Professional Documents

Culture Documents

Pearl GTL Project

Uploaded by

Abhiyan Anala ArvindCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pearl GTL Project

Uploaded by

Abhiyan Anala ArvindCopyright:

Available Formats

Pearl Gas-to-Liquids Project, Ras Laffan, Qatar

Key Data Following the successful opening of the first phase of the Oryx gas-to-liquids f acility in June 2006 Qatar Petroleum launched its new GTL project 'Pearl' in Jul y 2006. The project is jointly owned by Qatar Petroleum and Royal Dutch Shell an d includes the development of two offshore natural gas resources in the Qatar No rth Field. The Pearl GTL project also includes transporting and processing the gas to extra ct natural gas liquids and ethane, and the conversion of the remaining gas into liquid hydrocarbon products through the construction of a new fully integrated G TL complex in Ras Laffan Industrial City situated 80km north of Doha. The offshore platforms are connected to the plant through a 60km pipeline. Construction of the plant began in February 2007. The first sour gas began to fl ow into the plant in March 2011. When fully operational, the Pearl GTL project will have a capacity to produce 14 0,000bpd of GTL products and 120,000bpd oil equivalent of LPG, condensate and et hane. Over its lifetime the integrated project will produce upstream resources of appr oximately three billion barrels of oil equivalent. Technology and investment in Pearl GTL "The first sour gas began to flow into the Pearl GTL plant in March 2011." The Pearl GTL project is based on Shell's proprietary GTL technology, which has been used for more than ten years following the first commercial GTL plant of it s type in Bintulu, Malaysia. The GTL project, which began the planning process in July 2004, was developed un der a development and production sharing agreement with the Government of the St ate of Qatar. The agreement covers offshore and onshore costs, with Shell providing 100% of th e project's funding, which is estimated to be between $18bn and $19bn. Production from the first Pearl GTL train (phase I) began in March 2011. Start-u p of the second train is expected to follow by 2012 (phase II). The plant uses S hell's proprietary Shell Middle Distillates Synthesis (SMDS) technology. The fac ilities are operated by Qatar Shell GTL, a Shell subsidiary. Contractors for the Pearl GTL project JGC Corporation of Japan and Kellogg Brown and Root (KBR) were awarded the proje ct management contract for the project in mid-2005. In addition to the developme nt of offshore upstream gas production facilities, the project comprises the dev elopment of the onshore GTL plant. The JGC / KBR joint venture completed the basis of design / basis design package and the subsequent front end engineering design in late 2004. The JGC / KBR rol e included project management and start-up support of the overall onshore Pearl GTL complex, along with engineering, procurement and construction management of the GTL synthesis, utilities and infrastructure sections of the complex. In June 2005, Honeywell was awarded a contract to provide front-end engineering design for the automation and control systems. Honeywell's work included process automation and control including asset management and fieldbus solutions, safet y, fire and gas, and the specification for a multi-purpose dynamic simulator to be used for dynamic studies, engineering verifications and operator training. "The JGC / KBR joint venture completed the basis design package and FEED in late 2004." Honeywell, in consultation with Shell, developed the Shell Engineering Toolkit t o meet the tender requirements. Honeywell provided the solutions that meet the s tandards of instrumentation engineering solutions powered by INtools. In August

