Professional Documents

Culture Documents

Control Valve System: PN 16 / 40 DN 15 - 150 Application

Uploaded by

cico_ctOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control Valve System: PN 16 / 40 DN 15 - 150 Application

Uploaded by

cico_ctCopyright:

Available Formats

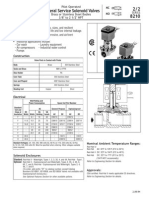

Product Specifications PSS 4-24A1 F

PN 16 / 40 DN 15 - 150

Application

Control of gases, vapours and liquids.

The modular concept of valve, multi spring actuator

and digital FO XBO RO /Eckardt positioner Type

SRD 992, facililates trouble free expansion to allow

for the communication capability of the FOXTOP

Valve System.

With its simple design the FOXTOP modular con-

cept has a wide range of application.

Product features

Body shape gives optimum flow

characteristic

Excellent flow dynamics when correctly selected

Heavy top guided plug

Largest possible kvs-values

Long service life and operational

reliability

With aggressive or evaporating media due to

sturdy design

Strong guides, give minimum vibration and wear

Replaceable trim

Simple maintenance as the valve body remains

in the piping when trim is replaced

Seat = DN, screwed seat

Wide range of application

Up to 10 kvs-values are available per size

Trims are generally interchangeable

" TA-Luft" design

Quick delivery

FOXTOP Control Valves can be delivered promptly

from stock

Quality assurance system certificated acc.

ISO 9001/ EN 29001.

Control Valve System

FOXTOP Control Valve System

The System

2

Actuators

98 S

C

H ER

R

Bonnets

Trims

Bodies

Within the series the following

combinations of bodies, trim, bon-

nets and actuators for each valve

size are possible:

Three-Flange Body, flanged Three-Flange Body, welded ends

Gasket

Screwed Seat

Gasket

M ulti-Hole Plug

Disk Plug

Contoured Plug

Pneumatic linear

Actuator

PSL-Electric

linear Actuator

Linear thrust Unit for

Electric rotaryActuators

Haselhofer-Electric

linear Actuator

Bellows seal Bonnet Standard Bonnet Finned Bonnet Extension Bonnet Double seal Bonnet

Valve Selection

3

Body with Flange Connection

M aterial Certificate

acc. EN 10 209

Pressure/Tightness Certificate

acc. EN 10 204

Nominal Size DN

Body

D

Three-

flange

M aterial

1.0619

1.4308

1.5419

1.4581

O

without

B

3.1 B

Z

2.2

A

3.1 A

O B

3.1 B

Z

2.2

A

3.1 A without

Nominal Pressure Level, Form of Connection

Form C

Connection Face

acc. to

DIN 2526 Form R

Form N

Form of Connection

Nominal Size DN

PN

16

40 Form D

150 80 65 50 40 32 25 20 15 100

Body with Welded End Connection

M aterial Certificate

acc. EN 10 204

Pressure/Tightness Certificate

acc. EN 10 204

Nominal Size DN

Body

D

Three-

flange

M aterial

1.0619

1.5419

1.4581

O

without

B

3.1 B

Z

2.2

A

3.1 A

O B

3.1 B

Z

2.2

A

3.1 A without

15 25 40 50 80 150 100

Nominal Pressure Level, Form of Connection

Standard welded ends based on DIN 3239

Section 1, Table 1 ( Special welded end dimensions available! )

Form of Connection

Nominal Size DN Di-

men-

sion

d

3

s

PN

16

to

40

100

114, 3

5, 0

80

88, 9

4, 0

50

60, 3

3, 2

40

48, 3

2, 6

25

33, 7

2, 6

15

21, 3

2, 0

150

168, 3

5, 6

Pressure- Temperature Ratings ( acc. to DIN 2401 )

BodyM aterial W.Nr.: 1.0619, GS-C 25

PN

(bar)

safe load operating pressure in bar at C

16

40

-200 -60 -10 0 120 200 250 300 350 400 450 500

16 16 16 14 13 11 10 8

40 40 40 35 32 28 24 21

-85

12

30

BodyM aterial W.Nr.: 1.4581, G-X5CrNiMoNb 1810

PN

(bar)

safe load operating pressure in bar at C

16

40

-200 -60 -10 0 120 200 250 300 350 400 450 500

16 16 14 12 11, 5 11 10, 5 10

40 40 35, 5 30, 5 29 28 27 26

-85

12

30

4

10

BodyM aterial W.Nr.: 1.5419, GS-22 Mo4

PN

(bar)

safe load operating pressure in bar at C

16

40

-200 -85 -10 0 120 200 250 300 350 400 450 500

16 16 14 13 12, 5

40 40 35 31 30

12

28

-60

16

40

16

40

16

40

BodyM aterial W.Nr.: 1.4308, G-X 6 CrNi 18 9

PN

(bar)

safe load operating pressure in bar at C

16

40

-200 -85 -10 0 120 200 250 300 350 400 450 500

16 16 13

40 40 33

16

40

16

40

-60

16

40

10

26

9, 5

24

5, 8*

23*

* Not suitable for permanence use at 300C!

Standard

Extended Standard

Possible Custom Design

150 100 80 65 50 40 32 25 20 15

4

Kvs-Values

Bonnet

Bonnet

Body-M aterials Pressure Balancing

1.0619

1.4581

1.0619

1.4581

Sizes

15

to

150

Unbalanced,

Shaft guided

65

1)

to

150

V-Ring balanced

-10C to 250 C

Piston-Ring balanced

exeeds 250 C to 450 C

Standard Bonnet

Use:

General,

-10 C to 250 C

Bellows seal Bonnet

Use:

Toxic, smell

strong, searching, costly

media or vacuum,

-10 C to 450 C

Finned Bonnet

Use:

R educe the temperature

and protect the actuator if

temperature

exeeds 250 C to 450 C

Double seal Bonnet

Use:

By strong safety require-

ments of pressure or vacu-

um operating

-10 C to 250 C

Extension Bonnet

Use:

Reduce the danger of icing

of the packing box

-200 C to -10 C

1.5419

1.0619

1.5419

1.4308

1)

onlyport size 53

Packing Box

Plug

Disk Plug

Characteristic: on / off

Bonnet

Type of Packing

PTFE-Rings - 200 C 250 C, general use, BAM

Pure Graphite-Rings - 200 C 450 C, general use, BAM s

t

a

n

d

a

r

d

s

p

r

in

g

-

lo

a

d

e

d

PTFE / Graphite core ( Latty) - 10 C 250 C, general use, " TA-Luft"

PTFE-Rings - 200 C 250 C, general use, BAM

Pure Graphite-Rings - 200 C 450 C, general use, BAM

PTFE V-Rings ( TDM -seal set ) - 200 C 250 C, general use

Bellows seal Bonnet Standard Bonnet Finned Bonnet Double seal Bonnet Extension Bonnet

