Professional Documents

Culture Documents

Main Component of Diesel Engine

Uploaded by

Laxman Singh SankhlaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Main Component of Diesel Engine

Uploaded by

Laxman Singh SankhlaCopyright:

Available Formats

MAIN COMPONENTS OF INTERNAL COMBUSTION ENGINES. By Er.Laxman Singh Sankhla B.E.Mech.

, Chartered Engineer Jodhpur, India Mail ID: laxman9992001@yahoo.co.in

MAIN COMPONENTS OF INTERNAL COMBUSTION ENGINES. The essential parts of a diesel engine are similar to a gas engine except for the ignition system. The combustion chamber consists of a cylinder, usually fixed, that is closed at one end in which a close-fitting piston slides. The in-and-out motion of the piston varies the volume of the chamber between the inner face of the piston and the closed end of the cylinder. The outer face of the piston is attached to a crankshaft by a connecting rod.

Figure 5.0 The crankshaft transforms the reciprocating motion of the piston into rotary motion. In multi cylindered engines the crankshaft has one offset portion, called a crankpin, for each connecting rod, so that the power from each cylinder is applied to the crankshaft at the appropriate point in its rotation. Crankshafts have heavy flywheels and counterweights, which by their inertia minimize irregularity in the motion of the

shaft. An engine may have from 1 to as many as 28 cylinders. Entire top engine section is assembled on a frame/bed plate and the frame/bed plate assembly is installed on a foundation and bolted down/grouted. The main parts of a single cylinder diesel engine are shown in Figure 5.0., and their functions are noted below: 1. Engine structure holds the cylinders, crankshaft and main bearings in firm relation to each other. This structure usually includes all the fixed parts that hold the engine together i.e. bed plate, base or pan and frame. 2. A piston sliding in a cylinder. The piston has two jobs: to compress the air charge and to receive the pressure of the gases while they are burning and expanding. A piston typically carries piston rings (compression rings for sealing the space between the liner and piston and oil control rings for scraping the oil from the liner. Piston is connected to the connecting rod by a wrist pin which moves free inside the piston bushing. 3. A cylinder head which closes the top end of the cylinder so as to make a confined space in which to compress the air and to confine the gases while they are burning or expanding. Cylinder head carries inlet and exhaust valves, injection nozzle and sometimes the air starting valve and auxiliary combustion chamber. 4. Valves or ports to admit the air and to discharge the gases. 5. Connecting rod to transmit forces in either direction between the piston and the crank of the crankshaft. It is connected to the piston through wrist pin bearing and wrist pin and at the crank shaft end by crank pin bearing to the crank shaft. 6. Crankshaft and main bearings which support the crankshaft and permit it to rotate. 7. Fuel injection pump to force the oil into the cylinder; also a fuel injection nozzle to break up the oil into a fine spray as it enters the cylinder. 8. Camshaft, driven by the crankshaft to operate the fuel injection pump and also to open the valves (in engines which use valves). Camshaft is connected to the crankshaft through camshaft timing gears for controlled motion. 9. Flywheel, to store up surplus energy on the power stroke and to return that energy when the piston is being pushed upward on the compression stroke. 10. Governor or throttle, to regulate the amount of fuel supplied at each stroke, and thus control engine speed and power. 11. Auxiliary parts such as piping to supply air and remove exhaust gases, muffler to dampen the exhaust noise, lubricating system to lubricate the moving parts, water jackets to cool the cylinders, starters to start the engine (diesel engines are not self starting), fuel supply system (tank, strainer, transfer pump, fuel piping), engine cooling system and instrumentation for engine control, safeguarding, alarm and shutdown.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Yamaha Outboard F115 Service Repair ManualDocument395 pagesYamaha Outboard F115 Service Repair Manualevangalos96% (52)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Volkswagen Jetta (A5) Service Manual: 2005-2010 - ExcerptDocument8 pagesVolkswagen Jetta (A5) Service Manual: 2005-2010 - ExcerptBentley Publishers64% (11)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- kx019 4 1 PDFDocument8 pageskx019 4 1 PDFFarNo ratings yet

- Pump Packing and Mechanical SealsDocument3 pagesPump Packing and Mechanical SealsLaxman Singh SankhlaNo ratings yet

- (Ssangyong) Manual de Taller Ssangyong Rexton 2004 2005Document1,991 pages(Ssangyong) Manual de Taller Ssangyong Rexton 2004 2005Domingo Vasquez100% (2)

- MTX - Tier 3Document330 pagesMTX - Tier 3Andrei Mihai100% (1)

