Professional Documents

Culture Documents

Construction of Ordnance.: Lnventqr

Uploaded by

asdfasfOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Construction of Ordnance.: Lnventqr

Uploaded by

asdfasfCopyright:

Available Formats

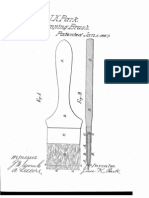

- W. E. WOODBRIDGE.

Construction of Ordnance.

No. 60,979.

Patented Jan. 1, 1867

Witnesses:

lnventqr:

guitar was arm @ffm.

W. n. woonnninen, 0F LITTLE FALLS, NEW YORK.

Letters Patent No. 60,979, dated January 1, 1867.

IMPROVEMENT IN TBIB CONSTRUCTION OF ORDNANGE. .

digs ?dpimiz mama-111m Enters @atmt mm tithing put in the same.

TO ALL WHOM IT MAY CONCERN:

Be it known that I,

E. WOODBRTDGE, of the village of Little Falls, county of Herkimcr, and State oi

New York, have invented a new and usefullinprovement in the Construction of vCannon ; and I do hereby declare that the'follojving is a fulla-nd exact descriptionof the same, reference bei-n'ghad to the accompanying drawings. The nature of my invention consists in the disposition of helices of wire constitutin g in general the prin cipal part ,of the mass of the cannon, and their union by a more fusible metal employed as a solder, and also used, when desired, as thematerial forming the walls of the bore. The helices herein referred to may most conveniently be formed by winding the wire in successive layers on a cylindric mandrel or former, which should be enough larger than the intended bore of the gun to admit of ?nishing the bore,including the grooves, if it is intended for a ri?e, entirely within the inner helix of wire, and without coming in contact with it, as it is better that the surface of the bore should be of uniform vmetal. The mass of wire thus wound must, of course, be proportionate to the size of the intended gun. In order topmeet the combined strains to which a cannon is subjected, tending to rupture 'itgboth longitudinally and transversely, it is desirable that the wire should be wound in spirals of considerable obliquity, (which may be dictated by winding 3. number of wires placed side by side at the'same time,) and that the obliquity should be reversed in thealternate layers, the wires of each layer crossing those of the layer immediately under or over it. It will be perceived that in this way the tendency to unwind under the action of internal pressure in any particular layer will be

counteracted by that contiguous to it. The proper degree of obliquity may be attained by winding such a num

ber of wires at once as shall form a band about equal in width to the diameter of the bore. This rule is based upon the supposition that a metal equal in tenacity to bronze, or nearly so, is used as a roller; but when aless

tenacious metal is employed, the obliquity may be advantageously increased; in no case, however, needit exceed that produced by winding a band of wires once and a half in width the diameter of the bore. The arrangement of- the wire above described and its position in relation to the ?nished gun are illustrated in the accompanying

drawings.

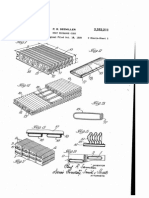

Figure 1 gives an external view of a glin composed bf ?ve helical layers of wires, (3. smaller number will often beused in practice, but convenient for illustration,) and shows-the course of - the wires, indicated by the

dotted lines a a, in four layers, whose surfaces are exposed in parts of the gun diil'ering in diameter. . The for

ward part of the gun, composed of two layers, presents but one at the surface, though both are shown in section

in ?gs. 2 and 3. _

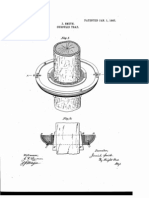

Figure 2 presents a section of the gun on the axis of its ?gure. Figure 3, across-section on A B of ?g. 2. The dotted lines I) b show the lines of contact between the di?erentdayers. C is theubore of the gun, and c c the metal forming its walls within the innermost helix. In general the mass ofwound wire is withdrawn from the mandrel or former before soldering, unless the latter be made of the metal to be used as a solder, in which case it may be unnecessary, as it will be melted in the process. The mandrel may, in other cases, be made of a material of which it is desired to form the walls of'the bore, when it is evident it should-be allowed to remain and become united to the wire. I also propose to use in place of wire, in some cases, especially-when cast iron is to be used as a. solder, rods of metal, iron or steel, drawn out by rolling or hammering. - The solder: ing of the iron may be effected by anyknown process, and with any metal or alloy suited to the purpose, the

