Professional Documents

Culture Documents

Hydrocarbon Processing - Optimize Olefin Operations - 4-2012

Uploaded by

Srihari Kodimela0 ratings0% found this document useful (0 votes)

82 views0 pagesolefin plan optimization

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentolefin plan optimization

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

82 views0 pagesHydrocarbon Processing - Optimize Olefin Operations - 4-2012

Uploaded by

Srihari Kodimelaolefin plan optimization

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 0

SPECIALREPORT

Optimize olefin operations

This operating company used process models

to find solutions to poor separation performance

K. ROMERO, Pequiven S. A., Ana Maria Campos Complex, Venezuela

B

ulk petrochemical manufacturing is a highly competitive

global industry. When margins are tight, manufacturers

seek ways to optimize performance and to reduce costs

while maximizing yields and revenue. Optimization options

include alternative feeds, plant/process revamps and improved

operations to achieve better separation and yields to lower

energy consumption, to minimize product loss and to decrease

maintenance costs.

Case history. Pequiven is a leading petrochemical company

based in Venezuela. Its products include fertilizers (ammonia and

urea), chlor-alkali, methanol, methyl tertiary butyl ether (MTBE),

aromatics, olefins (ethylene and propylene) and other plastics.

Fig. 1 shows Pequivens Ana Maria Campos petrochemicals

complex, Venezuela. This facility began operating in 1976, and

it was expanded in 1992. This petrochemical complex has two

olefin plants with a combined capacity of 635,000 metric tpy of

ethylene and up to 250,000 metric tpy of propylene for 100%

propane feed and uses ethane and propane as feedstocks.

Propane/propylene splitter study. The olefin plants

performance had deteriorated. The conditions resulted in sig-

nificant propylene losses, higher energy consumption and rising

maintenance costs. To improve performance, Pequiven needed a

better understanding of process problems and a list of possible

cost-effective solutions. Pequiven elected to simulate targeted

sections of the olefin plant. Results from the models would

provide more insight into the root causes of the poor operat-

ing performance. This article discusses the simulation study

for the propane/propylene splitters. The

study focused on the conceptual design

and what-if analyses for various revamp

options. Using the study results, Pequiven

selected the best option to optimize the

distillation columns.

Pequiven olefin process. The

Olefins I Plant at the Ana Maria Campos

Complex was designed to produce 250,000

metric tpy of ethylene and 120,000 metric

tpy of propylene, using feedstocks rang-

ing from 100% propane to a mixed feed of

30% propane and 70% ethane. Fig. 2 is the

process flow diagram of the Olefins I plant.

The site processing operations are:

Pyrolysis. This plant uses three sets of furnaces. The furnace

effluent is first quenched and then cooled to condense the dilu-

tion steam, oils and polymers. All are removed by a circulating

water system.

Process-gas compression. The process stream is compressed

and cooled to separate ethylene and propylene (principal products)

from other byproducts and unconverted feed. Five compression

stages are used, with acetylene conversion, caustic scrubbing and

gas-drying occurring between the fourth and fifth stages. The pro-

cess gas from the fifth-stage discharge filters is chilled in three stages

using refrigerants and a hydrogen/tail-gas stream from the process.

Feedstocks

Pyrolysis

Ethylene

Propylene

Ethane

Propane

Efuent

water

scrubbing

Chilling

section

Acetylene

conversion

Caustic and

water wash

Process gas

drying

Ethane/propane recycle

Splitting

section

Process gas

compression

stages

I II III IV V

Process flow diagram of Olefins I plant. FIG. 2

Pequivens Ana Maria Campos petrochemical complex. FIG. 1

Originally appeared in:

April 2012, pgs 1-5.

Used with permission.

HYDROCARBON PROCESSING APRIL 2012

PETROCHEMICAL DEVELOPMENTS SPECIALREPORT

Separation. The cryogenically chilled stream is processed

through a series of distillation columns. Several columns are

needed to separate out the desired products. This process sec-

tion consists of a demethanizer, ethane/ethylene and propane/

propylene splitters, and a debutanizer, as shown in Fig. 3.

This study focused on revamping the propane/propylene (C

3

)

splitters to maximize recovery of propane and propylene with

greater efficiency and reduced losses. Fig. 4 shows an in-depth

description of the C

3

splitter section.

The deethanizer bottoms stream (at approximately 21.3

kg/cm

2

g and 62C) is split into parallel C

3

splitter systems

primary and secondary trains. Each parallel train consists of

two splitter columns. The feed is distributed between the two

systems. The primary C

3

splitter train receives 60% of the

propane feed flow.

