Professional Documents

Culture Documents

Two-Phase Flow - Condensate Drain Lines Design Guide

Uploaded by

c_nghiaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Two-Phase Flow - Condensate Drain Lines Design Guide

Uploaded by

c_nghiaCopyright:

Available Formats

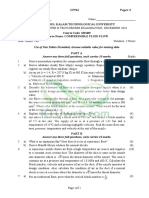

PROCEDURE NO.

PAGE

OF

PTD-DGS-120

PREPARED BY

1

DATE

PROCESS TECHNOLOGY PROCEDURES

DEPART,ENTSUB%ECT-

Edited from existi ! do" #$ %.R. B&r '&rt

APPRO/ED BY

A(ri) *0+ 2000

PROCESS ENG.NEER.NG

%RB

RE/.S.ON DATE RE/.

T0O-P1ASE F2O0 3 CONDENSATE DRA.N 2.NES DES.GN GU.DE

11401402

1.0

SCOPE

This design guide1 defines line sizing for condensate drain lines. 2.0 RESPONSIBILITIES

The process engineer is responsible for sizing condensate drain lines. 3.0 CONDENSATE LOADS 3.1 Determination

The condensate load is determined by the instantaneous discharge rate of the steam trap. Intermittent drain traps (e.g., the impulse type) discharge condensate intermittently at the rated capacity of the traps. Continuous drain traps (e.g., the float and thermostatic type) discharge condensate as it is formed. 3.2 Intermittent Tra !

For intermittent traps, the condensate return line must be sized to simultaneously handle the total instantaneous discharge of the steam traps. For most loads, assume 5 percent of the traps discharge simultaneously. For !ery hea!y loads, assume " to # percent of the traps $ill discharge simultaneously. 3.3 Contin"o"! Tra !

For continuous traps, the condensate line must be sized to handle the total condensing rate of all the e%uipment being drained. 3.# Boi$er B$o%&o%n Line!

&oiler blo$do$n lines must be the same size as the boiler blo$do$n !al!e connection, usually as determined by the boiler manufacturer. #.0 PROCEDURE

Re5. 0 of t'e Desi! G6ide 7&s &d&(ted 7it' mi im&) "'& !es from & P&s&de & do"6me t+ DSG-,P8G+ 9492

PROCEDURE NO.

RE/.

DATE

PAGE OF

PTD-DGS-120 T0O-P1ASE F2O0 3 CONDENSATE DRA.N 2.NES DES.GN GU.DE

10

11401402

#.1

Determine Steam'Li("i& )$o%rate!

Find' Flo$rate for steam and li%uid at the condensate recei!er inlet h h WS = L1 L ( hv WL = W WS $here' , - condensate flo$rate, pound.hour , / - flo$rate of steam at condensate recei!er inlet, pound.hour , 0 - flo$rate of li%uid at condensate recei!er inlet, pounds.hour h01 - enthalpy of li%uid at trap inlet, &ritish thermal unit (&tu).pound h0( - enthalpy of li%uid at recei!er inlet, &tu.pound h! - latent heat of !aporization at recei!er conditions, &tu.pound #.2 Si*in+ Ret"rn Line! ()%. *+1)

()%. *+()

,hen hot condensate is discharged into a return line, some flashes into steam. The return line must be sized to handle the t$o+phase flo$ that results. The ma1imum acceptable !elocity is 23 feet.second, for mi1ed+phase flo$. 4se the flo$rates calculated in e%uations *+1 and *+( and the physical properties of the flashed steam and li%uid at recei!er conditions, as inputs to a flo$ computer program, to determine line size and pressure drop.

You might also like

- Validation Report On The 2 Phase Line Sizing 3 PDFDocument18 pagesValidation Report On The 2 Phase Line Sizing 3 PDFJoseph MedinaNo ratings yet

- Calculate Saturated-Gas Loads For Vacuum SystemsDocument3 pagesCalculate Saturated-Gas Loads For Vacuum SystemsFred FaberNo ratings yet

- GoyalDocument3 pagesGoyalVan LeNo ratings yet

- Section 7 - Separation EquipmentDocument9 pagesSection 7 - Separation Equipmentlulis171No ratings yet

- Tank Venting Capacity-Fire CaseDocument1 pageTank Venting Capacity-Fire CaseAjay TiwariNo ratings yet

- Distillation Column: Major Equipment DesignDocument45 pagesDistillation Column: Major Equipment Designrubesh_rajaNo ratings yet

- 2 Phase Seperator PDFDocument66 pages2 Phase Seperator PDFKanthan DevanNo ratings yet

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 pagesSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801No ratings yet