particular process and .the subsequent ?nishing of the gun'forming no part of my. present claim. The use of cast iron as a solder is'recommcnd'ed by its cheapness,.'and it should be employed with wire of very large size,

or with rods larger than are drawn into wire. This is rendered desirable by the action of cast iron on iron con

taining less carbon, to which it imparts, at the high temperature requisite for its employment as a solder, a portion of its own, changing to some extent the properties of both metals. The same action renders it desirable that the spaces for thepassage of the melted metal into the interior of the mass to be soldered should be larger than when bronze is employed, and round wire is therefore more suitable than square, which leaves when wound much

smaller spaces between its turns. It is recommended that when cast iron is used as a solder, the walls of the bore and the closure of that cavity at the breech of the gun should be constituted of the same metal, supplied

for that purpose, within the inner helix of wire, during the process of soldering, as represented in ?gs 2 and 3

some

at c c. This remark may also apply to the use of: any'metal as a solder which possesses the requisite qualities

for forming the bore of a gun. When the mandrel 'upon which the wire is wound is retained to constitute the walls of the bore, a portion of the same may be allowed to remain in'the formation of the breech, or the bore may be closed in anjr other way that may be preferred. In order to carry my invention into effect it is neces

sary that the fused metal employed as a solder should unite with the wires or rods, and not merely surround them without adhering thereto. The materials which I esteem the best for the construction of guns, irrespective of cost, are steel wire of aquality usually called low steel, drawn square, or nearly so, with a hard bronze asv

a solder; hutI also propose, in some cases, to use wire wound under constant tension, and united with a solder of low fusihility, so that the'elastic tension of the wire may not be disturbed in the process. I also propose to

apply the mode of construction herein described to tubes other than cannon when the mechanical requirements

are similar. ' '

What I claim'as my invention, anddesire to secure by'Letters Patent, is1. The employment in the structure ,of cannon of helices of wire oi. reversed obliquity, applied one over

another, and brought into union by the intervention of a more fusible metal employed as a solder.

2. I claim, in general terms, the construction of cannon, substantially as herein described, modifying the

selection and use of materials as herein set forth.

3. I also claim the application of the mode of construction herein described to tubes other than cannon,

when the mechanical requirements are similar.

'

Witnesses:

j

'

__

'

WQE. WOODBRIDGE.

EDM. F. Brown, Jso. Jonson.

You might also like

- Lab 2 - StoichiometryDocument4 pagesLab 2 - Stoichiometryapi-272470922100% (3)

- Zhang, Xiangwu - Fundamentals of Fiber Science-DeStech Publications (2014)Document431 pagesZhang, Xiangwu - Fundamentals of Fiber Science-DeStech Publications (2014)Fawad hameed100% (1)

- Land Telegraph LinesDocument26 pagesLand Telegraph LinesAlex WarHorseNo ratings yet

- Determining Weld SizeDocument22 pagesDetermining Weld SizeJose Luis Olivares Lopez100% (1)

- Heat Exchange Core Patent DetailsDocument7 pagesHeat Exchange Core Patent DetailsRadnumNo ratings yet

- San Antionio OralDocument15 pagesSan Antionio OralMercedez BenzNo ratings yet

- Como Hacen Cañones Er18980121Document24 pagesComo Hacen Cañones Er18980121flamenquitoNo ratings yet

