Professional Documents

Culture Documents

CONIPURHG

Uploaded by

Dan George IIICopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CONIPURHG

Uploaded by

Dan George IIICopyright:

Available Formats

CONIPUR HG

Standard Point Elastic Indoor Sports Surfacing System IHF and FIBA Approved

Fields of application Sports halls, school sports

System data

product consumption application In case of concrete moister higher than 4 % (e.g. early age concrete), CONIPOX 75 can be used as a primer. Please refer to the corresponding product data sheet or to our Technical Service. The mat type must be approved by CONICA. As an alternative, also an in-situ installed rubber granule mat can be used. Please refer to our Technical Service. The thickness of the elastic layer is limited to 10 mm (12 mm when CONIPUR 226 is used as a coating). remarks

for asphalt: Primer

no primer necessary

for concrete:

CONIPUR 73

0.20 kg/m

paint roller

Elastic Layer

CONIPUR 111

0.80 kg/m

notched squeegee

Prefabricated rubber granule mat CONIPUR 220 Intermediate layer Top layer CONIPUR 224

(CONIPUR 226, CONIPUR 227)

Sealing Pore Coating Coating lacquer Sealer

0.80 kg/m 0.5 kg/m

(0.5 kg/m, 0.55 kg/m)

straight edged trowel notched squeegee notched squeegee paint roller paint roller (paintbrush)

This step is necessary in order to avoid open pores in the elastic layer which could give rise to bubbles in the final coating layer.

CONIPUR 224

(CONIPUR 226, CONIPUR 227)

2.3 kg/m

(2.3 kg/m, 2.5 kg/m)

CONIPUR 67

(CONIPUR 67 N)

0.15 kg/m

Line Paint

CONIPUR 45

15 g/m

Total thickness of the system x + 2 mm x = thickness of elastic layer x 10 mm (for CONIPUR 224 and CONIPUR 227) x 12 mm (for CONIPUR 226)

CONIPUR HG, December 2006, page 1

Selected technical properties

Thickness in mm (elastic layer + coating) 4+2 6+2 7+2 7+3 9+2 10+3 12+3 (only CONIPUR 226) 4+2 6+2 7+2 7+3 9+2 10+3 12+3 (only CONIPUR 226) all thicknesses 4+2 6+2 7+2 7+3 9+2 10+3 12+3 (only CONIPUR 226) 4+2 6+2 7+2 7+3 9+2 10+3 12+3 (only CONIPUR 226) all thicknesses result 14 % 20 % 21 % 28.3 % 32 % 34.8 % 41 % 0.99 mm 1.01 mm 1.10 mm 0.99 mm 1.55 mm 1.17 mm 1.80 mm 1000 11 Nm 11 Nm 11 Nm 13 Nm 10 Nm 12 Nm 15 Nm 0.21 mm 0.30 mm 0.32 mm 0.17 mm 0.37 mm 0.24 mm 0.11 mm 98-99 % requirement remarks Data taken from DIN test reports. Coating for test samples was CONIPUR 224 and CONIPUR 226 (for 12 mm elastic layer). Elastic layer as specified in test report. For use of other elastic layers please consult our Technical Service. Data taken from DIN test reports. Coating for test samples was CONIPUR 224 and CONIPUR 226 (for 12 mm elastic layer). Elastic layer as specified in test report. For use of other elastic layers please consult our Technical Service. Data taken from DIN test reports. Data taken from DIN test reports. Coating for test samples was CONIPUR 224 and CONIPUR 226 (for 12 mm elastic layer). Elastic layer as specified in test report. For use of other elastic layers please consult our Technical Service. Data taken from DIN test reports. Coating for test samples was CONIPUR 224 and CONIPUR 226 (for 12 mm elastic layer). Elastic layer as specified in test report. For use of other elastic layers please consult our Technical Service. Data taken from DIN test reports.

Shock absorption

51 % (Category 1) 45 % (Category 2)

Standard deformation

3.5 mm (Category 1) 3.0 mm (Category 2)

Rolling load DIN V 18032-2

1000

Impact resistance at 10 C

8 Nm

Residual impression

0.5 mm

Ball rebound

90 %

Sliding properties

all thicknesses

0.40-0.51

0.40-0.60

Data taken from DIN test reports.

All technical figures given above are taken from test reports and refer to the main products. Depending on the substrate and application conditions or in case of using alternative products, results may vary.

