4 pagesShenzhen Green Electricity Kang Technology Co., LTDPatrick Cenci PagliariNo ratings yet

- 20 PTT I Brush Carbon Brush Cloud Monitoring Mersen PDFDocument4 pages20 PTT I Brush Carbon Brush Cloud Monitoring Mersen PDFunifim1102No ratings yet

- BLPM DCM - Unit IVDocument41 pagesBLPM DCM - Unit IVpviveknaiduNo ratings yet

- Files - 1593002672 - 2014544866 2nd Year ElDocument99 pagesFiles - 1593002672 - 2014544866 2nd Year ElSarbeswar bataNo ratings yet

- Unit 3 EEEDocument81 pagesUnit 3 EEERitesh DeshmukhNo ratings yet