Professional Documents

Culture Documents

Gearbox Project Report

Uploaded by

alexpatowCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gearbox Project Report

Uploaded by

alexpatowCopyright:

Available Formats

BOSTON UNIVERSITY

ME 359 Final Project Report

Group #5

Alex Patow, ME 2015 John Griese, ME 2015 Michael Gonzalez, ME 2014 Abby Dutke, ME 2015

12/1/2013

ME359 Final Project Report

Description

The objective of this project is to design a manufacturable prototype gear box. The gear box is required to have a ratio of 1/240, and a minimum life of 25,000 hours. The input and output shafts are orthogonal and a maximum of 1.5 inches past the outer surface of the gearbox. The output shaft and its bearing must support an eccentric load of 50lbf, and have a maximum input shaft rotation speed of 240rpm. Alex Patow Spec Parts, CAD, CAD Drawings, Presentation and Report Michael Gonzalez Spec Parts, CAD Drawings, Tolerancing, Presentation and Report John Griese CAD, CAD Drawings, Tolerancing, Life Analysis, Presentation and Report Abby Dutke Spec Parts, CAD Drawings, Presentation and Report

Design Review

The final design of the project includes a 10 tooth spur gear, a 100 tooth spur gear, a 1 start worm, and a 24 tooth worm gear. The input shaft houses the worm, which is paired with the worm gear. The 10 tooth gear shares the same shaft as the worm gear and is paired with the 100 tooth spur gear. This gives us a gear ratio of 1/240 and the orientation of the worm and gears makes the input and output shafts perpendicular. The input and output shafts both protrude 1 inch (nominally) from the surface of the box. All bearings were specified to support a 50lbf eccentric load with a maximum speed of 240rpm with a lifetime of 25,000 hours under these most strenuous conditions.

Our gear box housing is made out of 304-Stainless Steel sheet metal which is 0.060 thick. There are two parts to the housing. One fits into the other and they are connected by self-clinching nuts. The holes will be drilled into the flat sheet metal pieces, which will then be bent in a set of presses to achieve the desired shapes. Page 1 of 10

ME359 Final Project Report

Ninput = # input teeth input = input torque input = input rotation speed

GR = gear ratio

Noutput = # output teeth output = output torque output = output rotation speed

Gear Speed Relation

v = velocity at gear tooth contact R = radius of gear = rotation speed DP= diametral pitch

F = force at gear tooth contact PD = pitch diameters N= number of teeth

Gear Torque Relation ( ) Page 2 of 10

ME359 Final Project Report ( ) ( ) ( ) ( Gear Trains without Shared Axles ( ( ) [( ) ) ] ( ) ( ) ) ( )

Gear Trains with Shared Axles

Tolerance Analyses

We encountered significant problems with SDP-SIs catalog, which led to discrepancies in tolerancing. When we measured some of the downloaded parts with Smart Dimension in SolidWorks they were different, about twice as large in certain cases, than the size stated on the website. The most intensive analysis was for the input shaft because it drives the dimensions in spacing the rest of the features. For the input shaft (shown below) we performed a detailed circuit analysis. This was not necessary for the rest of the components for which we did basic tolerance analysis.

Page 3 of 10

ME359 Final Project Report Input Shaft

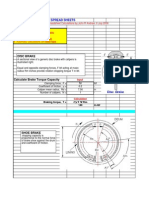

Calculate distance from outer face to 2nd Shaft hole (J), J = - F.W. - O.S. + W.H + P.D.P Measurement Nominal (in) Upper + (in) Lower - (in) MAX MIN Flange Width (F.W.) 0.045 0.000 0.002 0.025 Outer Shaft (O.S.) 1.000 0.005 0.005 1.005 Worm Hole (W.H.) 1.730 0.005 0.005 1.735 Pitch Diameter Center (P.D.C.) 0.438 0.000 0.000 0.438 2nd Shaft Hole (J) 1.123 0.010 0.012 1.133 First Groove (G1) Measurement Outer Shaft (O.S.) Bearing Width (B.W.) First Groove (G1) O.S + B.W. = G1 Nominal (in) Upper + (in) Lower - (in) MAX 1.000 0.005 0.005 1.005 0.188 0 0.005 1.188 0.005 0.01

0.021 0.995 1.725 0.438 1.111

MIN 0.995 0.188 1.193 0.183 1.178

*The greyed cell indicated the critical dimension, i.e. the dimension which, the actual part cannot be greater or less that without a chance that the part will not fit.

