Professional Documents

Culture Documents

10 M M Rahman 29072010 8 Clean

Uploaded by

Paul Praveen PeterOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10 M M Rahman 29072010 8 Clean

Uploaded by

Paul Praveen PeterCopyright:

Available Formats

International Journal of Automotive and Mechanical Engineering (IJAME)

ISSN: 1985-9325(Print); ISSN: 2180-1606 (Online); Volume 1, pp. 91-104, January-June 2010

Universiti Malaysia Pahang

91

STUDY OF FLOW IN AIR-INTAKE SYSTEM FOR ASINGLE-CYLINDER

GO-KART ENGINE

S. A. Sulaiman, S. H. M. Murad, I. Ibrahimand Z. A. Abdul Karim

Department of Mechanical Engineering, Universiti Teknologi PETRONAS

31750 Tronoh, Perak, Malaysia

Phone: +605-3687013, Fax: +605-3656461

Email: shaharin@petronas.com.my

ABSTRACT

Intake-air manifolds have a major effect on a vehicles engine performance and

emission of noise and pollutants. Differences in engine outputs and applications require

different designs of intake-air manifolds in order to achieve the best volumetric

efficiency and thus the best engine performance. In the present work, the flow

characteristics of air flowing in various designs of air-intake manifold of a 200-cc four-

stroke Go-Kart engine are studied. The study is done by three dimensional simulations

of the flow of air within six designs of air-intake manifold into the combustion chamber

by using commercial CFD software, Fluent version 6.2. The simulation results are

validated by an experimental study performed using a flow bench. The study reveals

that the variations in the geometry of the air-intake system can result in a difference of

up to 20% in the mass flow rate of air entering the combustion chamber.

Keywords: Air Flow, Go-Kart, Air-Intake

INTRODUCTION

In Go-Kart racing, it is common that the race format is a sprint race, which takes place

on dedicated kart circuits resembling small road courses, with left and right turns. The

lengths of tracks for racing range from 400 to 1600 meters (James, 2004). During

sprinting, the engine is ramped quickly at various speeds due to the twisty course tracks.

It is very seldom that an engine could go at high speed for a long time. The Go-Kart

constantly needs to apply brakes and re-accelerate when taking corners. Thus, it is

important that the engine can deliver a high torque at even low speeds; this can be

achieved with modification of the air intake manifold. In a single cylinder engine, the

maximum output performance achievable is related to the amount of air that is trapped

in the combustion chamber. This is defined by the volumetric efficiency,

v

, which is

the ratio of the mass of air trapped in the cylinder to that contained in the swept volume

of the cylinder at inlet manifold density. If the volumetric efficiency could be increased

significantly even at low speeds, the engine output would be expected to be higher.

It has long been realized that the design of air intake manifolds has a large effect

on the performance of reciprocating engines. The unsteady nature of the induction

means that the effect of the manifold on charging and discharging is dependent on the

engine speed. The manifold must be designed to enable the engine to ingest air

(Pulkrabek, 2004), and thus the inside diameter of the manifold must be able to

accommodate the bulk air flow in order to avoid low volumetric efficiency. On the other

hand, if the manifold flow path is too restrictive, the desired high air velocity and

S. A. Sulaiman et al. / International Journal of Automotive and Mechanical Engineering 1 (2010) 91-104

92

turbulence cannot be assured, and this will consequently affect its capability in carrying

fuel droplets as well as in enhancing evaporation and airfuel mixing (Winterbone and

Pearson, 1999). In order to minimize flow resistance, the manifold should have no sharp

bends and the interior wall surface should be smooth. Furthermore, the impedance of

the manifold is a function of the frequency of the pulses entering it (Fontana et al.,

2003), and thus it is possible to tune engine manifolds to give a particular power output

characteristic as a function of speed.

Study of the effect of the geometry of the intake manifold was previously done

using various designs, without changing the engine specifications, in a wide open

throttle condition (Winterbone and Pearson, 1999). The intake manifold used was of a

modular construction so that the primary pipe length, plenum volume and secondary

pipe length could be varied. It was reported that the plenum volume could have a

profound effect on the control at idling speed, which could be beneficial, although it

reduced the engines performance. The motion of fluid into the combustion chamber is

important to speed up the evaporation of fuel, to enhance air-fuel mixing and to increase

combustion speed and efficiency (Srinivasan, 2001). Due to the high velocities

involved, the air flow within the engine system is turbulent, which causes the

thermodynamic heat transfer rates within the engine to increase by an order of

magnitude. As the engine speed increases, the flow rate increases, and consequently

increases the swirl, squish and turbulence intensity (McLandress et al., 1996). This

increases the real time rate of fuel evaporation, mixing of the fuel vapour and air and

combustion. The high turbulence near the top-dead-center when ignition occurs is very

desirable for combustion, as it breaks up and spreads the flame front many times faster.

