Professional Documents

Culture Documents

Healttthcare Industry Brief 0610

Uploaded by

Kuber SethiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Healttthcare Industry Brief 0610

Uploaded by

Kuber SethiCopyright:

Available Formats

MOTOROLA LEADERSHIP SERIES

Reducing healthcare costs with supply chain best practices. How standardized

data capture saves time and improves care.

The challenge: cumbersome manual processes in the healthcare supply chain affect budgets and impact the delivery of care

INSIDE:

With extreme pricing pressures on todays healthcare providers, reducing costs while delivering high-quality medical care is a top strategic imperative. To achieve this objective, provider efforts have been focused primarily on eliminating waste in clinical operations, for example, through initiatives that reduce unnecessary testing and the length of hospital stays. While these are valid and important ways to reduce healthcare costs, one area that consumes nearly one third1 of all hospital operating budgets often remains overlooked the healthcare supply chain. When it comes to expenses, supplies are second only to labor, with millions of products moving along the supply chain every day through manufacturers, distributors, Group Purchase Organizations (GPOs) and healthcare providers to patients. Although the healthcare supply chain is one of the oldest and most complex, it remains immature1 in its level of collaboration, driven by a lack of data standards and paper forms that drive errors and duplication into the process. Cycle times increase and data accuracy shrinks, ultimately increasing supply chain costs, general healthcare costs and potentially affecting patient safety. The impact on healthcare supply chain costs Inconsistent data standards for product, trading partner and customer locations translate into substantial inefciencies in the healthcare supply chain, where manual data processing is typically required as orders and product shipments travel through as many as 17 different locations.2 Inefciencies may start inside the hospital at the beginning of the demand cycle, where inventory management procedures require workers to collect information on paper that must then be entered into the computer a double-touch of

The challenge: cumbersome manual processes in the healthcare supply chain A two-pronged solution: adopting data standards and mobile technology Benets from mobilized standards Summary: the potential upside $16 billion in annual cost savings and improved patient safety

R E D U C I N G H E a Lt H C ar E C O sts W I t H s U P P LY C H a I N b E st P ra C t I C E s

MOTOROLA LEADERSHIP SERIES

data that introduces ample opportunity for errors. Orders are compiled using product identiers from the rst distributor in the supply chain. As the order continues its journey, lack of standardized identiers forces distributors and manufacturers in any particular order chain to manually translate the incoming product numeric identiers to their own legacy identiers. Time, cost and errors are added into the end-to-end order fulllment process from pricing discrepancies that delay payments, to the delivery of wrong products, or address errors that result in costly mis-shipments and late deliveries.

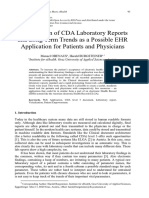

Supply Chain Management: A Top Operating Cost in Healthcare

Indicate what percent of your annual operating expense is used to support healthcare supply chain costs.

Manufacturers

8%

8%

8%

5%

7%

37%

GPOs

5%

26%

4% 4%

18%

56%

Distributors

19%

16%

14%

11%

7%

67%

Providers

9%

10%

3% 4%

5%

31%

Inventory Management

Order Management

Transportation

Shipping/Receiving

Other

Sample size = 204; Source: 2009, Nachtman and Pohl

Figure 1: Supply chain management consumes between one-third and two-thirds of the annual operating costs for healthcare providers, distributors, GPOs and manufacturers. Two specic activities represent approximately half of those costs: inventory management and order management. The State of Healthcare Logistics: Cost and Quality Improvement; Center for Innovation in Healthcare Logistics; Heather Nachtmann, Ph.D and Edward A. Pohl, Ph.D; University of Arkansas; July 2009

R E D U C I N G H E a Lt H C ar E C O sts W I t H s U P P LY C H a I N b E st P ra C t I C E s

MOTOROLA LEADERSHIP SERIES

The impact on patient care These paper-based processes plus a lack of data standards reach beyond back ofce operations right to the patient, potentially affecting the quality of care. The slow movement of information inherent in paper-based processes combines with legacy product identiers, increasing the complexity of reverse logistics and asset tracking, and hampering the identication of products that have been recalled, from a medical device to medication. The resulting delay in transferring information between manufacturer and healthcare provider could result in the inadvertent use of recalled equipment or the administration of tainted medication situations that may put patient health and safety at risk.

