Professional Documents

Culture Documents

Start Test

Uploaded by

help3rOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Start Test

Uploaded by

help3rCopyright:

Available Formats

Starting System Tests

The function of a vehicle's starting system is to rotate the engine's crankshaft fast enough so that combustion can take place, and the engine can begin to run under its own power. This system, is commonly referred to as the "cranking system". Providing the cranking power needed for reliable engine starts requires all starting system components to be in good working order. Testing the starting system can confirm that it is functioning properly, or provide valuable diagnostic information to isolate a problem in the system. The STARTING SYSTEM TEST measures starter current draw and cranking voltage. If the engine cranking speed is good, and the starter current draw amperage and cranking voltage readings are within specifications, you can generally conclude that the starting system is functioning properly. But, if the starter does not crank, cranks too slowly, or the amps and/or volts reading are not within specifications, further testing will be required. Before performing the STARTING SYSTEM TEST, the starting system should be visually inspected for physical defects, and some preliminary checks should be performed that will aid you in diagnosing a starting system problem. These are taken care of during the pretest. PRETEST 1. To prevent possible personal injury and protect the vehicle from damage, inspect the starting system for defects. Check for the following; then repair and/or replace any defective components. .Battery defects .Frayed or broken electrical wiring .Corroded or loose connections .Loosely mounted starter motor, series-parallel switch, magnetic switch, solenoid, starter relay, etc. 2. Check state-of-charge of battery. For accurate starter current draw test results, the battery must be fully charged. 3. BE SURE TO USE FENDER COVERS to avoid damaging the vehicle paint due to battery acid on the tester cables.

STARTING SYSTEM TEST 1. Perform PRETEST (previous page). NOTE: Battery should be fully charged and engine at normal operating temperature. A cold or overheated engine draws more amps during starter current draw test. 2. Turn off all of the vehicle's electrical accessories. 3. Disable the ignition or fuel system as follows to prevent engine from starting during test: 4. With the LOAD KNOB in the OFF position (fully counterclockwise), connect LOAD LEADS to battery (red to positive and black to negative) 5. Press AMPS 0 KEY to zero display, if it does not read zero (0). 6. Make sure BATTERY volts function indicator is ON 7. Connect the AMPS PROBE around either the positive or negative starter cable. 8. Crank engine and observe AMPS and VOL TS readings (after readings have leveled off - not peak readings). CAUTION: TO PREVENT STARTER DAMAGE, DO NOT CRANK ENGINE FOR MORE THAN 15 SECONDS AND ALLOW 2 MINUTES FOR COOLING BETWEEN CRANKING TESTS. 9. Compare test readings to specifications. If starter current draw is too high, voltage is below 10 volts, or the engine cranks slowly a problem is indicated. Starter current draw specifications vary considerably, depending on engine size, type (gas or diesel), compression ratio, etc. The following auto and light truck current draw information (for 12 volt systems) is a general guideline. It is normal for some starting systems to draw more amperage. 4 cylinder gas engine -typically draws up to 160 amps 4 cylinder diesel -typically draws up to 350 amps. 6 cylinder gas engine -typically draws up to 210 amps. 6 cylinder diesel -typically draws up to 450 amps. 8 cylinder gas -typically draws up to 250 amps. 8 cylinder diesel -typically draws up to 650 amps.

You might also like

- 1999 Jeep TJ Wrangler Service Manual - 08. Electrical SystemsDocument434 pages1999 Jeep TJ Wrangler Service Manual - 08. Electrical Systemsbfranklin3390% (10)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Operator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesFrom EverandOperator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesRating: 5 out of 5 stars5/5 (3)

- Workshop Manual Sisu 7 Cylinder PDFDocument70 pagesWorkshop Manual Sisu 7 Cylinder PDFMuhammad Faizal Axel100% (2)

- Denso Common Rail Inyector PDFDocument1 pageDenso Common Rail Inyector PDFCarlos QuispeNo ratings yet

- 176Document12 pages176[VLVH] Vo Thanh DuyNo ratings yet

- Service Manual Picanto Ion g3hgDocument13 pagesService Manual Picanto Ion g3hgrectificamosNo ratings yet

- STARTER MOTOR TEST PROCEDURE GUIDEDocument13 pagesSTARTER MOTOR TEST PROCEDURE GUIDEwei fooNo ratings yet

- Injection Actuation PressureDocument20 pagesInjection Actuation Pressureabdelrhmangbr8682% (11)

- Outboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairFrom EverandOutboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairRating: 3 out of 5 stars3/5 (1)

- ZF Rack and Pinion Power Steering Gears: For Passenger Cars and Light Commercial VehiclesDocument14 pagesZF Rack and Pinion Power Steering Gears: For Passenger Cars and Light Commercial VehiclesAniket SankpalNo ratings yet

