Professional Documents

Culture Documents

Valve Seat Material Guide

Uploaded by

Anuj Shahi0 ratings0% found this document useful (0 votes)

74 views0 pagesvalve seat

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentvalve seat

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

74 views0 pagesValve Seat Material Guide

Uploaded by

Anuj Shahivalve seat

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 0

MODENTIC

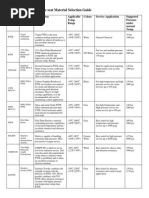

Valve Seat Material Selection Guide

Valve Seat Material Selection Guide :

SEAT

CODE

MATERIAL DESCRIPTI

APPLICABLE

TEMP. RANGE

SUGGESTED

PRESSURE

UNDERNORMAL

TEMP.

ON COLOR

SERVICE

APPLICATION

PTFE

Virgin

Polytetrafluoro-

ethylene

-45 C~160 C

(-49 F~320 F)

70 bar

1000 psi

140 bar

2000 psi

140 bar

2000 psi

140 bar

2000 psi

140 bar

2000 psi

400 bar

5000 psi

425 bar

6000 psi

350 bar

5000 psi

150 bar

2130 psi

-45 C~180 C

(-49 F~356 F)

-57 C~180 C

(-70 F~356 F)

-45 C~200 C

(-49 F~392 F)

-45 C~180 C

(-49 F~356 F)

-45 C~260 C

(-49 F~500 F)

-40 C~80 C

(-40 F~176 F)

-30 C~80 C

(-22 F~176 F)

-28 C~220 C

(-18 F~428 F)

White General Chemical

RTFE

15% Glass Filled

Reinforced PTFE

Off-White

For low and medium

pressure service for steam

service up to 150 psig

TFM1600

Modified PTFE

(PFA & PTFE)

White

Ideal for application

requiring higher purity

such as semi-conductor

CTFE

MG1241

Carbon Graphite

Reinforced PTFE

Black

For high temperature and

high pressure service for

steam service up to 450

psig

MS02

MG1431

MS02 Filled PTFE Grey

For high temperature and

high pressure service for

steam service up to 450

psig

PEEK Poly Ether Keton Grey

Best suited for high

temperature and pressure

service up to 3000 psig.

DELRIN

Dupont's Acetal

Homopolymer

(Delrin)

Creamy

White

Best suited for high

Pressure service up to

6000 psig

UHMW-PE

Ultra High

Molecular Weight

Polyethylene

White

Best suited for tobbaco

duty and abrasion

resistance

SS/PTFE

Stainless Powder

PTFE

Grey

Best suited for abrasion

resistance and control

steam application

Virgin PTFEis the most common sealing material

and is suitablefor almost all media as it has excelent

chemical resistance.

15% Glass Filled Reinforced PTFEchemical

resistance is compatible to PTFEand improved

cycle life and greater pressure temperature rating

Second Generation PTFE,offers better creep. Lower

coefficient of friction provides lower torque values

and resist deformation. This is excellent application

Glass and Metal Oxide PTFEfilled withstand

pressure than CTFE. Good resistance under load

and not reccomended for foodstuff.

Poly Ether Keton a material which outstanding

pressure capabilities at elevated temperature and

has excellent chemical and abrasion resistance

Delrin is capable of handling extremely high

pressure. Must not used for oxygen service.

Carbon Graphite Reinforced PTFEan excellent seat

material for steam and thermal services and having

good abrasion resistance.Due to its high cycling

capabilities, it is the reccomended soft seat for

modulating control application.

UHMW-PEis ideal for use in low level radiation

service. This seat also meets the requirements of the

tobbaco industry where PTFEis prohibited and its

offers an excellent resistance to abrasion medium.

Stainless Powder is combines the strength of metal

with the lubricity of PTFE. 50% SS316 powder

combines with 50% PTFEoffers abrasion resistance

of metal with higher pressure and temperature rating

than RTFE.