The primary train has 277 trays between the first column

(124 trays) and second column (153 trays). Both columns use

multi-downcomer trays. Feed enters the first column above tray

35 (tray 188 for the combined column) for the propane case,

or above tray 51 (tray 204 for the combined column) in the

mixed-feed case. The secondary train is configured and oper-

ated similarly to the first train with a total of 198 trays between

the first column (88 trays) and the second column (110 trays).

The secondary system has sieve trays. The feed enters the first

column on tray 26 (tray 136 for the combined column) for the

propane case or on tray 36 (tray 146 for the combined column)

for the mixed-feed case.

The C

3

splitter system was designed to produce 99.6 mol% of

propylene in the overhead stream. The bottom stream from the

C

3

section is sent to the debutanizer column where the top prod-

uct, containing propane and butane, is recycled to the pyrolysis

furnaces. The heavier components are recovered as a C

5

+

pyrolysis

gasoline stream. In the mixed-feed case, there are fewer heavier

components to recover.

Plant operating problems. During 20052009, the pro-

pane/propylene system experienced several problems. Gradually,

TABLE 1. Results from the Revamp Proposal A

simulation modeling study

Column C (from secondary Primary propane/

system) depropanizer propylene splitter

1

Feed flowrate, metric tph 16.98 14.16

Stages 88 277

Feed stream stage 36 171

Distillate rate, metric tph 14.16 6.9

Mol purity propylene, top 0.484 0.998

Mol purity propane, top 0.513 0.001

Bottom rate, metric tph 2.8 7.3

Mol purity propane, bottom 0.0007 0.992

Top pressure, bar 18.9 18.9

Reflux rate, metric tph 22.7 146

Reboiler duty, MW 2.9 12.3

TABLE 2. Results from the Revamp Proposal B

simulation modeling study

Column D (from secondary Primary propane/

system) depropanizer propylene splitter

1

Feed flowrate, metric tph 16.9 14.2

Stages 88 277

Feed stream stage 36 171

Distillate rate, metric tph 14.2 6.9

Mol purity propylene, top 0.484 0.998

Mol purity propane, top 0.513 0.001

Bottom rate, metric tph 2.8 7.3

Mol purity propane, bottom 0.0007 0.992

Top pressure, bar 18.9 18.9

Reflux rate, metric tph 22 146

Reboiler duty, MW 2.85 12.3

Chilling

section

Compressed

gas

Separators

Demethanizer

Methane

Propane,

propylene

and heavier

components

Propane and butane

Propane

and heavier

components

Propylene

Ethane and ethylene

Ethane

Ethylene

Deethanizer

Debutanizer

C

2

splitter

C

3

splitter section

(2 trains each

with 2 columns)

C

5

+

/pygas

Separation section of the Olefins I plant. FIG. 3

C

3

/C

3

=

/C

4

+

deethanizer

bottoms

C

5

+

Propane

and C

4

+

Debutanizer

Propylene

Propane and butane

to pyrolysis furnaces

Propylene

Secondary splitter

system

Primary splitter

system

Propane/propylene splitter section of the existing unit. FIG. 4

HYDROCARBON PROCESSING APRIL 2012 HYDROCARBON PROCESSING APRIL 2012

PETROCHEMICAL DEVELOPMENTS SPECIALREPORT

the facility operating performance worsened. Performance issues

included:

High propylene loss, 25 mol% vs. design < 1 mol%

Poor separation and high energy usage of the C

3

splitters

Fouling in the splitter reboilers

Low propylene and propane recovery, problems with the

overhead-product purity and high concentration of unsaturates

in the recycle propane to the pyrolysis furnaces.

These problems resulted in significant propylene loss that

cumulatively amounted to more than 70,000 metric tons over five

years. The lost products were valued at over $75 million. Fouling

of reboilers due to using oily water as the hot utility, and coking

of the transfer line exchangers from higher propylene content in

recycle propane, contributed to higher maintenance costs.

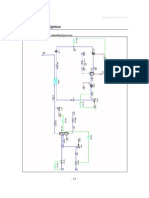

Process simulation study. The objectives of the modeling

were to:

Understand the root causes for these problems

Develop suitable and cost-effective solutions

Provide ongoing guidance for troubleshooting

Improve unit performance.