- ZFPumpen E 08Document22 pagesZFPumpen E 08help3rNo ratings yet

- Heui PDFDocument42 pagesHeui PDFMarlon Montenegro100% (12)

- Aprilia 3-Phase Recharging System DiagnosisDocument15 pagesAprilia 3-Phase Recharging System DiagnosisManuallesNo ratings yet

- 14 CUX Cold Start UpdateDocument16 pages14 CUX Cold Start UpdateAldous Cosmo GitlesNo ratings yet

- Engine Brake Tests (Mack E-Tech™ Engine With J-Tech™ Engine Brake) Operational TestsDocument10 pagesEngine Brake Tests (Mack E-Tech™ Engine With J-Tech™ Engine Brake) Operational TestsVictor ValenciaNo ratings yet

- Starting SystemDocument21 pagesStarting Systemmkisa70No ratings yet

- SM 11Document40 pagesSM 11Robert CooperNo ratings yet

- Piaggio 3 Phase Charging CheckingDocument15 pagesPiaggio 3 Phase Charging Checkingminekkell1No ratings yet

- Ignition System OperationDocument28 pagesIgnition System OperationAllen CastorNo ratings yet

- PL Starting 8B - 1Document8 pagesPL Starting 8B - 1Pelis CloneNo ratings yet

- Starting System Safety PrecautionDocument38 pagesStarting System Safety PrecautionsolomonNo ratings yet

- Starting System Guide for Complete Diagnosis and RepairDocument14 pagesStarting System Guide for Complete Diagnosis and RepairLiliana Rebeca Santos santosNo ratings yet

- 175 Alternators - KTRv3Document17 pages175 Alternators - KTRv3Quintin Du PlooyNo ratings yet

- Chrysler Charging SystemDocument23 pagesChrysler Charging SystemFred Passeau100% (1)

- E 391 Manual 1Document6 pagesE 391 Manual 1naruto akatcyNo ratings yet

- Onan RV Troubleshooing GuideDocument17 pagesOnan RV Troubleshooing GuideJohn Larson100% (3)

- Starter Chevrolet S10Document22 pagesStarter Chevrolet S10Maxi SardiNo ratings yet

- Carolina CAT Construction Equipment Starter Systems GuideDocument49 pagesCarolina CAT Construction Equipment Starter Systems GuideSundar MahalingamNo ratings yet

- Basic TroubleshootingDocument3 pagesBasic TroubleshootingJeremy RydmanNo ratings yet

- Engine Electrical System OverviewDocument28 pagesEngine Electrical System Overview2791957No ratings yet

- Onan RV Troubleshooting GuideDocument17 pagesOnan RV Troubleshooting GuideBruce EgglestonNo ratings yet

- Engine StartDocument7 pagesEngine StartThwin Zaw BoNo ratings yet

- Prueba de Motor c6.6Document7 pagesPrueba de Motor c6.6hyromecNo ratings yet

- 2002-04 Ford Escape Starting and Charging Systems GuideDocument26 pages2002-04 Ford Escape Starting and Charging Systems GuideluisNo ratings yet

- Venox 16-18Document22 pagesVenox 16-18Fernando HenaoNo ratings yet

- WJ - 00 - 08B - Starting SystemDocument12 pagesWJ - 00 - 08B - Starting SystemCesar BartzNo ratings yet

- Cb750 Service 2Document136 pagesCb750 Service 2gabimaier31No ratings yet

- Voltage During CrankingDocument5 pagesVoltage During CrankingGomzalez Bin GembozNo ratings yet

- Charging System Troubleshooting (1406) : Instrucción EspecialDocument16 pagesCharging System Troubleshooting (1406) : Instrucción EspecialMiguel GutierrezNo ratings yet

- A Map Battery WebDocument2 pagesA Map Battery WebCornel BicaNo ratings yet

- Group 14 Starting SystemDocument10 pagesGroup 14 Starting SystemMister_YNo ratings yet

- TJ Starting Systems 8B - 1Document10 pagesTJ Starting Systems 8B - 1Art DoeNo ratings yet

- Starter Circuit TroubleshootingDocument5 pagesStarter Circuit Troubleshootingeshopmanual limaNo ratings yet

- PEEC Electronic System Functional TestsDocument66 pagesPEEC Electronic System Functional TestsRichard Chua0% (1)

- ESP-Operation & Trouble ShootingDocument11 pagesESP-Operation & Trouble ShootingnawarsNo ratings yet

- Manual Luv Motor C22neDocument0 pagesManual Luv Motor C22neEfrain ContrerasNo ratings yet

- Engine Cranks But Does Not StartDocument5 pagesEngine Cranks But Does Not StartNay Soe100% (1)