- CEPC25 Dec 2019Document2 pagesCEPC25 Dec 2019Lokesh Kumar MeenaNo ratings yet

- MVMK Mm. .: File?d Jan. 29, 1944Document4 pagesMVMK Mm. .: File?d Jan. 29, 1944Syed Umair RizviNo ratings yet

- R. Meredith, U.S. Patent 2,274,631Document5 pagesR. Meredith, U.S. Patent 2,274,631Erivaldo ConstantNo ratings yet

- Us1235153 PDFDocument2 pagesUs1235153 PDFAnonymous tvNMzJ2No ratings yet

- Peters v. Active Manuf'G CoDocument3 pagesPeters v. Active Manuf'G CoScribd Government DocsNo ratings yet

- When When WhenDocument1 pageWhen When WhenreacharunkNo ratings yet

- Public Lecture Theme: Submerged Arc Welding: Mechanical Faculty Zenica University ZenicaDocument15 pagesPublic Lecture Theme: Submerged Arc Welding: Mechanical Faculty Zenica University ZenicaAlma JusufovicNo ratings yet

- F. Hennebioue.: No. 6,907. Construction of Joists, Girders, and The LikeDocument3 pagesF. Hennebioue.: No. 6,907. Construction of Joists, Girders, and The LikeguillermoNo ratings yet

- It Is FailDocument1 pageIt Is FailreacharunkNo ratings yet

- Structures terminology assignment exampleDocument12 pagesStructures terminology assignment exampleamirthraj74No ratings yet

- Patente Sapata 2Document13 pagesPatente Sapata 2ELM EngenhariaNo ratings yet

- Ucture: of Practice FailureDocument20 pagesUcture: of Practice FailureKosygin LeishangthemNo ratings yet

- Theory: of ArchitectureDocument1 pageTheory: of ArchitecturereacharunkNo ratings yet

- EmeDocument13 pagesEmeAnkur SagarNo ratings yet

- Us3467410 PDFDocument4 pagesUs3467410 PDFNaza GavaputriNo ratings yet

- For Other Uses, See - This Article Is About Wire. For Wiring in Buildings, SeeDocument9 pagesFor Other Uses, See - This Article Is About Wire. For Wiring in Buildings, SeeMichael FelicianoNo ratings yet

- The Evolution of Wiredrawing TechniquesDocument5 pagesThe Evolution of Wiredrawing Techniquesngkisa113No ratings yet

- The Theory of Tube Producing MethodsDocument16 pagesThe Theory of Tube Producing MethodsJosé B. CorreaNo ratings yet

- Chap 03-Rotary Percussive Drilling Accessories PDFDocument12 pagesChap 03-Rotary Percussive Drilling Accessories PDFpnakurNo ratings yet

- Bantog - Finals HW 1Document4 pagesBantog - Finals HW 1Penuel G. BantogNo ratings yet

- ArticleDocument16 pagesArticleGuido OviedoNo ratings yet

- Eastern Venetian Blind Co. v. Acme Steel Co, 188 F.2d 247, 4th Cir. (1951)Document10 pagesEastern Venetian Blind Co. v. Acme Steel Co, 188 F.2d 247, 4th Cir. (1951)Scribd Government DocsNo ratings yet

- Welding of Nonferrous Metal and Their AlloysDocument62 pagesWelding of Nonferrous Metal and Their AlloysKhin Aung ShweNo ratings yet

- Probe DesignDocument10 pagesProbe DesignsenartconNo ratings yet

- Welding Lecture and OrientationDocument57 pagesWelding Lecture and OrientationHenry SyNo ratings yet

- United States Patent 1191 1111 3,956,085: Haas (45) May 11, 1976Document4 pagesUnited States Patent 1191 1111 3,956,085: Haas (45) May 11, 1976Alejandro Saravia AlcócerNo ratings yet

- Us2475875 PDFDocument4 pagesUs2475875 PDFchecolonoskiNo ratings yet

- The Manufacture of Cartridge Cases For Quick Firing Guns 1905 ArticleDocument75 pagesThe Manufacture of Cartridge Cases For Quick Firing Guns 1905 Articlemoonsix oneNo ratings yet