Second Groove (G2) Measurement Flange Width (F.W.) Outer Box Lenth (O.B.L) Bearing Width (B.W.) Second Groove (G2) - B.L. + F.W. + O.B.L. + F.W. -B.L. = G2 Nominal (in) Upper + (in) Lower - (in) MAX 0.045 0.000 0.002 5.811 0.188 5.525 0.005 0 0.005 0.005 0.005 0.019

MIN 0.025 5.816 0.188 5.530 0.021 5.806 0.183 5.506

Bearings (from SDP-SI)

Measurement Bore Diameter Outer Diameter Bearing Width (B.W.) Flange Width (F.W.) Nominal (in) Upper + (in) 0.25 0.5 0.188 0.045 0 0 0 0 Lower - (in) MAX 0.002 0.003 0.005 0.002 MIN 0.25 0.5 0.188 0.025 0.248 0.497 0.183 0.021

Worm (from SDP-SI)

Measurement Groove Diameter Groove Width Nominal (in) Upper + (in) Lower - (in) MAX (in) MIN (in) 0.21 0.003 0 0.213 0.21 0.029 0.003 0 0.032 0.029

Retaining Rings (from McMaster-Carr)

Measurement Bore Diameter Face Width Overall Width Outside Diameter Hub Diameter Nominal (in) Upper + (in) Lower - (in) MAX (in) MIN (in) 0.25 0.0008 0 0.2508 0.25 0.625 0.875 0.583 0.375

Page 4 of 10

ME359 Final Project Report

P.D. 0.5

Second Shaft

Calculate Total Length Measurement Bearing Width (B.W.) Interior Width (I.W.) Total Length B.W. + I.W. + B.W. Nominal (in) Upper + (in) Lower - (in) MAX 0.281 0.000 0.005 2.000 0.000 0.010 2.562 0.000 0.020

MIN 0.281 2.000 2.562 0.276 1.990 2.542

Bearings (from SDP-SI)

Measurement Bore Outer Diameter Bearing Width (B.W.) Flange Width (F.W.) Nominal (in) Upper + (in) Lower - (in) MAX 0.1875 0.0000 0.0020 0.3125 0.0000 0.0030 0.125 0.000 0.005 0.023 0.000 0.002 MIN 0.1875 0.3125 0.125 0.023 0.1855 0.3095 0.120 0.021

Retaining Rings (from McMaster-Carr)

Measurement Groove Diameter Groove Width Nominal (in) Upper + (in) Lower - (in) MAX (in) MIN (in) 0.147 0.002 0.000 0.149 0.147 0.029 0.003 0.000 0.032 0.029

Worm Gear (from SDP-SI)

Measurement Bore Diameter Hub Diamter Hub Projection Length P.D. Nominal (in) Upper + (in) Lower - (in) MAX (in) MIN (in) 0.1869 0.0010 0.0000 0.1879 0.1869 0.625 0.3125 0.5625 1.000

10 Tooth Gear (from SDP-SI)

Measurement Bore Diameter P.D. O.D. Nominal (in) Upper + (in) Lower - (in) MAX (in) MIN (in) 0.1873 0.0005 0.0000 0.1878 0.1873 0.4167 0.5

Output Shaft

Calculate Total Length Measurement Bearing Width (B.W.) Interior Width (I.W.) Output Length (O.L.) B.W. + I.W. + B.W. + O.L Nominal (in) Upper + (in) Lower - (in) MAX MIN 0.281 0.000 0.005 0.281 2.000 0.000 0.010 2.000 1.000 0.005 0.005 1.005

0.276 1.990 0.995

Page 5 of 10

ME359 Final Project Report

Total Length 3.562 0.005 0.025 3.567 3.537

Bearings (from SDP-SI)

Measurement Bore Outer Diameter Bearing Width (B.W.) Flange Width (F.W.) Nominal (in) Upper + (in) Lower - (in) MAX 0.375 0.000 0.002 0.875 0.000 0.003 0.281 0.000 0.005 0.062 0.000 0.002 MIN 0.375 0.875 0.281 0.062 0.373 0.872 0.276 0.060

Retaining Rings (from McMaster-Carr)

Measurement Groove Diameter Groove Width Nominal (in) Upper + (in) Lower - (in) MAX (in) MIN (in) 0.303 0.003 0.000 0.306 0.303 0.039 0.003 0.000 0.042 0.039