- Hks EvcDocument16 pagesHks EvcKok Leong WongNo ratings yet

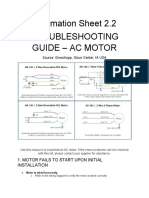

- Information Sheet 2.2 Troubleshooting Guide - Ac Motor: Source: Groschopp, Sioux Center, IA USADocument4 pagesInformation Sheet 2.2 Troubleshooting Guide - Ac Motor: Source: Groschopp, Sioux Center, IA USAthereseNo ratings yet

- 1.troubleshoot Engine Crank But Cant StartDocument3 pages1.troubleshoot Engine Crank But Cant StartsyahrilNo ratings yet

- 6-06 Starting SystemDocument23 pages6-06 Starting SystemJ.A.G.ANo ratings yet

- Troubleshooting Your TBI Fuel Injection SystemDocument24 pagesTroubleshooting Your TBI Fuel Injection SystemAndres Enrique Gonzalez GilNo ratings yet

- Lucas Fault Diagnosis Service ManualDocument48 pagesLucas Fault Diagnosis Service ManualStephen RöhmNo ratings yet

- Generator, Starter, Battery and Spark Plug Repair InstructionsDocument10 pagesGenerator, Starter, Battery and Spark Plug Repair InstructionsSoporte Tecnico AutoMotrixNo ratings yet

- Testing The Starter On The Engine (1453,1450,1401)Document6 pagesTesting The Starter On The Engine (1453,1450,1401)Cristopher LaosNo ratings yet

- Pump ED 101: Centrifugal Pump Motor Selection, Installation & Start UpDocument5 pagesPump ED 101: Centrifugal Pump Motor Selection, Installation & Start Upabdulyunus_amirNo ratings yet

- Data-Tech 1995 Nissan Pickup - Motor Sistema Controles - 3.0L Pruebas BasicasDocument5 pagesData-Tech 1995 Nissan Pickup - Motor Sistema Controles - 3.0L Pruebas BasicasRubenNo ratings yet

- ESP Operation and Troubleshooting GuideDocument11 pagesESP Operation and Troubleshooting GuideJayNo ratings yet

- Lichtmaschine BoschDocument23 pagesLichtmaschine BoschJames PonzoNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsFrom EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsNo ratings yet

- Lenksysteme NKW eDocument40 pagesLenksysteme NKW eKabilan Muthukannan100% (2)

- Alternator Prestolite 4000Document4 pagesAlternator Prestolite 4000help3rNo ratings yet

- PDF Manual r900 With Mondial Amp Cat 70Document48 pagesPDF Manual r900 With Mondial Amp Cat 70help3rNo ratings yet

- Owner'S Manual: Automatic Positive Locking Traction DifferentialDocument24 pagesOwner'S Manual: Automatic Positive Locking Traction Differentialhelp3r0% (1)

- Delco 10SI TechnicalDocument8 pagesDelco 10SI Technicalhelp3rNo ratings yet

- Czujniki Temperatury MOTOMETERDocument7 pagesCzujniki Temperatury MOTOMETERhelp3rNo ratings yet

- Volvo Penta 2002 WorkshDocument35 pagesVolvo Penta 2002 Workshhelp3rNo ratings yet

- CX New EngineDocument68 pagesCX New Enginehelp3r100% (1)

- Alternators ISKRADocument21 pagesAlternators ISKRAhelp3rNo ratings yet

- Lenksysteme NKW eDocument40 pagesLenksysteme NKW eKabilan Muthukannan100% (2)

- Rozruszniki DensoDocument2 pagesRozruszniki Densohelp3rNo ratings yet

- Conectores IIDocument404 pagesConectores IIPancho CamposNo ratings yet

- 3334SIDocument30 pages3334SIElectrival Tcataller0% (1)

- Delco - 44MT BrochureDocument4 pagesDelco - 44MT Brochurehelp3rNo ratings yet

- Denso r5 App Guide d1473.331Document28 pagesDenso r5 App Guide d1473.331help3rNo ratings yet

- Denso r5 App Guide d1473.331Document28 pagesDenso r5 App Guide d1473.331help3rNo ratings yet

- Heavy Duty Starters for Toughest EnginesDocument2 pagesHeavy Duty Starters for Toughest Engineshelp3rNo ratings yet

- R5.0 Starters for On-Road Applications Quick Reference GuideDocument2 pagesR5.0 Starters for On-Road Applications Quick Reference Guidehelp3rNo ratings yet

- Industrial VDO CatalogDocument44 pagesIndustrial VDO Cataloghelp3rNo ratings yet

- Rozruszniki DensoDocument2 pagesRozruszniki Densohelp3rNo ratings yet

- High torque. Outstanding durability. So you can be stress freeDocument2 pagesHigh torque. Outstanding durability. So you can be stress freehelp3rNo ratings yet

