Professional Documents

Culture Documents

Detecting and preventing lack of sidewall and inter-run fusion in welds

Uploaded by

guru_terexOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detecting and preventing lack of sidewall and inter-run fusion in welds

Uploaded by

guru_terexCopyright:

Available Formats

Demagnetising a pipe

Weld defects/imperfections in welds - lack of sidewall and inter-run fusion

This article describes the characteristic features and principal causes of lack of sidewall and inter-run fusion. General guidelines on best practice are given so that welders can minimise the risk of imperfections during fabrication.

Identification

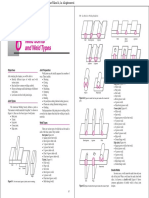

Lack of fusion imperfections can occur when the weld metal fails to fuse completely with the sidewall of the joint (Fig. ! to penetrate ade"uately the previous weld bead (Fig. #!.

Fig. 1. Lack of side wall fusion

Fig. 2. Lack of inter-run fusion

Causes

The principal causes are too narrow a joint preparation$ incorrect welding parameter settings$ poor welder techni"ue and magnetic arc blow. %nsufficient cleaning of oily or

scaled surfaces can also contribute to lack of fusion. These types of imperfection are more likely to happen when welding in the vertical position.

Joint preparation

Too narrow a joint preparation often causes the arc to be attracted to one of the side walls causing lack of side wall fusion on the other side of the joint or inade"uate penetration into the previously deposited weld bead. Too great an arc length may also increase the risk of preferential melting along one side of the joint and cause shallow penetration. %n addition$ a narrow joint preparation may prevent ade"uate access into the joint. For e&le$ this happens in ''( welding when using a large diameter electrode$ or in '%G welding where an allowance should be made for the si)e of the no))le.

Welding parameters

%t is important to use a sufficiently high current for the arc to penetrate into the joint sidewall. *onse"uently$ too high a welding speed for the welding current will increase the risk of these imperfections. +owever$ too high a current or too low a welding speed will cause weld pool flooding ahead of the arc resulting in poor or non-uniform penetration.

Welder technique

,oor welder techni"ue such as incorrect angle or manipulation of the electrode-welding gun$ will prevent ade"uate fusion of the joint sidewall. .eaving$ especially dwelling at the joint sidewall$ will enable the weld pool to wash into the parent metal$ greatly improving sidewall fusion. %t should be noted that the amount of weaving may be restricted by the welding procedure specification limiting the arc energy input$ particularly when welding alloy or high notch toughness steels.

Magnetic arc blow

.hen welding ferromagnetic steels lack of fusion imperfections can be caused through uncontrolled deflection of the arc$ usually termed arc blow. (rc deflection can be caused by distortion of the magnetic field produced by the arc current (Fig. /!$ through0 residual magnetism in the material through using magnets for handling earth1s magnetic field$ for e&le in pipeline welding position of the current return The effect of welding past the current return cable which is bolted to the centre of the place is shown in Fig. 2. The interaction of the magnetic field surrounding the arc and that generated by the current flow in the plate to the current return cable is sufficient to deflect the weld bead. 3istortion of the arc current magnetic field can be minimised by positioning the current return so that welding is always towards or away from the clamp and$ in ''( welding$ by using (* instead of 3*. 4ften the only effective means is to demagnetise the steel before welding.

Fig. 3. Interaction of magnetic forces causing arc deflection

Fig. 4. Weld bead deflection in D !!" welding caused b# welding past t$e current return connection

Best practice in prevention

The following fabrication techni"ues can be used to prevent formation of lack of sidewall fusion imperfections0 use a sufficiently wide joint preparation select welding parameters (high current level$ short arc length$ not too high a welding speed! to promote penetration into the joint side wall without causing flooding ensure the electrode-gun angle and manipulation techni"ue will give ade"uate side wall fusion use weaving and dwell to improve side wall fusion providing there are no heat input restrictions if arc blow occurs$ reposition the current return$ use (* (in ''( welding! or demagnetise the steel

cceptance standards

The limits for incomplete fusion imperfections in arc welded joints in steel are specified in 56 78 #9: ; (%64 9: ;! for the three "uality levels (see Table!. These types of imperfection are not permitted for <uality Level 5 (stringent! and * (intermediate!. For <uality level 3 (moderate! they are only permitted providing they are intermittent and not surface breaking. For arc welded joints in aluminium$ long imperfections are not permitted for all three "uality levels. +owever$ for "uality levels * and 3$ short imperfections are permitted but the total length of the imperfections is limited depending on the butt weld or the fillet weld throat thickness. cceptance limits for specific codes and application standards