A two-pronged solution: adopting data standards and mobile technology to automate the supply chain from provider to manufacturer

In order to improve the efciency of the healthcare supply chain, data must ow seamlessly and automatically around the globe from providers to distributors and manufacturers in real-time, leading to two requirements that are readily available today: universal GS1 data standard identiers and the automatic capture and transmission of information via bar code scanning throughout the healthcare supply chain. Step 1: a single data standard for location and product identication A global data standard that uniquely identies products and locations has been developed by GS1 to streamline processes and improve operational inefciencies in the healthcare supply chain. Created by the healthcare industry itself, these standards are designed to address the industrys supply chain challenges by providing a single, rich, global repository of accurate up-to-date information that can be leveraged by healthcare providers, distributors and manufacturers to simplify inventory management. GS1 data standards include: The Global Location Number (GLN) to identify the location of transacting entities The Global Trade Identication Number (GTIN) for the identication of the products

These data standards reside in the GLN Registry, a global directory of all the GS1 data standards in the healthcare supply chain. Providers, distributors, manufacturers and GPOs then subscribe to the Global Data Synchronization Network (GDSN) to register and access data standards.

R E D U C I N G H E a Lt H C ar E C O sts W I t H s U P P LY C H a I N b E st P ra C t I C E s

MOTOROLA LEADERSHIP SERIES

The GS1-128 1D and GS1 DataMatrix 2D bar codes can accommodate a wealth of information, including: The GTINs Secondary product related information, such as serial numbers, lot numbers and expiration dates Pedigree information, including the specic manufacturing plant where the product was produced, providing accurate and cost-effective traceability The hospitals GLNs, including GLNs for the hospital itself as well as specic locations inside the hospital, such as a cardiac intensive care unit (ICU) supply cabinet on a specic oor of the hospital

GS1-128 and GS1 DataMatrix

GS1-DataMatix bar code GS1-128 bar code

Flexible GS1-DataMatrix 2D bar codes are designed to hold a wealth of information in a very compact space, allowing serial numbers, expiration dates and other product details to be attached to the smallest of products. In addition, this bar code can also be utilized as a direct part mark (DPM), which can be permanently etched or stamped into surgical instruments, allowing hospitals to easily track and trace these critical implements.

The GS1-128 bar code is the gold standard in logistics. This linear symbology is more compressed than the typical linear symbologies, allowing manufacturers and distributors to embed the additional information required to support track and trace throughout the healthcare supply chain.

Bar code source: The Value and Benets of the GS1 System of Standards; GS1 AISBL; www.gs1.org

R E D U C I N G H E a Lt H C ar E C O sts W I t H s U P P LY C H a I N b E st P ra C t I C E s

MOTOROLA LEADERSHIP SERIES

The GS1 data standards eliminate the need to transpose the information on orders as they move up and down the supply chain, increasing order processing speed and data accuracy. In addition, GS1 DataMatrix can be applied directly to products or product components. Known as direct part marking (DPM), the ability to etch or engrave the bar code permanently into the surface of a product allows hospitals to easily track and trace surgical instruments and other medical equipment. Step 2: mobile automated data capture While the GS1 standards provide the foundation for healthcare supply chain automation, the ability to automatically identify and capture the information from the point of arrival (POA) to the point of use (POU) provides the true inventory transparency required to achieve maximum efciency in inventory replenishment and management processes.

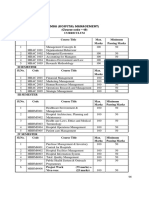

The new streamlined healthcare supply chain

In the hospital, when GS1 bar coded materials are scanned as they are used, the inventory system is updated in real time. Since the GS1 system allows secondary information to be appended to the GTINs, the hospital can automatically determine not only the inventory in the hospital, but also the inventory in each supply cabinet on every oor.

When the shipment is delivered to the hospital, a quick scan of the GS1 bar codes allows instant and automatic reconciliation of the order, complete with granular putaway information the specic location inside the hospital walls where the item should be stored.