100 Tooth Gear (from SDP-SI)

Measurement Bore Diameter P.D. Length Nominal (in) Upper + (in) Lower - (in) MAX (in) MIN (in) 0.3747 0.0005 0.0000 0.3752 0.3747 4.1667 4.1667 4.1667 0.787 0.787 0.787

Bearing Fits Shaft Tolerance Conditions: Normal Load Rotating in Direction of Load All Shafts are <.71 Tolerance Classification: J5 For All Shafts: Tolerance is +.0002, -.0001 Housing Tolerance: Conditions: Outer Ring Stationary Housing Not Split Axially Tolerance Classification: H6 For All Shafts: Tolerance is +0, -.0005

Component Life Analyses

Requirements 50lbf over hung load at output shaft Output shaft is 1.5 max Max speed of 240 rpm Life of 25,000 hours Page 6 of 10

ME359 Final Project Report Assumptions Assume no axial load, all load radially Wear on the gears should be negligible compared to wear on the bearings Weight of the shaft and shaft components is negligible compared to the 50lbf eccentric load

Force Analysis Where: P = dynamic load;

x = .6 (from tables);

Fr = 50lbf

Lifetime Analysis ( ) Where: m=3 (ball bearings); P=dynamic load; C=dynamic load rating; L10=life in millions of hours

Input shaft:

( ( ) )

All Gears with 0.375 Bore All bearings are rated for well over 50lbf static load and also well over the 30lbf dynamic load, including a 1.5x safety factor. Even adding that 50lbf load, the static load rating (273lbf) exceeds the minimum requirements for both the input and output shafts. We specified our bearings to the input rotational velocity. Any section between input and output will be rotating slower than the input velocity.

Page 7 of 10

ME359 Final Project Report

Work Estimate and Actual

Preliminary Work Estimate: Part/Assy Description Sprocket Shaft Body Assembly Arm 1 Arm 2 Arm Assembly 1 Arm Assembly 2 Responsible Engineer Alex Patow Mike Gonzalez John Griese Abby Dutke Alex Patow Mike Gonzalez John Griese Abby Dutke Model Time Completion Estimate [min] 45 45 30 60 30 30 45 45 Drawing Time Completion Estimate [min] 30 30 30 30 30 30 30 30

Page 8 of 10

ME359 Final Project Report

Actual Work Estimate Part/Assy Description Spec/Find PartsWorm & Worm Gear Spur Gears Bearings Retaining Rings Self-Clinching Nuts CADBox Input Shaft Output Shaft Assembly Modify Downloaded CAD Models CAD DrawingsWorm Worm Gear 10 Tooth Spur Gear 100 Tooth Spur Gear Box Pt 1 Box Pt 2 Input Shaft Output Shaft Assembly WrittenTolerancing Life Analysis Project Report Project Presentation Responsible Engineer \\\\\\\\\\\\\\\\\\\\\\\ Alex & Mike Alex & Mike Alex & Abby Alex & Abby Alex \\\\\\\\\\\\\\\\\\\\\\\ Alex Alex & John Alex & John Alex Alex \\\\\\\\\\\\\\\\\\\\\\\ Alex & Abby Alex & Abby Alex Alex Mike Mike Alex & John Alex & John Alex \\\\\\\\\\\\\\\\\\\\\\\ John & Mike John & Abby Abby & Mike & John & Alex Abby & Mike & John & Alex Completion Time Estimate [min] \\\\\\\\\\\\\\\\\\\\\\\ 60 60 20 15 5 \\\\\\\\\\\\\\\\\\\\\\\ 60 45 45 60 45 \\\\\\\\\\\\\\\\\\\\\\\ 30 30 20 20 30 30 40 40 45 \\\\\\\\\\\\\\\\\\\\\\\ 480 150 300 210