2006, the Hyundai Engineering & Construction and Toyo Engineering consortium won the engineering, procurement and construction contract for the liquid processin g unit. In September 2006 General Electric won the contract to supply six gas tu rbines, equipped with dual fuel Integrated Gasification Combined Cycle combustio n systems. In addition to the 42MW gas turbine-generators, the scope of the contract includ ed IGCC combustion engineering, combustion system lab testing, spare parts and t raining. The gas turbines are installed in the Pearl GTL plant in a cogeneration configuration to produce 180MW of power for use in the facility. In July 2008, Cannonway Consultants were contracted to provide commercial, contr actual and quantity surveying services for the GTL plant. In January 2011, Qatar Shell GTL awarded the framework agreement to Kentz Corporation for providing pl ant change request execution services for three years. Pearl operations At the upstream end of the operation 1.6 billion cubic feet per day of wellhead gas will be produced from the North Field and transported and processed to produ ce approximately 120,000 barrels of oil equivalent per day of condensate, liquef ied petroleum gas and ethane. At the downstream end dry gas is used as feedstock for a new onshore integrated GTL complex, which will manufacture an additional 140,000bpd of liquid hydrocarb on products. The Pearl GTL complex will consist of two 70,000bpd GTL trains and associated fa cilities. The plant will produce a range of clean liquid products and fuels, com prising naphtha, GTL fuel, normal paraffins, kerosene and lubricant-based oils. GTL fuel is the largest component of the product slate and is suitable for use i n existing light- and heavy-duty diesel engines. It also has lower emissions at the point of use, which makes it important as a low sulphur fuel in Europe and t he US (both introduced more stringent emissions policies in 2005). Qatar's GTL ambitions "Qatar aims to become the leading exporter of LNG in the world by 2012." Qatar aims to become the leading exporter of LNG in the world by 2012, by which time the country's annual gas production will reach 77 million tonnes. Qatar's o il production will also increase from 800,000bpd to one million bpd by the end o f 2011. Qatar is committed to investing over $130bn in oil and gas infrastructure projec ts to increase its annual production to 18 million tonnes by 2016. The Pearl GTL project will accelerate the strategy of diversifying natural gas u sage and will serve to promote Qatar's ambition of being the GTL capital of the world. The Pearl Gas-to-Liquids project is situated at Ras Laffan, 80km north of Doha , Qatar. The Pearl GTL project is totally integrated and involves upstream and downstre am production. Pipe racks such as these will be part of the Pearl GTL complex. Honeywell is providing automation and control equipment, including one of the largest fieldbuses ever constructed. Storage tank farms will be important to store products prior to export.

You might also like

- Top Ten GTL Projects of The WorldDocument8 pagesTop Ten GTL Projects of The Worldhimadri.banerji60No ratings yet

- BrownDocument3 pagesBrown3azeezNo ratings yet

- Pearl GTL: Making Liquids Out of Gas on a Grand ScaleDocument3 pagesPearl GTL: Making Liquids Out of Gas on a Grand ScaleLeonardo AmpueroNo ratings yet

- Shell GTLDocument1 pageShell GTLJorge Da Costa SeabraNo ratings yet

- 599ba9f5685ec58cc43993da9760b722Document65 pages599ba9f5685ec58cc43993da9760b722Cm SinghNo ratings yet

- VGO HydrocrackingDocument14 pagesVGO HydrocrackingAndy DolmanNo ratings yet

- JamnagarDocument3 pagesJamnagarkallurisuryaNo ratings yet

- ERC Refinery ProjectDocument16 pagesERC Refinery ProjectSameh El-Sabbagh100% (3)

- PR Project UpdateDocument68 pagesPR Project UpdateAbdulaheemNo ratings yet

- Sag15010 P 02F 0023 PDFDocument142 pagesSag15010 P 02F 0023 PDFrizwan khanNo ratings yet

- PID and Refinery TutorialDocument20 pagesPID and Refinery TutorialSatpal SinghNo ratings yet

- Refinería Kirkuk PDFDocument11 pagesRefinería Kirkuk PDFcesarinarragaNo ratings yet

- 24 Jun 2016 1304322739hcqxsdeannexure3commonpfrDocument166 pages24 Jun 2016 1304322739hcqxsdeannexure3commonpfrSrikanthNo ratings yet

- Reficar, Cartagena, Colombia, Cdhydro Cdhds SomDocument408 pagesReficar, Cartagena, Colombia, Cdhydro Cdhds Som•It's Mari Cami•No ratings yet

- Introduction to VR HCR TechnologyDocument26 pagesIntroduction to VR HCR TechnologyRey100% (2)

- Aramco and Affiliates - PoonamDocument2 pagesAramco and Affiliates - PoonamTarun BhandariNo ratings yet

- EIA Report for Petrochemical Plant in Sohar, OmanDocument672 pagesEIA Report for Petrochemical Plant in Sohar, OmanAhmed Ibrahim Ahmed EissaNo ratings yet

