Professional Documents

Culture Documents

STRUCTURAL GLASS DESIGN REPORT

Uploaded by

samgivp2869Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STRUCTURAL GLASS DESIGN REPORT

Uploaded by

samgivp2869Copyright:

Available Formats

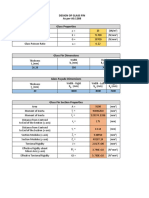

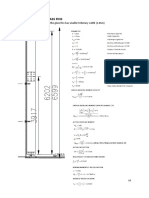

PROJECT : CLIENT : JOB NO. : DATE : Structural Glass Design, Based on ASTM E1300 & CAN/CGSB-12.

20, using Finite Element Method INPUT DATA & DESIGN SUMMARY GLASS PANEL SIZE

PAGE : DESIGN BY : REVIEW BY :

W= L=

1.5 5

ft, (457 mm) ft, (1524 mm)

GLASS PANEL THICKNESS Weight = 77 CONNECTION TYPE ( 0 or 1)

t = 0.7874 in, (20 mm) lbs, (35 kg) 0 , only corner pinned. 3.5 ksi,

2 (24 N / mm )

ALLOWABLE GLASS STRENGTH

s allow =

(Annealed: 3.5 ksi, Heat-strengthened: 6.5 ksi, Tempered: 14.5 ksi - verify reqd.) ALLOWABLE DEFLECTION L / 240 ( The max value suggested: L / 60 for window or curtain wall, L / 180 for stair.) UNIFORM AREA LOAD (Perpendicular to Plane) POINT LOAD (Including Impact Factor) D= P= 10 0.3 psf, ASD level kips, ASD level

THE DESIGN IS ADEQUATE.

ANALYSIS GLASS PROPERTIES g = 156 E= 10150 u = 0.22

lbs / ft 3 (2500 kg / m 3 ) 2 ksi (70 kN / mm ) , Poisson's ratio

JOINT DEFLECTIONS, REACTIONS, & PLATE SECTION FORCES kips,( Point load at Joint 9.) P= 0.3 Joint Number 1 2 3 4 5 6 7 8 9 D in 0 0.14 0.21 0.00 0.14 0.21 0.00 0.14 0.21 R kips -0.09

Bending

Section 7-8 8-9 3-6 6-9

M ft-k/ft 0.03 0.04 0.42 0.42

CHECK BENDING CAPACITY M n / W b = s allow d t 2 / 6 = Where

4.34

ft-k/ft

>

M =

0.42

ft-k/ft

[Satisfactory] d= 12 in, (1 ft) M = (M 6-9 2 + M 8-9 2 ) 0.5 = 0.42 ft-k/ft

CHECK DEFLECTION D max = 0.21 Where

in

<

[Satisfactory] 60.0 in

L / 240

0.25

in

L = Max (L , W) =

You might also like

- ASTM E1300-09A GLASS DEFLECTION CALCULATIONDocument1 pageASTM E1300-09A GLASS DEFLECTION CALCULATIONwaweng22No ratings yet

- Glass Laminate Thicknesses and PropertiesDocument1 pageGlass Laminate Thicknesses and PropertiesLaurence Sarmiento100% (1)

- Glass analysis calculations for structural wall projectDocument8 pagesGlass analysis calculations for structural wall projectARYA100% (1)

- Glass Laminate Thicness - No Reduc For Cantilever GlassDocument1 pageGlass Laminate Thicness - No Reduc For Cantilever GlassLaurence Sarmiento100% (1)

- Glass PanelDocument2 pagesGlass PanelEIWAA50% (2)

- Deflection of Glass Center CalculationDocument1 pageDeflection of Glass Center CalculationAlbert de GuzmanNo ratings yet

- Design of Glass Fin for Glass FaçadeDocument4 pagesDesign of Glass Fin for Glass FaçadeZaido Al HalabiNo ratings yet

- Bolted Glass AssembliesDocument4 pagesBolted Glass AssembliesTomás Aires PereiraNo ratings yet

- Structural Glass Design-UBCDocument6 pagesStructural Glass Design-UBCmsiddiq1100% (1)

- Structural Glass Design-BS6399Document6 pagesStructural Glass Design-BS6399msiddiq1100% (2)

- STRUCTURAL GLASS DESIGN OF HAND RAIL BALCONYDocument5 pagesSTRUCTURAL GLASS DESIGN OF HAND RAIL BALCONYmsiddiq1No ratings yet

- 1analysis For Curtain Wall GlassDocument2 pages1analysis For Curtain Wall GlassEIWAANo ratings yet

- Curtain Wall-Report REv 1-10-21Document11 pagesCurtain Wall-Report REv 1-10-21MuraleedharanNo ratings yet