Page 9 of 10

ME359 Final Project Report

Bill of materials

ITEM NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 PART NUMBER 102 101 103 104 602 603 601 201 202 203 301 302 704 703 502 501 503 702 701 DESCRIPTION 24 TOOTH WORM 1 FLUTE START 10 TOOTH SPUR 100 TOOTH SPUR SECOND SHAFT OUTPUT SHAFT INPUT SHAFT INPUT SHAFT SECOND SHAFT OUTPUT SHAFT BOX PT. 1 BOX PT. 2 PEM NUT 6-32 MACHINE SIDE-MOUNT SIDE-MOUNT SIDE-MOUNT SHAFT PIN KEY VENDOR SDP-SI P/N: A 1B 6-N24024 SDP-SI P/N: A 1C55-N24 SDP-SI P/N: S1084Z-024A010 SDP-SI P/N: S1VS24-100F1524 SDP-SI P/N: A 7Y55-FS3118G SDP-SI P/N: A 7Y55-FS8737G SDP-SI P/N: A 7Y55-FS5025G MCMASTER-CARR P/N: 8984K823 MCMASTER-CARR P/N: 8984K823 MCMASTER-CARR P/N: 8984K823 MCMASTER-CARR P/N: 8983K62 MCMASTER-CARR P/N: 8983K62 PEM P/N: S-632-0 ZI--N MCMASTER-CARR P/N: 91735A142 MCMASTER-CARR P/N: 97431A280 MCMASTER-CARR P/N:97431A300 MCMASTER-CARR P/N:97431A320 MCMASTER-CARR P/N: 92373A106 MCMASTER-CARR P/N: 98535A130 MANUFACTURING PROCESSES DRILL QTY. 1 1 1 1 2 2 2 1 1 1 1 1 8 8 2 2 2 2 1

MILLING

TURNING/DRILL TURNING/MILLING TURNING/MILLING SHEET METAL SHEET METAL

MILLING

Drawings

(Attached)

Page 10 of 10

You might also like

- Machine Elements I - AMEM 316 Assignment 1: Shaft DesignDocument67 pagesMachine Elements I - AMEM 316 Assignment 1: Shaft DesignFarid Nasri100% (1)

- Gear Box Design Assignment S2 2012Document10 pagesGear Box Design Assignment S2 2012Nang TruongNo ratings yet

- Shaft LayoutDocument21 pagesShaft LayoutAmmar SafwtNo ratings yet

- Lecture 16 - Worm Gears Worked Out ProblemsDocument19 pagesLecture 16 - Worm Gears Worked Out ProblemsApurba haldar50% (2)

- Gearbox Project ReportDocument15 pagesGearbox Project ReportPARTHA PRATIM PURKAIT100% (1)

- Gear FormulaeDocument13 pagesGear Formulaeian_newNo ratings yet

- Gear DesignDocument22 pagesGear DesignKhalil Raza100% (4)

- Fundamentals of Turbomachines: Centrifugal Compressors ExplainedDocument24 pagesFundamentals of Turbomachines: Centrifugal Compressors ExplainedVIRAJ HADKARNo ratings yet

- Gearbox Design IitDocument25 pagesGearbox Design IitSrini VasanNo ratings yet

- Spur Gear DesignDocument51 pagesSpur Gear Designmshebbal2212100% (1)

- Shaft Design ProjectDocument14 pagesShaft Design Projectjwm6085% (13)

- Machine Shaft Design GuideDocument48 pagesMachine Shaft Design GuideHammad RazaNo ratings yet

- Machine Design Lec3Document75 pagesMachine Design Lec3sam0415No ratings yet

- Spur Gear Design 1Document16 pagesSpur Gear Design 1Nagu SriramaNo ratings yet

- Gearbox DesignDocument94 pagesGearbox DesignHema KumarNo ratings yet

- BISRAT GIRMA Gearbox DesignDocument92 pagesBISRAT GIRMA Gearbox DesignŠmřű Žăm Ğ Bøýž0% (1)

- UNIT-2 Design of Spur GearDocument56 pagesUNIT-2 Design of Spur GearMarthandeNo ratings yet

- Introduction To Direct Gear DesignDocument15 pagesIntroduction To Direct Gear DesignburaktuncerNo ratings yet

- Gear Box DesigningDocument38 pagesGear Box DesigningAlpesh Panchal67% (3)

- Design of a Two-Stage GearboxDocument131 pagesDesign of a Two-Stage Gearboxnigusu sisayNo ratings yet

- Simply Gearbox DesignDocument39 pagesSimply Gearbox DesignJean Pablo Valverde MoraNo ratings yet

- Helical Gears: DefinitionDocument29 pagesHelical Gears: DefinitionMuthuvel MNo ratings yet

- Bearing DesignDocument58 pagesBearing DesignCaryann GumbanNo ratings yet

- 6 Shafts PDFDocument23 pages6 Shafts PDFViven SharmaNo ratings yet

- Spur GearDocument98 pagesSpur Geargautham_93No ratings yet

- Gear Trains - Lecture 10Document22 pagesGear Trains - Lecture 10priyankar007No ratings yet

- Design of Gear Box Prepared By: Yaried Worku Muket AGMASDocument34 pagesDesign of Gear Box Prepared By: Yaried Worku Muket AGMASyared sitotaw100% (1)