- Cdu-Vdu Feed PropertiesDocument36 pagesCdu-Vdu Feed PropertiesYADAV ANIL KUMARNo ratings yet

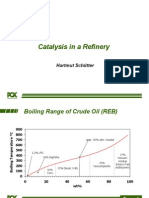

- Catalysis in A RefineryDocument54 pagesCatalysis in A RefineryJacqueline WoodsNo ratings yet

- Final Report 2 PsDocument27 pagesFinal Report 2 PsNishant AsharNo ratings yet

- NSRP Overview (From WWW - Idemitsu.com)Document2 pagesNSRP Overview (From WWW - Idemitsu.com)Scribd_delNo ratings yet

- Ruwais Refinery Expansion ProjectDocument1 pageRuwais Refinery Expansion ProjectgenergiaNo ratings yet

- POE Bitumen eDocument9 pagesPOE Bitumen eSafiullah KhanNo ratings yet

- Capture Plan – COTC Project Overview and Next StepsDocument9 pagesCapture Plan – COTC Project Overview and Next StepsAri BinukoNo ratings yet

- RP267B Toc PDFDocument7 pagesRP267B Toc PDFManasNo ratings yet

- HYSYS-Report Ammonia PlantDocument21 pagesHYSYS-Report Ammonia PlantDouglas Ross HannyNo ratings yet

- GCC 39 S Key Oil and Gas Projects To Be Awarded in 2015 PDFDocument3 pagesGCC 39 S Key Oil and Gas Projects To Be Awarded in 2015 PDFAmitabhaNo ratings yet

- Att#20 - 7077T-000-PP-0000-108 - 00 List of Codes and StandardsDocument62 pagesAtt#20 - 7077T-000-PP-0000-108 - 00 List of Codes and Standardsabdelmalek boudjemaaNo ratings yet

- Delloite Oil and Gas Reality Check 2015 PDFDocument32 pagesDelloite Oil and Gas Reality Check 2015 PDFAzik KunouNo ratings yet

- Unit 040 NHDS PresentationDocument35 pagesUnit 040 NHDS PresentationNguyễn Ngọc Tưởng100% (1)

- 00 PR PH 00002 - 2 Service Definition PhilosophyDocument8 pages00 PR PH 00002 - 2 Service Definition PhilosophyStevanNikolicNo ratings yet

- Chevron Richmond Refinery Revised Renewal Project - Conditional Use Permit/Amended EIR ApplicationDocument20 pagesChevron Richmond Refinery Revised Renewal Project - Conditional Use Permit/Amended EIR ApplicationCVX_Richmond_RenewalNo ratings yet

- Hydrogen Production in RefineriesDocument9 pagesHydrogen Production in RefineriesNirmit DaveNo ratings yet

- Witness Joint & Sampling MatrixDocument13 pagesWitness Joint & Sampling MatrixPazhamalai RajanNo ratings yet

- Mechanical Datasheet - Wellhead Compressor PackageDocument12 pagesMechanical Datasheet - Wellhead Compressor PackageRokan Pipeline100% (1)

- Skimming Job GeneralDocument5 pagesSkimming Job Generalvishal bailurNo ratings yet

- Amine Loading To SystemDocument6 pagesAmine Loading To SystemRathinavel PerumalNo ratings yet

- 003 - Syngas Generation For GTL PDFDocument91 pages003 - Syngas Generation For GTL PDFMubarik AliNo ratings yet

- Terminal ProjectsDocument37 pagesTerminal ProjectssubashNo ratings yet

- Group C Presentation - Petrochemicals (UPDATED)Document52 pagesGroup C Presentation - Petrochemicals (UPDATED)sunliasNo ratings yet

- Petroleum Regeneration and Processing Facility - Phase Ii: Employer'S RequirementsDocument72 pagesPetroleum Regeneration and Processing Facility - Phase Ii: Employer'S RequirementsChitradeep FalguniyaNo ratings yet

- Standard Specification: LPG Loading / Unloading ArmDocument19 pagesStandard Specification: LPG Loading / Unloading ArmANIL KUMAR100% (1)