The objective of the present work is to study the flow characteristics of air

flowing in various designs of air-intake manifold used for a single-cylinder Go-Kart

engine. The study is conducted by experiments and also by using computational fluid

dynamics (CFD) simulation software, Fluent. The effects of different air intake

geometry or configurations are studied. The experiments, which are conducted by using

a commercial flow bench, are also used to validate the CFD simulation results. The

parameters of interest are the flow rate and the flow coefficient of air entering the

combustion chamber.

EXPERIMENTAL SETUP

The air-intake manifold was meant to serve a single cylinder 4-stroke spark ignition

engine of an undisclosed manufacturer. The engines displacement was 199 cm

3

with a

bore and stroke of 70 mm and 51.8 mm respectively. There were only two valves for the

cylinder; each for the air intake and the exhaust. The intake valve diameter was 32 mm.

A challenge for the manufacturer would be to get the highest air flow rate entering

through the single valve opening. In the present work, only the engines cylinder head

was used.

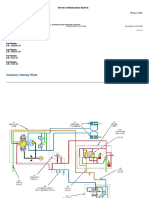

The flow bench equipment, SuperFlow SF-1020, was used to measure the

characteristics of air entering the intake manifold and combustion chamber. Some of the

experimental results using the flow bench would also be used to validate the results of

the CFD simulations. The flow bench consisted of an open circuit ducting system that

had an air pump at the downstream to induce air flow. The pressure within the ducting

system could be varied by changing the speed of the air pump. The flow bench

equipment setting is shown in Figure 1. The engines cylinder head with complete

valves assembly was attached to an acrylic chamber, which resembled the engines

Study of flow in air-intake system for a single-cylinder Go-Kart engine

93

cylinder, at the top of the bench. A dial gauge was mounted at the top of the intake

valve to enable precision variation of the valve lifts. The intake manifold was attached

to the cylinder head to seal the air from leakage. The measurement instrumentations for

the system were linked to a data acquisition system. The specifications of the flow

bench system are shown in Table 1. Detailed descriptions of the system were reported

elsewhere (Ismail et al., 2008).

Figure 1: Setting of the flow bench test

Table 1: Specifications of the flow bench system

Parameters Value

Make and Model SuperFlow, SF-1020

Flow Measurement Accuracy:

0.05%

Flow Repeatability:

0.25%

Flow Range: 12 - 470 l/s

Pressure Accuracy

0.13 cmof water

Pressure Range 0-165 cm of water

Temperature Accuracy

0.3 C

In the experiments, only the intake valve lift, L, was varied, while the exhaust

valve remained close at all time. The intake valve was lifted, from a fully closed

position, at an increment of one millimeter to a maximum lift of 8.2 mm. The

experiments were monitored in term of the ratio of valve lift (L) to valve diameter (D)

or L/D ratio. Such a universal ratio is used elsewhere (Ismail et al., 2008) to enable the

comparison of parameters such as flow efficiencies regardless of the size of the valve.

In each of the experiments, the air flow rate was recorded. In addition, the air

temperature was measured to determine the density of air flowing through the intake

Dial Gauge

Valve Knob

Cylinder

Head

Intake Manifold

Flange Adapter

S. A. Sulaiman et al. / International Journal of Automotive and Mechanical Engineering 1 (2010) 91-104

94

manifold. The pressure difference was set to about 508 mm water column to ensure

negative pressure at the downstream of the flow bench.

(a) with intake manifold; l = 204 mm (b) with intake manifold; l = 102 mm

(c) with intake manifold and surge

tank

(d) with surge tank and intake

manifold

(e) with surge tank only (f) without intake manifold

* Not to scale

Figure 2: Variations of the intake manifold configurations for testing with the flow

bench

Figure 2 shows the variations of intake manifold configurations tested in the

experiments. In Figures 2 (a) and (b), the intake manifolds were straight stainless steel

pipes with lengths of 204 mm and 102 mm, respectively. The internal diameter of the

pipe was 23.4 mm and its thickness was 1.5 mm. The surface roughness was 0.5 m.