- Select the Right Industrial Gearbox in 15 StepsDocument4 pagesSelect the Right Industrial Gearbox in 15 StepssanjushaNo ratings yet

- Design II MDE 221 Mott CH 8 and CH 9 Spur GearsDocument42 pagesDesign II MDE 221 Mott CH 8 and CH 9 Spur GearsThieroy PelendaNo ratings yet

- Design procedure of a screw jackDocument6 pagesDesign procedure of a screw jacksupratim saha100% (1)

- Flat Belt CalculationDocument19 pagesFlat Belt CalculationAstri NgentNo ratings yet

- Design of Flat Belt DriveDocument18 pagesDesign of Flat Belt DriveSaravanan Kumar50% (2)

- Rack and PinionDocument16 pagesRack and PinionjeronimoisraelNo ratings yet

- Cotter JointDocument18 pagesCotter JointritNo ratings yet

- Tooth ThicknessDocument9 pagesTooth ThicknessPraveen VundrajavarapuNo ratings yet

- Rack and Pinion Gear DesignDocument32 pagesRack and Pinion Gear DesignSrini KumarNo ratings yet

- Bearing CalculationDocument4 pagesBearing CalculationAnonymous lTQDM21No ratings yet

- Design of Flexible Bush Pin Coupling For Asamnew PRORESSDocument13 pagesDesign of Flexible Bush Pin Coupling For Asamnew PRORESSLewi100% (1)

- Machine Design - Design of ClutchesDocument12 pagesMachine Design - Design of ClutchesSachin Chaturvedi90% (21)

- Rubber Roller DesignDocument20 pagesRubber Roller DesignGaneshNo ratings yet

- Flange Coupling DesignDocument16 pagesFlange Coupling DesignJaspreet KhattraNo ratings yet

- Design of CouplingDocument75 pagesDesign of CouplingVatsal BhalaniNo ratings yet

- Gear 1Document9 pagesGear 1Ariyant CreativeNo ratings yet

- Research and Design of Hydraulic AGC System Model of Cold Rolling MillDocument8 pagesResearch and Design of Hydraulic AGC System Model of Cold Rolling MillOmid Behniya100% (1)

- Design V-belt drive to transmit 100 kW powerDocument75 pagesDesign V-belt drive to transmit 100 kW powerS A ABDUL SUKKURNo ratings yet

- Brake Design and CalculationDocument2 pagesBrake Design and CalculationDavid Lambert89% (9)

- Design of The Toggle JackDocument30 pagesDesign of The Toggle Jackkoanakist91% (11)

- Screw-Jack - Mechanical Engineering AssignmentDocument35 pagesScrew-Jack - Mechanical Engineering AssignmentDavy JacobNo ratings yet

- Spur Gear DesignDocument15 pagesSpur Gear DesignMaharaja KanthasamyNo ratings yet

- Final Project ReportDocument11 pagesFinal Project ReportoddomancanNo ratings yet

- Final Pipe Bending MachineDocument27 pagesFinal Pipe Bending MachineVitthal GawhaleNo ratings yet

- Design and Calculation ShaftDocument115 pagesDesign and Calculation ShaftDavid Lambert100% (3)

- Final Pot Ptfe Design Sheet - 02.01.13Document47 pagesFinal Pot Ptfe Design Sheet - 02.01.13Sandeep Kumar75% (4)

- Air Receiver Sample CalcDocument49 pagesAir Receiver Sample CalcBrian Edwin RodriguezNo ratings yet

- Calculation Results: SKF Belt Frequency Meter (PHL FM 10/400) Belt Tension Pen Gauge (PUB PSD C1/007)Document2 pagesCalculation Results: SKF Belt Frequency Meter (PHL FM 10/400) Belt Tension Pen Gauge (PUB PSD C1/007)geneccwNo ratings yet

- This Kisssoft Demoversion May Not Be Used For Professional Application ! Important Hint: at Least One Warning Has Occurred During The CalculationDocument7 pagesThis Kisssoft Demoversion May Not Be Used For Professional Application ! Important Hint: at Least One Warning Has Occurred During The Calculationpablo_stzNo ratings yet

- Electric FieldsDocument37 pagesElectric FieldsM.K 1013No ratings yet

- Q1. The Graph Shows The Distribution of Rod Cells and Cone Cells Across The Retina of A HumanDocument6 pagesQ1. The Graph Shows The Distribution of Rod Cells and Cone Cells Across The Retina of A HumanQuang Huy PhạmNo ratings yet