- Carbon Capture, Utilization & StorageDocument18 pagesCarbon Capture, Utilization & Storagebiblioteca mailfenceNo ratings yet

- Shell Middle Distillate Synthesis (SMDS) Process: F. J. M. SchrauwenDocument16 pagesShell Middle Distillate Synthesis (SMDS) Process: F. J. M. SchrauwenBharavi K SNo ratings yet

- Iran ClientDocument103 pagesIran Clientraja sivajiNo ratings yet

- Index - 2017 - Integrated Gasification Combined Cycle IGCC Technologies PDFDocument23 pagesIndex - 2017 - Integrated Gasification Combined Cycle IGCC Technologies PDFrusdanadityaNo ratings yet

- IOCL Barauni Refinery BS-IV Project Pre-Feasibility ReportDocument35 pagesIOCL Barauni Refinery BS-IV Project Pre-Feasibility ReportSwastika DasNo ratings yet

- Acetic Acid: US Chemical ProfileDocument1 pageAcetic Acid: US Chemical ProfileJESSICA PAOLA TORO VASCONo ratings yet

- Asian Refining GrowningDocument40 pagesAsian Refining GrowninggustavoemirNo ratings yet

- J18 780 PEC Chapter 5 Project DescriptionDocument43 pagesJ18 780 PEC Chapter 5 Project DescriptionAjlaa Rahim100% (1)

- Synthetic Fuels GTL f1 Fischer Tropsch Process2588570496085257524Document8 pagesSynthetic Fuels GTL f1 Fischer Tropsch Process2588570496085257524Ishu Vohra100% (1)

- Op. Center JOB N - Op. Center Doc. N - A 8474L-023 ML 001: Process Data SheetDocument216 pagesOp. Center JOB N - Op. Center Doc. N - A 8474L-023 ML 001: Process Data SheetBùi Hữu SơnNo ratings yet

- Mont Belvieu, Texas Ethane Storage Hub: Warnings For AppalachiaDocument7 pagesMont Belvieu, Texas Ethane Storage Hub: Warnings For AppalachiaJames BruggersNo ratings yet

- Celanese PFD of MethanolDocument1 pageCelanese PFD of MethanolJessica CehNo ratings yet

- Qatar Liquified Gas Company Limited (II) : QG2, The Designs and Technologies For A 7.8 MTPA TrainDocument16 pagesQatar Liquified Gas Company Limited (II) : QG2, The Designs and Technologies For A 7.8 MTPA TrainweldsvNo ratings yet

- HP Top Project AwardsDocument9 pagesHP Top Project AwardsSterlingNo ratings yet

- HP Top Project AwardsDocument9 pagesHP Top Project AwardsSterlingNo ratings yet

- Overview of Shell Global Solutions' Worldwide Gasification DevelopmentsDocument7 pagesOverview of Shell Global Solutions' Worldwide Gasification DevelopmentsAdwait ParanjpeNo ratings yet

- Substation Energization - LEADDocument11 pagesSubstation Energization - LEADAbhiyan Anala Arvind100% (1)

- Progress StatisticsDocument5 pagesProgress StatisticsAbhiyan Anala ArvindNo ratings yet

- Commissioning Schedule L2 - System Wise - 24-07-17Document8 pagesCommissioning Schedule L2 - System Wise - 24-07-17Abhiyan Anala ArvindNo ratings yet

- SRU PresentationDocument44 pagesSRU PresentationAbhiyan Anala ArvindNo ratings yet

- Commissioning Schedule L2 - System Wise - For LEAD - 15-Jul-17Document8 pagesCommissioning Schedule L2 - System Wise - For LEAD - 15-Jul-17Abhiyan Anala ArvindNo ratings yet

- Palisade2011 PaulGillDocument22 pagesPalisade2011 PaulGillAbhiyan Anala ArvindNo ratings yet

- Building Manpower Histogramm: Tra deDocument3 pagesBuilding Manpower Histogramm: Tra deAbhiyan Anala ArvindNo ratings yet

- Commissioning Schedule L2 - System Wise - For LEAD - 15-Jul-17Document8 pagesCommissioning Schedule L2 - System Wise - For LEAD - 15-Jul-17Abhiyan Anala ArvindNo ratings yet