CONIPUR HG, December 2006, page 2

Preparation Substrates to be coated have to be firm, dry and load bearing, free of loose and brittle particles and substances which impair adhesion such as oil, grease, rubber skid marks, paint or other contaminants. A concrete subbase must contain a moisture barrier (damp proof membrane D.P.M.). The moisture level must not exceed 4 % (check with CM equipment), which corresponds to maximum 75 % relative humidity according to ASTM F 2170. If using the calcium chloride test, the maximum allowable vapour emissions is 4.0 lbs. as per ASTM F 1869. The temperature of the substrate must be at least 3 C above the current dew point temperature.

In order to ensure a 100 % seal of the elastic layer apply approx. 0.5 kg/m CONIPUR 224 onto the sealed surface, using a notched trowel or straight edge trowel or squeegee. After overnight cure the remaining CONIPUR 224 is applied using a notched trowel or squeegee. Seal the surface with CONIPUR 67 by using lambskin or mohair rollers, rolling out well to eliminate roller marks. Alternatively, CONIPUR 67 can be sprayed onto the surface using a low pressure airless spraying equipment. The coverage rate in this case will be approx. 0.20-0.25 kg/m. Remarks If the thickness of the elastic layer exceeds 10 mm or the sports hall is for multipurpose use, an additional reinforcing fabric has to be used. Please refer to CONIPUR HG extreme. As an elastic layer, both prefabricated elastic mats and in-situ applied rubber mats can be used. For a 10 mm in-situ applied base layer, mix 1.40 kg/m CONIPUR 322 (CONIPUR 326) with 6.5 kg/m of recycled granules (1-3mm) using a specially designed mixer and apply the homogenous mix with a specially designed paver onto the primed surface. Suitable machinery for installing the in situ base layer is e.g. Plano Matic and Mixmatic from SMG, Vhringen/Germany. For further information, please refer to the technical data sheets of the products or contact our Technical Service. For application conditions, General Application Guidelines for Sports Systems Indoor and Outdoor published by CONICA Technik applies.

Application Apply primer CONIPUR 73 on the pre-treated concrete substrate (in case of asphalt no bonding primer is needed) using a low pressure airless spraying equipment or a paint roller, overlapping and reoverlapping to thin out and obtain the correct coverage rate. Apply adhesive CONIPUR 111 with a notched trowel onto the primed surface and embed the pre-cut rubber mat in the fresh CONIPUR 111. The lengths of the mat are held in place by using weights, paying particular attention to the joints. It is very important that there are no open joints. Roll over the surface after 30-60 minutes (depending on the temperature) using a 50 kg roller. The weights are left on the mat until the adhesive has fully cured (normally overnight). Seal the pores of the elastic layer with CONIPUR 220 using a straight edged trowel or squeegee.

BASF Construction Chemicals Europe AG Division CONICA Technik Industriestrasse 26 CH-8207 Schaffhausen Switzerland

Tel.: + 41 58 958 2525 Fax: + 41 58 958 3623 infoconica@basf.com www.conica.basf.com

Whilst any information contained herein is true, accurate and represents our best knowledge and experience, no warranty is given or implied with any recommendations made by us, our representatives or distributors, as the conditions of use and the competence of any labour involved in the application are beyond our control.

As all CONICA products are updated on a regular basis, it is users responsibility to obtain the most recent issue. Registered users can obtain the actual data sheets from our webpage. Hard copies are available upon request.

CONIPUR HG, December 2006, page 3

You might also like

- Conipur SW PDFDocument3 pagesConipur SW PDFJosé MiguelNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Conrema Repair Material Steelcord BeltsDocument24 pagesConrema Repair Material Steelcord BeltsPetros IosifidisNo ratings yet

- CEILCOTE 163 CorocreteDocument2 pagesCEILCOTE 163 CorocreteGabor VictorNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Nitoseal 777 PDFDocument4 pagesNitoseal 777 PDFmilanbrasinaNo ratings yet

- Floor Levelling CompoundDocument2 pagesFloor Levelling CompoundandrijapopovicNo ratings yet

- Planitop HDM MaxiDocument4 pagesPlanitop HDM MaxidraganugNo ratings yet

- MBond 200 Strain Gage Installation GuideDocument4 pagesMBond 200 Strain Gage Installation GuideChetan B ArkasaliNo ratings yet