"pplication Steel

ode%&tandard ISO 5817:1992

"cceptance limit Level B and C not permitted. Level D intermittent and not surfa e !rea"in#.

$luminium

Levels B' C' D. Lon# imperfe tions not permitted. ISO 1%%&2:1992 Levels C and D. S(ort imperfe tions permitted. *ot permitted *ot permitted .l. not #reater t(an 15mm /dependin# on ,all t(i "ness0 .l. not #reater t(an 25mm /less ,(en ,eld len#t( 1-%%mm0

)ressure vessels BS55%%:1997 Stora#e tan"s )ipe,or" Line pipe BS2+5&:1989 BS2+--:1987 $)I 11%&:198-

!etection and remedial action

%f the imperfections are surface breaking$ they can be detected using a penetrant or magnetic particle inspection techni"ue. For sub-surface imperfections$ detection is by radiography or ultrasonic inspection. =ltrasonic inspection is normally more effective than radiography in detecting lack of inter-run fusion imperfections. >emedial action will normally re"uire their removal by localised gouging$ or grinding$ followed by re-welding as specified in the agreed procedure. %f lack of fusion is a persistent problem$ and is not caused by magnetic arc blow$ the welding procedures should be amended or the welders retrained.

You might also like

- Lamellar tearing in welded steel platesDocument6 pagesLamellar tearing in welded steel platesguru_terexNo ratings yet

- Alloy 6moDocument2 pagesAlloy 6moqshaath100% (1)

- Schaeffler Diagram PDFDocument16 pagesSchaeffler Diagram PDFrajesh_14No ratings yet

- Welding Procedure Data SheetDocument2 pagesWelding Procedure Data SheetAmanSharmaNo ratings yet

- VT Acceptance Criteria WeldsDocument14 pagesVT Acceptance Criteria WeldsCharwin Xiao100% (1)

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- Cast Carbon Steels in AWS D1.1 PDFDocument3 pagesCast Carbon Steels in AWS D1.1 PDFIndra NainggolanNo ratings yet

- Weld Joint Detail PDFDocument9 pagesWeld Joint Detail PDFKosit WongpinkaewNo ratings yet

- ASME ASTM Difference PDFDocument5 pagesASME ASTM Difference PDFSiddharth PawarNo ratings yet

- Catalog Fabricante TechnipDocument9 pagesCatalog Fabricante Technipjimy GutiérrezNo ratings yet

- Highlights On ASME Essential VariablesDocument8 pagesHighlights On ASME Essential VariableschowhkNo ratings yet

- Welding - Group G - Welding-02Document27 pagesWelding - Group G - Welding-02christofer kevinNo ratings yet

- Duplex Stainless Steel - Part 2 - TWIDocument6 pagesDuplex Stainless Steel - Part 2 - TWItuanNo ratings yet

- (First Revision) : Indian StandardDocument8 pages(First Revision) : Indian StandardBhanu Pratap ChoudhuryNo ratings yet

- Positive Material IdentificationDocument2 pagesPositive Material IdentificationGovindKrishnanNo ratings yet

- Welding Procedure Data Sheet for Steel Groups 1-3Document1 pageWelding Procedure Data Sheet for Steel Groups 1-3suronocaturatmojoNo ratings yet

- Welding Martensitic Stainless SteelsDocument4 pagesWelding Martensitic Stainless SteelsBabar Manzoor GhauriNo ratings yet

- Mechanical Engineering Questions on Welding Standards and ProcessesDocument5 pagesMechanical Engineering Questions on Welding Standards and ProcessesEhab Harb100% (1)