- Ss - Ler Building Schedule 21.02.2020Document32 pagesSs - Ler Building Schedule 21.02.2020Abhiyan Anala ArvindNo ratings yet

- Fieldbus Basics PDFDocument37 pagesFieldbus Basics PDFsalic2013No ratings yet

- Pigging in Pipeline Pre-Commissioning PDFDocument8 pagesPigging in Pipeline Pre-Commissioning PDFAbhiyan Anala Arvind100% (1)

- VBA Book PDFDocument121 pagesVBA Book PDFAriadiKetutNo ratings yet

- PR-1073 - Gas Freeing, Purging and Leak Testing of Process Equipment (Excluding Tanks)Document35 pagesPR-1073 - Gas Freeing, Purging and Leak Testing of Process Equipment (Excluding Tanks)romedic36100% (1)

- How Were The Weekdays NamedDocument1 pageHow Were The Weekdays NamedAbhiyan Anala ArvindNo ratings yet

- Microsoft Excel 2007: Advanced Topics: ImportingDocument12 pagesMicrosoft Excel 2007: Advanced Topics: ImportingSambaSiva NaiduNo ratings yet

- Matching A Date in A Date Range v2Document3 pagesMatching A Date in A Date Range v2Abhiyan Anala ArvindNo ratings yet

- TB 2005 17 EngDocument2 pagesTB 2005 17 EngRuchi Ragvendra BistNo ratings yet

- How To Create A Gantt Chart Using ExcelDocument1 pageHow To Create A Gantt Chart Using ExcelAbhiyan Anala ArvindNo ratings yet

- Citrix Access Procedures-ShjDocument4 pagesCitrix Access Procedures-ShjAbhiyan Anala ArvindNo ratings yet

- TCF Variance Report for Reggane Nord Development ProjectDocument19 pagesTCF Variance Report for Reggane Nord Development ProjectAbhiyan Anala ArvindNo ratings yet

- Reasons For The Delay (20151031) 1534 20151103Document1 pageReasons For The Delay (20151031) 1534 20151103Abhiyan Anala ArvindNo ratings yet

- Citrix Access Procedures-ShjDocument4 pagesCitrix Access Procedures-ShjAbhiyan Anala ArvindNo ratings yet

- Site Office: Arabiyah / HasbahDocument2 pagesSite Office: Arabiyah / HasbahAbhiyan Anala ArvindNo ratings yet

- LEAD Variance Report (BSekfali) 1430 20150518Document18 pagesLEAD Variance Report (BSekfali) 1430 20150518Abhiyan Anala ArvindNo ratings yet

- Dumbbell Shrug The Key To Building Huge TrapsDocument4 pagesDumbbell Shrug The Key To Building Huge Trapsandres0126No ratings yet

- ABP CST P3 Narrative and Attachments v1.3Document63 pagesABP CST P3 Narrative and Attachments v1.3Abhiyan Anala ArvindNo ratings yet

- Monte Carlo SimDocument29 pagesMonte Carlo SimAbhiyan Anala Arvind100% (1)

- Operating Schedule ToolkitDocument23 pagesOperating Schedule ToolkitAbhiyan Anala ArvindNo ratings yet

- Car Visual GlossaryDocument11 pagesCar Visual GlossaryAbhiyan Anala ArvindNo ratings yet

- Inspect & Service Cooling SystemsDocument33 pagesInspect & Service Cooling SystemsRruga EdibresNo ratings yet

- QPED-9742R1 Pipe Line ConstructionDocument26 pagesQPED-9742R1 Pipe Line ConstructionPiping_Specialist100% (3)

- Data Overview - LEADING FIREMAN PDFDocument2 pagesData Overview - LEADING FIREMAN PDFSoji JosephNo ratings yet

- QP 2010 Annual ReportDocument37 pagesQP 2010 Annual ReportbenjamindineshkarNo ratings yet

- ShijuDocument3 pagesShijurfvz6sNo ratings yet

- Consider Qatar GuideDocument16 pagesConsider Qatar GuideibnrafeeqNo ratings yet