1 5 2

When a pre-set inventory threshold is reached on an item, the hospitals inventory system can automatically create an electronic order that is sent to the hospitals purchasing department to initiate a re-order.

4

A quick scan of the bar coded products as they are picked, packed, shipped and delivered on their journey through the healthcare supply chain enables rapid and accurate processing of shipments.

Once the order is released from the hospital, it is sent electronically to distributors and manufacturers. Additional required information is simply appended to the electronic order such as order fulllment location and pricing. Paper-based processes and manual translation of product or customer location numbers is eliminated.

R E D U C I N G H E a Lt H C ar E C O sts W I t H s U P P LY C H a I N b E st P ra C t I C E s

MOTOROLA LEADERSHIP SERIES

The resulting automation greatly reduces the time and cost involved in logistics throughout the entire healthcare supply chain with an estimated industry-wide annual savings of $16 billion.3 In addition, bar code scanning at patient bedside provides instant access to a wealth of product information that can help prevent medical errors. For example, expired or recalled medication or medical equipment can be instantly identied, better protecting the health of patients. The nal link in the streamlined supply chain: real-time locationing for mobile medical equipment Once consumable products inside the hospital can be scanned at the point of arrival and point of use, the resulting real-time inventory visibility allows the automation of the replenishment process. But while consumables have a specic storage spot, medical equipment does not. Devices such as IV pumps, wheelchairs, heart monitors and more are always on the move throughout the hospital. When the hospital elects to encode the GS1 identier for these devices on a Wi-Fi or RFID tag, the real-time location of the equipment is always visible. Now, whether the equipment is required for a patient, recalled or simply due for service, it can be located instantly. Patient safety is enhanced. Staff efciency is greatly improved: biomedical engineers, nurses and transport staff spend signicantly less time searching for assets and more time on critical tasks. And the continuous visibility allows hospitals to maximize the use of existing assets, ensuring capital budgets are spent on the most judicious purchases.

Washington Regional Medical Center: putting GS1 Data Standards to the test

The objective of the Center for Innovation in Healthcare Logistics (CIHL) Data Standards (DS) project is to help facilitate GS1 standards adoption with hospital providers. CIHL is partnering with pilot participants to design, test and evaluate the challenges and benets of early GSI standards adoption. While the examination of key metrics and benets in internal and external transactions are currently in process, Washington Regional Medical Center comments on its ongoing pilot:

Industries such as manufacturing, retail and distribution have long utilized 1D bar code scanning and the use of supply chain data standards to streamline and error-proof business processes. GS1 data standards and highperformance 2D bar code scanning can bring those same benets to the end-to-end healthcare supply chain, with three major additional benets improving the quality of care and the patient experience as well as reducing risk for both patient and hospital. Process automation and availability of data at the point of care: ensure that materials are available when needed; reduce cycle times; and prevent mistakes that can threaten lives. The result? Faster delivery of the right care to the right patient.

- Jack B Morris, Vice President- Operations, Washington Regional Medical Center, Fayetteville, Arkansas

*The Center for Innovation in Healthcare Logistics (CIHL) is an industry-university partnership that leads a nationwide effort to identify and foster system-wide adoption of ground-breaking healthcare supply chain and logistic innovations.

R E D U C I N G H E a Lt H C ar E C O sts W I t H s U P P LY C H a I N b E st P ra C t I C E s

MOTOROLA LEADERSHIP SERIES

Benets from mobilized standards

GS1 healthcare standards coupled with mobile bar code scanning technologies benet everyone in the healthcare supply chain, including manufacturers, distributors, shippers and hospitals as well as product end users such as physicians, nurses, task workers and patients. Healthcare professionals and patients While clinical staff and patients are not part of the traditional healthcare supply chain, they as the ultimate users and consumers of products and equipment do stand to benet signicantly from the pairing of consistent data standards and mobile automated data capture solutions. These benets include: Improved patient safety. Bar code scanning allows healthcare providers to: verify that the right medication is about to be administered to the right patient; ensure that perishable items have not expired or been recalled; and provide seamless and instant access to the patients electronic medical record (EMR). Improved productivity and quality of care. The ability to replace volumes of paperwork with GS1 bar codes reduces the administrative burden on healthcare workers, freeing more time for direct patient care. And RFID tagging ensures that outdated, expired or faulty equipment can be rapidly located and removed from service.