PTFE/O il-Rings ( M erkel ) - 10 C 250 C, general use, " TA-Luft"

Design Guide of Plug Flow

on / off

equal percentage

linear

Top guided

Flow Action

tends to

open Valve

Flow Action

tends to

close Valve

Characteristic Plug Type

Contoured Plug

general use

Disk Plug

M ulti-Hole Plug in case of cavitation,

high differential pressure bygases, vapours,

for reducing noise 15 dB(A)

equal percentage

linear

RLS-Unit 2-step, series 1

for reducing noise 20 dB(A)

equal percentage

linear

standard

partial

stellited

full

stellited

soft

seated

hardened

tenifer

treated

1.4571

1

1

1

1

1

1

1

1

1 100

80

67

50

40

34

25

20

16

K vs

(m /h)

3

200

140

90

53

35, 5

25

16

9

6, 3

Incorporable seat diameter depends on nominal size DN M aterial / Design

Stroke = 20 mm 40 mm

Seat

Guide

of plug

15 20 25 32 40 50 65 80 100 150

60 mm

1 130 400

standard soft seated

5

Contoured Plug

Characteristic: modified - equal percentage

Incorporable seat diameter depends on nominal size DN M aterial / Design

1.4571 1.4122

Stroke = 20 mm 40 mm

K vs

(m /h)

3

180

160

125

100

80

63

47, 5

40

31, 5

25

22, 4

16

14

10

8

6, 3

5, 6

4, 0

2, 5

1, 6

0, 63

0, 25

0, 16

Seat

100

84

80

67

67

53

50

42

40

34

34

25

25

20

20

16

16

12

10

8

6

4

4

Guide

of

plug

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

* Seat facing for seat diameter < 10 mm = 10, 5 mm

15 20 25 32 40 50 65 80

60 mm

100 150

250 105

1

355 130

1

standard

partial

stellited

full

stellited

soft

seated

hardened standard

Contoured Plug

Characteristic: linear

1.4571

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1 100

84

80

67

67

53

50

42

40

34

34

25

25

20

20

16

16

12

K vs

(m /h)

3

180

160

125

100

80

63

47, 5

40

31, 5

25

22, 4

16

14

10

8

6, 3

5, 6

4, 0

Incorporable seat diameter depends on nominal size DN M aterial / Design

Stroke = 20 mm 40 mm

Seat

Guide

of

plug

15 20 25 32 40 50 65 80 100 150

60 mm

1 105 250

1 130 355

standard partial stellited soft seated

0, 40 4

1

6

Multi-Hole Plug

Characteristic: equal percentage

Incorporable seat diameter depends on nominal size DN M aterial / Design

Stroke = 20 mm 40 mm

Seat

Guide

of

plug

1.4571 1.4122

K vs

(m /h)

3

112

100

80

71

63

56

40

28

25

20

16

14

10

6, 3

4, 0

2, 5

100

84

80

67

67

53

42

50

42

40

34

34

25

20

20

20

160 105

200 130

65 80 150 50 40 32 25 20 15 100

60 mm

125 84

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

standard hardened tenifer treated

Multi-Hole Plug

Characteristic: linear

1.4571 1.4122

K vs

(m /h)

3

140

125

100

90

71

63

40

35, 5

25

25

16

10

6, 3

4, 0

2, 5

100

84

80

67

67

53

42

50

42

40

34

25

20

20

20

Incorporable seat diameter depends on nominal size DN M aterial / Design

Stroke = 20 mm 40 mm

Seat

Guide

of

plug

100 80 65 50 40 32 25 20 15 150

40 mm 60 mm

160 84

200 105

280 130

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

standard hardened tenifer treated

7

Actuator Selection

Multi-Spring Actuator

Actuators are selected for use on

FOXTOP dependent upon spring action

and air supply pressure:

Effective area

( cm

2

)

Air supply

(bar)

spring closes Spring opens

Spring ranges (bar)

125 2, 9

2, 0 - 4, 8

250

500

5, 0

2, 9

5, 0

2, 9

5, 0

3, 5

3, 5

0, 5 - 1, 9

1, 5 - 2, 7

0, 2 - 1, 0

2, 0 - 4, 8 0, 2 - 1, 0

0, 2 - 1, 0

0, 2 - 1, 0

1, 5 - 2, 7

2, 0 - 4, 8

1, 5 - 2, 7 *

3, 5 0, 5 - 1, 9

700 2, 9

5, 0

3, 5 0, 2 - 1, 0

0, 2 - 1, 0

1, 5 - 2, 7

2, 0 - 4, 8

4, 3 0, 2 - 1, 0

* for on / off service only!

2, 6 1, 0 - 2, 4

Using the Actuator Selection Table requires special knowledge !

Actuator Selection for Standard Bonnet

Seat

DN

S

t

r

o

k

e

(mm)

20

40

max. differential pressure in bar for actuator selection

Effective area 125 cm

2

Spring range-

Air supply(bar)

Spring closes

Spring range-

Air supply(bar)

Spring opens

Effective area 250 cm

2

Spring range-

Air supply(bar)

Spring closes

Spring range-

Air supply(bar)

Spring opens

Effective area 500 cm

2

Spring range-

Air supply(bar)

Spring closes

Spring range-

Air supply(bar)

Spring opens

Effective area 700 cm

2

Spring range-

Air supply(bar)

Spring closes

Spring range-

Air supply(bar)

Spring opens

60

84

84

80

67

53

50

42

40

34

25

20

16

12

10

8

6

42

130

105

4

100

15, 20, 25

15, 20 , 25, 32

15, 20, 25, 32, 40

25, 32, 40, 50

32, 40, 50

40

50

50

65

65, 80

80

100

100

150

150

65, 80, 100

150

1

,

5

-

2

,

7

2, 9

40

40

40

40

40

40

38

6

3, 7

23

11

7

2

,

0

-

4

,

8

5, 0

40

40

40

40

40

40

40

11

12

36

18

7

0

,

5

-

1

,

9

3, 5

40

26

12

8

40

40

40

40

40

40

7

4, 3

0

,

5

-

1

,

9

5, 0

40

33

23

40

40

40

40

40

40

40

21

14

1

,

5

-

2

,

7

2, 9

40

40

40

40

40

40

40

40

31

22

20

13

2

,

0

-

4

,

8

5, 0

40

32

29

20

40

40

40

40

40

40

40

40

0

,

2

-

1

,

0

3, 5

40

40

38

26

40

40

40

40

40

40

40

40

0

,

2

-

1

,

0

5, 0

40

40

40

40

40

40

40

40

40

40

40

40

1

,

5

-

2

,

7

2, 9

40

27

16

11

10

7

2

,

0

-

4

,

8

5, 0

38

23

16

14

10

40

0

,

2

-

1

,

0

3, 5

30

21

19

13

40

40

0

,

2

-

1

,

0

5, 0

36

32

22

40

40

40

1

,

5

-

2

,

7

2, 9

40

40

25

17

15

11

2

,

0

-

4

,

8

5, 0

40

40

35

24

22

15

21

13

8, 4

0

,

2

-

1

,

0

3, 5

40

40

40

31

28

19

27

17

11

0

,

2

-

1

,

0

4, 3

40

40

40

40

37

26

0

,

2

-

1

,

0

5, 0

40

29

19

1

,

0

-

2

,

4

2, 6

8, 5

5

3

8

Positioner System

Product features

SRD 992 digital positioner ( direct mounting ! )