The simulation model was constructed from design data from

the operating manuals and engineering drawings, as shown in

Fig. 5. This model was tuned and validated against other data

sets. This tuning included comparing different thermodynamic

methods and selecting the best with respect to accuracy. The

Peng-Robinson (PR) and Soave-Redlich-Kwong (SRK) models

were used to describe thermodynamic behavior and equilibrium

coefficients. Both methods are commonly used for hydrocarbon

systems. For the Olefins I plant, Peng-Robinson provided an

accurate fit with the design cases.

Several commercially available simulation programs were used

to simulate the C

3

splitters while also considering the existing col-

umn geometries and tray efficiencies. This distillation model is a

core element. It helped predict column performance and ensured

robust initialization and convergence. The rate-based algorithm also

significantly improved the models accuracy compared to the equi-

librium-based and first-generation rate-based distillation models.

Simulation resultssuch as column pressure, operating tem-

perature, reflux ratio, composition, reboiler/condenser duties,

column stages, feedrate, overhead and bottoms yield, and tray

detailswere specified to achieve 99.6% propylene recovery.

Propane/propylene (principal products), isobutane, butanes,

butenes and heavier components (traces) were also considered

in this model. Once the model was tuned, it was used to study

a series of conceptual design alternatives, including energy and

economic analysis for the different proposals.

Revamp Proposals A and B. The first two options (A and

B) were similar. They both involved reconfiguration and using one

of the columns in the secondary splitter system as a depropanizer,

while taking the other column out of service, as shown in Fig. 6.

The simulation model showed that this approach would improve

propane/propylene recovery and increase the recycle propane to

TABLE 3. Results from the Revamp Proposal C

simulation modeling study

Secondary propane/propylene Primary propane-

splitter (depropanizer) propylene splitter

1

Feed flowrate, metric tph 17 14.4

Stages 198 277

Feed stream stage 37 172

Distillate rate, metric tph 14.4 6.8

Mol purity propylene, top 0.489 0.999

Mol purity propane, top 0.494 0.0002

Bottom rate, metric tph 2.6 7.6

Mol purity propane, bottom 0 0.996

Top pressure, bar 18.9 18.9

Reflux rate, metric tph 23 182

Reboiler duty, MW 2.9 60.9

TABLE 4. Results from the revamp proposal D

simulation modeling study*

Primary Secondary

propane/propylene propane/ propylene

system LP steam system LP steam

1

Required temperature, C 128.7 128.7

Required pressure, bar 2.75 2.75

Propylene recovery composition 0.9985 0.9985

Required flowrate, metric tph 24,366 19,035

Total cost, $ million/yr 1.41 1.102

*Based on the original design with propylene losses of less than 1%

Simulation model of the propane/propylene splitter

system.

FIG. 5

C

3

/C

3

=

/C

4

+

deethanizer

bottoms

C

3

/C

3

=

C

5

+

C

4

+

Debutanizer

Depropanizer

Butane to pyrolysis furnaces

Propane to

pyrolysis furnaces

Propylene

Secondary splitter

system

Revamp

Proposals

A and B

Primary splitter

system

Proposals A and B: Use one column in the secondary C

3

splitter as a depropanizer.

FIG. 6

HYDROCARBON PROCESSING APRIL 2012 HYDROCARBON PROCESSING APRIL 2012

PETROCHEMICAL DEVELOPMENTS SPECIALREPORT

the pyrolysis furnaces. Proposal A studied using the first column as

the depropanizer, and Proposal B looked at using the second col-

umn for this purpose. Tables 1 and 2 summarize the study results.

Findings for Proposals A and B. The operating condi-

tions for Proposals A and B are similar to the original design. A

depropanizer in the C

3

splitter system does increase propane and

propylene recovery (about 99 mol%). Heating requirements are

significantly reduced15.2 MW vs. 22.8 MW from the original

design. Jet flooding is 0.65 (well below the maximum jet flooding

limit of 0.85). There is no evidence of overloading in the multi-

downcomer trays, in spite of the high reflux rate requirements.

3

Revamp Proposal C. This option considered using the entire

secondary C

3

splitter system (both columns) as a depropanizer,

as shown in Fig. 7. The objectives were to improve propane and

propylene recovery and to increase recycle propane to the pyrolysis

furnaces. Table 3 summarizes results from this processing option.

Findings for Proposal C. The operating conditions are similar

to the original design. A depropanizer in the C

3

splitter system

increases propane and propylene recovery (about 99.8 mol%).

Additional heating is required60.9 MW vs. 22.8 MW specified

in the original design. The risk of jet flooding in multi-down-

comer trays in the primary system was identified. Due to tray

overloading, this process option was not pursued further.