The purpose of having two different pipe lengths was to study the effect of intake

manifold length to the air flow. The effect of surge tank within the intake manifold, as

shown in Figures 2(c), (d) and (e), was also investigated. The difference between the

D = 23.4 mm

204 mm

Cylinder

Head

D = 23.4 mm

102 mm

Cylinder

Head

Cylinder

Head

D = 72 mm

102 mm

150 mm

102 mm

D = 72 mm

Cylinder

Head

150 mm

Cylinder

Head

Cylinder

Head

150 mm

D = 72 mm

Study of flow in air-intake system for a single-cylinder Go-Kart engine

95

three configurations was only the position of the surge tank. The surge tank was a

cylindrical stainless steel chamber with an internal diameter of 72 mm and length of 150

mm. The reason for conducting the experiments with a surge tank was because it could

provide a better air flow rate at higher engine speeds, and thus an increased power at

high end RPM during racing. In Figure 2(e), the surge tank was arranged with no pipe.

For comparison purpose, a test was also conducted without the use of intake manifold.

From the experimental measurements, the flow coefficient of air passing through the

intake valve was determined in order to assess its efficiency. The flow coefficient, C

D

is

given by:

t

a

D

m

m

C

= (1)

where

a

m and

t

m are the actual and theoretical mass flow rate of air entering the

combustion chamber, respectively. The actual mass flow rate is determined

experimentally and is given by:

RT

P

Q m

a

=

(2)

where Q is the volume flow rate, P is the local pressure at the downstream of the intake

valve, R is the gas constant of air and T is the local air temperature. The theoretical mass

flow rate is calculated by:

s k s t

v A m =

(3)

where v

s

is the isentropic air density and A

k

is the valve seat area. The isentropic flow

velocity, v

s

, is given by:

(

(

(

|

|

.

|

\

|

1

1

2

1

1

2

P

P

RT v

s

(4)

where P

1

and P

2

are the air pressures at the upstream and downstream of the intake

valve and is the index of isentropic expansion.

SIMULATION SETUP

The intake air manifold system and the combustion chamber were modelled in three

dimensions using graphic software, CATIA V5. The model design would resemble the

path of air entering the combustion chamber. Shown in Figure 3 is the model of the

combustion chamber with the air intake path and valve. The model was meshed with

tetrahedral type by using meshing software, Gambit. The meshes were considerably

finer (1,437,285 mesh volumes) in the combustion chamber where the results of

analysis were critical. The flow simulation was performed by using the CFD software,

Fluent. The simulations were run based on the NavierStokes equations under the Kc

S. A. Sulaiman et al. / International Journal of Automotive and Mechanical Engineering 1 (2010) 91-104

96

two-equation turbulent model at steady state. The air density was assumed to be

constant in the simulation. The Reynolds number was calculated to be 23,765.

Figure 3: The engines combustion chamber and air intake valve

The overall view of the modelled system is shown in Figure 4, in which l is the

intake manifold length. Shown in Table 2 are the variations and boundary conditions in

each of the CFD simulations conducted in the present work. The simulation setting

using an intake manifold with a length of 204 mm is similar to that shown in Figure

2(a), and thus the CFD and experimental results can be compared. Similarly, the setting

without intake manifold is similar to that shown in Figure 2(f). The third simulation was

conducted using an intake manifold of a different design that resembled a surge tank but

with a smooth transition of edge between the tank and the pipe. A bell mouth inlet was

incorporated with the intake manifold to smooth the in-flowing air. The design and

dimensions of the intake manifold for the third simulation are shown in Figure 5.

Figure 4: View of the simulated system with an intake manifold length, l, of 204 mm

l

Combustion Chamber

Intake Valve

Intake Manifold

Air Flow Direction

Study of flow in air-intake system for a single-cylinder Go-Kart engine

97

Table 2: Intake manifold configurations and boundary conditions

Simulation Intake Manifold configuration

1 With intake manifold; l = 204 mm

2 Without intake manifold

3 Surge tank and bell mouth (Figure 5)

Boundary Conditions

Parameters Conditions

Inlet Pressure 101.32 kPa

Outlet Pressure 96.08 kPa

Intake Manifold Wall

Roughness

0.5 m

No Slip Condition

Stationary Wall

Cylinder Head Wall

Roughness

25 m

No Slip Condition

Stationary Wall

Figure 5: Design of the intake manifold with surge tank and bell-mouth inlet

RESULTS AND DISCUSSION

Experimental Results

Shown in Figure 6 is the variation of air flow rate into the combustion chamber with the

valve lift, as measured in the experiment. In general, it is seen that the trend of

increment of flow rate with valve lift is similar for all test variations. Nevertheless, the

rate of change of the flow rate can be divided into three regimes: A, B and C.

