Professional Documents

Culture Documents

Tender #1796 MSP049 Shop Painting

Uploaded by

iwantheaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tender #1796 MSP049 Shop Painting

Uploaded by

iwantheaCopyright:

Available Formats

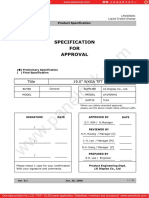

PT.

INTERNATIONAL NICKEL INDONESIA

SPECIFICATION NO. TITLE : SHOP PAINTING

MSP.049

Rev.0

PAGE 1 OF 5 EWR

CONTENTS

1.0 2.0 3.0

SCOPE EQUIPMENT AND MATERIALS TO BE PAINTED DETAILS OF CONSTRUCTION

0

REV. NO . ISSUE DATE APPROVAL QUOTATION PURCHASE OTHER (SPECIFY) JOB ENGR. SUPV. ENGR. PROJ. ENGR. SUPT. ENGG. OWNER

DATE

REMARKS

APPROVAL

PT. INTERNATIONAL NICKEL INDONESIA

SPECIFICATION NO. TITLE : SHOP PAINTING 1.0. 1.1.

MSP.049

Rev.0

PAGE 2 OF 5 EWR

Scope The VENDOR shall furnish all materials, tools, equipment, and labor required for safe and satisfactory shop painting. These shall include : 1. 2. 3. Preparation of the surfaces to be painted. Prime coat painting. Finish coat painting (where specified).

2.0. 1.2. 2.2. 2.3.

Equipment and Materials to be Painted All structural and plate steel (such as beams, columns, trusses, brackets, supports, handrails, ladders, stairs, etc) shall be shop primed. All carbon steel chutes, ductwork, stacks, hoods, etc, shall be shop primed. All mechanical equipment (such as pumps, fans, conveyors, speed reducers, motors, electrical and control panels, etc) shall be shop primed and painted with Manufacturers Standard finish coat. Items with hot metal surfaces such as dryers, kilns, or electric furnace shells require no paint. Details of Construction No painting or finishing shall be done when the air is dust laden or the surface temperature of material to be painted is below dew point resulting in the condensation of moisture. Paints of different sources and composition shall not be mixed together. Where necessary to suit surface conditions and where areas to be painted are exposed to high temperatures, the method of modifying paint and its applications shall be performed in strict accordance with the paint manufacturers written directions, but in no case shall the use of thinners exceed one pint per gallon of paint. The use of thinner for any reason shall not relieve the VENDOR from obtaining complete hiding of each coat of paint. Equipment surfaces to be painted shall be dry, free from dirt, grease, corrosive scale, loose rust, welding slag before applying primer and paint or finish coat. Oil and grease shall be removed with clean cloths and cleaning solvents prior to mechanical cleaning. Cleaning and painting shall be so programmed that dust and other contaminants shall not fall on wet or newly painted surfaces. No stainless steel or non-ferrous metal surfaces shall be painted. Cleaning and Painting Application (Base Quote)

3.0. 3.1. 3.2.

3.3.

3.4. 3.5

PT. INTERNATIONAL NICKEL INDONESIA

SPECIFICATION NO. TITLE : SHOP PAINTING 3.5.1. 3.5.2.

MSP.049

Rev.0

PAGE 3 OF 5 EWR

Any traces of oil, grease, welding flux residues and salts shall first be removed by solvent cleaning methods as outlined in Specification SSPC-SP-1-63. All surfaces to be coated shall be cleaned of all loose mill scale and all loose or non-adherent rust and all loose paint by one or more of the following methods : 3.5.2.1. Power wirebrushing 3.5.2.2. Power impact tool cleaning 3.5.2.3. Power grinding

3.5.3. 3.5.4.

All cleaned surfaces shall be subject to inspection by Owners Representative at all times. The cleaned surfaces shall be free of dust and other loose matter. If detrimental amounts of grease or oil are still present, these areas shall be spot cleaned with solvent. The prime coat of paint shall be applied as soon as possible after cleaning and before further deterioration of the surface occurs. The resultant surface preparation shall conform to Steel Structures Painting council Surface Preparations Power Tool Cleaning (SSPC-SP-3-63). Apply one coat of red oxide primer. Apply one coat oil base Enamel as the finish coat. The total mid thickness shall be 1.5 to 2 mils.

3.5.5. 3.5.6. 3.5.7. 3.5.8. 3.5.9 3.6.

Cleaning and Painting Application (Option A) 3.6.1. 3.6.2. Any traces of oil or grease shall be removed by solvent washing before blasting, SSPC-SP-1-63 solvent cleaning. All weld spatter or buckshot shall be removed prior to the blasting operation.

PT. INTERNATIONAL NICKEL INDONESIA

SPECIFICATION NO. TITLE : SHOP PAINTING 3.6.3.

MSP.049

Rev.0

PAGE 4 OF 5 EWR

The resultant surface preparation, after the blasting operation, shall conform to Steel Structures Painting Council Surface Preparations Commercial Blast Cleaning, (SSPC-SP6-63). Apply one coat anti-corrosive primer (Nor-Var X131 or equal) Apply one coat red anti-corrosive (Nor-Var 256 or equal) as the finish coat. The total mil thickness should be 1.5-2 mils

3.6.4. 3.6.5. 3.6.6. 3.7.