- Conbextra GPIDocument4 pagesConbextra GPIVenkata Raju KalidindiNo ratings yet

- Solvent-free single component binder for elastic layersDocument3 pagesSolvent-free single component binder for elastic layerskilkamishNo ratings yet

- Sikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal CoatDocument6 pagesSikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal Coatthe pilotNo ratings yet

- Technical Mortar for Injection and GroutingDocument3 pagesTechnical Mortar for Injection and GroutingMuhsin KhanNo ratings yet

- Cmci Cmci: Euco-Guard 100Document2 pagesCmci Cmci: Euco-Guard 100pravi3434No ratings yet

- Flexitec 2020 Application Manual 01 2021Document32 pagesFlexitec 2020 Application Manual 01 2021KeelNo ratings yet

- SES Amercoat Dimetcote 9Document4 pagesSES Amercoat Dimetcote 9kamalkashNo ratings yet

- Conbextra GP2 (T)Document4 pagesConbextra GP2 (T)Vikas Singh ChandelNo ratings yet

- AI HEMPADUR 35760 English Fibre MatDocument4 pagesAI HEMPADUR 35760 English Fibre MatAnonymous rYZyQQot55No ratings yet

- Nitoproof 600Document4 pagesNitoproof 600Balasubramanian AnanthNo ratings yet

- FINAT Technical Handbook 6th Edition, 2001Document84 pagesFINAT Technical Handbook 6th Edition, 2001andresjypNo ratings yet

- Sikafloor - 262 AS: 2-Part Epoxy Electrostatically Conductive Self-Smoothing SystemDocument6 pagesSikafloor - 262 AS: 2-Part Epoxy Electrostatically Conductive Self-Smoothing Systemthe pilotNo ratings yet

- Conbextra HFDocument4 pagesConbextra HFUbaid Mazhar Abidi SyedNo ratings yet

- Nitoproof 100 PDFDocument2 pagesNitoproof 100 PDFmilanbrasinaNo ratings yet

- Methodology For TERRACE Waterproofing NITOPROOF 600 PDFDocument7 pagesMethodology For TERRACE Waterproofing NITOPROOF 600 PDF폴로 쥰 차100% (1)

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- Sealbond Optimastic PU1K 60 Polyurethane WaterproofingDocument4 pagesSealbond Optimastic PU1K 60 Polyurethane WaterproofingMel GarciaNo ratings yet

- Sikafloor - 161: 2-Part Epoxy Primer, Levelling Mortar, Intermediate Layer and Mortar ScreedDocument6 pagesSikafloor - 161: 2-Part Epoxy Primer, Levelling Mortar, Intermediate Layer and Mortar ScreedhvduylinhNo ratings yet

- Colpor 200PF : Cold Applied, High Performance, Pitch Free, Polyurethane Pavement Joint SealantDocument4 pagesColpor 200PF : Cold Applied, High Performance, Pitch Free, Polyurethane Pavement Joint SealantatharkNo ratings yet

- Conbextra GP2 (T)Document4 pagesConbextra GP2 (T)Gautam PaulNo ratings yet

- Nitoseal 290Document4 pagesNitoseal 290Venkata RaoNo ratings yet

- CEFILAIR English A4 Low ResDocument16 pagesCEFILAIR English A4 Low ResAnonymous IpqcBBNo ratings yet

- C510WNDocument2 pagesC510WNEdgarDavidDiazCamposNo ratings yet

- SonoShield HLM 5000 - Bitumen MembraneDocument6 pagesSonoShield HLM 5000 - Bitumen MembraneOgbedande Awo OrunmilaNo ratings yet

- 7GS 5000Document5 pages7GS 5000subhaschandraNo ratings yet

- Expoband H45Document3 pagesExpoband H45Balasubramanian AnanthNo ratings yet

- Vulcoferran 2194.20140129.en - TI.sy000152K00Document2 pagesVulcoferran 2194.20140129.en - TI.sy000152K00domingo_carbajalNo ratings yet

- 2929 Bondply Multi-Layer Board Processing GuidelinesDocument4 pages2929 Bondply Multi-Layer Board Processing GuidelinesEduardo Ruiz PalominoNo ratings yet

- Nitoproof 30 - Water Proofing CompoundDocument2 pagesNitoproof 30 - Water Proofing CompoundChethan BhatNo ratings yet

