Professional Documents

Culture Documents

Job Hazard Analysis Sample Tag Confined Space

Uploaded by

omer1980Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Hazard Analysis Sample Tag Confined Space

Uploaded by

omer1980Copyright:

Available Formats

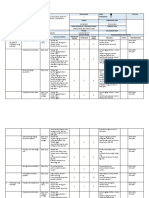

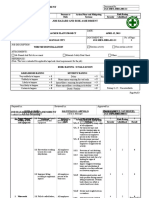

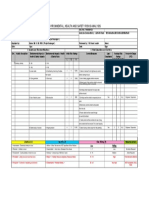

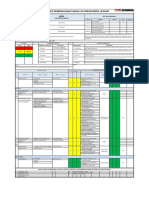

Sample Job Hazard Analysis Cleaning Inside Surface of Chemical Tank - Top Manhole Entry

STEP

1. Select and train operators.

HAZARD

Operator with respiratory or heart problem, other physical limitation Untrained operator--failure to perform task

NEW PROCEDURE OR PROTECTION

Examination by industrial physician for suitability to work Train operators Dry run [Reference: National Institute for Occupational Safety and Health (NIOSH) Doc #80-406] Obtain work permit signed by safety, maintenance and supervisors Test air by qualified person Ventilate to 19.5% - 23% oxygen and less than 10% LEL of any flammable gas. Steaming inside of tank, flushing and draining, then ventilating, as previously described, may be required Provide appropriate respiratory equipment - SCBA or air line respirator Provide protective clothing for head, eyes, body and feet Provide parachute harness and lifeline [Reference: OSHA standards 1910.106, 1926.100, 1926.21(b)(6); NIOSH Doc #80-406] Tanks should be cleaned from outside if possible Arrange hoses, cords, lines and equipment in orderly fashion, with room to maneuver safely Use ground-fault circuit interrupter

2. Determine what is in the tank, what process is going on in the tank, and what hazards this can pose.

Explosive gas Improper oxygen level Chemical exposure Gas, dust, vapor: Irritant Toxic Liquid: Irritant Toxic Corrosive Solid: Irritant Corrosive

3. Set up equipment.

Hoses, cord, equipment tripping hazards Electrical - voltage too high, exposed conductors Motors not locked out and tagged

Lockout and tag mixing motor, if present 4. Install ladder in tank. 5. Prepare to enter tank. Ladder slipping Gas or liquid in tank Secure to manhole top or rigid structure Empty tank through existing piping Review emergency procedures Open tank Check of job site by industrial hygienist or safety professional Install blanks in flanges in piping to tank (Isolate tank) Test atmosphere in tank by qualified person (long probe) Use mechanical-handling equipment Provide guardrails around work positions at tank top Provide personal protective equipment for conditions found [Reference: NIOSH Doc #80-406; OSHA CFR 1910.134) Provide outside helper to watch, instruct and guide operator entering tank, with capability to lift operator from tank in emergency Provide protective clothing and equipment for all operators and helpers Provide lighting for tank (Class I, Div. I) Provide exhaust ventilation Provide air supply to interior of tank Frequent monitoring of air in tank Replace operator or provide rest periods Provide means of communication to get help, if needed Provide two-man standby for any emergency Dry run Use material-handling equipment

6. Place equipment at tank-entry position. 7. Enter tank.

Trip or fall Ladder - tripping hazard

Exposure to hazardous atmosphere

8. Cleaning tank.

Reaction of chemicals, causing mist or expulsion of air contaminant

9. Cleaning up.

Handling of equipment, causing injury

You might also like

- HIRADC Installation PipeDocument4 pagesHIRADC Installation PipeamizanNo ratings yet

- Operational Control Procedure For Excavation.: 1.0 PurposeDocument3 pagesOperational Control Procedure For Excavation.: 1.0 Purposebabu541No ratings yet

- Hi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisDocument3 pagesHi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisPHH9834100% (1)