Global GS1 standards will bring the whole healthcare supply chain industry together around uniform and unequivocal identiers which facilitate automation, system interoperability, enhance patient safety, and contribute to operational excellence. Potential cost savings and quality improvements from manufacturer to patient are substantial.

Professor Ronald L. Rardin, Director, Center for Innovation in Healthcare Logistics (CIHL) John and Mary Lib White Systems Integration Chair and Distinguished Professor Department of Industrial Engineering, University of Arkansas

R E D U C I N G H E a Lt H C ar E C O sts W I t H s U P P LY C H a I N b E st P ra C t I C E s

MOTOROLA LEADERSHIP SERIES

Hospitals GS1 standards directly impact operational efciency in the hospital. Process-specic benets include: More efcient order replenishment Better inventory management for reduced costs Faster inventory availability from dock to stock Better monitoring and management of products with a short shelf life

The integration of standard supply chain data into other everyday processes inside the hospital walls provides incremental benets beyond the traditional supply chain, including: Better charge capture Improved inspections, maintenance scheduling and compliance reporting Improved asset utilization Allows the creation of automated asset lists as required for Sarbanes-Oxley (SOX) compliance

Implementation steps for the healthcare provider For hospitals, streamlining the supply chain requires three key initiatives: 1. Implementation of the GS1 data standards into the hospital back-end systems and applications 2. Integration of a bar code strategy into the appropriate clinical and operational workows 3. The deployment of bar code scanners and/or mobile computers capable of reading the GS1 1D and 2D bar codes and RFID tags if real-time locationing is desired for medical equipment In addition, hospitals can phase in use of the GS1 data standards to simplify deployment and minimize business disruption: Level 1: With minimal change to existing business processes, hospitals can begin using GTINs and GLNs in business transactions (such as purchase orders) internally and with external trading partners. Level 2: Incorporate scanning of the GTINs and GLNs embedded in the GS1 bar codes to support best-practice automation and error-reduction initiatives throughout business processes from receiving and inventory management to pointofcare solutions (for example, to verify medication prior to administration). Level 3: Incorporation and use of secondary data (such as expiration date, lot and serial numbers) to achieve incremental benets that further streamline business processes and improve patient safety such as the ability to automatically identify items that have expired or been recalled.

R E D U C I N G H E a Lt H C ar E C O sts W I t H s U P P LY C H a I N b E st P ra C t I C E s

MOTOROLA LEADERSHIP SERIES

Manufacturers, Distributors and Shipping When hospitals adopt GS1 healthcare data standards, the effects reach all the way through the supply chain, impacting the GPO, and all distributors as well as manufacturers. Upstream benets realized in the supply chain include: Reduced administrative costs Accurate ordering and pricing Accurate and consistent administration fees, rebates and charge backs Accurate picking in the warehouse Accurate shipment tracking and deliveries

Improved speed and accuracy in forward and reverse logistics Better product traceability Faster and more targeted recalls

Reduced capital expenditures Improved asset management and utilization Priority handling of perishable products Cost-effective inventory takes and more inventory turns

Reduced operational expenditures Global availability of the physical characteristics of products (such as dimensions, weight and temperature storage requirements) allows better utilization of transportation services and warehouse space

Summary: the potential upside $16 billion in annual cost savings and improved patient safety

All across the world, governments and healthcare institutions are grappling with the need to expand the availability of high quality healthcare to more people, without increasing costs. Much of the focus to date has centered around clinical efciencies through the adoption of Electronic Medical Records (EMR) and the establishment of Health Information Exchanges. However, the deployment of mobile automated data capture technologies within the framework of GS1 data standards can enable a more mature and universal global healthcare delivery network, thereby substantially reducing one of the largest operational costs in the healthcare industry today supply chain management. Projected labor savings associated with order fulllment for the entire healthcare supply chain is a massive $16 billion annually.3

R E D U C I N G H E a Lt H C ar E C O sts W I t H s U P P LY C H a I N b E st P ra C t I C E s