You might also like

- Seat Material Selection in Ball ValvesDocument2 pagesSeat Material Selection in Ball Valvescoolguy12345No ratings yet

- Valve Seat Selection GuideDocument4 pagesValve Seat Selection Guideim4uim4uim4uNo ratings yet

- Valve Seat Material Selection GuideDocument1 pageValve Seat Material Selection GuideHo Minh VietNo ratings yet

- Valve Seat Seal Selection GuideDocument2 pagesValve Seat Seal Selection Guideecovarrubias1No ratings yet

- Products Valves Sanitary PBM Series 9, 2 WayDocument40 pagesProducts Valves Sanitary PBM Series 9, 2 Waydingobk1No ratings yet

- File-1452328935 DBBDocument2 pagesFile-1452328935 DBBSalman100% (1)

- MuellerDocument24 pagesMuellerAhmad NasserNo ratings yet

- Global Valve & Controls: Depend On Us, We Can Handle The PressureDocument4 pagesGlobal Valve & Controls: Depend On Us, We Can Handle The PressurealeeimeranNo ratings yet

- Lateral Tee: What Is The Difference Between Lateral Tee and True WYEDocument2 pagesLateral Tee: What Is The Difference Between Lateral Tee and True WYEAnonymous 6ZWS6IG2J9No ratings yet

- API 598, EN 12266-1 Leakage RatesDocument2 pagesAPI 598, EN 12266-1 Leakage RatesjshadwanNo ratings yet

- BP GS162-1 Valves PDFDocument24 pagesBP GS162-1 Valves PDFMohd Khairul100% (1)

- Sour Service Pipes - Annexure HDocument6 pagesSour Service Pipes - Annexure HSubhajit Bhattacharya100% (1)

- Chemical Resistance GuideDocument32 pagesChemical Resistance GuidevsvineeshNo ratings yet

- Bolt Tightening Procedure GuideDocument6 pagesBolt Tightening Procedure Guideal arabiNo ratings yet

- To Rerate or Not To RerateDocument6 pagesTo Rerate or Not To ReratekblaxtonNo ratings yet

- PLD-108 Anchor FlangeDocument7 pagesPLD-108 Anchor FlangeBiginch100% (1)

- Collar BoltsDocument2 pagesCollar BoltsMahdi HocineNo ratings yet

- 5.3 CES-1002-F-Seat Leakage Testing PDFDocument22 pages5.3 CES-1002-F-Seat Leakage Testing PDFbowoNo ratings yet

- Ansi Valve Leakage Standards Gemco ValveDocument1 pageAnsi Valve Leakage Standards Gemco ValvenithyaNo ratings yet

- Garlock Gasketing Products: Performance With Proven ReliabilityDocument64 pagesGarlock Gasketing Products: Performance With Proven ReliabilitySiva SubramaniNo ratings yet

- DUBAI ACCREDITATION DEPARTMENT INSPECTION REQUIREMENTSDocument21 pagesDUBAI ACCREDITATION DEPARTMENT INSPECTION REQUIREMENTSPmohamedFazilNo ratings yet

- 45 Samss 009Document6 pages45 Samss 009naruto256No ratings yet

- Safety ValvesDocument3 pagesSafety ValvesGiovanni LerasNo ratings yet

- FlowTek Ball Valve DesignDocument0 pagesFlowTek Ball Valve DesignGohilakrishnan ThiagarajanNo ratings yet

- Valve and Pipeline Design Notes - Part 1Document29 pagesValve and Pipeline Design Notes - Part 1vikky123100% (1)

- Process & Piping Design Section Plug Valves Technical SpecificationDocument14 pagesProcess & Piping Design Section Plug Valves Technical Specificationashish.mathur1100% (1)

- 61 PDFDocument46 pages61 PDFashishpearlNo ratings yet

- MSDS 001139212Document7 pagesMSDS 001139212danny_sosa_3No ratings yet

- External Coatings For Corrosion Protection of Steel Pipes and ComponentsDocument120 pagesExternal Coatings For Corrosion Protection of Steel Pipes and ComponentsadelNo ratings yet

- Valve HandbookDocument52 pagesValve Handbookshivam100% (1)

- GP 06-25 - Design For The PrevDocument24 pagesGP 06-25 - Design For The Prev1339979No ratings yet

- Valve Material TypesDocument3 pagesValve Material TypesimanadbNo ratings yet

- Valve Company's Floating & Trunnion Ball ValvesDocument15 pagesValve Company's Floating & Trunnion Ball ValvesAlienshowNo ratings yet

- DBB Vs DIBDocument3 pagesDBB Vs DIBrsb72No ratings yet

- Carpenter & Paterson Hardware Price Book CP-0213Document54 pagesCarpenter & Paterson Hardware Price Book CP-0213Sargunam SankaravadivelNo ratings yet