S. A. Sulaiman et al. / International Journal of Automotive and Mechanical Engineering 1 (2010) 91-104

98

0

5

10

15

20

25

30

35

40

45

0 1 2 3 4 5 6 7 8 9

Valve lift (mm)

F

l

o

w

r

a

t

e

(

l

/

s

)

w/o Intake Manifold

204-mm Pipe

102-mm Pipe

Pipe +Surge Tank

Surge Tank +Pipe

Surge Tank only

Regime-A

Regime-B

Regime-C

Figure 6: Variation of flow rate of air with the valve lift positions for various designs

In Regime-A, during which the valve lifts are between 0 and 3 mm, the flow

rates are seen to be nearly the same for all tests. The largest difference in flow rate

within Regime-A is only 1.4 l/s. The small variation within this regime is probably

caused by the limited amount of air flowing into the combustion chamber as a result of

the small opening of the valve. In other word, the design or configuration of the intake

air manifold is shown to have no significant effect on the air flow rate within this

regime. The average mass flow rate at 3 mm valve lift is 19.5 l/s, after which the results

are seen to be diverging from each other. The divergence is sustained until a valve lift of

6 mm, and this is identified as Regime-B. When no intake manifold is used it is seen

that the mass flow rate is the highest, probably due to reduced flow restriction.

Interestingly, the slope for the experiment without intake manifold is seen to be higher

in Regime-B than that in Regime-A. This is possibly due to a further reduction of

friction loss when the valve lift is higher than 3 mm. Conversely, for other tests in

Regime-B, the slopes are seen to be decreasing, probably due to an increase in friction

losses within the intake air manifold. With the incorporation of a surge tank, the friction

loss is even higher due to the sudden change in diameter, and this causes lower air flow

rates. Due to the variation in flow rates, it is suggested that the condition in Regime-B is

the most crucial in deciding the design of the intake manifold.

In Regime-C, it is seen that the slopes of the graphs reduce more but are all

maintained at nearly the same gradient. Further variation of the intake manifold does

not cause any significant change in the air flow rate. It must be noted that although the

highest amount of air flow rate into the combustion chamber is experienced when

operated without an intake manifold, such a configuration is not possible for the engine

due to the need to pre-mix the fuel and air. During the pre-mixing, the fuel is atomized

to enhance the power of the engine and to lower the emission rate.

Study of flow in air-intake system for a single-cylinder Go-Kart engine

99

CFD Simulation Results

Validations of the CFD simulation results were performed for two settings, which were

the engine without intake manifold and with a 204-mm intake manifold. The air intake

for these comparisons was set up to a maximum valve lift of 8.2 mm, or wide open

throttle. Shown in Figure 7 (a) is the variation of flow coefficient with the ratio of valve

lift/diameter (L/D) for the experimental results (from Figure 6) and the CFD results

without the intake manifold. It is seen that the trends of results are similar for both the

experiment and CFD simulation. The difference between the results is seen to be

reasonable. The graph shows a consistent increase in the flow coefficient for the CFD

simulation. However, in the experimental results the rate of increase in the flow

coefficient is seen to reduce slightly at L/D ratios of 0.2 or higher.

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.00 0.10 0.20 0.30

L/D

F

l

o

w

C

o

e

f

f

i

c

i

e

n

t

Experi ment

CFD

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.00 0.10 0.20 0.30

L/D

F

l

o

w

C

o

e

f

f

i

c

i

e

n

t

Experi ment

CFD

(a) without intake manifold (b) with intake manifold

Figure 7: Variation of flow coefficients with L/D

Shown in Figure 7(b) is the variation of the flow coefficient with the ratio L/D

for the experimental and CFD results, using a 204-mm length pipe intake manifold. The

results in Figure 7(b) are seen to have similar trends to those in Figure 7(a). Likewise,

the differences between the experimental and CFD simulation results are reasonable.