- BU48A02B00 00E N - 007 (ProSafe ProjRef)Document12 pagesBU48A02B00 00E N - 007 (ProSafe ProjRef)Broken WindowNo ratings yet

- Company Status: Ilshin Valves Co., LTDDocument51 pagesCompany Status: Ilshin Valves Co., LTDJefferson OliveiraNo ratings yet

- Business Guide QatarDocument17 pagesBusiness Guide QatarMeeta AnandNo ratings yet

- QafcoDocument15 pagesQafcoImtiaz HussainNo ratings yet

- Data Overview - MARINE PILOTDocument2 pagesData Overview - MARINE PILOTabdusy syukuurNo ratings yet

- Civil Designer CVDocument4 pagesCivil Designer CVPratikNo ratings yet

- L&T NewsnViews Jan Mar 2010Document40 pagesL&T NewsnViews Jan Mar 2010Manjadi MaverickNo ratings yet

- Unabridged Annual Report 2013-14-0Document180 pagesUnabridged Annual Report 2013-14-0Shekhar ShekharNo ratings yet

- Kamalakannan ResumeDocument4 pagesKamalakannan ResumeKamalakannan AyyaduraiNo ratings yet

- The Qatar Kuwait Pipeline Project - Economic ModelDocument7 pagesThe Qatar Kuwait Pipeline Project - Economic Modeladeel499No ratings yet

- Project Construction Manager Resume Example National Petroleum Construction Company - Horicon, WisconsinDocument4 pagesProject Construction Manager Resume Example National Petroleum Construction Company - Horicon, WisconsinRakesh DasNo ratings yet

- Qatar PetroleumDocument25 pagesQatar PetroleumShabin ShabiNo ratings yet

- Qatar Petroleum Employee ReviewsDocument17 pagesQatar Petroleum Employee ReviewsZulkarnain Dahalan100% (1)

- Qatar Online Business DirectoryDocument13 pagesQatar Online Business DirectoryTed LiptakNo ratings yet

- QLS-DT-039 - QP PVLDocument50 pagesQLS-DT-039 - QP PVLVedran KosanovicNo ratings yet

- Pre-Qualification Profile for Total Flooring SolutionsDocument102 pagesPre-Qualification Profile for Total Flooring SolutionsAli100% (1)

- Data Overview - ICT GENERAL TECHNICIAN (Offshore)Document2 pagesData Overview - ICT GENERAL TECHNICIAN (Offshore)balj balhNo ratings yet

- Piping Design Professional: Kamalakannan ADocument4 pagesPiping Design Professional: Kamalakannan AKamalakannan AyyaduraiNo ratings yet

- Giignl The LNG Industry 2011Document38 pagesGiignl The LNG Industry 2011srpercy100% (1)

- Gas To Liquid (GTL) TechnologyDocument13 pagesGas To Liquid (GTL) TechnologyPratick Tibrewala100% (1)

- QGL-CE-001Guidelines For Corridors and Corridor CrossingsRev2Document29 pagesQGL-CE-001Guidelines For Corridors and Corridor CrossingsRev2tomNo ratings yet

- Expanding Globally and Maximizing Qatar's Energy ResourcesDocument113 pagesExpanding Globally and Maximizing Qatar's Energy ResourcesxsupermanNo ratings yet

- Pearl GTL ProjectDocument2 pagesPearl GTL ProjectAbhiyan Anala ArvindNo ratings yet

- His Highness Sheikh Tamim Bin Hamad Al-Thani and Sheikh Hamad Bin Khalifa Al-Thani Annual ReportDocument49 pagesHis Highness Sheikh Tamim Bin Hamad Al-Thani and Sheikh Hamad Bin Khalifa Al-Thani Annual ReportjokotsNo ratings yet

- Introduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandIntroduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (3)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationFrom EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationRating: 1 out of 5 stars1/5 (1)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Waves and Beaches: The Powerful Dynamics of Sea and CoastFrom EverandWaves and Beaches: The Powerful Dynamics of Sea and CoastRating: 4 out of 5 stars4/5 (1)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)