- Nitocote EN901Document4 pagesNitocote EN901kalidindivenkatarajuNo ratings yet

- Nitoproof 600 PDFDocument4 pagesNitoproof 600 PDFmilanbrasinaNo ratings yet

- Amercoat 253Document4 pagesAmercoat 253Sherif AbdelhameedNo ratings yet

- A Solvent-Free Non-Staining Acrylic-Adhesive in Water DispersionDocument4 pagesA Solvent-Free Non-Staining Acrylic-Adhesive in Water DispersionFloorkitNo ratings yet

- Dm-dsi-SPEC09 - Corrosion PR & Odor CNTRLDocument13 pagesDm-dsi-SPEC09 - Corrosion PR & Odor CNTRLhardikNo ratings yet

- Nitoseal 290Document4 pagesNitoseal 290shanon33No ratings yet

- GMS-Nitowrap-CW-GW-structural Strenthening PDFDocument8 pagesGMS-Nitowrap-CW-GW-structural Strenthening PDFjohn paulNo ratings yet

- Technical Services: Installation Instructions For Gerflor Homogeneous Vinyl SheetgoodsDocument7 pagesTechnical Services: Installation Instructions For Gerflor Homogeneous Vinyl SheetgoodsMark GoducoNo ratings yet

- ISO - 11998 - Wet Scub Resistance and CleanabilityDocument6 pagesISO - 11998 - Wet Scub Resistance and Cleanabilityichsan hakim100% (1)

- Flexible Pu SealantDocument2 pagesFlexible Pu SealantGi GoNo ratings yet

- Roof GuardDocument2 pagesRoof Guardpravi3434No ratings yet

- Uzin KE 2428Document2 pagesUzin KE 2428FloorkitNo ratings yet

- Nitoproof 230 PDFDocument2 pagesNitoproof 230 PDFmilanbrasinaNo ratings yet

- GCPAT Procor Composite Waterproofing System Us 1676Document7 pagesGCPAT Procor Composite Waterproofing System Us 1676Saurav Negi EtherealNo ratings yet

- TDS Pattex BondsealfillDocument5 pagesTDS Pattex BondsealfilldknisNo ratings yet

- Substrate Preparation and System Guide 08.08.2019Document10 pagesSubstrate Preparation and System Guide 08.08.2019Volkmar LullNo ratings yet

- Interzone 101Document0 pagesInterzone 101hennawijayaNo ratings yet

- Nitoseal 125Document2 pagesNitoseal 125Hantu TuahNo ratings yet

- Nitoseal 130Document2 pagesNitoseal 130Venkata RaoNo ratings yet

- ContiTech Power Transmission SystemsDocument87 pagesContiTech Power Transmission SystemsRamírez Vilca JulioNo ratings yet

- Woodwork Joints 1917Document53 pagesWoodwork Joints 1917cornel_bursucel7099100% (4)

- Create Your Own Custom Carpet Tile Design in 3 StepsDocument1 pageCreate Your Own Custom Carpet Tile Design in 3 StepsDan George IIINo ratings yet

- Vetromagic Tutorial Ok 1Document2 pagesVetromagic Tutorial Ok 1Dan George IIINo ratings yet

- 3M Professional Floor Sanding Products Catalog: InnovationDocument28 pages3M Professional Floor Sanding Products Catalog: InnovationDan George IIINo ratings yet

- WelcomeFolder BasicDocument4 pagesWelcomeFolder BasicDan George IIINo ratings yet

- Datenblatt Consul 02 GB - KV1Document2 pagesDatenblatt Consul 02 GB - KV1Dan George IIINo ratings yet

- Contract Carpet & Tile ManufacturerDocument11 pagesContract Carpet & Tile ManufacturerDan George IIINo ratings yet

- Guide To Vinyl Floor WeldingDocument4 pagesGuide To Vinyl Floor WeldingDan George IIINo ratings yet

- Hertfordshire County MapDocument1 pageHertfordshire County MapDan George IIINo ratings yet

- Area Required in Relation To Footfall PDFDocument1 pageArea Required in Relation To Footfall PDFDan George IIINo ratings yet

- Area Required in Relation To Footfall PDFDocument1 pageArea Required in Relation To Footfall PDFDan George IIINo ratings yet

- Installation Instructions For APF SeriesDocument5 pagesInstallation Instructions For APF SeriesDan George IIINo ratings yet

- emco entrance matting load specsDocument1 pageemco entrance matting load specsDan George IIINo ratings yet