- Guide For AWS D1.1 2020 Visual Weld Inspection 1Document6 pagesGuide For AWS D1.1 2020 Visual Weld Inspection 1Nima SharifiNo ratings yet

- Effect of Heat InputDocument9 pagesEffect of Heat InputshrikantajitNo ratings yet

- EGW Welding Wire Guide for 490MPa SteelDocument2 pagesEGW Welding Wire Guide for 490MPa SteelpratishgnairNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- NDT Code Book Made Easy For AsmeDocument398 pagesNDT Code Book Made Easy For AsmeJosé Pablo Espinoza SolísNo ratings yet

- Pressure Vessel RT TestDocument3 pagesPressure Vessel RT TestAriq FauzanNo ratings yet

- HeadDocument1 pageHeadabdulloh_99No ratings yet

- The ASME Impact Test RequirementDocument7 pagesThe ASME Impact Test Requirementrosli2503No ratings yet

- DIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationDocument12 pagesDIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationHector Flores GarciaNo ratings yet

- Table 6 1 AWS D1 1 D1 1M 2010 PDFDocument1 pageTable 6 1 AWS D1 1 D1 1M 2010 PDFFu AdNo ratings yet

- Weldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructuresDocument8 pagesWeldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructurestheijesNo ratings yet

- Defects Hydrogen Cracks IdentificationDocument5 pagesDefects Hydrogen Cracks Identificationarif maulanafNo ratings yet

- A 1031 - 04 Qtewmze - PDFDocument4 pagesA 1031 - 04 Qtewmze - PDFqueno1No ratings yet

- Weld Repair AWS D1.1Document3 pagesWeld Repair AWS D1.1Hemant PatelNo ratings yet

- Cswip Section 13 Mig Mag WeldingDocument23 pagesCswip Section 13 Mig Mag WeldingNsidibe Michael EtimNo ratings yet

- New materials for sour gas drill pipeDocument2 pagesNew materials for sour gas drill pipeamigofirmNo ratings yet

- Indian Standard: Specification For Steel ScaffoldingsDocument27 pagesIndian Standard: Specification For Steel Scaffoldingshari6krishnanNo ratings yet

- Stainless Steel Grade AISI 321Document2 pagesStainless Steel Grade AISI 321Mitul RawatNo ratings yet

- Radiography Cheat SheetDocument1 pageRadiography Cheat SheetbplturnerNo ratings yet

- D1 4scopeDocument3 pagesD1 4scopesunparamarNo ratings yet

- Aisi 4140 En8 En19Document1 pageAisi 4140 En8 En19Jose KurianNo ratings yet

- JIS G3452 PipeDocument0 pagesJIS G3452 PipefaridyeniNo ratings yet

- Addressing Some Issues in Drop Weight Testing - A Material Science ApproachDocument16 pagesAddressing Some Issues in Drop Weight Testing - A Material Science ApproachManish BhadauriaNo ratings yet

- Welding TypesDocument6 pagesWelding TypestNo ratings yet

- Production Test CouponDocument4 pagesProduction Test CouponAbhijeet SahuNo ratings yet

- API 2H50 Data Sheet 2012 04 02Document2 pagesAPI 2H50 Data Sheet 2012 04 02alvaedison00No ratings yet

- EIL - Specification Sheet123Document1 pageEIL - Specification Sheet123Dinesh ChouguleNo ratings yet

- RT Acceptance Criteria GuideDocument1 pageRT Acceptance Criteria GuidevikasNo ratings yet

- Como Soldar 4140Document4 pagesComo Soldar 4140Luis Jose DuranNo ratings yet

- AISI 4145 HT (Oiled Spec.) : Sin Thai Special Steel Co., LTDDocument1 pageAISI 4145 HT (Oiled Spec.) : Sin Thai Special Steel Co., LTDl_aguilar_mNo ratings yet

- Welding Certifications and Welder Qualification Tests PDFDocument7 pagesWelding Certifications and Welder Qualification Tests PDFArjun JpNo ratings yet