- F10ca004-Gb 0597Document8 pagesF10ca004-Gb 0597gabyorNo ratings yet

- Definition and Details of FlangesDocument23 pagesDefinition and Details of Flangesvishan2kNo ratings yet

- Valve Selection GuideDocument5 pagesValve Selection Guiderajeshn1100% (1)

- Consolidated Model 2700 Pressure Safety and Relief ValvesDocument44 pagesConsolidated Model 2700 Pressure Safety and Relief Valvesjromero_rpgNo ratings yet

- Lateral Tee 16'' Sch. 20 With Reinforcement Rev 01Document1 pageLateral Tee 16'' Sch. 20 With Reinforcement Rev 01HarryNo ratings yet

- Valves 101: Gobind KhianiDocument56 pagesValves 101: Gobind Khianikongara_inst1118No ratings yet

- Offshore Underwater HTPDocument4 pagesOffshore Underwater HTPPhilip Ul100% (1)

- Pipeline Equipment - Ball Valves EtcDocument43 pagesPipeline Equipment - Ball Valves Etckrish69No ratings yet

- Flexpipe PDS FlexCord EnglishDocument2 pagesFlexpipe PDS FlexCord EnglishpsycopaulNo ratings yet

- Iso 9001 CertifiedDocument4 pagesIso 9001 CertifiedLuis R. Salas SotoNo ratings yet

- Scope: PurposeDocument6 pagesScope: Purposezahid_497No ratings yet

- Teflone (PTFE) Seat SuggetionDocument1 pageTeflone (PTFE) Seat SuggetionBharat PrajapatiNo ratings yet

- Valve Seat Material Selection GuideDocument1 pageValve Seat Material Selection Guidemurtuza5No ratings yet

- 5L E45 Purch Guidelines R0 201306Document1 page5L E45 Purch Guidelines R0 201306Ansuman KalidasNo ratings yet

- Valve Seat Material GuideDocument1 pageValve Seat Material GuidewawanNo ratings yet

- Valve Seat Material Guide PDFDocument1 pageValve Seat Material Guide PDFmolinachNo ratings yet

- Engineering Bulletin: Rev. 10/07 Page 1 of 4Document5 pagesEngineering Bulletin: Rev. 10/07 Page 1 of 4Iván López PavezNo ratings yet

- Valve Seat Seal Selection GuideDocument4 pagesValve Seat Seal Selection GuideDhim131267No ratings yet

- Valves Eat Seal Materials and Service TypesDocument3 pagesValves Eat Seal Materials and Service Typescoolguy12345No ratings yet

- Seats and Seals Selection Guide: Share ThisDocument4 pagesSeats and Seals Selection Guide: Share ThisArjed Ali ShaikhNo ratings yet

- Valves Eat Seal Materials and Service TypesDocument3 pagesValves Eat Seal Materials and Service Typess.mladinNo ratings yet

- Ball Valve SeatDocument2 pagesBall Valve Seatmrkadu_61No ratings yet

- T5500 - T6500 Pressure GaugesDocument8 pagesT5500 - T6500 Pressure GaugesTrịnh Đức HạnhNo ratings yet

- Seat Material PDFDocument2 pagesSeat Material PDFkrisNo ratings yet

- Non-Intrusive Magnetic Pig SignallerDocument2 pagesNon-Intrusive Magnetic Pig SignallerAndresNo ratings yet

- Code of Practice LNG FacilitiesDocument65 pagesCode of Practice LNG FacilitiesAhmed EldeebNo ratings yet

- Article 1cDocument4 pagesArticle 1cAndresNo ratings yet

- 1 Piping CostingDocument33 pages1 Piping Costingamoldhole97% (34)

- TECHLOK Clamp Connector Technical WebversionDocument32 pagesTECHLOK Clamp Connector Technical WebversionAndresNo ratings yet

- 1990 Palmer Upheaval BucklingDocument10 pages1990 Palmer Upheaval Bucklingppyim2012100% (1)

- Pikotek Installation BrochureDocument2 pagesPikotek Installation BrochureAndresNo ratings yet

- 1990 Palmer Upheaval BucklingDocument10 pages1990 Palmer Upheaval Bucklingppyim2012100% (1)

- CharttorqueswgDocument2 pagesCharttorqueswgYutana RuxnakNo ratings yet

- Electrical Formulas and Calculations - E-Book - (2005) National Electrical CodeDocument14 pagesElectrical Formulas and Calculations - E-Book - (2005) National Electrical Codemagdy473No ratings yet