Product Specifications PSS EVEA106 A

Auto-calibration

Configuration via local panel

Signal 4 - 20 mA or programmable split-ranges

Low air consumption

Resistant to vibration in all directions

Air supply up to 6 bar

Single and double-acting

Direct mounting with integral pipework in compliance with US Health and

Safety Act; alternatively according IEC 534 Teil 6 (NAM UR)

Enclosure IP65

EEx ia IIC T4 according CENELEC " Intrinsic safety" according FM and CSA

Limit switch set optional

O ptional gauges for supply and output

Volume booster optional

SRD 991 intelligent positioner ( direct mounting ! )

Product Specifications PSS EVEA105 A

Technical data same as SRD 992 with additional features

Self-diagnostics

Communication via HART or FO XCO M

Configuration via hand-terminal, PC or I/A - System

Analog or digital input signal

Built-in valve diagnostics features

O ptional pressure sensors to control supply and output

SRP 981 pneumatic positioner

Product Specifications PSS EVEA101 A

Input signal 0, 2 - 1, 0 bar 3 split ranges adjustable

Independent adjustment of zero and span

Extreme low vibration influence

Air supply up to 6 bar

Single- and double acting version

M ounting according IEC 534 Teil 6 ( NAM UR - recommandation )

Limit switch set optional

O ptional gauges for signal, supply and output

Volume booster optional

FRS B72G airset

M ax. supply pressure up to 10 bar

O utput range 0, 3 - 10 bar

Filter 5 m

M anually operated drain

With gauge

MV - valve ( direct mounting ! )

2401109.0827 - 6, 8 Watt, 24 VDC, IP 65, standard-version

2401109.3960 - 3, 9 Watt, 24 VDC, EEx em II T5/6-version

2401109.2001 - 1, 5 Watt, 24 VDC, EEx ib IIC T6-version

Alternative voltages on request !

Tubing

Plastic-pipe ( standard )

Steel, chromatised

Stainless steel

Anyfurther information see product specifications sheet.

SRP 981 pneumatic positioner

SRD 992 digital positioner

9

PSL-Actuator

Actuators are selected for use on

FOXTOP:

Linear actuator Voltage Power input

AB 201

AB 102

AB 202

alternating

current

230 V, 50 Hz

10, 7 W

11, 9 W

Actuator Selection for Standard Bonnet

Seat

(mm)

DN

Stroke

(mm)

AB 201 AB 102 AB 202 AB 204 AB 208 AB 210

max. differential pressure in bar for actuator selection

40

20

11

5, 2

1, 2 40

28

25 40

17 35 40

24 40

39 14 30

24 8, 1 18

16 5, 3 12

4, 7 11 15

AB 204 21 W

AB 208 49 W

AB 210 49 W

40

26

12

8, 1

7, 1

4, 3

5, 6

2, 7

40

40

Using the Actuator Selection Table requires special knowledge !

11, 9 W

p. f. 1 kN p. f. 2 kN p. f. 2 kN p. f. 4, 5 kN p. f. 8 kN p. f. 10 kN

84

80

67

53

50

42

40

34

25

20

16

12

10

8

6

42

4

100

15, 20, 25

15, 20 , 25, 32

15, 20, 25, 32, 40

25, 32, 40, 50

32, 40, 50

40

50

50

65

65, 80

80

100

100

65, 80, 100

20

40

40

40

40

40

1, 1

40

26

12

8, 1

7, 1

4, 3

5, 6

2, 7

40

1, 1

40

3, 0 7, 4 9, 9

40

10

Haselhofer-Actuator

Actuators are selected for use on

FOXTOP:

Linear actuator Voltage Power input ( 230V, 50Hz )

EB 12

EB 20

EB 25

alternating

current

230 V, 50 Hz

400 V, 50 Hz

direct current

24 V

Actuator Selection for Standard Bonnet

Seat

(mm)

DN

Stroke

(mm)

EB 1, 2

p. f. 1, 2 kN

EB 4, 5 EB 8 EB 12 EB 20 EB 25

max. differential pressure in bar for actuator selection

Using the Actuator Selection Table requires special knowledge !

EB 8

EB 4, 5 28 W / 32 W

EB 1, 2 7 W

60 W / 130 W

60 W / 130 W

145 W / 165 W

145 W / 165 W

p. f. 2, 0 kN p. f. 4, 5 kN p. f. 6, 0 kN p. f. 8, 0 kN p. f. 12 kN p. f. 15 kN p. f. 20 kN p. f. 25 kN

40

30

17 40

9, 3 40 26

3, 4 40 12

1, 7 28 40 8, 1

1, 3 25 36 7, 1 40

17 25 4, 3 35

24 34 40 40

14 21 40 30

8, 1 12 29 38 18 40

5, 3 8, 3 20 26 12 36

4, 7 7, 4 18 24 11 33

4, 9 13 16 29 7, 4 23

7, 1 18 23 40 11 32

4, 2 11 15 26 6, 5 20

40

40

40

40

40

40

84

84

80

67

53

50

42

40

34

25

20

16

12

10

8

6

42

130

105

4

100

15, 20, 25

15, 20 , 25, 32

15, 20, 25, 32, 40

25, 32, 40, 50

32, 40, 50

40

50

50

65

65, 80

80

100

100

150

150

65, 80, 100

150

20

40

60

3, 0

2, 4 3, 9 6, 9 9, 2 13 17

40

40

11

Linear thrust Unit

Thrust Unit are selected for use on

FOXTOP:

Linear thrust Unit Connection max. Torque

LB 12

LB 16

LB 20

acc. to

DIN 3210 form A

trapezoid thread

24 x 5 left

50 Nm

30 Nm

80 Nm

Actuator Selection for Standard Bonnet

Seat

(mm)

DN

Stroke

(mm)

LB 12 LB 16 LB 20

max. differential pressure in bar for actuator selection

Using the Actuator Selection Table requires special knowledge !