- Design of Mullion-BS enDocument16 pagesDesign of Mullion-BS enPrasad kapure100% (1)

- GLASS BALUSTRADE DESIGN CALCULATIONSDocument8 pagesGLASS BALUSTRADE DESIGN CALCULATIONSmsiddiq1100% (2)

- Fin Glass 6Document6 pagesFin Glass 6EIWAA100% (1)

- Alum SampleDocument2 pagesAlum Samplewaweng22No ratings yet

- Fin DesignDocument12 pagesFin DesignMuraleedharanNo ratings yet

- Bolted Connection in Glass StructureDocument52 pagesBolted Connection in Glass StructureCristiana Gruia-Paun100% (2)

- Advanced Design of Glass Structures and FinsDocument7 pagesAdvanced Design of Glass Structures and FinsAmro Ahmad Ali100% (2)

- ConnectionDocument2 pagesConnectionEIWAANo ratings yet

- Sg12 Frameless Balustrades Structural CalculationsDocument12 pagesSg12 Frameless Balustrades Structural CalculationsAhmed Mohamed LabibNo ratings yet

- SKYLIGHT REPORT - Rev 01Document16 pagesSKYLIGHT REPORT - Rev 01Muraleedharan100% (1)

- 1-1) Typical Glass Balustrade PanelDocument7 pages1-1) Typical Glass Balustrade PaneldanieldumapitNo ratings yet

- Check For Glass Fins: The Location Where We Have The Glass Fins Has Smaller Tributary Width (1.44m)Document5 pagesCheck For Glass Fins: The Location Where We Have The Glass Fins Has Smaller Tributary Width (1.44m)Laurence SarmientoNo ratings yet

- Structural Glass DesignDocument84 pagesStructural Glass Designgks6043100% (4)

- Glass Balustrade Design EN 16612Document2 pagesGlass Balustrade Design EN 16612Ciprian POPANo ratings yet

- Glass CalculationDocument2 pagesGlass Calculationpradeeshpg50% (2)

- Design Calculations For Aluminium Profile 13794Document14 pagesDesign Calculations For Aluminium Profile 13794Wilson PesantezNo ratings yet

- Glass Balustrade DesignDocument18 pagesGlass Balustrade Designveereshan100% (1)

- Check glass capacity deflectionDocument7 pagesCheck glass capacity deflectionMuraleedharanNo ratings yet

- Curtain Wall CalculationDocument8 pagesCurtain Wall CalculationKenneth OkoyeNo ratings yet

- Load CalculationDocument108 pagesLoad Calculationvpshreekanth71% (14)

- DESIGN CALCULATIONS FOR ALUMINIUM GLAZINGDocument8 pagesDESIGN CALCULATIONS FOR ALUMINIUM GLAZINGmsiddiq1100% (1)

- Fin Glass 6Document4 pagesFin Glass 6EIWAANo ratings yet

- As1288 Glass Deflection CriteriaDocument1 pageAs1288 Glass Deflection Criteriaahsan khanNo ratings yet

- 10-1-17 Struc Calc UCW T2Document2,832 pages10-1-17 Struc Calc UCW T2ady pramanaNo ratings yet

- Structural Silicone GlazingDocument20 pagesStructural Silicone GlazingWynel Balweg SadsadNo ratings yet

- Strength Design Methods - For Glass StructuresDocument147 pagesStrength Design Methods - For Glass Structuresasdriana100% (1)

- Check For Glass Fins and Continuous Channel: Page 8Document2 pagesCheck For Glass Fins and Continuous Channel: Page 8waweng22100% (1)

- Structural Calculation Curtain WallDocument93 pagesStructural Calculation Curtain Wallashaswamy100% (1)

- Project Name: Glass BalustradeDocument11 pagesProject Name: Glass BalustradeNp Pw100% (1)

- DGU Design For Glass DivisionDocument3 pagesDGU Design For Glass DivisionShafeeq KT100% (1)

- 200205-MYH-MYS-000-021 Structural Analysis of Aluminum Cladding Under Co...Document74 pages200205-MYH-MYS-000-021 Structural Analysis of Aluminum Cladding Under Co...Dana KadriNo ratings yet

- Initial Verification for Glass Panel Wind Load CalculationDocument5 pagesInitial Verification for Glass Panel Wind Load Calculationwaweng22No ratings yet

- Effective Glass Thickness DeterminationDocument1 pageEffective Glass Thickness Determinationjay_senjaliaNo ratings yet

- Structural Glass Design SummaryDocument1 pageStructural Glass Design SummaryEr Chandra BoseNo ratings yet

- The Design Is Inadequate, See AnalysisDocument1 pageThe Design Is Inadequate, See AnalysisZiyad MonierNo ratings yet