Revamp Proposal D. This option evaluated replacing oily

water with low-pressure (LP) steam as the heating medium in the

C

3

splitter reboilers. The change could reduce fouling on tube

surfaces, as shown in Fig. 8. The conceptual design and analysis

are based on revamping the original design for the most limiting

conditions, as represented by the 100% propane feed case.

2

Table

4 lists the study results.

Annual steam costs are estimated at $1.41 million and $1.102

million, respectively, for the primary and secondary systems. The

total steam consumption across the C

3

splitter system is approxi-

mately $2.51 million/yr.

Revamp Proposal D project costs. Option D not only

addresses exchanger tube-side fouling and maintenance, but it

also reduces propylene losses in the splitter bottoms. This will

improve propylene recovery from the product and propane for

recycle. The economics for this case were evaluated in detail. Table

5 summarizes cost estimates and project economics.

The total capital investment is estimated at $3.025 million,

with an annual steam utility cost of $2.51 million as reported ear-

lier. These process improvements are expected to result in 8,915

metric tpy of incremental propylene production. At $1,080/met-

ric ton, the increased production represents $9.62 million of addi-

tional annual revenue. This is an excellent return on investment

for the project. Switching to LP steam reduces exchanger fouling

and enables easier cleaning and maintenance of the thermosiphon

reboilers. Annual savings of $500,000 are expected from reduced

cleaning and maintenance costs.

Lessons learned and other findings. The overview of

the entire study raised several interesting findings:

Proposals A and B. This design delivers the best performance

for the C

3

splitter system. The depropanizer aids in increasing

product recovery (about 99 mol%) and improves operations for

high-purity propylene (approximately 99.6 mol%). This design

lowers heating requirements (15.2 MW vs. 22.8 MW for the orig-

inal design). There is no evidence of overloading (flooding) in the

C

3

/C

3

=

/C

4

+

deethanizer

bottoms

C

5

+

C

4

+

Debutanizer

Butane to pyrolysis furnaces

Propane to

pyrolysis furnaces

Propylene

Secondary splitter

system

Primary splitter

system

C

3

/C

3

=

Depropanizer

Revamp

Proposal C

Proposal C: Use the secondary splitter system as a

depropanizer.

FIG. 7

Propylene

Propane/

propylene

splitters

TC

TG

Propane and C

4

+

LP steam

Process water

Process water return

Condensate return Revamp

Proposal D

Proposal D: Using LP steam as the heating medium in

reboilers.

FIG. 8

TABLE 5. Pequiven C

3

splitter revamp proposal D

economic analysis

1

Cost estimates USD, thousand

Basic and detailed engineering 500

Reboiler modification, process oily water to LP steam 250

Condensate removal system 1,200

Stainless steel pipe, 16 in. 18.5

Stainless steel pipe, 14 in. 13.7

Stainless steel pipe, 12 in. 10.8

Stainless steel pipe, 2 in. 5.3

Isolation 2.8

Installation and manpower costs 1,024

Total 3,025

Total investment (CAPEX) 3,025

Steam utilities and operating costs (OPEX) 2,510

Propylene incremental annual production 9,620

% profitability, propylene recovered/CAPEX x 100 318%

HYDROCARBON PROCESSING APRIL 2012

PETROCHEMICAL DEVELOPMENTS SPECIALREPORT

multi-downcomer trays, even with high reflux rate requirements.

Proposal C. This alternative is not practical due to a high risk

of tray flooding and higher energy requirements.

Proposal D. This design uses LP steam to meet reboiler duty

requirements. The switch in heating medium provides easier

cleaning and lowers maintenance time for reboilers. Greater

recovery of propylene and increased purity of recycle propane are

possible. This option improves furnace operations.

This study demonstrated that revamping the C

3

splitter sys-

tem to use one of the columns from the secondary C

3

splitter

as a depropanizer (Proposal A or B) results in propane recovery

close to 100%. Heating requirements for the revamped system

are lower, with easier cleaning and maintenance of reboilers.

Propylene recovery would be 100% while the probability of tray

flooding or weeping is low.

Simulation studies also indicated that it is not techni-

cally possible to use the primary splitter system or one of its

columns as a depropanizer, and the second one as propane/

propylene splitter. This arrangement risks overloading trays

and has higher heating requirements and reflux rates compared

to the original design.