- Carbon Steel Forgings, Class 2: Corporate Purchase Specification AA 193 31 Rev. No. 11 Preface SheetDocument7 pagesCarbon Steel Forgings, Class 2: Corporate Purchase Specification AA 193 31 Rev. No. 11 Preface Sheetraghav248No ratings yet

- 5 - Section 14 - Arc Welding ConsumablesDocument11 pages5 - Section 14 - Arc Welding Consumablesrizkialia12No ratings yet

- Materials Guide for Over 50 AlloysDocument8 pagesMaterials Guide for Over 50 AlloysMark RomeroNo ratings yet

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocument10 pagesA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaNo ratings yet

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Weld DefectsDocument45 pagesWeld DefectsEhigiator Joseph100% (5)

- Weld Defects or Imperfections in Welds - Lack of Sidewall and Inter-Run FusionDocument4 pagesWeld Defects or Imperfections in Welds - Lack of Sidewall and Inter-Run FusionmanimaranNo ratings yet

- All Metal Melting PointsDocument2 pagesAll Metal Melting Pointsguru_terex100% (1)

- PrintReceipt BSNL 19 Feb 2015Document1 pagePrintReceipt BSNL 19 Feb 2015GirishNairNo ratings yet

- 021 002 935 - Phasec 3 PDFDocument185 pages021 002 935 - Phasec 3 PDFvrapciudorian0% (1)

- 50018-EN-Broch Locator Phasec PDFDocument12 pages50018-EN-Broch Locator Phasec PDFguru_terexNo ratings yet

- Asme V Si UnitsDocument3 pagesAsme V Si UnitsvidhisukhadiyaNo ratings yet

- Defects Reheat CrackingDocument5 pagesDefects Reheat Crackingguru_terexNo ratings yet

- Defects/imperfections in Welds - Porosity: IdentificationDocument4 pagesDefects/imperfections in Welds - Porosity: Identificationguru_terexNo ratings yet

- 50018-EN-Broch Locator Phasec PDFDocument12 pages50018-EN-Broch Locator Phasec PDFguru_terexNo ratings yet

- Defects Slag InclusionsDocument4 pagesDefects Slag Inclusionsguru_terexNo ratings yet

- Theory and Application of Precision Ultrasonic Thickness GagingDocument17 pagesTheory and Application of Precision Ultrasonic Thickness Gagingguru_terexNo ratings yet

- SS Schenectady tanker failure causesDocument4 pagesSS Schenectady tanker failure causesguru_terexNo ratings yet

- Prevent hydrogen cracking in steels with preheating and low-hydrogen weldingDocument6 pagesPrevent hydrogen cracking in steels with preheating and low-hydrogen weldingguru_terexNo ratings yet

- Defects Hydrogen Cracks IdentificationDocument5 pagesDefects Hydrogen Cracks Identificationguru_terexNo ratings yet

- Table 1: Literature Values For Speed of Sound in SteelsDocument1 pageTable 1: Literature Values For Speed of Sound in Steelsguru_terexNo ratings yet

- For Global RemoteDocument1 pageFor Global Remoteguru_terexNo ratings yet

- For Global RemoteDocument1 pageFor Global Remoteguru_terexNo ratings yet

- Covering LetterDocument2 pagesCovering Letterguru_terexNo ratings yet

- Ultrasonic formula guideDocument5 pagesUltrasonic formula guideguru_terexNo ratings yet

- User ManualDocument3 pagesUser Manualguru_terexNo ratings yet

- Ultrasonic formula guideDocument5 pagesUltrasonic formula guideguru_terexNo ratings yet

- Eddy Current TestingDocument13 pagesEddy Current Testingguru_terexNo ratings yet

- AssemblyinstructionsDocument12 pagesAssemblyinstructionsPriscila AzevedoNo ratings yet

- RF Power Measurements Basic PrinciplesDocument27 pagesRF Power Measurements Basic PrinciplesHector Velasco100% (1)

- Ielts Band 9 Sample Essay NoDocument5 pagesIelts Band 9 Sample Essay NoNhã NguyễnNo ratings yet

- Lab - Activity CCNA 2 Exp: 7.5.3Document13 pagesLab - Activity CCNA 2 Exp: 7.5.3Rico Agung FirmansyahNo ratings yet