- JHA - To Carry Out Reinstate of Interlock StonesDocument7 pagesJHA - To Carry Out Reinstate of Interlock Stoneslinga201450% (2)

- JSA-Substructure Concrete WorksDocument5 pagesJSA-Substructure Concrete WorksUMUTNo ratings yet

- Jsa For PCCDocument6 pagesJsa For PCCCICON EngineersNo ratings yet

- JGS SHES JHRA 002 13 Wire Mesh InstallationDocument2 pagesJGS SHES JHRA 002 13 Wire Mesh Installationarnel sungkip100% (1)

- Lim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMDocument2 pagesLim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMVaradaraju ThirunavukkarasanNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- Material Handling SOPDocument1 pageMaterial Handling SOPRajesh Sharma100% (1)

- Annexure 9 - Declaration by The Subcontractor For HSE ComplianceDocument1 pageAnnexure 9 - Declaration by The Subcontractor For HSE ComplianceShamim Mahmudur RahmanNo ratings yet

- Excavation of RoadDocument7 pagesExcavation of RoadCharles LambNo ratings yet

- Tool Box Talk: House KeepingDocument1 pageTool Box Talk: House KeepingAli Alqaisy100% (1)

- Contractors Waste Management Tracking FormDocument1 pageContractors Waste Management Tracking FormAshimolowo BabatundeNo ratings yet

- PP-HSE-FORM-005 PTW-Confined SpaceDocument2 pagesPP-HSE-FORM-005 PTW-Confined SpaceDimas Dwi SwarnaNo ratings yet

- Pha ExcavationDocument13 pagesPha ExcavationirshadNo ratings yet

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- JGS SHES JHRA 001 13 Grating Installation and RemovalDocument2 pagesJGS SHES JHRA 001 13 Grating Installation and Removalarnel sungkip100% (2)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- 1 (Hazard Analysis) For Earth Works Gurun Jsa G 001 Rev 002Document3 pages1 (Hazard Analysis) For Earth Works Gurun Jsa G 001 Rev 002nurul sarahNo ratings yet

- Hira - Back FillingDocument5 pagesHira - Back FillingSatya NaiduNo ratings yet

- Risk Assesment-Rebar Loading & UnloadingDocument1 pageRisk Assesment-Rebar Loading & Unloadingmainraj rajNo ratings yet

- Jsa-046 Highway Crossing and Steel CasingDocument11 pagesJsa-046 Highway Crossing and Steel CasingMajdiSahnounNo ratings yet

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- HIRA 008 Height Work.Document4 pagesHIRA 008 Height Work.srinibas mohapatraNo ratings yet

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- Jos Safety AnalysisDocument9 pagesJos Safety AnalysisFairus Md Yusof100% (1)

- 26 Barricades&TapeDocument3 pages26 Barricades&TapeMohammed MinhajNo ratings yet

- Wall Painting Risk AssesmentDocument3 pagesWall Painting Risk AssesmentJacob ChirayilNo ratings yet

- JS A Excavation Work For Electrical CableDocument3 pagesJS A Excavation Work For Electrical CableMohammed MinhajNo ratings yet

- Water Tank Cleaning TRADocument5 pagesWater Tank Cleaning TRAyehia sayedNo ratings yet

- JOB HAZARD ANALYSIS Deep Excavation-2Document9 pagesJOB HAZARD ANALYSIS Deep Excavation-2jay RNo ratings yet

- 024 - Mobile Scaffold Inspection ChecklistDocument1 page024 - Mobile Scaffold Inspection ChecklistFaiez AripiNo ratings yet

- HSE Policy SampleDocument1 pageHSE Policy SampleRajkumar NandaNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- RA Arc, Welding 150310Document4 pagesRA Arc, Welding 150310Mohd FikryNo ratings yet

- Jha New - PWHTDocument6 pagesJha New - PWHTSalam AlkataluniNo ratings yet

- Boring & Cone Penetration test-JSA-01Document3 pagesBoring & Cone Penetration test-JSA-01Akash Shukla67% (3)