Optimization study. The results from this simulation and

engineering study show that Proposals B and D are the opti-

mal revamp alternatives. They deliver improved operability and

performance for propane/propylene separation with lower duty

requirements, better product recovery and purities and lower

utilities and maintenance costs. These options would improve

conversion and lengthen the service life for the furnaces, reboilers

and distillation columns. However, due to budgetary constraints,

only Proposal D is being implemented firstmodification of

reboilers from wash water to LP steam heating.

Pequiven is executing the project. The scope includes further

developing the conceptual design, basic engineering and Class

4 cost estimates ( 20%). Project duration is expected to be

around 24 months. When completed, this revamp will deliver

8,915 metric tpy of incremental propylene product valued at

$9.62 million/yr, and additional annual savings of $500,000

through reduced reboiler cleaning and maintenance costs.

The process simulation and conceptual estimates in this study

were invaluable. Both helped Pequiven gain clearer insight into

its olefin plant operations. With such information, Pequiven was

able to develop a better understanding of plant and equipment

performance problems. HP

ACKNOWLEDGMENT

The author thanks Sanjeev Mullick of AspenTech for his help in preparing

this article for publication.

LITERATURE CITED

1

Aspen Plus and Aspen Capital Cost Estimator documentation, Aspen

Technology, Inc., Massachusetts, USA.

2

Billet, R., Distillation Engineering, M. Wulfinghoff Chemical Publishing Co.,

New York, New York, 1979.

3

Hsi-Jen, C. and L.Yeh-Chin, Case Studies on Optimum Reflux Ratio of

Distillation Towers in Petroleum Refining Processes, Tamkang Journal of

Science and Engineering, Tamsui, Taiwan, Vol. 4, No. 2, pp. 105-110, 2001.

4

Romero, K., Optimizing a Propane-Propylene Splitter in an Olefins Plant,

OPTIMIZE 2011, AspenTech Global Conference, Washington, DC.

Karen Romero is a process engineer at Pequiven. She has over 10 years of experi-

ence in oil and gas and petrochemicals, with a focus on design, development, manage-

ment and execution of projects. Ms. Romero is a chemical engineering graduate from

the University of Zulia . She holds an MS degree in gas engineering. Ms. Romero is also

an instructor professor of gas processing at Universidad Rafael Maria Baralt, Venezuela.

Article copyright 2012 by Gulf Publishing Company. All rights reserved. Printed in U.S.A.

Not to be distributed in electronic or printed form, or posted on a website, without express written permission of copyright holder.

HYDROCARBON PROCESSING APRIL 2012

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Using Aspen HYSYS Dynamics With ColumnsDocument20 pagesUsing Aspen HYSYS Dynamics With Columnsac2475No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Oil Stab Op Tim IzationDocument30 pagesOil Stab Op Tim IzationCHANADASNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Compressor - Reference MaterialDocument45 pagesCompressor - Reference MaterialSrihari KodimelaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Nhdt-Chintan ThakarDocument1 pageNhdt-Chintan ThakarSrihari Kodimela100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- PRO MAX FoundationsManualEnDocument69 pagesPRO MAX FoundationsManualEnSrihari KodimelaNo ratings yet

- LPG Plant ReportDocument104 pagesLPG Plant Reportmsh_jaazNo ratings yet

- P&ID Check ListDocument6 pagesP&ID Check ListSrihari Kodimela0% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Block Flow DiagramDocument1 pageBlock Flow DiagramSrihari KodimelaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Appendix CDocument99 pagesAppendix CSrihari KodimelaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- D86 To TBPDocument3 pagesD86 To TBPSrihari KodimelaNo ratings yet

- 100 Overview of Tank DesignDocument20 pages100 Overview of Tank Designkoparan35No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- SA JER AG221 DALM 649001 - Rev04Document26 pagesSA JER AG221 DALM 649001 - Rev04Srihari KodimelaNo ratings yet

- CoalescerDocument18 pagesCoalescer112dharmesh0% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Gas Power Plant PFDDocument1 pageGas Power Plant PFDSrihari KodimelaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Nonboiling Liq Outflow F Vertical Cyl VesselDocument26 pagesNonboiling Liq Outflow F Vertical Cyl VesselSrihari KodimelaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Debottleneck Crude-Unit Preheat Exchanger Network Inefficiencies - Hydrocarbon Processing - February 2012Document8 pagesDebottleneck Crude-Unit Preheat Exchanger Network Inefficiencies - Hydrocarbon Processing - February 2012Srihari KodimelaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- API Standards For Heat Transfer Equipments, Pumps Ad TanksDocument3 pagesAPI Standards For Heat Transfer Equipments, Pumps Ad TanksSrihari KodimelaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- AcknowledgementDocument4 pagesAcknowledgementPurna GuptaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tips On Printing Half-Sheet PDF Booklets: 1. Print 1 Page of A Booklet To A Full Sheet of PaperDocument3 pagesTips On Printing Half-Sheet PDF Booklets: 1. Print 1 Page of A Booklet To A Full Sheet of Papermyco samNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- CCNA - Access List QuestionsDocument3 pagesCCNA - Access List QuestionsBaaska214No ratings yet