- Tliesl-In Ttie Is Tlie Tliis IsDocument1 pageTliesl-In Ttie Is Tlie Tliis IsreacharunkNo ratings yet

- VivekDocument29 pagesVivekshreyanshNo ratings yet

- Neral Capítulo.9 PDFDocument24 pagesNeral Capítulo.9 PDFtrinoNo ratings yet

- Creep in 9 CR + BoroDocument11 pagesCreep in 9 CR + Borodiego morNo ratings yet

- Network Arch Bridge DesignDocument36 pagesNetwork Arch Bridge DesignSergio Adolfo ParedesNo ratings yet

- Divergence Plumb LinesDocument4 pagesDivergence Plumb Linesindio007No ratings yet

- Radial Air Core Alternator FunDocument5 pagesRadial Air Core Alternator FunMiguel CabreraNo ratings yet

- Book Round and Square: Zinc. CommonDocument1 pageBook Round and Square: Zinc. CommonreacharunkNo ratings yet

- Drawing Extremely Fine WiresDocument6 pagesDrawing Extremely Fine Wiresfazal ahmadNo ratings yet

- Scientific American Supplement, No. 531, March 6, 1886 by VariousDocument84 pagesScientific American Supplement, No. 531, March 6, 1886 by VariousGutenberg.orgNo ratings yet

- Welding DictionaryDocument18 pagesWelding DictionaryEswar Enterprises QcNo ratings yet

- Instructions on Modern American Bridge BuildingFrom EverandInstructions on Modern American Bridge BuildingNo ratings yet

- Design of Riveted JointDocument12 pagesDesign of Riveted JointYogesh DandekarNo ratings yet

- School of Mechanical Engineering: Lab Manual of Semester - V U5AEA20 - Aircraft Structures Repair LabDocument31 pagesSchool of Mechanical Engineering: Lab Manual of Semester - V U5AEA20 - Aircraft Structures Repair LabAasto Ashrita AastikaeNo ratings yet

- Naval Gun Barrel Construction (Website Capture) WWDocument26 pagesNaval Gun Barrel Construction (Website Capture) WWquinnrandall100% (1)

- Metal Turning LatheDocument12 pagesMetal Turning LatheEugen50% (2)

- 1837 Contributions To Electricity and Magnetism Henry InglesDocument8 pages1837 Contributions To Electricity and Magnetism Henry Inglesjeremias romeroNo ratings yet

- Unit 4 Welded Joints: StructureDocument13 pagesUnit 4 Welded Joints: StructureDEEPAKNo ratings yet

- The Serpent in The Sword: Pattern-Welding in Early Medieval SwordsDocument6 pagesThe Serpent in The Sword: Pattern-Welding in Early Medieval SwordsMariella GiorginiNo ratings yet

- Cold Pressure Welding Is A Form of Solid Phase WeldingDocument6 pagesCold Pressure Welding Is A Form of Solid Phase WeldingSatish BabuNo ratings yet

- Introduction To Welding TechnologyDocument4 pagesIntroduction To Welding TechnologyLorena Grijalba LeónNo ratings yet

- CE6306 STRENGTH OF MATERIALS PART-B TOPICSDocument8 pagesCE6306 STRENGTH OF MATERIALS PART-B TOPICSnkchandruNo ratings yet

- Beams Structural Design Using Bs 8110Document6 pagesBeams Structural Design Using Bs 8110Okareme PeaceNo ratings yet

- Thermopile and Galvanometer CombinedDocument4 pagesThermopile and Galvanometer CombinedCurter Lance LusansoNo ratings yet

- GunshotDocument2 pagesGunshotasdfasfNo ratings yet

- Socket Programing GuideDocument101 pagesSocket Programing GuideAnurag AggarwalNo ratings yet