- Job Hazard Analysis: IP-OPS-066Document9 pagesJob Hazard Analysis: IP-OPS-066ananthu.uNo ratings yet

- Grinding ActivityDocument1 pageGrinding ActivityKrishna Patil100% (2)

- JSA Welding & Cutting WorksDocument1 pageJSA Welding & Cutting WorksCherry BetonioNo ratings yet

- Jsa For Ut TestDocument2 pagesJsa For Ut Testnasar_mahsood50% (2)

- Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBDocument13 pagesRisk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBnsadnanNo ratings yet

- BOCW and SafetyDocument31 pagesBOCW and Safetydreamboy87No ratings yet

- Waste Treatment Plant HiraDocument5 pagesWaste Treatment Plant HiraBharath KumarNo ratings yet

- HIRARC Warehouse 2022 - 01Document2 pagesHIRARC Warehouse 2022 - 01Alamindris Dris100% (1)

- JSA For Blinding and De-Blinding (Opening Process Equipment)Document11 pagesJSA For Blinding and De-Blinding (Opening Process Equipment)Thái Đạo Phạm Lê100% (1)

- TRA 13 Loading or Unloading Chems With ForkliftDocument2 pagesTRA 13 Loading or Unloading Chems With ForkliftPirlo Polo100% (1)

- JHA Pump CreteDocument2 pagesJHA Pump CretePopo EaldamaNo ratings yet

- Project No. 074-10 JHA No. 1Document20 pagesProject No. 074-10 JHA No. 1Adel SukerNo ratings yet

- Job Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9Document4 pagesJob Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9OGBONNAYA MARTINSNo ratings yet

- JSA Demolish Existing Concrete Foundation EDGDocument1 pageJSA Demolish Existing Concrete Foundation EDGWidya PrasetyaNo ratings yet

- 10 JSA Excavation, Lowering, Back FillingDocument8 pages10 JSA Excavation, Lowering, Back FillingYosua SitumorangNo ratings yet

- 01 JSA CLEANING COMPRESSOR Rev 05 015 BIDocument8 pages01 JSA CLEANING COMPRESSOR Rev 05 015 BIMohd Khaidir100% (1)

- TFU-Risk Assessment RA-11 - Use of Grooving & Threading MachinesDocument1 pageTFU-Risk Assessment RA-11 - Use of Grooving & Threading Machinesarshin wildanNo ratings yet

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- Chemical Tank Cleaning PDFDocument1 pageChemical Tank Cleaning PDFeastNo ratings yet

- Job Safety AnalysisDocument22 pagesJob Safety AnalysisAariz ZaidNo ratings yet

- Oil - Gas - Industry Standards ManualDocument90 pagesOil - Gas - Industry Standards ManualAlabi GodfavourNo ratings yet

- Enclosed Space Entry Precautions Onboard ShipsDocument5 pagesEnclosed Space Entry Precautions Onboard ShipsSumit Sama100% (2)

- Becg Unit-1Document8 pagesBecg Unit-1Bhaskaran Balamurali0% (1)

- 10.MIL 9. Current and Future Trends in Media and InformationDocument26 pages10.MIL 9. Current and Future Trends in Media and InformationJonar Marie100% (1)

- Seafood Serving Tools Make The Task of Cleaning Seafood and Removing The Shell Much Easier. ForDocument32 pagesSeafood Serving Tools Make The Task of Cleaning Seafood and Removing The Shell Much Easier. Forivy l.sta.mariaNo ratings yet

- Distribution Optimization With The Transportation Method: Risna Kartika, Nuryanti Taufik, Marlina Nur LestariDocument9 pagesDistribution Optimization With The Transportation Method: Risna Kartika, Nuryanti Taufik, Marlina Nur Lestariferdyanta_sitepuNo ratings yet

- Thesis RadioactivityDocument13 pagesThesis RadioactivitysaanvicodingNo ratings yet