MOTOROLA LEADERSHIP SERIES

This single initiative can not only help control rising healthcare costs, but also improve the quality of care, helping to better protect the 1.5 million patients impacted each year by medication errors and reduce the associated $3.5 billion annual pricetag.4 In addition, the GS1 data standards and bar code automation that reduce supply chain costs and improve patient safety can also improve the hospitals internal supply chain. For example, the ability to strip wasted time spent searching for products, equipment or duplicating paper-based efforts improves the productivity of nurses, physicians, lab technicians, pharmacists, clinical engineers and more, increasing overall staff utilization. And the ability to automatically collect and document medication administration as well as inspections and maintenance data for medical equipment and the physical hospital facilities in real time enables cost-effective compliance with existing and emerging industry and government regulations from the Joint Commission on Accreditation of Healthcare Organizations (JCAHO) to the EMR initiative.

F or more information

For more information on how Motorolas mobile pointof-care and healthcare supply chain solutions are enhancing patient safety, improving productivity and decreasing costs throughout the healthcare industry, please visit www.motorola.com/healthcare, access our global contact directory at www.motorola.com/enterprisemobility/contactus or call 800.526.8637.

10

R E D U C I N G H E a Lt H C ar E C O sts W I t H s U P P LY C H a I N b E st P ra C t I C E s

MOTOROLA LEADERSHIP SERIES

Footnotes

1. The State of Healthcare Logistics: Cost and Quality Improvement; Center for Innovation in Healthcare Logistics; Heather Nachtmann, Ph.D and Edward A. Pohl, Ph.D; University of Arkansas; July 2009. http://cihl.uark.edu/ The_State_of_Healthcare_Logistics_July_2009.pdf 2. The Case for Global Standards; Michigan State University School of Packaging; Prepared for the GS1 Global Healthcare Users Group; Sept 10, 2007; Page 11 3. Premier Healthcare Alliance, GNYHA Ventures Identify More Than $317 Billion in Hospital Cost Savings; June 15, 2009; http://www.businesswire.com/ portal/site/home/permalink/?ndmViewId=news_view&newsId=200906150 06185&newsLang=en 4. To Err is Human: Building a Safer Health System; Institute of Medicine; 2000; National Academy Press (page 268)

11

R E D U C I N G H E a Lt H C ar E C O sts W I t H s U P P LY C H a I N b E st P ra C t I C E s

MOTOROLA LEADERSHIP SERIES

This article is one of a series examining the challenges, the opportunities and the realities of how technological innovation and enterprise mobility inuence and affect the global community.

Motorola, Inc. 1301 E. Algonquin Road, Schaumburg, Illinois 60196 U.S.A. www.motorola.com/healthcare

MOTOROLA and the stylized M Logo are registered in the U.S. Patent and Trademark Ofce. All other products or service names are the property of their registered owners. Motorola, Inc. 2010 IB-ISG-HCSPLYBP-0610

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Enterpriseussd 140311071714 Phpapp02 PDFDocument22 pagesEnterpriseussd 140311071714 Phpapp02 PDFKuber SethiNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Supply Chain Visibility in Healthcare - Beyond The DashboardDocument7 pagesSupply Chain Visibility in Healthcare - Beyond The DashboardKuber SethiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Resume Points Training&DevelopmentDocument3 pagesResume Points Training&DevelopmentKuber SethiNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- SCM - Handout IDocument12 pagesSCM - Handout IKuber SethiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Highperformanceplmebook2012july 120710131130 Phpapp01Document18 pagesHighperformanceplmebook2012july 120710131130 Phpapp01Kuber SethiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Legal Protection of Patient Data in Electronic Medical RecordsDocument11 pagesLegal Protection of Patient Data in Electronic Medical Recordsprodi apikesbandungNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- p74-MedBlock - Efficient and Secure Medical Data Sharing Via BlockchDocument11 pagesp74-MedBlock - Efficient and Secure Medical Data Sharing Via BlockchDevi SriNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Indus HospitalDocument20 pagesThe Indus Hospitalibrahim khanNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Importance of Interoperability in HealthcareDocument4 pagesImportance of Interoperability in HealthcareInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Mobileframe Healthcare Application Suite: Configurable Mobile ApplicationsDocument4 pagesMobileframe Healthcare Application Suite: Configurable Mobile ApplicationsSteveEpsteinNo ratings yet