- Process Design: Vessel Sizing (Liquid & Vapour Separators)Document36 pagesProcess Design: Vessel Sizing (Liquid & Vapour Separators)Krishanu SahaNo ratings yet

- Thermosyphon Reboiler HydraulicsDocument2 pagesThermosyphon Reboiler HydraulicsMichael HaiseNo ratings yet

- Process Engineer - PSV SizingDocument3 pagesProcess Engineer - PSV SizingLaorenciaNo ratings yet

- Reboiler HydraulicDocument3 pagesReboiler Hydraulic54yreyeNo ratings yet

- Flow and Pressure Drop in Valves and Fittings. Valve Resistance Coefficient and DiameterDocument21 pagesFlow and Pressure Drop in Valves and Fittings. Valve Resistance Coefficient and Diameterjroman33No ratings yet

- Design Practices - SVsDocument12 pagesDesign Practices - SVsagarwalashwin32No ratings yet

- Cálculo de Eficiencia de Un HornoDocument29 pagesCálculo de Eficiencia de Un HornoFranklin Santiago Suclla PodestaNo ratings yet

- Separator SizingDocument16 pagesSeparator SizingMichael J. BaneNo ratings yet

- Process Calculation Sheet Tag No.: 1. PurposeDocument10 pagesProcess Calculation Sheet Tag No.: 1. PurposeAJAY1381No ratings yet

- Thermosyphon Reboiler (Horizontal) GPSADocument6 pagesThermosyphon Reboiler (Horizontal) GPSAsyamsudin2006No ratings yet

- Volume and Wetted Area of Partially Filled Horizontal VesselsDocument11 pagesVolume and Wetted Area of Partially Filled Horizontal VesselsMelvin MagbanuaNo ratings yet

- TECHNOLOGY New Program Sizes Pressure-Relief Drums: CloseDocument7 pagesTECHNOLOGY New Program Sizes Pressure-Relief Drums: CloseCalcetinNo ratings yet

- Offsites and UtilitiesDocument70 pagesOffsites and Utilitiesankitalalwani100% (1)

- PSVDocument1 pagePSVsalman ahmedNo ratings yet

- RD 810Document73 pagesRD 810Ashish MishraNo ratings yet

- Restriction Orifice Flow Control GuideDocument3 pagesRestriction Orifice Flow Control Guidemsr22No ratings yet

- Friction LossesDocument34 pagesFriction LossesTahaNo ratings yet

- Pump CalcDocument1 pagePump CalcMoch WildanNo ratings yet

- Process Calculation ManualDocument13 pagesProcess Calculation ManualDHAVAL PANCHALNo ratings yet

- Dresser Italia S.r.l. Safety Relief Valve ReportDocument4 pagesDresser Italia S.r.l. Safety Relief Valve Reportwinlugue3059No ratings yet

- Operating case simulation and hydraulic calculationDocument2 pagesOperating case simulation and hydraulic calculationsri9987No ratings yet

- PSV Sizing - Blocked Outlet GasDocument1 pagePSV Sizing - Blocked Outlet GasSilas Onyekwe100% (1)

- Class Example Pump Sizing-Module 5 - Sep28Document6 pagesClass Example Pump Sizing-Module 5 - Sep28Stefan De BeerNo ratings yet

- A New Approach For Finger Storage Slug CatcherDocument8 pagesA New Approach For Finger Storage Slug CatcherfanziskusNo ratings yet

- Flare Knock Out Drum Sizing ReportDocument4 pagesFlare Knock Out Drum Sizing ReportSaid Ahmed Salem100% (1)

- Pumping TrapsDocument36 pagesPumping TrapsjonathanyflorenciaNo ratings yet

- Air Receivers Volume CalculationDocument123 pagesAir Receivers Volume CalculationsdgthdtrtretNo ratings yet

- Vent Line Pressure Drop CalculationDocument4 pagesVent Line Pressure Drop CalculationRubensBoerngenNo ratings yet

- Infytq With SolutionsDocument37 pagesInfytq With SolutionsÃbhilâśh Rêddÿ100% (1)

- Volume and Wetted Area of Partially Filled Vertical Vessels - Neutrium PDFDocument12 pagesVolume and Wetted Area of Partially Filled Vertical Vessels - Neutrium PDFdaimon_p100% (1)

- Sizing, Specifying and Selecting Centrifugal Pumps (CE) PDFDocument5 pagesSizing, Specifying and Selecting Centrifugal Pumps (CE) PDFjdgh1986100% (1)

- Tank CalcDocument21 pagesTank CalcInggitNo ratings yet

- Liquid Distributor DesignDocument3 pagesLiquid Distributor Designanon_414493592No ratings yet