- Power Systems Kuestion PDFDocument39 pagesPower Systems Kuestion PDFaaaNo ratings yet

- Marimba ReferenceDocument320 pagesMarimba Referenceapi-3752991No ratings yet

- Bebras2021 BrochureDocument5 pagesBebras2021 BrochureJeal Amyrrh CaratiquitNo ratings yet

- LGBT in Malaysia: Social Welfare SystemDocument24 pagesLGBT in Malaysia: Social Welfare SystemMuhammad Syazwan Ahmad Fauzi100% (1)

- Josephine Morrow: Guided Reflection QuestionsDocument3 pagesJosephine Morrow: Guided Reflection QuestionsElliana Ramirez100% (1)

- OS W2020 3140702 APY MaterialDocument2 pagesOS W2020 3140702 APY MaterialPrince PatelNo ratings yet

- Extinction Summary Handout PDFDocument1 pageExtinction Summary Handout PDFJohn DNo ratings yet

- Instant Download Ebook PDF Entrepreneurship The Practice and Mindset by Heidi M Neck PDF ScribdDocument41 pagesInstant Download Ebook PDF Entrepreneurship The Practice and Mindset by Heidi M Neck PDF Scribdjohn.brandt885100% (47)

- Plant-Biochemistry-by-Heldt - 2005 - Pages-302-516-79-86 PDFDocument8 pagesPlant-Biochemistry-by-Heldt - 2005 - Pages-302-516-79-86 PDF24 ChannelNo ratings yet

- Listen The Song and Order The LyricsDocument6 pagesListen The Song and Order The LyricsE-Eliseo Surum-iNo ratings yet

- Business Law Term PaperDocument19 pagesBusiness Law Term PaperDavid Adeabah OsafoNo ratings yet

- AWS PowerPoint PresentationDocument129 pagesAWS PowerPoint PresentationZack Abrahms56% (9)

- Fmi Unit 2Document86 pagesFmi Unit 2Pranav vigneshNo ratings yet

- Temario de Oposiciones De: InglésDocument25 pagesTemario de Oposiciones De: Inglésvanesa_duque_3100% (1)

- LIVING IN THE WORLD OF WARCRAFT: Construction of Virtual Identities Among Online GamersDocument81 pagesLIVING IN THE WORLD OF WARCRAFT: Construction of Virtual Identities Among Online GamersVirginia Bautista100% (2)

- People Vs SantayaDocument3 pagesPeople Vs SantayaAbigail DeeNo ratings yet

- Interpretive Dance RubricDocument1 pageInterpretive Dance RubricWarren Sumile67% (3)

- Timeline of Jewish HistoryDocument33 pagesTimeline of Jewish Historyfabrignani@yahoo.com100% (1)

- PD10011 LF9050 Venturi Combo Lube Filter Performance DatasheetDocument2 pagesPD10011 LF9050 Venturi Combo Lube Filter Performance DatasheetCristian Navarro AriasNo ratings yet

- Power Electronics For RenewablesDocument22 pagesPower Electronics For RenewablesShiv Prakash M.Tech., Electrical Engineering, IIT(BHU)No ratings yet

- FR Cayat Vs COMELEC PDFDocument38 pagesFR Cayat Vs COMELEC PDFMark John Geronimo BautistaNo ratings yet

- Sony Ht-ct390 Startup ManualDocument1 pageSony Ht-ct390 Startup Manualalfred kosasihNo ratings yet

- SSoA Resilience Proceedings 27mbDocument704 pagesSSoA Resilience Proceedings 27mbdon_h_manzano100% (1)

- NLP - Neuro-Linguistic Programming Free Theory Training Guide, NLP Definitions and PrinciplesDocument11 pagesNLP - Neuro-Linguistic Programming Free Theory Training Guide, NLP Definitions and PrinciplesyacapinburgosNo ratings yet

- Chicago Citation and DocumentDocument8 pagesChicago Citation and DocumentkdemarchiaNo ratings yet