Thus it is suggested that the CFD software and setting are accurate and thus the

simulation results can be used with confidence in decisions related to design of the

intake manifold. The consistently higher values of flow coefficient for the CFD

simulations than those for the experiments, as shown in Figure 7, are probably due to

the simplification of the geometry of the intake port and valve, which results in the

model being not exactly the same as the actual system. Furthermore, there could have

been various sources of friction losses within the flow bench system that could not be

accounted for in the CFD simulation. Sources of friction losses using similar flow bench

can be found in the reference (Ismail et al., 2008). Although the flow coefficient in the

combustion chamber is important due to its relations to volumetric efficiency, other

important aspects should not be neglected. Within the study, the effects of swirl and

S. A. Sulaiman et al. / International Journal of Automotive and Mechanical Engineering 1 (2010) 91-104

100

tumble are evidenced in the flows. A comparison was made to qualitatively investigate

the effect of different lengths of intake manifold on the resulting swirl and tumble.

Shown in Figures 8 and 9 are velocity vector plots of the air flow within the combustion

chamber for visualization of tumble and swirl , respectively. The simulations were

carried out for straight pipe intake manifolds of different lengths. Comparison of

tumbles in Figures 8 (a) and (b) shows that there are more eddies in the combustion

chamber when a longer intake manifold is used. In Figure 8 (a), it is also seen that there

is a stagnant-like zone (bottom right of image), which is less desirable.

(a) Tumble: l = 200 mm (b) Tumble: l = 230 mm

Figure 8: Typical velocity vector plots for visualization of tumble in the combustion

chamber using different lengths of intake manifold

The swirl motions within the combustion chamber are shown in Figures 9 (a)

and (b). With the intake manifold length of 200 mm, the swirl motion is seen to be less

significant. However, with a longer intake manifold (l = 230 mm), the swirl effect is

obvious with the presence of a few large eddies, and hence would lead to enhanced fuel-

air mixing.

(a) Swirl: l = 200 mm (b) Swirl: l = 230 mm

Figure 9: Typical velocity vector plots for visualization of swirl in the combustion

chamber using different lengths of intake manifold

Study of flow in air-intake system for a single-cylinder Go-Kart engine

101

In general, it is seen from the results in Figures 8 and 9 that a longer intake

manifold can increase the effects of tumble and swirl, which are necessary for fuel-air

mixing. Nevertheless, it is also shown in the experiment that increasing the intake

manifold length will reduce the flow coefficient. Hence, a trade-off between the effects

of swirl/tumble and flow coefficient must be considered in the selection of air-intake

manifold design.

Investigation of the Boundary Layer Within the Intake Manifold

The presence of contact surface within the intake manifold is related to friction loss; this

also explains the high flow rate of air for the experiment without intake manifold. The

fluid particles in the layer in contact with the surface of the pipe come to a complete

stop due to the no-slip condition. This layer also causes the fluid particles in the

adjacent layers to slow down gradually as a result of friction. To make up for this

velocity reduction, the velocity of the fluid at the mid section of the pipe has to increase

to keep the mass flow rate through the pipe constant. The region of flow in which the

effects of the viscous shearing forces caused by the fluid viscosity are felt is the velocity

boundary layer. In the boundary layer, the viscous effects and velocity changes are

significant. For the fluid flow in the entrance region of a pipe, the wall shear stress is

usually the highest at the pipe inlet where the thickness of the boundary layer is

smallest. Therefore the pressure drop is expected to be higher at the entrance region of

a pipe.

The hydrodynamic entry length, which is the region from the pipe inlet to the

point at which the boundary layer merges at the centerline for the turbulent flow, can be

approximated as (Cravalho et al., 2005):

25 . 0

.

Re 359 . 1

D turb h

D L = (5)

where D is the internal diameter of the pipe and Re

D

is the Reynolds number. The

calculated entry length is found to be 0.533 m and thus a fully developed air flow

cannot be achieved because the intake pipe has only a maximum total length of 0.3 m.

The air flow will not be able to develop fully due to insufficient length of pipe. This is

also illustrated in Figure 10 by the velocity profiles as determined from the CFD results.

It is seen in Figure 10 that the boundary layer of the air flow within is not fully

developed. This is due to insufficient length for the velocity profile to become fully

developed. The boundary layer may be differently developed for different air intake

manifold geometry. In addition, the surface roughness of the intake manifold may

determine the pattern of the boundary layer (Merkle et al., 1977).