- Bulk Water SeparationDocument1 pageBulk Water SeparationSean MiddletonNo ratings yet

- Recip Compressor Calculations For GCP-3Document4 pagesRecip Compressor Calculations For GCP-3Greg GolushkoNo ratings yet

- Structured PackingDocument8 pagesStructured PackingUsama IqbalNo ratings yet

- Mihir's Handbook Chapter 7Document10 pagesMihir's Handbook Chapter 7heyheyNo ratings yet

- Selección de CompresoresDocument23 pagesSelección de CompresoresjowarNo ratings yet

- Shell K.O.drum SeparatorDocument11 pagesShell K.O.drum SeparatorChitu Ionut LaurentiuNo ratings yet

- Demister DatasheetDocument1 pageDemister Datasheetdeion29No ratings yet

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2Document33 pagesSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2MaheshNo ratings yet

- Plant Air SystemDocument7 pagesPlant Air SystemAnuj ShahiNo ratings yet

- Sample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Document15 pagesSample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Mustafa AhsanNo ratings yet

- Calculation Sheet For Pump Hydraulic (Fps Unit)Document1 pageCalculation Sheet For Pump Hydraulic (Fps Unit)chemical todiNo ratings yet

- 750-326 Blowdown Separator 11 2015Document10 pages750-326 Blowdown Separator 11 2015osamaNo ratings yet

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityDocument7 pagesMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHINo ratings yet

- Simple ORC Model SQ110918Document9 pagesSimple ORC Model SQ110918radanpetricaNo ratings yet

- Tube Rupture Relief CalculationDocument1 pageTube Rupture Relief CalculationAmin RoisNo ratings yet

- Vapor Liquid Equilibrium of Water + Ethanol + GlycerolDocument8 pagesVapor Liquid Equilibrium of Water + Ethanol + GlycerolcsandrasNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- g01 PDFDocument1 pageg01 PDFpradeepdesaiuchNo ratings yet

- Feb 10Document46 pagesFeb 10c_nghiaNo ratings yet

- Feb 10Document29 pagesFeb 10c_nghia100% (1)

- Feb 10Document38 pagesFeb 10c_nghiaNo ratings yet

- Heat Exchanger Student HandoutDocument39 pagesHeat Exchanger Student HandoutkotiNo ratings yet

- Feb 10Document50 pagesFeb 10c_nghiaNo ratings yet

- Jul 98Document38 pagesJul 98c_nghia100% (2)

- Feb 10Document55 pagesFeb 10c_nghiaNo ratings yet

- Feb 10Document59 pagesFeb 10c_nghiaNo ratings yet

- Feb 10Document41 pagesFeb 10c_nghiaNo ratings yet

- Dec 07Document44 pagesDec 07c_nghiaNo ratings yet

- Nov 09Document23 pagesNov 09c_nghiaNo ratings yet

- Instrument Signal LineDocument62 pagesInstrument Signal Linedewking198875% (4)

- Jan 10Document45 pagesJan 10c_nghia100% (1)

- Sep 02Document44 pagesSep 02c_nghiaNo ratings yet

- Dec 08Document31 pagesDec 08c_nghia100% (1)

- Mar 09Document30 pagesMar 09c_nghia100% (1)

- Dec 07Document55 pagesDec 07c_nghia100% (1)

- Jul 97Document28 pagesJul 97c_nghiaNo ratings yet

- Nov 09Document30 pagesNov 09c_nghiaNo ratings yet

- Jul 08Document61 pagesJul 08c_nghiaNo ratings yet

- Dec 08Document45 pagesDec 08c_nghia100% (1)

- Sep 09Document24 pagesSep 09c_nghia50% (2)

- Jan 98Document30 pagesJan 98c_nghiaNo ratings yet

- Jul 97Document35 pagesJul 97c_nghiaNo ratings yet

- Dec 98Document25 pagesDec 98c_nghia100% (1)

- May 2011Document33 pagesMay 2011c_nghia100% (1)

- Jul 97Document41 pagesJul 97c_nghiaNo ratings yet

- Jul 97Document68 pagesJul 97c_nghia100% (1)

- Jan 10Document44 pagesJan 10c_nghiaNo ratings yet

- Sep 02Document19 pagesSep 02c_nghia100% (1)

- Schematics of A Refrigeration Cycle: Air ConditionerDocument1 pageSchematics of A Refrigeration Cycle: Air ConditionerAndre EinsteinNo ratings yet

- Use of Gas Tables Permitted, Assume Suitable Value For Missing DataDocument2 pagesUse of Gas Tables Permitted, Assume Suitable Value For Missing DataVenkitaraj K PNo ratings yet