- Structural Glass Design FEMDocument1 pageStructural Glass Design FEMBoy BangusNo ratings yet

- Structural Glass Design FEMDocument1 pageStructural Glass Design FEMErick Santiago CubillosNo ratings yet

- Basement Column Supporting Lateral Resisting Frame Based On ACI 318-11 Input Data & Design SummaryDocument46 pagesBasement Column Supporting Lateral Resisting Frame Based On ACI 318-11 Input Data & Design SummaryHizbar ArsjadNo ratings yet

- Warehouse Roof Design and AnalysisDocument51 pagesWarehouse Roof Design and AnalysisAnonymous q0irDXlWAm100% (2)

- Structural GlassDocument1 pageStructural GlassFred SalgadoNo ratings yet

- API 650 Design TanksDocument34 pagesAPI 650 Design TanksSyedZainAli100% (13)

- SEO-Optimized Beam Design CalculationDocument169 pagesSEO-Optimized Beam Design CalculationabuzahrauNo ratings yet

- 11kV Worked ExampleDocument15 pages11kV Worked ExampleHeather CarterNo ratings yet

- 1030 - Embedded Plate Design - 4 - S7.00Document9 pages1030 - Embedded Plate Design - 4 - S7.00rajedmaglinte100% (2)

- Potable Water Tank CalculationDocument37 pagesPotable Water Tank Calculationcamycax0% (1)

- Anchorage To ConcreteDocument18 pagesAnchorage To ConcreteNEONo ratings yet

- Design of Grade Slab for Medical Research CentreDocument7 pagesDesign of Grade Slab for Medical Research CentreersivarajNo ratings yet

- Rc:Prngnpiy Unit Bis. NRW Drlhi. IndiaDocument1 pageRc:Prngnpiy Unit Bis. NRW Drlhi. Indiasamgivp2869No ratings yet

- Profile - KingstonDocument26 pagesProfile - Kingstonsamgivp2869No ratings yet

- Malayalam KeyboardDocument1 pageMalayalam Keyboardssreejith69No ratings yet

- Dolby 3D For DevicesDocument0 pagesDolby 3D For Devicessamgivp2869No ratings yet

- Malayalam KeyboardDocument1 pageMalayalam Keyboardssreejith69No ratings yet

- Dolby 3D For DevicesDocument0 pagesDolby 3D For Devicessamgivp2869No ratings yet

- Stair A. Plot 39Document1 pageStair A. Plot 39samgivp2869No ratings yet

- Purlin DetailsDocument1 pagePurlin Detailssamgivp2869No ratings yet

- Purlin DetailsDocument1 pagePurlin Detailssamgivp2869No ratings yet

- ProductScanReport 1 5 Equity FundsDocument3 pagesProductScanReport 1 5 Equity Fundssamgivp2869No ratings yet

- Dolby 3D For DevicesDocument0 pagesDolby 3D For Devicessamgivp2869No ratings yet

- ProductScanReport 3Document3 pagesProductScanReport 3samgivp2869No ratings yet

- Zurich Vista Switch FormDocument1 pageZurich Vista Switch Formsamgivp2869100% (1)

- GRACO King 45-1 PartsDocument10 pagesGRACO King 45-1 Partssamgivp2869No ratings yet

- Beam - Column Connection - Ver W2.5.04 - 20 Jul 2010 Title: Code of Practice: Created: Notes and AssumptionsDocument14 pagesBeam - Column Connection - Ver W2.5.04 - 20 Jul 2010 Title: Code of Practice: Created: Notes and Assumptionssamgivp2869No ratings yet

- Purlin DetailsDocument1 pagePurlin Detailssamgivp2869No ratings yet

- Primary Load & Load CominationDocument1 pagePrimary Load & Load Cominationsamgivp2869No ratings yet

- Purlin DetailsDocument1 pagePurlin Detailssamgivp2869No ratings yet

- Alum WindowDocument1 pageAlum Windowsamgivp2869No ratings yet

- ProductScanReport 1 5 Equity FundsDocument3 pagesProductScanReport 1 5 Equity Fundssamgivp2869No ratings yet

- Honeywell Eng. ProfileDocument6 pagesHoneywell Eng. Profilesamgivp2869No ratings yet

- Obaid Hareb Building Contracting LLC: "Turnkey Structural Solutions"Document6 pagesObaid Hareb Building Contracting LLC: "Turnkey Structural Solutions"samgivp2869No ratings yet

- Honeywell Eng. ProfileDocument6 pagesHoneywell Eng. Profilesamgivp2869No ratings yet

- Honeywell Eng. ProfileDocument6 pagesHoneywell Eng. Profilesamgivp2869No ratings yet