S. A. Sulaiman et al. / International Journal of Automotive and Mechanical Engineering 1 (2010) 91-104

102

Figure 10: Schematic of the computed velocity profiles in the intake manifold of 204-

mm length pipe

Simulation of the New Design of Intake Manifold

Figure 11 shows the variation of flow coefficient obtained from CFD simulation for the

new design of intake manifold as depicted in Figure 5. Also shown in the figure are the

results for the designs without intake manifold and with the 204-mm pipe for

comparison. The simulation conditions for each of the setting were the same.

Comparison of the results in Figure 11 shows a slight improvement in the flow

coefficient as compared to simulation with a 204-mm intake manifold particularly at

L/Dratios of greater than 0.10. Nevertheless, the flow coefficient for the system without

intake manifold is seen to be the highest, as earlier elaborated for Figure 6. Thus, it is

proposed that the new design has the potential of increasing the flow coefficient and

volumetric efficiency, particularly if the carbureted system were to be replaced by a fuel

injection system within the intake manifold.

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35

L/D

F

l

o

w

C

o

e

f

f

i

c

i

e

n

t

w/o I M

I M 204-mm pi pe

New I M Desi gn

Figure 11: Variation of simulated flow coefficients with L/Dfor various intake manifold

designs

Study of flow in air-intake system for a single-cylinder Go-Kart engine

103

CONCLUSIONS

The present work shows that the flow of air through the intake valve, as a result

of various intake manifold configurations, can be divided in three regimes. At small

valve lifts (0 to 3 mm), the flow rates are indifferent to the intake manifold. Within the

second regime, when the valve lifts are between 3 and 6 mm, the flow rates of air within

the intake valve differ individually depending on the configuration or design of the

intake manifold. It is suggested that the behaviour of flow in this regime be used as one

of the main considerations in choosing a manifold design. Although it is seen that the

highest amount of air flow rate into the chamber is experienced when operated without

the intake manifold, it is not possible for the engine to have such a configuration due to

the need to pre-mix the fuel and air and to atomize the liquid fuel; unless a direct

injection system is adopted. Despite the good effects of swirl and tumble demonstrated

by the use of long intake air manifold in the CFD simulation, it is seen from the

experiment that long manifolds would result in a drop in the flow coefficient. Thus a

trade off between the effects of swirl and tumble and good flow coefficient must be

studied in choosing the best intake manifold configuration.

Comparisons between the experimental and simulation results with two intake

manifold configurations show reasonably good agreement, thus suggesting the

reliability of the simulation in demonstrating the effects of valve lifts and intake

manifold configurations. From the simulation work it is seen that the flow in the intake

manifold can never become fully developed due to the short pipe length, and this may

probably affect the flow coefficient. In the simulation using a new design of intake

manifold, which had a surge tank with tapered edges and bell mouth inlet, the flow

coefficient is shown to be improved by up to 6% and is found to be better than the

existing carbureted system (actual data belongs to the undisclosed manufacturer and is

therefore confidential). This implies that the new design is capable of increasing the

volumetric efficiency, and should be considered if the present carbureted system were to

be replaced by a fuel injection system.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the support of Universiti Teknologi

PETRONAS in the present work.

REFERENCES

Cravalho, E.G., Smith, J.L., Brisson, J.G. and McKinley, G.H. (2005) An Integrated

Approach to Thermodynamics, Fluid Mechanics and Heat Transfer.

Cambridge, MA: Oxford University Press.

Fontana, G., Galloni, E., Jannelli, E. and Palmaccio, R. (2003) Influence of the

Intake System Design on a Small Spark-Ignition Engine Performance: A

Theoretical Analysis. SAE Paper No. 2003-1-3134.

Ismail, A.R., Bakar, R.A. and Semin (2008) An Investigation of Valve Lift Effect on

Air Flow and CD of Four Stroke Engines Based on Experiment. American

Journal of Applied Sciences, 5: 963971.

James, O. D. 2004. Gokartracer. August 2008, www.gokartracer.com.

S. A. Sulaiman et al. / International Journal of Automotive and Mechanical Engineering 1 (2010) 91-104

104

McLandress, A., Emerson, R., McDowell, P. and Rutland, C.J. (1996) Intake and In-

Cylinder Flow Modeling: Characterization of Mixing and Comparison With

Flow Bench Results. SAE Transactions, 105: 868881.

Merkle, C.L., Tzou, K.T.S. and Kubota, T. (1977) An Analytical Study of The Effect

of Surface Roughness on Boundary-Layer Stability. Technical Report, Defense

Technical Information Center.