- Push Pull PDR ReportDocument4 pagesPush Pull PDR ReportBrian AliasgharNo ratings yet

- Project TimesheetDocument2 pagesProject TimesheetAmanpreet SinghNo ratings yet

- 020 - MDCC For Sluice GatesDocument1 page020 - MDCC For Sluice GatesYOGESH PHALKENo ratings yet

- Atoll 3.3.2 Technical Reference Guide RadioDocument912 pagesAtoll 3.3.2 Technical Reference Guide Radioratelekoms100% (4)

- Module 6 DrillingDocument18 pagesModule 6 DrillingdejanflojdNo ratings yet

- Research Paper Summary Knowledge GraphsDocument1 pageResearch Paper Summary Knowledge GraphsTrust KaguraNo ratings yet

- LogDocument2 pagesLogFerdian SumbaNo ratings yet

- Model Space & Layout (Paper) SpaceDocument7 pagesModel Space & Layout (Paper) SpaceIonela Lioara TutaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- NORMA - ANSI-AMCA Standard 250-05 Laboratory Methods of Testing Jet Tunnel Fans For PerformanceDocument33 pagesNORMA - ANSI-AMCA Standard 250-05 Laboratory Methods of Testing Jet Tunnel Fans For PerformanceJose Antonio100% (1)

- Edtpa 2nd Lesson PlanDocument5 pagesEdtpa 2nd Lesson Planapi-297045693No ratings yet

- Chapter 4 (Digital Modulation) - Review: Pulses - PAM, PWM, PPM Binary - Ask, FSK, PSK, BPSK, DBPSK, PCM, QamDocument7 pagesChapter 4 (Digital Modulation) - Review: Pulses - PAM, PWM, PPM Binary - Ask, FSK, PSK, BPSK, DBPSK, PCM, QamMuhamad FuadNo ratings yet

- Fortinet Configuration Report: Hostname: "FG3600-Internet"Document21 pagesFortinet Configuration Report: Hostname: "FG3600-Internet"rizkymulyawan89No ratings yet

- Husqvarna 2008Document470 pagesHusqvarna 2008klukasinteria100% (2)

- Particle Packing in Concrete 30-04-20Document49 pagesParticle Packing in Concrete 30-04-20b ramachandraNo ratings yet

- Project TemplatesDocument64 pagesProject TemplatesMahad AbdiNo ratings yet

- MSDS - LPGDocument9 pagesMSDS - LPGPrathamesh ShevaleNo ratings yet

- Sika Cemflex 1Document3 pagesSika Cemflex 1rasasiNo ratings yet

- MSDS Argon Compressed GasDocument6 pagesMSDS Argon Compressed Gassajid aliNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- NetflixDocument16 pagesNetflixGianluca VenturiNo ratings yet

- KBC Nano in English PDFDocument57 pagesKBC Nano in English PDFBHUKKAD BOX100% (1)

- Electronic Circuits - II Lab ManualDocument26 pagesElectronic Circuits - II Lab Manualbalabasker100% (1)

- DIN 3900 1984 04 Compression CouplingsDocument3 pagesDIN 3900 1984 04 Compression Couplingsjangaswathi0% (1)

- Block Diagram: PowerDocument96 pagesBlock Diagram: PowerBrennan GriffinNo ratings yet

- Horizontal Cylindrical Steam Autoclave: Main FeaturesDocument2 pagesHorizontal Cylindrical Steam Autoclave: Main FeaturesMahroelNo ratings yet

- G1 Group 1CDocument72 pagesG1 Group 1CNH SyzlnNo ratings yet

- Online Assignment - Aritificial LiftDocument10 pagesOnline Assignment - Aritificial LiftfatenamiraNo ratings yet

- TechTrax 09 2003 ScreenReaderVersionDocument84 pagesTechTrax 09 2003 ScreenReaderVersionMCKINNONBNo ratings yet