- DENSO 24v Planetary Gear Redution Starter Sell SheetDocument2 pagesDENSO 24v Planetary Gear Redution Starter Sell Sheethelp3rNo ratings yet

- Delco - 44MT BrochureDocument4 pagesDelco - 44MT Brochurehelp3rNo ratings yet

- Delco 2009Document0 pagesDelco 2009JIMJEONo ratings yet

- Rozruszniki DIXI DENSODocument0 pagesRozruszniki DIXI DENSOhelp3rNo ratings yet

- Wp220 Service ManualDocument0 pagesWp220 Service Manualhelp3rNo ratings yet

- AZ D Permanent Magnet Starter Motors GuideDocument32 pagesAZ D Permanent Magnet Starter Motors Guidehelp3rNo ratings yet

- TaxonomyDocument3,060 pagesTaxonomyDia Putranto HarmayNo ratings yet

- Panduan PPM D375A-5Document33 pagesPanduan PPM D375A-5aarizal100% (1)

- 2005 Seadoo 4 Tech Shop ManualDocument314 pages2005 Seadoo 4 Tech Shop Manualkatsika11100% (2)

- Summer Training Report On Shri Ram Piston and Rings LimitedDocument89 pagesSummer Training Report On Shri Ram Piston and Rings LimitedKevin Joy75% (4)

- Pooley SDocument83 pagesPooley SPratham SinhaNo ratings yet

- Ficha Tecnica de MotorDocument4 pagesFicha Tecnica de MotorIuri BragaNo ratings yet

- Vanos ErrorDocument4 pagesVanos ErrorRaphael De Marco100% (1)

- Planning of Optimal Power SystemsDocument9 pagesPlanning of Optimal Power Systemsaliscribd46No ratings yet

- BlowerDocument18 pagesBlowerLuwīsi Karikamo RomaniNo ratings yet

- Engine System and ComponentsDocument18 pagesEngine System and ComponentsGb NYlztEn100% (1)

- Mahle GrafalDocument273 pagesMahle GrafalErnesto CruzaltaNo ratings yet

- Dongtai Catalog2022.4.29Document335 pagesDongtai Catalog2022.4.29Flores Brayan100% (1)

- Excatavor Doosan DX300 LCADocument3 pagesExcatavor Doosan DX300 LCAAndini M. Patria100% (1)

- Denso Inj PDFDocument1 pageDenso Inj PDFອູ່ ໄຊ ອິນເຕີNo ratings yet

- SPC Avenger 160 Street Rev 03 Dec 19Document82 pagesSPC Avenger 160 Street Rev 03 Dec 19Bharat Malviya50% (2)

- Polaris Trail 600-RMK Switchback Service - Manual - 2005Document308 pagesPolaris Trail 600-RMK Switchback Service - Manual - 2005Valerică HizanuNo ratings yet

- Cartilla de Reparacion Corolla Negro KINALDocument10 pagesCartilla de Reparacion Corolla Negro KINALNico ArtNo ratings yet

- 192 Engine Parts manual-MYDocument18 pages192 Engine Parts manual-MYDuvan Garridt MillanNo ratings yet

- Chapter 7 ThermodynamicDocument56 pagesChapter 7 ThermodynamicshahrulNo ratings yet

- Hyster Reachstacker RS45-27 RS45-31 RS46-36 RS46-41L RS46-41S RS46-41LS (C222) Parts ManualDocument822 pagesHyster Reachstacker RS45-27 RS45-31 RS46-36 RS46-41L RS46-41S RS46-41LS (C222) Parts ManualProsperino Peña100% (2)

- Petronas Urania CF: High-Performance Single Grade Diesel Engine Oils Exceeding API Service CF Performance LevelsDocument1 pagePetronas Urania CF: High-Performance Single Grade Diesel Engine Oils Exceeding API Service CF Performance Levelsbarrysmith77No ratings yet

- Engine Rebuild Guide for 2007 Ford Expedition 5.4LDocument58 pagesEngine Rebuild Guide for 2007 Ford Expedition 5.4LGeorgy AlmeidaNo ratings yet

- 006 - 1.6 L Engine Marelli 1AV 55 KW, Engine Code Letters ALMDocument9 pages006 - 1.6 L Engine Marelli 1AV 55 KW, Engine Code Letters ALMAndres ChoqueNo ratings yet

- Ejector Type Nozzle & Thrust ReversalDocument9 pagesEjector Type Nozzle & Thrust ReversalAnonymous VKv75qe98No ratings yet

- Cylinder Liner: SpecificationsDocument2 pagesCylinder Liner: SpecificationsGolbert GolbiNo ratings yet