Pulkrabek, W.W. (2004) Engineering Fundamentals of the Internal Combustion

Engine. New Jersey: Prentice Hall.

Srinivasan, S. (2001) Automotive Engines. New Delhi: Tata McGraw-Hill.

Winterbone, D.E. and Pearson, R.J. (1999) Design Techniques for Engine Manifolds:

Wave Action Methods for IC Engines. USA: Society of Automotive Engineers.

You might also like

- Unmatched Boldness. Unrivaled Dominance.: Presenting The Imposing New Innova CrystaDocument9 pagesUnmatched Boldness. Unrivaled Dominance.: Presenting The Imposing New Innova CrystaPaul Praveen PeterNo ratings yet

- Development of Additive ManufacturingDocument10 pagesDevelopment of Additive ManufacturingrhusheinNo ratings yet

- Webinar On Digital Twin For Smart Product Lifecyle PDFDocument1 pageWebinar On Digital Twin For Smart Product Lifecyle PDFPaul Praveen PeterNo ratings yet

- MECH 502: Advanced/Additive Manufacturing Engineering: Course DescriptionDocument4 pagesMECH 502: Advanced/Additive Manufacturing Engineering: Course Descriptionparveenrathee123No ratings yet

- 16Mncr5: Steel GradeDocument3 pages16Mncr5: Steel GradePaul Praveen PeterNo ratings yet

- Material Specification Sheet Saarstahl - 16Mncr5 - 16Mncrs5Document1 pageMaterial Specification Sheet Saarstahl - 16Mncr5 - 16Mncrs5manjuNo ratings yet

- May 2020-June 2021 Calendar - IndiaDocument1 pageMay 2020-June 2021 Calendar - IndiaPaul Praveen PeterNo ratings yet

- NEXA XL6 Brochure Mobile PDFDocument6 pagesNEXA XL6 Brochure Mobile PDFemmodoju vikramNo ratings yet

- Return TicketDocument1 pageReturn TicketPaul Praveen PeterNo ratings yet

- Es116 Cunningham 2012 o PDFDocument21 pagesEs116 Cunningham 2012 o PDFPaul Praveen PeterNo ratings yet

- BrochureDocument7 pagesBrochurePaul Praveen PeterNo ratings yet

- Me Qualifying Exam GuidelinesDocument9 pagesMe Qualifying Exam GuidelinesPaul Praveen PeterNo ratings yet

- Accomodation at Catalyst - Paul Praveen PeterDocument1 pageAccomodation at Catalyst - Paul Praveen PeterPaul Praveen PeterNo ratings yet

- NiCd and NiMH Battery Pack Design PDFDocument10 pagesNiCd and NiMH Battery Pack Design PDFPaul Praveen PeterNo ratings yet

- T5 List of Top Ten Tier 1 Global SuppliersDocument2 pagesT5 List of Top Ten Tier 1 Global SuppliersrudolfpeterssonNo ratings yet

- NTN TR77 en p051 055 PDFDocument5 pagesNTN TR77 en p051 055 PDFPaul Praveen PeterNo ratings yet

- TasksDocument21 pagesTasksPaul Praveen PeterNo ratings yet

- Master of Body Language PDFDocument10 pagesMaster of Body Language PDFreversoNo ratings yet

- 12 GoalsDocument29 pages12 GoalsPaul Praveen PeterNo ratings yet

- Custm Battery PacksDocument4 pagesCustm Battery PacksPaul Praveen PeterNo ratings yet

- Financial Literacy EbookDocument34 pagesFinancial Literacy Ebookr0ck888100% (1)

- 2dpipe Ge31111313131omDocument13 pages2dpipe Ge31111313131omnilesh0001No ratings yet

- Success Magazine Top 25 BooksDocument2 pagesSuccess Magazine Top 25 BooksPaul Praveen PeterNo ratings yet

- Mathematical Overview CFDDocument34 pagesMathematical Overview CFDkoszioNo ratings yet

- Dimensional Tolerance ChartDocument1 pageDimensional Tolerance Chartpushkar_k123No ratings yet

- Checklist For Buying A PropertyDocument7 pagesChecklist For Buying A PropertyPaul Praveen PeterNo ratings yet

- Fit and TolerancesDocument15 pagesFit and TolerancesRajasekaran Vt100% (1)