- Perkins 1103 &1104 Series: Workshop Manual SpecificationsDocument42 pagesPerkins 1103 &1104 Series: Workshop Manual SpecificationsTASHKEEL100% (6)

- Centrifugal Pump Routine ChecksDocument1 pageCentrifugal Pump Routine ChecksLaxman Singh SankhlaNo ratings yet

- Radial - and Axial-Flow PumpsDocument2 pagesRadial - and Axial-Flow PumpsLaxman Singh SankhlaNo ratings yet

- Textile Yarns: Process of Yarn Manufacturing Classification of Yarns Yarn Numbering Sewing ThreadsDocument4 pagesTextile Yarns: Process of Yarn Manufacturing Classification of Yarns Yarn Numbering Sewing ThreadsLaxman Singh SankhlaNo ratings yet

- Pump Wear RingsDocument1 pagePump Wear RingsLaxman Singh Sankhla100% (1)

- Pump VoluteDocument2 pagesPump VoluteLaxman Singh SankhlaNo ratings yet

- Centrifugal Pump Operation in SeriesDocument2 pagesCentrifugal Pump Operation in SeriesLaxman Singh SankhlaNo ratings yet

- Pump ClassificationDocument3 pagesPump ClassificationLaxman Singh SankhlaNo ratings yet

- Level Control Valve - LCVDocument2 pagesLevel Control Valve - LCVLaxman Singh SankhlaNo ratings yet

- Drawing of Centrifugal PumpDocument1 pageDrawing of Centrifugal PumpLaxman Singh SankhlaNo ratings yet

- Emergency Shut Down Valves - ESDDocument2 pagesEmergency Shut Down Valves - ESDLaxman Singh SankhlaNo ratings yet

- Centrifugal Pump Drawing and PartsDocument2 pagesCentrifugal Pump Drawing and PartsLaxman Singh SankhlaNo ratings yet

- PUMP Bearing Housing and CouplingDocument2 pagesPUMP Bearing Housing and CouplingLaxman Singh SankhlaNo ratings yet

- Air Required For Combustion Per Pound of CoalDocument1 pageAir Required For Combustion Per Pound of CoalLaxman Singh SankhlaNo ratings yet

- Diaphragm Valves By: Er. Laxman Singh Sankhla B.E.Mech., Chartered Engineer Jodhpur, IndiaDocument1 pageDiaphragm Valves By: Er. Laxman Singh Sankhla B.E.Mech., Chartered Engineer Jodhpur, IndiaLaxman Singh Sankhla100% (1)

- Pressure Relief ValvesDocument1 pagePressure Relief ValvesLaxman Singh SankhlaNo ratings yet

- Check Non Return ValvesDocument3 pagesCheck Non Return ValvesLaxman Singh SankhlaNo ratings yet

- Motor Operated Valve MOVDocument1 pageMotor Operated Valve MOVLaxman Singh Sankhla100% (1)

- Globe Valves By: Er. Laxman Singh Sankhla B.E.Mech., Chartered Engineer Jodhpur, IndiaDocument1 pageGlobe Valves By: Er. Laxman Singh Sankhla B.E.Mech., Chartered Engineer Jodhpur, IndiaLaxman Singh SankhlaNo ratings yet

- SEALING OF Valves. By: Er. Laxman Singh Sankhla B.E.Mech., Chartered Engineer Jodhpur, IndiaDocument2 pagesSEALING OF Valves. By: Er. Laxman Singh Sankhla B.E.Mech., Chartered Engineer Jodhpur, IndiaLaxman Singh SankhlaNo ratings yet

- Rising Stem Gate ValveDocument1 pageRising Stem Gate ValveLaxman Singh SankhlaNo ratings yet

- Air Operated Valves AOVDocument2 pagesAir Operated Valves AOVLaxman Singh SankhlaNo ratings yet

- Function of A Valve Valve MaterialsDocument1 pageFunction of A Valve Valve MaterialsLaxman Singh SankhlaNo ratings yet

- Non Rising Stem Gate ValveDocument1 pageNon Rising Stem Gate ValveLaxman Singh SankhlaNo ratings yet

- Laxman9992001@yahoo - Co.in: Gate Valves byDocument1 pageLaxman9992001@yahoo - Co.in: Gate Valves byLaxman Singh SankhlaNo ratings yet

- Main Parts of A ValveDocument2 pagesMain Parts of A ValveLaxman Singh SankhlaNo ratings yet