- Us 60951Document2 pagesUs 60951asdfasfNo ratings yet

- Us 60946Document2 pagesUs 60946asdfasfNo ratings yet

- US60932 Page 1Document1 pageUS60932 Page 1asdfasfNo ratings yet

- Us 60947Document2 pagesUs 60947asdfasfNo ratings yet

- Us 60954Document2 pagesUs 60954asdfasfNo ratings yet

- 01V96 ManualDocument334 pages01V96 ManualDario Luna Popunjeni ProfilNo ratings yet

- US60942 PageDocument1 pageUS60942 PageasdfasfNo ratings yet

- Patented Jan. 1, I867 V: Z. SperryDocument3 pagesPatented Jan. 1, I867 V: Z. SperryasdfasfNo ratings yet

- Us 60945Document2 pagesUs 60945asdfasfNo ratings yet

- @értitrh .. Tstrs Gaunt @ffirn.: Amor Smith, 0F Cincinnati, OhioDocument1 page@értitrh .. Tstrs Gaunt @ffirn.: Amor Smith, 0F Cincinnati, OhioasdfasfNo ratings yet

- Improved Sheepskin Mitten ConstructionDocument3 pagesImproved Sheepskin Mitten ConstructionasdfasfNo ratings yet

- Us 60941Document2 pagesUs 60941asdfasfNo ratings yet

- Us 60953Document3 pagesUs 60953asdfasfNo ratings yet

- Gems "Tetra GM": Ffinr.: John '1 . Sohenck, JR, or ' Matteawan, New YorkDocument1 pageGems "Tetra GM": Ffinr.: John '1 . Sohenck, JR, or ' Matteawan, New YorkasdfasfNo ratings yet

- N. Puckett. - : Centering ToolDocument2 pagesN. Puckett. - : Centering ToolasdfasfNo ratings yet

- Lathe Rest Movement ControlDocument3 pagesLathe Rest Movement ControlasdfasfNo ratings yet

- Us 60943Document2 pagesUs 60943asdfasfNo ratings yet

- Chemical Preservation of Butter and MeatsDocument1 pageChemical Preservation of Butter and MeatsasdfasfNo ratings yet

- Nitrii Tetra Gaunt Ffirr.: Adolphe Roque, of Brire, France, Assignor To Jacques Guedin, ofDocument1 pageNitrii Tetra Gaunt Ffirr.: Adolphe Roque, of Brire, France, Assignor To Jacques Guedin, ofasdfasfNo ratings yet

- Making Eyelets MachineDocument3 pagesMaking Eyelets MachineasdfasfNo ratings yet

- Us 60933Document2 pagesUs 60933asdfasfNo ratings yet

- Us 60935Document2 pagesUs 60935asdfasfNo ratings yet

- Refrigerator.: 2 Sheets Sheet 1.' C. F. Pike"Document5 pagesRefrigerator.: 2 Sheets Sheet 1.' C. F. Pike"asdfasfNo ratings yet

- Us 60959Document2 pagesUs 60959asdfasfNo ratings yet

- F. F. Reynolds.: No. 60,938. ' Patented Jan. Ì, - 867Document2 pagesF. F. Reynolds.: No. 60,938. ' Patented Jan. Ì, - 867asdfasfNo ratings yet

- No. 60,932. - Patented Jan: 1, "1867.: S. J . PEETDocument2 pagesNo. 60,932. - Patented Jan: 1, "1867.: S. J . PEETasdfasfNo ratings yet

- Us 60931Document2 pagesUs 60931asdfasfNo ratings yet

- Instant railroad car brake from 1867 patentDocument2 pagesInstant railroad car brake from 1867 patentasdfasfNo ratings yet

- Micro 2000 - Deox 2000Document139 pagesMicro 2000 - Deox 2000Achr FFNo ratings yet

- Jakap Lace Pvt. LTD.: Material Test CertificateDocument1 pageJakap Lace Pvt. LTD.: Material Test CertificateMechtek LabNo ratings yet