40

40

31

28

40

29

p. f. 10, 4 kN p. f. 17, 3 kN p. f. 27, 7 kN

84

84

80

67

53

50

42

40

34

25

20

16

12

10

8

6

42

130

105

4

100

15, 20, 25

15, 20 , 25, 32

15, 20, 25, 32, 40

25, 32, 40, 50

32, 40, 50

40

50

50

65

65, 80

80

100

100

150

150

65, 80, 100

150

20

40

60

40

40

40

40

40

40

40

40

40

40

40

40

40

19

19

Parts List

12

3.9

3.10

3.11

3.6

3.8

3.4

3.20

3.3

3.22

3.21

3.5

2.4

3.2

3.2

1.4

3.1

2.3

1.1

2.8

3.16

3.13

3.14

2.15

2.6

3.17

1.2

2.1

2.5

2.2

2.7

3.15

1.3

3.3

3.12

3.3

13

3.23

Body

Designation Materials Part

1.1 1.0619 1.5419 1.4581 1.4308

Bonnet Gasket 1.2 Pure Graphite

1)

Stud Bolt 1.3 G G A2-70

Hex Nut 1.4 G G A2-70 A2-70

Screwed Seat 2.1 1.4571

Contoured Plug 2.2

Spring Pin 2.3 A2

Stem 2.4 1.4571 Cold-finished

Profil Ring 2.5 Pure Graphite

Hex Nut 2.6 1.4571 - -

Seal Carrier 2.7 1.4571 - -

Profil Ring 2.8 - -

Head Gasket 2.15

Standard Bonnet 3.1

1.0460

1.5415

1.4571

1.4571

Bottom Ring 3.2 1.4571

Packing

Box

3.3 PTFE-Rings

Stuffing Box 3.4

Stud Bolt 3.5

1.4404 ( DN 15 - 100 ) resp. 1.4571 ( DN 150 )

Hex Nut 3.6

Plain Washer 3.8

Hex Nut 3.9

Plain Washer 3.10

Belleville Spring 3.11

Lantern Ring 3.12

Gasket 3.13

Locking Screw 3.14 A2

Head 3.15 1.0460 - 1.4571 1.4571

Hex Nut 3.16 G A2-70 A2-70

Stud Bolt 3.17 G A2-70 A2-70

Distance Ring 3.20 1.4571

Pressure Spring 3.21 1.4310

Plain Washer 3.22 A2

Spacer 3.23 - PTFE

Bellows seal Bonnet

Finned Bonnet

Double seal Bonnet

Extension Bonnet

Disk Plug

M ulti-Hole Plug

Pure Graphite

1)

Pure Graphite

1)

-

Pure Graphite

-

-

unloaded

Spring

loaded

Pure Graphite Rings

PTFE/O el-Rings resp. PTFE/Graphite Core

TDM -seal set

A2-70

A2-70

1.4571

A2-70

A2

1.4571

A2

1.4310

1.4571

Pure Graphite

2)

-

1)

Pure Graphite on Support Plate from 1.4401

2)

Pure Graphite on Support Plate from M YLAR

K Plug Set

S Seat Set

D Gasket Set

Spare

Parts

D

S

K

K

K

S

D

D

D

D

D PTFE-Rings

Pure Graphite Rings

1.4571 1.4571 / 1.4122 1.4571 / 1.4122

1.4571 1.4571 1.4571 / 1.4122 1.4571 / 1.4122

1.4571 1.4571 1.4571 / 1.4122 1.4571 / 1.4122

-

-

14

Dimensions and Weights

Dimensions

BL Face to Face Dimensions in mm

H2 for Bellows seal Bonnet

Weight for Valves with Standard Bonnet

Welded Ends complywith

Weight for Valves with Extension Bonnet

Designation

Nominal Size DN

40 mm Stroke = 20 mm

DIN 3239 Section 1, Table 1

Flanges Drilled and Dimensioned acc. to DIN 2501, Form C, D, R, N

Weight for Valves with Double seal Bonnet

Weight for Valves with Finned Bonnet

Weight for Valves with Bellows seal Bonnet

H3 for Finned Bonnet

H4 for Double seal Bonnet

H5 for Extension Bonnet

H1 for Standard Bonnet

W

e

i

g

h

t

i

n

k

g

H

e

i

g

h

t

i

n

m

m

15

130

105

300

5

8

6

7

9

220

145

644

20

150

105

300

6

9

7

8

10

220

145

644

25

160

105

300

7

10

8

9

11

220

145

644

32

180

120

300

11

14

12, 5

13, 5

15

220

150

646

40

200

120

300

12

15

13, 5

14, 5

16

220

150

646

50

230

120

300

16

19

17, 5

18, 5

20

220

150

648

65

290

170

480

30

32

33

32

35

310

220

651

80

310

170

480

35

37

38

37

40

310

220

651

100

350

175

480

50

52

53

52

55

310

220

653

150

480

270

821

95

108

96

99

113

443

295

670

60 mm

Valve with

Extension Bonnet

H

5

Valve with

Bellows seal Bonnet

H

2

Valve with

Double seal Bonnet

H

4

BL

Valve with

Standard Bonnet

H

1

Valve with

Finned Bonnet

H

3

15

Pneumatic linear Actuator

127 Designation

Weight

252 502 700

A

H

kg

mm

mm

Area

Stroke 20 mm 40 mm

Designation

Weight

AB 210

A

H

kg

mm

mm

Actuator

Stroke 20 mm 20 / 40 mm

Designation

Weight

EB 25

A

H

20 mm 20/40 mm 60 mm

Designation

Weight

LB 20

A

H

kg

mm

mm

Linear Unit

Stroke 20 mm 40 mm

PSL - Electric linear Actuator

Haselhofer - Electric linear Actuator

Linear thrust Unit

A

H

60 mm

405

600

46

405

547

40

352

436

31

265

310

16

198

303

11

AB 208 AB 204 AB 202 AB 102 AB 201

236

585

12

219

462

9, 5

236

585

12

219

462

5, 7

219

462

5, 7

219

462

5, 5

216

660

19

184

570

13

216

660

19

184

570

13

145

535

7, 5

145

505

6, 5

EB 20 EB 12 EB 8 EB 4, 5 EB 1, 2

20 / 40 / 60 mm

kg

mm

mm

Actuator

Stroke

60 mm

LB 16 LB 12

196

407

20

196

320

17

196

240

12

A

H

A

A

H

Continuation

Plug Guidance:

1 = top guided 1

Plug Characteristic:

G = modified equal percentage G

L = linear L

A = on / off A

Direction of Flow:

G = Flow to open G

I = Flow to close I

Seat / kvs:

EW = 4 mm - 0, 16 m

3

/h EW

EY = 4 mm - 0, 25 m

3

/h EY

IM = 4 mm - 0, 40 m

3

/h IM

EA = 6 mm - 0, 63 m

3

/h EA

EC = 8 mm - 1, 6 m

3

/h EC

EE = 10 mm- 2, 5 m

3

/h EE

EG = 12 mm- 4, 0 m

3

/h EG

EJ = 16 mm- 5, 6 m

3

/h EJ

EL = 16 mm- 6, 3 m

3

/h EL

EF = 20 mm- 2, 5 m

3

/h EF

EH = 20 mm- 4, 0 m

3

/h EH

EI = 20 mm- 6, 3 m

3

/h EI

EQ = 20 mm- 8, 0 m

3

/h EQ

ES = 20 mm- 9, 0 m

3

/h ES

EP = 20 mm- 10, 0 m

3

/h EP

EU = 25 mm- 10, 0 m

3

/h EU

ER = 25 mm- 14, 0 m

3

/h ER

ET = 25 mm- 16, 0 m

3

/h ET

HA = 34 mm- 14, 0 m

3

/h HA

HB = 34 mm- 16, 0 m

3

/h HB

HC = 34 mm- 22, 4 m

3

/h HC

HD = 34 mm- 25, 0 m

3

/h HD

HE = 40 mm- 20, 0 m

3

/h HE

HF = 40 mm- 25, 0 m

3

/h HF

HG = 40 mm- 31, 5 m

3

/h HG

HH = 40 mm- 35, 5 m

3

/h HH

BQ = 42 mm- 25, 0 m

3

/h BQ

HI = 42 mm- 40, 0 m

3

/h HI

HJ = 50 mm- 28, 0 m

3

/h HJ

HK = 50 mm- 35, 5 m

3

/h HK

HL = 50 mm- 47, 5 m

3

/h HL

HM = 50 mm- 53 m

3

/h HM

HN = 53 mm- 56 m

3

/h HN

HO = 53 mm- 63 m

3

/h HO

HP = 67 mm- 63 m

3

/h HP

HQ = 67 mm- 71 m

3

/h HQ

HR = 67 mm- 80 m

3

/h HR

HS = 67 mm- 90 m

3

/h HS

HT = 67 mm- 100 m

3

/h HT

HU = 80 mm- 80 m

3

/h HU

O E = 80 mm- 100 m

3

/h O E

O G = 80 mm- 125 m

3

/h O G

HV = 80 mm- 140 m

3

/h HV

HW = 84 mm- 100 m

3

/h HW

FK = 84 mm- 125 m

3

/h FK

HX = 84 mm- 160 m

3

/h HX

HY = 100 mm - 112 m

3

/h HY

HZ = 100 mm - 140 m

3

/h HZ

IA = 100 mm - 180 m

3

/h IA

IB = 100 mm - 200 m

3

/h IB

IC = 105 mm - 160 m

3

/h IC

ID = 105 mm - 200 m

3

/h ID

IF = 105 mm - 250 m

3

/h IF

IG = 130 mm - 200 m

3

/h IG

IJ = 130 mm - 280 m

3

/h IJ

IK = 130 mm - 355 m

3

/h IK

IL = 130 mm - 400 m

3

/h IL

Trim M aterial:

S = 1.4571- stainless steel S

K = 1.4122- chrome steel K

Actuator:

N = without N

I = with pneumatic actuator I

A = with PSL electric linear actuator A

E = with Haselhofer electric linear actuator E

L = with linear thrust unit L

FOXBORO Model-Code

Description M odel

V726 = Control Valve System FOXTOP V726

BodySize:

-0H = DN 15 -0H

-3Q = DN 20 -3Q

-01 = DN 25 -01

-5Q = DN 32 -5Q

-1H = DN 40 -1H

-02 = DN 50 -02

-2H = DN 65 -2H

-03 = DN 80 -03

-04 = DN 100 -04

-06 = DN 150 -06

BodyStyle:

D = Three-Flange Body, flanged D

B = Three-Flange Body, weld ends B

Pressure Class:

DN = PN 16 DN

DQ = PN 40 DQ

BodyM aterial:

Q = 1.0619- carbon steel Q

K = 1.4581- stainless steel K

G = 1.4308- stainless steel G

P = 1.5419- chrom moly P

End Connection:

C = Flanges acc. DIN 2526 Form C C

D = Flanges acc. DIN 2526 Form D D

R = Flanges acc. DIN 2526 Form R R

N = Flanges acc. DIN 2526 Form N N

B = Weld Ends acc. DIN 3239 B

Bonnet:

N = Standard Bonnet N

F = Bellows seal Bonnet F

R = Finned Bonnet R

K = Extension Bonnet K

L = Double seal Bonnet L

Packing:

A = PTFE, adjustable, BAM A

B = Graphite, adjustable, BAM B

N = PTFE, spring loaded, BAM N

G = Graphite, spring loaded, BAM G

O = PTFE / Graphite core, spring loaded, " TA-Luft" ( Latty) O

R = PTFE/O el, spring loaded, " TA-Luft" ( M erkel ) R

S = PTFE V-rings ( TDM -seal set ) S

M aterial Certificate:

N = without N

Z = acc. EN 10204 2.2 Z

B = acc. EN 10204 3.1 B B

A = acc. EN 10204 3.1 A A

Q = acc. TRB 801 Q

D = acc. TRD 110 D

Pressure and Leakage Test:

N = without N

Z = acc. EN 10204 Z.Z Z

B = acc. EN 10204 3.1 B B

A = acc. EN 10204 3.1 A A

Q = acc. TRB 801 Q

D = acc. TRD 110 D

Plug:

P = Contoured Plug, unbalanced P

L = M ulti-Hole Plug, unbalanced L

T = Disk Plug, unbalanced T

A = RLS-Unit, 2-step, series I, unbalanced A

O = Contoured Plug, O -ring balanced O

R = Contoured Plug, Piston-ring balanced R

Plug Design:

BM = standard BM

SP = partial stellited SP

SS = full stellited SS

SM = soft seated SM

HM = hardened HM

TN = tenifer treated TN

16

17

Description M odel

ITS = Pneumatic linear Actuator for FOXTOP ITS

Actuator Size:

-127 = 125 cm

2

-127

-252 = 250 cm

2

-252

-502 = 500 cm

2

-502

-700 = 700 cm

2

-700

Stroke:

A = 20 mm A

B = 40 mm B

C = 60 mm C

Spring Range:

A = 0, 2 - 1, 0 bar A

B = 0, 5 - 1, 9 bar B

V = 1, 5 - 2, 7 bar V

F = 2, 0 - 4, 8 bar F

O peration on air failure:

A = Spring opens A

Z = Spring closes Z

O ption:

-N = Actuator without Accessories -N

-P = with Positioner SRP 981 -P

-E = with Positioner SRD 992 -E

-I = with Positioner SRD 991 -I

-K = with Airset FRS 72 G -K

-O = with top mounted Hand Wheel -O

Description M odel

ABS = PSL-Electric linear Actuator for FOXTOP ABS

Size:

-A = 1 kN positioning force, 0, 25 mm/s -A

-B = 2 kN positioning force, 0, 5 mm/s -B

-E = 2 kN positioning force, 0, 25 mm/s -E

-C = 4, 5 kN positioning force, 0, 5 mm/s -C

-D = 8 kN positioning force, 0, 5 mm/s -D

-F = 10 kN positioning force, 0, 35 mm/s -F

Supply:

Z = 230 V / 50 Hz - AC Z

Positioning Feedback:

O = without O

E = 2 additional limit switches E

P = 1000 potentiometer P

Q = 1000 potentiometer and 2 additional limit switches Q

M = 4 - 20 mA positioning feedback M

N = 4 - 20 mA positioning feedback and 2 add. limit switches N

Positioning Electronics:

O = without O

M = Positioning electronics, Input in mA M

V = Positioning electronics, Input in V V

Description M odel

EBS = Haselhofer-Electric linear Actuator for FOXTOP EBS

Size:

-AA = 1, 2 kN positioning force, max. 20 mm Stroke -AA

-BB = 2 kN positioning force, max. 20 mm Stroke -BB

-BC = 4, 5 kN positioning force, max. 40 mm Stroke -BC

-CD = 6 kN positioning force, max. 60 mm Stroke -CD

-CE = 8 kN positioning force, max. 60 mm Stroke -CE

-DF = 12 kN positioning force, max. 60 mm Stroke -DF

-EG = 15 kN positioning force, max. 60 mm Stroke -EG

-EH = 20 kN positioning force, max. 60 mm Stroke -EH

-FI = 25 kN positioning force, max. 60 mm Stroke -FI

Supply:

Z = 230 V / 50 Hz -AC Z

D = 400 V / 50 Hz - AC D

G = 24 V - DC G

Positioning Feedback:

O = without O

P = 1000 potentiometer P

M = 4 - 20 mA positioning feedback M

Positioning Electronics:

O = without O

M = Positioning electronics, Input in mA M

V = Positioning electronics, Input in V V

Closing Speed:

A = 0, 23 mm/s A

B = 0, 28 mm/s B

C = 0, 42 mm/s C

D = 0, 83 mm/s D

Description M odel

LBS = Linear thrust Unit for FOXTOP LBS

Size:

-A = 10, 4 kN positioning force, max. 20 mm Stroke -A

-B = 17, 3 kN positioning force, max. 40 mm Stroke -B

-C = 27, 7 kN positioning force, max. 60 mm Stroke -C

Alternate positioners on request for direct- or NAM UR mountig !

Description M odel

SRD992 = Positioner for FOXTOP SRD992

Version:

-B = Single acting -B

Input / Communication:

I = Signal range 4 - 20 mA I

Additional Inputs / O utputs:

M = without M

Built-in limit switch:

S = without S

Electrical connection:

2 = Cable gland Pg 13, 5 2

Electrical certification:

EA4 = EEx ia IIC T4 EA4

Attachement kit:

D = for directlymounting ( not for DN 150 ) D

M anifold and Booster relay:

A = without

SPM - Code

18

50 V726 DCVNA 40 1.0619/ ZZ PN1GG 42 40 1.4571

Type DN PN Body./Cert. Plug Seat kvs Trim Actuator S

PTFE-rings, adjustable, BAM A

Graphite-rings, adjustable, BAM B

PTFE-rings, spring loaded, BAM N

Graphite-rings, spring loaded, BAM O

PTFE/Graphite core, s. l., " TA-Luft" Q

PTFE/O el, s. l., " TA-Luft" (M erkel) R

PTFE-V-Rings(TDM -seal set) S

Nominal Pressure PN 16 16

Nominal Pressure PN 40 40

N

D

K

W

H

T

standard

partial stellited

full stellited

soft seated

hardened

tenifer treated

Characteristic

G

L

A

equal percentage

linear

on / off

1.4571 Plug, Seat-M aterial

1.4122 kvs - Value 0, 16 - 400

Seat Diameter 4 - 130

Nominal Size 15 - 150

Flow tends to open Valve G

Flow tends to close Valve I

Contoured Plug P

Disk Plug T

M ulti-Hole Plug L

RLS-Unit, 2-step, serie I A

Unbalanced V

V-ring balanced O

Piston-ring balanced K

Form of Connection

Flange acc. to Form C

DIN 2526 Form D

Form R

Form N

Weld ends acc. S

DIN 3239

Standard Bonnet N

Bellows seal Bonnet F

Finned Bonnet R

Double seal Bonnet L

Extension Bonnet I

BodyM aterial 1.0619

1.4581

1.5419

1.4308

Certificates unaccording

International Standards

Cert. for pressure stressed parts

without O .

acc. EN 10 204 - 2.2Z Z .

acc. EN 10 204 - 3.1B B .

acc. EN 10 204 - 3.1A A .