Cleaning and Painting Application (Option B) 3.7.1. Same as Option A but the total thickness should be 3 mils.

3.8.

Application of Primer to Structural Steel 3.8.1. Coating applications shall be done in accordance with paint manufacturers recommendations and will be subject to inspection of Owners Representative at all times. Label directions must be read and followed. All spray equipment shall be inspected and approved by Owners Representative before any application is begun. A moisture trap shall be placed in line with the air supply to the pressure pot and spray gun. This trap shall be opened slightly to provide a continuous bleed. Pots shall be equipped with air activated agitators which shall be kept in motion at all times. Regulators and gauges shall be provided for air to both pressure pot and spray gun. Coating shall not be applied closer than 6 inches to 9 non-blasted surface area. No coating shall take place when the atmospheric temperature is below 400F.

3.8.2. 3.8.3. 3.8.4.

3.8.5. 3.8.6

PT. INTERNATIONAL NICKEL INDONESIA

SPECIFICATION NO. TITLE : SHOP PAINTING

MSP.049

Rev.0

PAGE 5 OF 5 EWR

3.8.7. Spray guns must be held perpendicular to the surface being sprayed and handled and adjusted in such a manner that dry overspray is kept to a minimum. 3.8.8 No steel shall be subjected to abrasion until the coating is dry to the touch and cannot be removed from the substrate with the thumbnail.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- IE 337: Materials & Manufacturing Processes: Metal Forming Operations 2Document31 pagesIE 337: Materials & Manufacturing Processes: Metal Forming Operations 2silverknights007No ratings yet

- Bateman PGM Capability Edition11Document8 pagesBateman PGM Capability Edition11borgiamatriceNo ratings yet

- 1) New Firms Added: Amendment-3 To Approved List (W.e.f. 1 Jan-2021) Page 1 of 8Document8 pages1) New Firms Added: Amendment-3 To Approved List (W.e.f. 1 Jan-2021) Page 1 of 8Subrata MukherjeeNo ratings yet

- Lm190wh1 Tla1 LGDocument32 pagesLm190wh1 Tla1 LGdiegoNo ratings yet

- Rae 10.2.17Document100 pagesRae 10.2.17RaeNo ratings yet

- CVD Vs PVD Advantages and Disadvantages 98752 r0Document1 pageCVD Vs PVD Advantages and Disadvantages 98752 r0Nuradityatama AditNo ratings yet

- About Welding Process 27Document1 pageAbout Welding Process 27XerexNo ratings yet

- Catalog SAE1075Document84 pagesCatalog SAE1075Woong BangNo ratings yet

- Special Steels 3Document100 pagesSpecial Steels 3ramanamurtytv7176No ratings yet

- Unconventional Machining Process Anna University SyllabusDocument6 pagesUnconventional Machining Process Anna University Syllabusabdur rahman100% (1)

- Ucm Anna Univ Question PapersDocument24 pagesUcm Anna Univ Question PapersNarayanan SubramanianNo ratings yet

- Arc Welding - Introduction and FundamentalsDocument30 pagesArc Welding - Introduction and FundamentalsShantha Kumar G C50% (2)

- Resistance WeldingDocument7 pagesResistance WeldingCristian GonzálezNo ratings yet

- Graphics Timeline 1Document5 pagesGraphics Timeline 1api-358369971No ratings yet

- A473 PDFDocument5 pagesA473 PDFYury100% (1)

- Asic Interview QuestionsDocument2 pagesAsic Interview Questionspritam044No ratings yet

- Alniz Display Catalogue - 2019Document187 pagesAlniz Display Catalogue - 2019Barış GürençNo ratings yet

- Welding TechnologyDocument18 pagesWelding TechnologySanjoy Biswas100% (3)

- Metallurgy of CopperDocument21 pagesMetallurgy of CopperhanyNo ratings yet

- The Specification For Stainless SteelDocument9 pagesThe Specification For Stainless SteelGangadhar Yeddala100% (1)

- Forging and Sheet Metal FormingDocument83 pagesForging and Sheet Metal FormingnvemanNo ratings yet

- Dwnload Full Microbiology An Introduction 10th Edition Tortora Test Bank PDFDocument35 pagesDwnload Full Microbiology An Introduction 10th Edition Tortora Test Bank PDFgambolrapinous.ggqcdr100% (7)

- AC7102.1D Nadcap Audit Criteria For BrazingDocument11 pagesAC7102.1D Nadcap Audit Criteria For BrazingrsjfidderNo ratings yet

- 2 Shortlist For VerificationDocument9 pages2 Shortlist For VerificationKinley WangdiNo ratings yet

- Brazing and Soldering - Learn Refrigeration PDFDocument2 pagesBrazing and Soldering - Learn Refrigeration PDFAblePraxisNo ratings yet

- Finfet Application Operation PDFDocument7 pagesFinfet Application Operation PDFSatishEducatioNo ratings yet

- Aluminum in AircraftDocument117 pagesAluminum in AircraftMark Evan Salutin91% (11)

- Motherboard The Common MOSFET (FET) Substitution TableDocument3 pagesMotherboard The Common MOSFET (FET) Substitution TableDhruv Gonawala100% (3)

- Lecture 5Document17 pagesLecture 5MuhammadFarooq44No ratings yet

- Sample RFQ For PrinterDocument1 pageSample RFQ For Printerjasy tevesNo ratings yet