- Ball Valves By: Er. Laxman Singh Sankhla B.E.Mech., Chartered Engineer Jodhpur, IndiaDocument1 pageBall Valves By: Er. Laxman Singh Sankhla B.E.Mech., Chartered Engineer Jodhpur, IndiaLaxman Singh SankhlaNo ratings yet

- Laxman9992001@yahoo - Co.in: Gate and Plug Valves byDocument2 pagesLaxman9992001@yahoo - Co.in: Gate and Plug Valves byLaxman Singh SankhlaNo ratings yet

- Laxman9992001@yahoo - Co.in: Types of Valve byDocument1 pageLaxman9992001@yahoo - Co.in: Types of Valve byLaxman Singh SankhlaNo ratings yet

- Why Mechanical Seals FailDocument1 pageWhy Mechanical Seals FailLaxman Singh SankhlaNo ratings yet

- 793D SERV1817-01 - SLIDE - Aug2006Document233 pages793D SERV1817-01 - SLIDE - Aug2006Ishan IqbalNo ratings yet

- Perform Test Data After Midlife Log EDG NCP2 NPU - 21 Feb 20Document1 pagePerform Test Data After Midlife Log EDG NCP2 NPU - 21 Feb 20MR BEANo ratings yet

- PG 186-100 (ELGi)Document4 pagesPG 186-100 (ELGi)Ismail AliNo ratings yet

- MaintenanceDocument442 pagesMaintenancetkamhlanga001No ratings yet

- C32B Tech SheetDocument2 pagesC32B Tech SheetLeon ZwijnenburgNo ratings yet

- PPMP 2023 - MO - Repair & MaintenanceDocument9 pagesPPMP 2023 - MO - Repair & MaintenanceRosalie Baldivino GarsulaNo ratings yet

- Pipe TermsDocument38 pagesPipe Termseuphris starfellNo ratings yet

- Juntas ToyotaDocument78 pagesJuntas ToyotaHewa PCNo ratings yet

- Operating Instructions: Atlas Copco Wagner IncDocument115 pagesOperating Instructions: Atlas Copco Wagner IncJuan Carlos Inga Vasquez100% (1)

- 120K Powertrain Hyd SystemDocument6 pages120K Powertrain Hyd SystemNoor RahmanNo ratings yet

- CS56 PDFDocument2 pagesCS56 PDFINVESTIGACION Y DESARROLLO100% (1)

- ALPHA Evo - 2019Document16 pagesALPHA Evo - 2019Сергій БоженкоNo ratings yet

- Komatsu Engine Lta 10c Workshop Manuals 3Document6 pagesKomatsu Engine Lta 10c Workshop Manuals 3howard100% (22)

- Volvo Ems 2 01Document92 pagesVolvo Ems 2 01Rodrigo Gera100% (15)

- Pre-Use Inspection Checklist - Boom TruckDocument1 pagePre-Use Inspection Checklist - Boom TruckSAVIO100% (1)

- Crypton R YamahaDocument76 pagesCrypton R YamahaNESTORIAM60% (5)

- Auto 12.module q.2 Module 1 XDocument22 pagesAuto 12.module q.2 Module 1 XNomer PacilanNo ratings yet

- For More Information:, Please Do Not Hesitate To Contact UsDocument4 pagesFor More Information:, Please Do Not Hesitate To Contact UsJavier Conesa OutedaNo ratings yet

- Argina s3 40 TdsDocument2 pagesArgina s3 40 TdsWajahat RasoolNo ratings yet

- Pump Calculations, Pump EquationsDocument3 pagesPump Calculations, Pump EquationsSpataru Marius0% (2)

- 4 Electricity Production: MAN B&W Diesel A/S S60MC-C Project GuideDocument27 pages4 Electricity Production: MAN B&W Diesel A/S S60MC-C Project GuideАлександр КозыревNo ratings yet

- Piping & Instrumentation Diagram (P&ID) : Learning Outcome From P&ID of Narshingdi Location-C, 311 Project of BGFCLDocument13 pagesPiping & Instrumentation Diagram (P&ID) : Learning Outcome From P&ID of Narshingdi Location-C, 311 Project of BGFCLlamia100% (4)

- Final Year Mechanical Engineering Projects in ChennaiDocument12 pagesFinal Year Mechanical Engineering Projects in ChennaiAbi NesanNo ratings yet

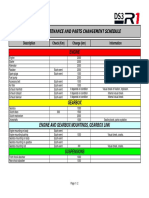

- ds3r1 (11 12 2012) Checks Maintenance and Parts Changement ScheduleDocument2 pagesds3r1 (11 12 2012) Checks Maintenance and Parts Changement Scheduletito titoNo ratings yet