- Optical Emission From SemiconductorsDocument36 pagesOptical Emission From SemiconductorsvardhanNo ratings yet

- Chemical Compatibility Reference Chart: Stainless SteelDocument15 pagesChemical Compatibility Reference Chart: Stainless SteelWbeimar Zuluaga ZuluagaNo ratings yet

- Chemical and Petrochemical Statistics at A Glance - 2018Document232 pagesChemical and Petrochemical Statistics at A Glance - 2018Nayan GhoshNo ratings yet

- A Simple Model For Quantisation Effects IN Heavily-Doped Silicon Mosfets at Inversion ConditionsDocument4 pagesA Simple Model For Quantisation Effects IN Heavily-Doped Silicon Mosfets at Inversion ConditionsmodasshirNo ratings yet

- CHEM 18 PROBLEM SET CHEMICAL THERMODYNAMICS AND EQUILIBRIUMDocument4 pagesCHEM 18 PROBLEM SET CHEMICAL THERMODYNAMICS AND EQUILIBRIUMDaniel Jann CotiaNo ratings yet

- Buffers BookletDocument38 pagesBuffers BookletdgmansoNo ratings yet

- Tutoral 3 SolutionDocument11 pagesTutoral 3 SolutionIshani GuptaNo ratings yet

- Distillation Columns PDFDocument40 pagesDistillation Columns PDFJithuJohn86% (7)

- PCA Ion Exchange Membranes - Technical Data SheetDocument2 pagesPCA Ion Exchange Membranes - Technical Data Sheettestuser010% (1)

- DISINFECTION in Health CareDocument86 pagesDISINFECTION in Health Caretummalapalli venkateswara raoNo ratings yet

- Effects of Substituent On Benzene RingDocument12 pagesEffects of Substituent On Benzene Ringyashfa khalidNo ratings yet

- Maximizing profits from heavy crude oils and reducing fuel oil productionDocument5 pagesMaximizing profits from heavy crude oils and reducing fuel oil productionsantiagoNo ratings yet

- Safety Data Sheet For ProductDocument5 pagesSafety Data Sheet For ProductAndrey HristovNo ratings yet

- Molecular Biology IB ReviewerDocument28 pagesMolecular Biology IB ReviewerCeline Garin ColadaNo ratings yet

- 4-Procedure Pipe To SoilDocument7 pages4-Procedure Pipe To SoilKhanh DTNo ratings yet

- UOP PX-Plus ™ XPDocument2 pagesUOP PX-Plus ™ XPana_dcz7154No ratings yet

- CHM 1321 Assignment 1 Answers: CN H H H H HDocument10 pagesCHM 1321 Assignment 1 Answers: CN H H H H HSara YuenNo ratings yet

- 1229.1 Steam Sterilization by Direct ContactDocument3 pages1229.1 Steam Sterilization by Direct ContactWasimNo ratings yet

- Fermi DistrbutionDocument17 pagesFermi DistrbutionnazarNo ratings yet

- Practice 4ADocument22 pagesPractice 4ACamha NguyenNo ratings yet

- Ganoderma laccase optimizationDocument9 pagesGanoderma laccase optimizationRajeshKumarNo ratings yet

- Point and Line SourceDocument41 pagesPoint and Line SourceNomanNo ratings yet

- Taylor & Francis E-BooksDocument6 pagesTaylor & Francis E-BooksVijaya Gosu0% (1)

- Steel Industry PackageDocument9 pagesSteel Industry Packagebatung144100% (1)

- Ferritic and Martensitic Casting Materials SpecificationsDocument2 pagesFerritic and Martensitic Casting Materials SpecificationsSinan YıldızNo ratings yet

- Wall Colmonoy Surfacing Alloys Selector ChartDocument3 pagesWall Colmonoy Surfacing Alloys Selector ChartAjimKe'enNo ratings yet