Pressure / Tightness Certificate

without . O

acc. EN 10 204 - 2.2Z . Z

acc. EN 10 204 - 3.1B . B

acc. EN 10 204 - 3.1A . A

19

LB 16 Linear thrust Unit

LB 12 actuating power 10, 4 kN

LB 16 actuating power 17, 3 kN

LB 20 actuating power 27, 7 kN

EB 8/8 ZPO 50 Positioning Speed

13, 5 13, 5 mm/min

17 17 mm/min

25 25 mm/min

50 50 mm/min

Positioning Electronics

O without

M Positioning electronics,

input in mA

V Positioning electronics,

input in V

Positioning Feedback

O without

P 1000 potentiometer

M 4 - 20 mA positioning

feedback

M ains Power

Z alternating current

230 V, 50 Hz

D alternating current

400 V, 50 Hz

G direct current

24 V

Haselhofer-Electric linear

Actuator

EB 1, 2/1, 2 actuating power 1, 2 kN

EB 4, 5/2 actuating power 2 kN

EB 4, 5/4, 5 actuating power 4, 5 kN

EB 8/6 actuating power 6 kN

EB 8/8 actuating power 8 kN

EB 12/12 actuating power 12 kN

EB 20/15 actuating power 15 kN

EB 20/20 actuating power 20 kN

EB 25/25 actuating power 25 kN

AB 204 ZQ O

Positioning Feedback

O without

E 2 add. limit switches

P 1000 potentiometer

M 4 - 20 mA positioning

feedback

Q 1000 potentiometer

and 2 add. limit switches

N 4 - 20 mA position feed-

back and 2 add. limit

switches

M ains Power

Z monophase current

230 V, 50 Hz

IT 252 AO Z O peration on air failure

A Stem retracted

Z Stem extended

Hand Wheel

O without

L top, light-weight-variant

Spring Ranges

A 0, 2 - 1, 0

B 0, 5 - 1, 9

V 1, 5 - 2, 7

F 2, 0 - 4, 8

Actuator Size

IT 127 Area 125 cm

2

IT 252 Area 250 cm

2

IT 502 Area 500 cm

2

IT 700 Area 700 cm

2

Positioning Electronics

O without

M Positioning electronics,

input in mA

V Positioning electronics,

input in V

PSL-Electric linear Actuator

AB 201 actuating power 1 kN

AB 102 actuating power 2 kN

AB 202 actuating power 2 kN

AB 204 actuating power 4, 5 kN

AB 208 actuating power 8 kN

AB 210 actuating power 10 kN

M

o

d

i

f

i

c

a

t

i

o

n

s

w

i

t

h

o

u

t

n

o

t

i

c

e

i

n

l

i

n

e

w

i

t

h

t

e

c

h

n

i

c

a

l

p

r

o

g

r

e

s

s

.

P

u

b

l

i

c

a

t

i

o

n

n

o

.

:

V

7

2

6

e

6

/

9

8

A Siebe Group Company

K asernengasse 6

Postfach 189

A-9500 Villach

Phone +43 (0) 42 42 / 41 1 81 - 0

Fax +43 (0) 42 42 / 41 1 81 - 50 or 51

SCHMIDT ARMATUREN

Gesellschaft m.b.H.

Plant:

You might also like

- Control Valve System: PN 16 / 40 DN 15 - 100 ApplicationDocument0 pagesControl Valve System: PN 16 / 40 DN 15 - 100 Applicationcico_ctNo ratings yet

- FlowPak - V725 - ANSI - English Veersion Free For ClientDocument12 pagesFlowPak - V725 - ANSI - English Veersion Free For ClientMisael Castillo CamachoNo ratings yet

- FoxPro V723 e - 09.99Document0 pagesFoxPro V723 e - 09.99cico_ctNo ratings yet

- Technical Bulletin: Valtek Mark One Control ValvesDocument20 pagesTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzNo ratings yet

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoNo ratings yet

- 'C' Series Control ValvesDocument12 pages'C' Series Control Valvesابزار دقیق100% (1)

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestNo ratings yet

- Bulletin B150-5 - Ball Valve For H2O2Document0 pagesBulletin B150-5 - Ball Valve For H2O2pdaga19691383No ratings yet

- Catalogo Regulador Watts Mod 152-ADocument2 pagesCatalogo Regulador Watts Mod 152-AGuatemalan1979No ratings yet

- Ss 01059 eDocument8 pagesSs 01059 eDavid LapacaNo ratings yet

- Unique Single Seat Valve-Simply UniqueDocument8 pagesUnique Single Seat Valve-Simply UniquelggomezupbNo ratings yet

- Econ Gate ValvesDocument22 pagesEcon Gate ValvesRiyas Udheen100% (1)

- Series B6400-SE Specification SheetDocument2 pagesSeries B6400-SE Specification SheetWattsNo ratings yet

- Re91401 A2foDocument20 pagesRe91401 A2foTaz Juan GNo ratings yet

- Ball Valves: For SteamDocument8 pagesBall Valves: For SteamcontorrresjulianNo ratings yet

- Butterfly ValveDocument20 pagesButterfly Valvenazar750No ratings yet

- AVT Ball & Butterfly Brochure 05 Latest 12 PageDocument12 pagesAVT Ball & Butterfly Brochure 05 Latest 12 PageshalbyNo ratings yet

- Catálogo Válvula DirecionalDocument20 pagesCatálogo Válvula DirecionalcristianoclemNo ratings yet

- About Axial Displacement Pump A4VSoDocument68 pagesAbout Axial Displacement Pump A4VSomrkadu_61No ratings yet

- Control Choke Valve 9000Document8 pagesControl Choke Valve 9000sabi_shi100% (2)

- Valvulas de Bola - JAMESBURYDocument4 pagesValvulas de Bola - JAMESBURYcasv9No ratings yet

- Pump STDRDocument7 pagesPump STDRsopian320No ratings yet

- Series LF25AUB-Z3 Specification SheetDocument2 pagesSeries LF25AUB-Z3 Specification SheetWattsNo ratings yet

- DM931 Variable Orifice Double Regulating Valve: PN16 Cast Iron Balancing Valve (VODRV), Flanged To BSEN 1092-2Document10 pagesDM931 Variable Orifice Double Regulating Valve: PN16 Cast Iron Balancing Valve (VODRV), Flanged To BSEN 1092-2Mohamed AdelNo ratings yet

- Interruptor de Presion - AscoDocument9 pagesInterruptor de Presion - AscoJosephGutierrezNo ratings yet

- Guth VSR Modulating ValvesDocument8 pagesGuth VSR Modulating ValvesRaul Guevara TorresNo ratings yet

- Series LFB6080, LFB6081 Specification SheetDocument2 pagesSeries LFB6080, LFB6081 Specification SheetWattsNo ratings yet

- Monoflanges VariAS BlocksDocument20 pagesMonoflanges VariAS BlocksamuihNo ratings yet

- Valve0114 PDFDocument14 pagesValve0114 PDFbinhjukiNo ratings yet

- AMRI ISORIA Broad Market Type Series Booklet DataDocument12 pagesAMRI ISORIA Broad Market Type Series Booklet Datarudiskw456No ratings yet

- SELENOIDE-Valv Solen 8210Document6 pagesSELENOIDE-Valv Solen 8210MARACO46No ratings yet

- Mustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetDocument7 pagesMustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetWattsNo ratings yet

- Válvula DurcoDocument12 pagesVálvula DurcoJames Henrry López EspejoNo ratings yet

- Sapag JHP Valves Jun04 enDocument18 pagesSapag JHP Valves Jun04 enanwar01No ratings yet

- General Service Solenoid Valves: NC NODocument6 pagesGeneral Service Solenoid Valves: NC NOAngel Azathoth GoetzNo ratings yet

- Prochem Ball ValvesDocument5 pagesProchem Ball Valvesmd_taheriNo ratings yet

- Mark 50 Series: Self-Operated Back Pressure RegulatorsDocument16 pagesMark 50 Series: Self-Operated Back Pressure RegulatorsDarren JohnstonNo ratings yet