- Bellino Issue 2 Article For WebsiteDocument3 pagesBellino Issue 2 Article For Websiteapi-400507461No ratings yet

- Olu Sanye Leg Be Dean Do Guns EyeDocument6 pagesOlu Sanye Leg Be Dean Do Guns EyeItz HarlartiseyNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hype Cycle For Real - 467856 NDX PDFDocument78 pagesHype Cycle For Real - 467856 NDX PDFJohn AdamNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- An Overview of Interoperability Standards For Electronic Health RecordsDocument8 pagesAn Overview of Interoperability Standards For Electronic Health RecordsCarlos Alberto Tangarife VillaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Nursing Informatics in Asia: - ObjectivesDocument13 pagesNursing Informatics in Asia: - ObjectivesDimple AnticamaraNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Visualization of CDA Laboratory Reports and Long Term Trends As A Possible EHR Application For Patients and PhysiciansDocument8 pagesVisualization of CDA Laboratory Reports and Long Term Trends As A Possible EHR Application For Patients and PhysiciansBora YüretNo ratings yet

- Automated Clinical Diagnosis: The Role of Content in Various Sections of A Clinical DocumentDocument8 pagesAutomated Clinical Diagnosis: The Role of Content in Various Sections of A Clinical DocumentAnkit ShuklaNo ratings yet

- Poster Presentation Nur 4242 KDocument1 pagePoster Presentation Nur 4242 Kapi-340245019No ratings yet

- Health Informatics Thesis TopicsDocument8 pagesHealth Informatics Thesis Topicsiapesmiig100% (1)

- Hand-Off Tool Evaluation 5Document58 pagesHand-Off Tool Evaluation 5api-538856946No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Clinical PathwayDocument28 pagesClinical Pathwayriandhani0% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Hospital Management 110913Document21 pagesHospital Management 110913Muhammad UsmaanNo ratings yet

- Confidentiality, Privacy, Access, and Data Security Principles For Health Information Including Electronic Health RecordsDocument9 pagesConfidentiality, Privacy, Access, and Data Security Principles For Health Information Including Electronic Health RecordsEric GozzerNo ratings yet

- Challenges of Professional Management of Medical Records in Nigerian Public HospitalsDocument19 pagesChallenges of Professional Management of Medical Records in Nigerian Public HospitalsVictor Chibueze IjeomaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Eop 32 01Document6 pagesEop 32 01Muhammad ArslanNo ratings yet

- Patient Management System Project ReportDocument67 pagesPatient Management System Project ReportMayuresh PanchalNo ratings yet

- Philippine EHealth Systems and Services Act GROUP 5Document54 pagesPhilippine EHealth Systems and Services Act GROUP 5Yvette SadacNo ratings yet

- Top 26 EHR Software for Physician Practices in USADocument11 pagesTop 26 EHR Software for Physician Practices in USAAmol DhanvijNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Nabimara Charles Cit PGD ReportDocument56 pagesNabimara Charles Cit PGD ReportArsalan FarooqNo ratings yet

- Digital Transformation Shaping The Future of European HealthcareDocument69 pagesDigital Transformation Shaping The Future of European HealthcareTomo AjaNo ratings yet

- Health Care Data 101Document17 pagesHealth Care Data 101Tilak DharNo ratings yet

- EHRIP Eligible Professionals Tip Sheet PDFDocument4 pagesEHRIP Eligible Professionals Tip Sheet PDFdnice408No ratings yet

- Clinical research queriesDocument3 pagesClinical research queriesAbdussalamElhanashiNo ratings yet

- NCM 103 Finals Part2Document206 pagesNCM 103 Finals Part2TADZMALYN JINANGNo ratings yet

- Implementation of A Violence Risk Assessment Tool and Its Impact On The Utilization of Physical Restraints in An Emergency DepartmentDocument24 pagesImplementation of A Violence Risk Assessment Tool and Its Impact On The Utilization of Physical Restraints in An Emergency DepartmentshahirahNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)