- Norcold 6162Document41 pagesNorcold 6162w4445555100% (1)

- Be Summer 2020Document2 pagesBe Summer 2020dhruvNo ratings yet

- Downterm ADocument2 pagesDownterm Awiyatmi0% (1)

- Heat Transfer Module Users GuideDocument702 pagesHeat Transfer Module Users GuideMerroun OssamaNo ratings yet

- Relativistic Kinematics: Raghunath Sahoo Indian Institute of Technology Indore, India-452020Document41 pagesRelativistic Kinematics: Raghunath Sahoo Indian Institute of Technology Indore, India-452020aleacunia87No ratings yet

- What Is A Buck Boost ConverterDocument4 pagesWhat Is A Buck Boost ConverterXavierNo ratings yet

- E103 - Lab ReportDocument7 pagesE103 - Lab ReportJamiel CatapangNo ratings yet

- Thermal Physics Unit Test High Level Paper 1: Instructions To CandidatesDocument10 pagesThermal Physics Unit Test High Level Paper 1: Instructions To Candidates黃涵涵No ratings yet

- Review Sheet For Newton's Laws Test 15Document3 pagesReview Sheet For Newton's Laws Test 15api-237866679No ratings yet

- 4 Standards For AC Motors PDFDocument37 pages4 Standards For AC Motors PDFEdú BrizuelaNo ratings yet

- Refrigeration Cycle ExperimentDocument10 pagesRefrigeration Cycle ExperimentJay NgNo ratings yet

- A. Doolitle - Introduction To Quantum Mechanics PDFDocument36 pagesA. Doolitle - Introduction To Quantum Mechanics PDFSebastian DuarteNo ratings yet

- Unit 3.2: Unit 3.2 Mass-Energy RelationshipDocument33 pagesUnit 3.2: Unit 3.2 Mass-Energy RelationshipGabriel FungNo ratings yet

- KU SPH 101 Electricity and Magnetism 1 NotesDocument107 pagesKU SPH 101 Electricity and Magnetism 1 NotesCallum Fallen100% (1)

- 05 - Integration Substitution Inv TrigDocument2 pages05 - Integration Substitution Inv TrigCrystine JhayneNo ratings yet

- A Review of Redshift and Its Interpretation in Cosmology and AstrophysicsDocument16 pagesA Review of Redshift and Its Interpretation in Cosmology and AstrophysicssxcastroNo ratings yet

- Ongc Hazira Plant A Techno Commercial Insight'Document21 pagesOngc Hazira Plant A Techno Commercial Insight'Bhavesh PatelNo ratings yet

- 2660 Thomas Medical Grade Compressor For Ventilator Oxygen ConcentratorDocument1 page2660 Thomas Medical Grade Compressor For Ventilator Oxygen ConcentratorAiman HashmiNo ratings yet

- Centrifugal PumpsDocument42 pagesCentrifugal PumpsMalaku HaileNo ratings yet

- 4.1. Interaction Light-Matter 2-7-08Document10 pages4.1. Interaction Light-Matter 2-7-08mladen lakicNo ratings yet

- June 2014 (R) QP - Unit 1 Edexcel Physics A-LevelDocument28 pagesJune 2014 (R) QP - Unit 1 Edexcel Physics A-LevelArun MosesNo ratings yet

- Combinepdf - 2023-05-15T135221.088Document2 pagesCombinepdf - 2023-05-15T135221.088JKI JakartaNo ratings yet

- Electrical ElectronicsDocument92 pagesElectrical ElectronicstechNo ratings yet

- Chapter: Mechanical - Kinematics of Machinery - Kinematics of Cam Mechanisms CamsDocument25 pagesChapter: Mechanical - Kinematics of Machinery - Kinematics of Cam Mechanisms CamsdhaNo ratings yet

- Calorimetry ProblemsDocument3 pagesCalorimetry ProblemsLeticia CarandangNo ratings yet

- An Integrated Distributed Generation Optimization Model For Distribution System PlanningDocument8 pagesAn Integrated Distributed Generation Optimization Model For Distribution System PlanningPervez AhmadNo ratings yet

- TNPSC Group 2 Complete Syllabus: TNPSC Group 2 Previous Questions: TNPSC Group 2 Model QuestionsDocument7 pagesTNPSC Group 2 Complete Syllabus: TNPSC Group 2 Previous Questions: TNPSC Group 2 Model QuestionsanbuNo ratings yet

- Isc Three Terminal Negative Voltage Regulator: INCHANGE Semiconductor Product SpecificationDocument2 pagesIsc Three Terminal Negative Voltage Regulator: INCHANGE Semiconductor Product SpecificationlisbanisNo ratings yet