- Emco DIPLOMAT With Ribbed Carpet Insert - RDocument1 pageEmco DIPLOMAT With Ribbed Carpet Insert - RDan George IIINo ratings yet

- IHF BASF Certificate 2010Document1 pageIHF BASF Certificate 2010Dan George IIINo ratings yet

- Warranty Tivoli24Document1 pageWarranty Tivoli24Dan George IIINo ratings yet

- Photo Gallery APFDocument1 pagePhoto Gallery APFDan George IIINo ratings yet

- 2tec2 FloorsDocument25 pages2tec2 FloorsDan George IIINo ratings yet

- Vertical and Horizontal Movement Admissions Table For APF SeriesDocument1 pageVertical and Horizontal Movement Admissions Table For APF SeriesDan George IIINo ratings yet

- Model Sm/Smc-100 Thru 400 Installation Instructions: Important InformationDocument4 pagesModel Sm/Smc-100 Thru 400 Installation Instructions: Important InformationDan George IIINo ratings yet

- Enia Imagebroschuere EnglischDocument20 pagesEnia Imagebroschuere EnglischDan George IIINo ratings yet

- Heavy Duty Aluminium Floor Flush SystemDocument1 pageHeavy Duty Aluminium Floor Flush SystemDan George IIINo ratings yet

- SMN 100Document1 pageSMN 100Dan George IIINo ratings yet

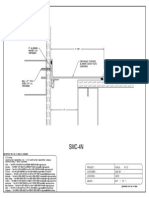

- SMC-4N: Scale: Project: Customer: Location: Job No.: - N.T.S.Document1 pageSMC-4N: Scale: Project: Customer: Location: Job No.: - N.T.S.Dan George IIINo ratings yet

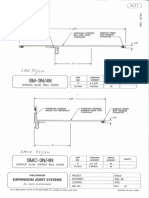

- SMN 100 and SMCN 100Document1 pageSMN 100 and SMCN 100Dan George IIINo ratings yet

- Heavy Duty Aluminium Floor Flush SystemDocument1 pageHeavy Duty Aluminium Floor Flush SystemDan George IIINo ratings yet

- CS CouvraneufDocument28 pagesCS CouvraneufDan George IIINo ratings yet

- CSTB Fire Test Report Feb. 2008 - For Acrovyn B - s2 - d0Document4 pagesCSTB Fire Test Report Feb. 2008 - For Acrovyn B - s2 - d0Dan George IIINo ratings yet

- Construction Specialties Acrovyn Protection File002010Document20 pagesConstruction Specialties Acrovyn Protection File002010Dan George IIINo ratings yet

- NewTrendsInLeadershipandManagement ArikkokDocument32 pagesNewTrendsInLeadershipandManagement Arikkoksocofem288No ratings yet

- Potato Peroxidase LabDocument2 pagesPotato Peroxidase LabKarla GutierrezNo ratings yet

- Powers of Central Govt under Environment Protection ActDocument13 pagesPowers of Central Govt under Environment Protection Actsirajudeen INo ratings yet

- Theory Is An Explanation Given To Explain Certain RealitiesDocument7 pagesTheory Is An Explanation Given To Explain Certain Realitiestaizya cNo ratings yet

- Gujarat Technological University: Emester ViDocument4 pagesGujarat Technological University: Emester ViPradeep SutharNo ratings yet

- Asus X553MA Repair Guide Rev2.0Document7 pagesAsus X553MA Repair Guide Rev2.0UMA AKANDU UCHENo ratings yet

- Psalms Magick of The Old Testament PDFDocument129 pagesPsalms Magick of The Old Testament PDFirrrs100% (1)

- Magnets Catalog 2001Document20 pagesMagnets Catalog 2001geckx100% (2)

- SSRN Id26238Document21 pagesSSRN Id26238Ayame KusuragiNo ratings yet

- Leica CS10 CS15 GSSensors QG v3.0.1 en PDFDocument16 pagesLeica CS10 CS15 GSSensors QG v3.0.1 en PDFMohammad Saiful AzamNo ratings yet

- EDIBLE VACCINES: A COST-EFFECTIVE SOLUTIONDocument21 pagesEDIBLE VACCINES: A COST-EFFECTIVE SOLUTIONPritish SareenNo ratings yet