- ETL Pressure Relief Valves Datasheet PDFDocument6 pagesETL Pressure Relief Valves Datasheet PDFNanasaheb PatilNo ratings yet

- KSB Valvula Diafragma SISTO10Document4 pagesKSB Valvula Diafragma SISTO10Sarah PerezNo ratings yet

- Catalogo - Cilindros Hidraulicos VEGADocument24 pagesCatalogo - Cilindros Hidraulicos VEGARaul Izquierdo MoralesNo ratings yet

- EJ Series Butterfly ValvesDocument12 pagesEJ Series Butterfly ValvesGia Minh Tieu TuNo ratings yet

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentNo ratings yet

- 1100 Series Standard Pressure Gauge MODEL:1100: ApplicationsDocument3 pages1100 Series Standard Pressure Gauge MODEL:1100: ApplicationsfatherbyteNo ratings yet

- Series 825Y Specification SheetDocument2 pagesSeries 825Y Specification SheetFEBCONo ratings yet

- Dezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bDocument24 pagesDezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bjasonlaiymNo ratings yet

- MasterSeries 850 Specification SheetDocument2 pagesMasterSeries 850 Specification SheetFEBCONo ratings yet

- Full Lift Spring Loaded Open PDFDocument4 pagesFull Lift Spring Loaded Open PDFVenkatespatange RaoNo ratings yet

- Es Lfu009Document4 pagesEs Lfu009WattsNo ratings yet

- PVRVDocument4 pagesPVRVbkkbrazil100% (1)

- Series TDV Specification SheetDocument2 pagesSeries TDV Specification SheetWattsNo ratings yet

- Series 909 Specification SheetDocument4 pagesSeries 909 Specification SheetWattsNo ratings yet

- Pulse Valves - Turbocontrols - It PDFDocument40 pagesPulse Valves - Turbocontrols - It PDFRicardo Ferrari TrevisanNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Cavity Quantum Electrodynamics For Superconducting Electrical Circuits - An Architecture For Quantum ComputationDocument14 pagesCavity Quantum Electrodynamics For Superconducting Electrical Circuits - An Architecture For Quantum ComputationHuỳnh NguyênNo ratings yet

- Sharp 2T-C32BG1X Service ManualDocument74 pagesSharp 2T-C32BG1X Service ManualA NguyenNo ratings yet

- 3.4 Diagnosis Code and Backup: 0.5V Boost Sensor 4.8VDocument1 page3.4 Diagnosis Code and Backup: 0.5V Boost Sensor 4.8VchinhNo ratings yet

- Batteries and InvertersDocument16 pagesBatteries and InvertersPratik VasagadekarNo ratings yet

- UntitledDocument41 pagesUntitled203005 ANANTHIKA MNo ratings yet

- 2nd Year PHYSICS Full Book Solved MCQs by Bismillah Academy 0300-7980055Document68 pages2nd Year PHYSICS Full Book Solved MCQs by Bismillah Academy 0300-7980055AFTABNo ratings yet

- Nyy 1CDocument1 pageNyy 1Chenry_gtNo ratings yet

- A Low-Cost Extendable Framework For Embedded Smart Car Security SystemDocument17 pagesA Low-Cost Extendable Framework For Embedded Smart Car Security Systemumaprakash111No ratings yet

- Toshiba Small Form Factor Disk Drive White PaperDocument3 pagesToshiba Small Form Factor Disk Drive White Papernjk19No ratings yet

- ++ 437-1692-1-PBDocument9 pages++ 437-1692-1-PBAli TarkashvandNo ratings yet

- ABB - Fuses Vs FuselessDocument18 pagesABB - Fuses Vs Fuselesskhalid100% (1)

- ZED F9P MovingBase - AppNote - (UBX 19009093)Document23 pagesZED F9P MovingBase - AppNote - (UBX 19009093)Nguyen Huu Cuong ThinhNo ratings yet

- Samcom Exit BoardDocument1 pageSamcom Exit BoardGlishna Peushan WidanapathiranaNo ratings yet

- TAS5612L-TAS5614LDDVEVM: User's GuideDocument36 pagesTAS5612L-TAS5614LDDVEVM: User's Guidefrangi frangioniNo ratings yet

- BENZ Me97 Engine Programming-EnDocument15 pagesBENZ Me97 Engine Programming-EnTaha NoamanNo ratings yet

- Westermo Ds md-45 PDFDocument2 pagesWestermo Ds md-45 PDFPablo TeránNo ratings yet

- ECE137Document6 pagesECE137Jonathan Zabala Jr.No ratings yet

- Aviat E-Band Wireless Technology V1.0 PDFDocument11 pagesAviat E-Band Wireless Technology V1.0 PDFtarreroNo ratings yet

- Paper - 062 - INTEGRATION OF SOLAR PHOTOVOLTAIC DISTRIBUTED GENERATION IN NIGERIAN POWER SYSTEM NETWORKDocument6 pagesPaper - 062 - INTEGRATION OF SOLAR PHOTOVOLTAIC DISTRIBUTED GENERATION IN NIGERIAN POWER SYSTEM NETWORKabera alemayehuNo ratings yet

- l7812cv Nte966Document3 pagesl7812cv Nte966ch3o108362660% (1)

- Deltalite II 2510-4: Neodymium SeriesDocument2 pagesDeltalite II 2510-4: Neodymium SeriesAji VerdeNo ratings yet

- LPBDocument6 pagesLPBalbertoNo ratings yet

- SP-275K-H1 - Datasheet - Ver20 - 20220909Document1 pageSP-275K-H1 - Datasheet - Ver20 - 20220909Victor StefanNo ratings yet

- Product Data: Fx4D Comfortt Series Fan Coil Sizes 019 Thru 061Document16 pagesProduct Data: Fx4D Comfortt Series Fan Coil Sizes 019 Thru 061Victor OrtegaNo ratings yet

- Brochure Hydran M2 English All-In-One Fact SheetDocument0 pagesBrochure Hydran M2 English All-In-One Fact SheetAlexandra-Roxana MoraruNo ratings yet

- Power Factor CalculationsDocument3 pagesPower Factor CalculationsM Kumar MarimuthuNo ratings yet

- Color Sensor Module User GuideDocument6 pagesColor Sensor Module User GuideSyrilleNo ratings yet

- Forum Diskusi 1-2 Electric Charge and Electric Field)Document7 pagesForum Diskusi 1-2 Electric Charge and Electric Field)heroNo ratings yet

- MHADA Investigation ReportDocument12 pagesMHADA Investigation Reportkuldip purohitNo ratings yet

- rr220402 Electrical TechnologyDocument8 pagesrr220402 Electrical TechnologySRINIVASA RAO GANTANo ratings yet