- Personal Expense Tracking Date Payee Category Memo Expense Revenue BalanceDocument1 pagePersonal Expense Tracking Date Payee Category Memo Expense Revenue BalancePaul Praveen PeterNo ratings yet

- 101in1001 New Year ResolutionsDocument1 page101in1001 New Year ResolutionsPaul Praveen PeterNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Rosemount 1495 Orifice PlateDocument6 pagesRosemount 1495 Orifice PlateRubénNo ratings yet

- SV-110 (110) CorrectedDocument16 pagesSV-110 (110) CorrectedMohamed AdelNo ratings yet

- LUDV Control Block of Mono and Sandwich Plate Design Type M7-22Document16 pagesLUDV Control Block of Mono and Sandwich Plate Design Type M7-22W Morales100% (2)

- Review of Fluid Review of Fluid MechanicsDocument40 pagesReview of Fluid Review of Fluid MechanicsNebiyou KorraNo ratings yet

- Internal Flow Through Pipes and Ducts PDFDocument30 pagesInternal Flow Through Pipes and Ducts PDFhirenkumar patelNo ratings yet

- 04 Sundyne Presentation Fscontrol SystemDocument27 pages04 Sundyne Presentation Fscontrol SystemjoseellargoNo ratings yet

- C P P Total SeriesDocument18 pagesC P P Total Serieskeyur1109No ratings yet

- Marine Auxiliary Machinery PDFDocument7 pagesMarine Auxiliary Machinery PDFReginNo ratings yet

- New Microsoft Office Word DocumentDocument9 pagesNew Microsoft Office Word DocumentjaimonjoyNo ratings yet

- Pump Performance Curve - XPS230-SS-VTSDocument1 pagePump Performance Curve - XPS230-SS-VTSjosephNo ratings yet

- Ansi Iiar 1-2012Document16 pagesAnsi Iiar 1-2012RozitaNo ratings yet

- Conventional-Spring Operated TypesDocument38 pagesConventional-Spring Operated Typesali murtadhoNo ratings yet

- Hydrotest Procedure For PipingDocument17 pagesHydrotest Procedure For PipingMohammad RizwanNo ratings yet

- Plumbing Pipe and Fitting SymbolsDocument8 pagesPlumbing Pipe and Fitting Symbolsburhansucipto0% (1)

- DR-A1N1: Piping Material SpecificationDocument5 pagesDR-A1N1: Piping Material Specificationshravan.office11No ratings yet

- Team Hot Tap BrochureDocument16 pagesTeam Hot Tap Brochurecloud23100% (2)

- Javadi, Sadegh - Investigation of Open-Channel Design of Non-Newtonian Thickened Tailings FlowDocument9 pagesJavadi, Sadegh - Investigation of Open-Channel Design of Non-Newtonian Thickened Tailings FlowsapoNo ratings yet

- 20 - RT-flex - Mechanical Features PDFDocument75 pages20 - RT-flex - Mechanical Features PDFИгорь БакановNo ratings yet

- V SeguridadDocument8 pagesV SeguridadARJONA_JGNo ratings yet

- Steering System PDFDocument7 pagesSteering System PDFallan lariosaNo ratings yet

- Vodovodne ArmantureDocument30 pagesVodovodne ArmantureJastreb SxeNo ratings yet

- Parker Sizing of ValvesDocument8 pagesParker Sizing of Valveskrishna106738No ratings yet

- Pump Sizing Calculation SheetDocument20 pagesPump Sizing Calculation Sheetvazzoleralex6884100% (1)

- Flow Measurement Design CriteriaDocument21 pagesFlow Measurement Design Criteriakathiresan nadarNo ratings yet

- FM&HM QuestionsDocument3 pagesFM&HM Questionsవిష్ణువర్ధన్రెడ్డిNo ratings yet

- SBH 00 02c Aa DW TM 0004 Rev.01 Water SupplyDocument12 pagesSBH 00 02c Aa DW TM 0004 Rev.01 Water SupplyAnonymous NR3qZ30No ratings yet

- ARI-Pressure Reducing Station, Self-Acting or With Electro-Pneumatic ControlDocument6 pagesARI-Pressure Reducing Station, Self-Acting or With Electro-Pneumatic ControlErdincNo ratings yet

- 4 - Fan Systems and AuditDocument72 pages4 - Fan Systems and AuditTamer Fathy100% (5)

- Air University Fire FightingDocument2 pagesAir University Fire FightingCE capital BuildersNo ratings yet