- Beyond VaR OfficialDocument76 pagesBeyond VaR OfficialmaleckicoaNo ratings yet

- PPC2000 Association of Consultant Architects Standard Form of Project Partnering ContractDocument5 pagesPPC2000 Association of Consultant Architects Standard Form of Project Partnering ContractJoy CeeNo ratings yet

- Ir Pc-1: Pre-Check (PC) Design Criteria For Freestanding Signs and Scoreboards: 2019 CBCDocument15 pagesIr Pc-1: Pre-Check (PC) Design Criteria For Freestanding Signs and Scoreboards: 2019 CBCAbrar AhmadNo ratings yet

- Ultimate Guide To Construction SubmittalsDocument10 pagesUltimate Guide To Construction SubmittalsDavid ConroyNo ratings yet

- PS Neo HSK2LCD ICON LED RF Keypad v1 0 Installation Guide R001 en FR Es PoDocument40 pagesPS Neo HSK2LCD ICON LED RF Keypad v1 0 Installation Guide R001 en FR Es Po7seguridadNo ratings yet

- How To Oven and Sun Dry Meat and ProduceDocument12 pagesHow To Oven and Sun Dry Meat and ProduceLes BennettNo ratings yet

- IntuitionDocument10 pagesIntuitionmailsonNo ratings yet

- CE ProblemDocument5 pagesCE ProblemJho FNo ratings yet

- Kara&Suoglu ProjectreportDocument4 pagesKara&Suoglu ProjectreportRicard Comas xacnóNo ratings yet

- ComputerDocument26 pagesComputer29.Kritika SinghNo ratings yet

- 20comm Um003 - en PDocument270 pages20comm Um003 - en PRogério BotelhoNo ratings yet

- Institutional Competency Assessment Instrument (ICAI)Document12 pagesInstitutional Competency Assessment Instrument (ICAI)Bea EtacNo ratings yet

- OM - Rieter - UNIMix A76Document321 pagesOM - Rieter - UNIMix A76Phineas FerbNo ratings yet

- Quality Management - QuestionDocument4 pagesQuality Management - QuestionLawzy Elsadig SeddigNo ratings yet

- Academic Writing & IdentityDocument218 pagesAcademic Writing & IdentityGustavo RegesNo ratings yet

- Detailed Lesson Plan in MAPEH III I. ObjectivesDocument19 pagesDetailed Lesson Plan in MAPEH III I. ObjectivesJenna FriasNo ratings yet

- 03 Seatwork 1 ProjectManagement SenisRachelDocument2 pages03 Seatwork 1 ProjectManagement SenisRachelRachel SenisNo ratings yet

- The Secret Language of AttractionDocument278 pagesThe Secret Language of Attractionsandrojairdhonre89% (93)

- Seminar 6 Precision AttachmentsDocument30 pagesSeminar 6 Precision AttachmentsAmit Sadhwani67% (3)

- Jamaica: A Guide to the Food & RestaurantsFrom EverandJamaica: A Guide to the Food & RestaurantsRating: 4 out of 5 stars4/5 (1)

- Secrets of the Millionaire Mind: Mastering the Inner Game of WealthFrom EverandSecrets of the Millionaire Mind: Mastering the Inner Game of WealthRating: 4.5 out of 5 stars4.5/5 (197)

- Proof of Heaven: A Neurosurgeon's Journey into the AfterlifeFrom EverandProof of Heaven: A Neurosurgeon's Journey into the AfterlifeRating: 3.5 out of 5 stars3.5/5 (165)

- Coastal Alaska & the Inside Passage Adventure Travel GuideFrom EverandCoastal Alaska & the Inside Passage Adventure Travel GuideNo ratings yet

- The Game: Penetrating the Secret Society of Pickup ArtistsFrom EverandThe Game: Penetrating the Secret Society of Pickup ArtistsRating: 4 out of 5 stars4/5 (131)

- Geneva, Lausanne, Fribourg & Western Switzerland Travel AdventuresFrom EverandGeneva, Lausanne, Fribourg & Western Switzerland Travel AdventuresNo ratings yet

- Hollywood & the Best of Los Angeles Travel GuideFrom EverandHollywood & the Best of Los Angeles Travel GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Aruba, Bonaire & Curacao Adventure GuideFrom EverandAruba, Bonaire & Curacao Adventure GuideRating: 5 out of 5 stars5/5 (2)

- Nassau & the Best of the Bahamas Travel GuideFrom EverandNassau & the Best of the Bahamas Travel GuideRating: 5 out of 5 stars5/5 (1)