- Revised Resume MainDocument2 pagesRevised Resume Mainapi-654538483No ratings yet

- JUAN BHETHELDIVINE P. Lab2Document19 pagesJUAN BHETHELDIVINE P. Lab2Bhethel Divine JuanNo ratings yet

- Chap8 Fundamental Joining ProcessDocument20 pagesChap8 Fundamental Joining ProcessjojoNo ratings yet

- S2 PHYSICS Unit-3 & 6 Revision NoteDocument16 pagesS2 PHYSICS Unit-3 & 6 Revision Noterayofthelight777100% (1)

- John Dirk Walecka Introduction To Modern Physics - Theoretical Foundations 2008 PDFDocument494 pagesJohn Dirk Walecka Introduction To Modern Physics - Theoretical Foundations 2008 PDFJavier Ruiz80% (5)

- Arihant Complex NumbersDocument112 pagesArihant Complex NumbersVarun JishnuNo ratings yet

- OBE Syllabus - PHYS TECH PDFDocument8 pagesOBE Syllabus - PHYS TECH PDFNicko CortoNo ratings yet

- Chapter 26 Capacitance & DielecricsDocument47 pagesChapter 26 Capacitance & DielecricsHaroon KhanNo ratings yet

- Graphical Representation and Interpretation of MotionDocument14 pagesGraphical Representation and Interpretation of MotionAmer MaladNo ratings yet

- Conductivité OptiqueDocument75 pagesConductivité OptiquevideolabNo ratings yet

- Design of State Variable Feedback Systems: ELEC-C8201 - Control and AutomationDocument27 pagesDesign of State Variable Feedback Systems: ELEC-C8201 - Control and AutomationOlalekan AturakaNo ratings yet

- Wang Et Al 2021Document13 pagesWang Et Al 2021RAMU BNo ratings yet

- RK500-13 Online EC/Salinity Sensor: FeaturesDocument3 pagesRK500-13 Online EC/Salinity Sensor: FeaturesigreenNo ratings yet

- (2016) A Review of The Evaluation, Control and Application Technologies For Drillstring S&V in O&G WellDocument35 pages(2016) A Review of The Evaluation, Control and Application Technologies For Drillstring S&V in O&G WellRoger GuevaraNo ratings yet

- Hardware of MRI SystemDocument9 pagesHardware of MRI SystemEbrahem SalmNo ratings yet

- Detailed Lesson Plan VIDocument5 pagesDetailed Lesson Plan VIDoresa Lila Cabag RagaNo ratings yet

- Vibrations SyllabusDocument5 pagesVibrations SyllabusAli SabahNo ratings yet

- Thevenin's Theorem: SolutionDocument30 pagesThevenin's Theorem: SolutionRaghupatiNo ratings yet

- MC20005 WHP WI P 0116 Sampling Connection Datasheet WI - Rev.D1Document8 pagesMC20005 WHP WI P 0116 Sampling Connection Datasheet WI - Rev.D1nguyenmainamNo ratings yet

- Ratio and Proportion Worksheet 4Document8 pagesRatio and Proportion Worksheet 4sangeetaagarwalangelNo ratings yet

- Live With Cuckoo ClocksDocument10 pagesLive With Cuckoo ClocksNebojsa MijicNo ratings yet

- Hydrogen Compatibility Handbook - I S For Stainless Steels 017051Document155 pagesHydrogen Compatibility Handbook - I S For Stainless Steels 017051Farid TataNo ratings yet

- ASTM D6938 (Densidad Método Nuclear)Document10 pagesASTM D6938 (Densidad Método Nuclear)Gerardo ChahuaNo ratings yet

- Mixing Nozzles-Korting PDFDocument8 pagesMixing Nozzles-Korting PDFGerman Enriquez VeraNo ratings yet

- Grade 4 Mathematics Practice Test: Nebraska Department of Education 2010Document14 pagesGrade 4 Mathematics Practice Test: Nebraska Department of Education 2010beauty kumariNo ratings yet

- Result of Analysis: NO. Test Method Results Spesification Test Item UnitDocument1 pageResult of Analysis: NO. Test Method Results Spesification Test Item UnitIkhsan RamdhaniNo ratings yet

- Design of 75Kl Zinc Alume (Znal) Elevated Water Storage TankDocument26 pagesDesign of 75Kl Zinc Alume (Znal) Elevated Water Storage TankSmit PatelNo ratings yet

- Bamboo joints techniquesDocument7 pagesBamboo joints techniquesAndrianNo ratings yet