- The Study of Accounting Information SystemsDocument44 pagesThe Study of Accounting Information SystemsCelso Jr. AleyaNo ratings yet

- Liability WaiverDocument1 pageLiability WaiverTop Flight FitnessNo ratings yet

- The Causes of Cyber Crime PDFDocument3 pagesThe Causes of Cyber Crime PDFInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Lab 2 ReportDocument9 pagesLab 2 Reportsherub wangdiNo ratings yet

- STS Chapter 5Document2 pagesSTS Chapter 5Cristine Laluna92% (38)

- Norms and specifications for distribution transformer, DG set, street light poles, LED lights and high mast lightDocument4 pagesNorms and specifications for distribution transformer, DG set, street light poles, LED lights and high mast lightKumar AvinashNo ratings yet

- Acknowledgment: George & Also To Our Group Guide Asst. Prof. Simy M Baby, For Their Valuable Guidance and HelpDocument50 pagesAcknowledgment: George & Also To Our Group Guide Asst. Prof. Simy M Baby, For Their Valuable Guidance and HelpKhurram ShahzadNo ratings yet

- Pass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppDocument1 pagePass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppAnoop SharmaNo ratings yet

- EDP/LRP Well Intervention System OverviewDocument22 pagesEDP/LRP Well Intervention System OverviewJerome LIKIBINo ratings yet

- BILL OF SALE Pre ApproveDocument1 pageBILL OF SALE Pre ApprovedidinurieliaNo ratings yet

- Specialized Government BanksDocument5 pagesSpecialized Government BanksCarazelli AysonNo ratings yet

- GSM Multi-Mode Feature DescriptionDocument39 pagesGSM Multi-Mode Feature DescriptionDiyas KazhiyevNo ratings yet

- Sample Feedback IELTS Academic Task 1 Band 6 Double GraphDocument3 pagesSample Feedback IELTS Academic Task 1 Band 6 Double GraphalinaemmeaNo ratings yet

- ETP Research Proposal Group7 NewDocument12 pagesETP Research Proposal Group7 NewlohNo ratings yet

- Modulus of Subgrade Reaction KsDocument1 pageModulus of Subgrade Reaction KsmohamedabdelalNo ratings yet

- DEFCON ManualDocument13 pagesDEFCON Manualbuyvalve100% (1)

- Vitamin D3 5GDocument7 pagesVitamin D3 5GLuis SuescumNo ratings yet

- Dewatering Construction Sites Below Water TableDocument6 pagesDewatering Construction Sites Below Water TableSOMSUBHRA SINGHANo ratings yet

- Uniform Bonding Code (Part 2)Document18 pagesUniform Bonding Code (Part 2)Paschal James BloiseNo ratings yet

- Jodi Ridgeway vs. Horry County Police DepartmentDocument17 pagesJodi Ridgeway vs. Horry County Police DepartmentWMBF NewsNo ratings yet

- Feb 22-Additional CasesDocument27 pagesFeb 22-Additional CasesYodh Jamin OngNo ratings yet

- De Thi Thu THPT Quoc Gia Mon Tieng Anh Truong THPT Hai An Hai Phong Nam 2015Document10 pagesDe Thi Thu THPT Quoc Gia Mon Tieng Anh Truong THPT Hai An Hai Phong Nam 2015nguyen ngaNo ratings yet

- Serras Tilted Arc Art and Non Art Senie in Art Journal 1989Document6 pagesSerras Tilted Arc Art and Non Art Senie in Art Journal 1989api-275667500No ratings yet

- Cycles in Nature: Understanding Biogeochemical CyclesDocument17 pagesCycles in Nature: Understanding Biogeochemical CyclesRatay EvelynNo ratings yet

- FOMRHI Quarterly: Ekna Dal CortivoDocument52 pagesFOMRHI Quarterly: Ekna Dal CortivoGaetano PreviteraNo ratings yet

- Domestic Water Consumption in ChennaiDocument18 pagesDomestic Water Consumption in Chennaimaaz0% (1)