Professional Documents

Culture Documents

Soil - Filling

Uploaded by

Giora RozmarinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Soil - Filling

Uploaded by

Giora RozmarinCopyright:

Available Formats

SECTION 02223 FILLING PART 1 1.

01 GENERAL

REQUIREMENTS INCLUDED A. B. C. Furnishing, placing, and compaction of common borrow fill. Placing and compaction of screened till from on-site till materials, procured by Owner. Coordination with the Engineer for completion of all required tests.

1.02

RELATED REQUIREMENTS A. B. C. D. E. F. G. Section 01300 - Submittals Section 01400 - Quality Assurance/Quality Control Section 02222 - Excavation Section 02232 - Stone Fill Section 02234 - Select Sand Section 02270 - Erosion Control Section 02930 - Loaming and Seeding

1.03

REFERENCES A. ASTM C136/C117 - Standard Test Method for Sieve Analysis of Fine and Coarse Aggregate and Standard Test Method for Materials Finer than 75-m (No. 200) Sieve in Mineral Aggregates by Washing ASTM D1557 Method C - Moisture-Density Relations of Soils and Soil-Aggregate Mixture using 10 lb. (4.54 kg) Hammer and 18-inch (457 mm) Drop. ASTM D1556 - Standard Test Method for Density of Soil in Place by the Sand-Cone Method. ASTM D6938 - 08a Standard Test Method for In-Place Density and Water Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth) ASTM D5084 - Standard Test Method for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter. ASTMD5321 Standard Test Method for Direct Shear Testing of Geosynthetic Material and Soil Interfaces.

B.

C. D. E. F. 1.04 TESTS

FILLING 861 - North Country Environmental Services Eastern Slope Closure 3/13 Revised 4/13

02223 - 1

A. B. C.

Soil testing and compaction tests shall be performed by the Engineer in coordination with the Contractor. Test and analysis of fill materials shall be performed by the Engineer in coordination with the Contractor. Tests and analyses of fill materials will be performed in accordance with ASTM C136/C117, ASTM D1557, ASTM D6938-08a, ASTM D5084 and ASTM D5321 and conditions set forth in Section 02223, 2.02 "Quality Control and Quality Assurance." PRODUCTS

PART 2 2.01 FILL A.

General For all fill materials to be used, samples, sieve analysis, and laboratory data indicating maximum dry densities and optimum moisture for field control tests shall be obtained by the Engineer prior to use as fill on site. The Contractor shall excavate, screen, and stockpile materials as required for sampling by the Engineer prior to delivery and placement.

B.

Common Borrow Fill Suitable borrow from off-site sources to be utilized as common borrow fill shall consist of soil with all rocks or material greater than 8" removed and no more than 30% passing the No. 200 sieve. Suitable fill shall be free from combustible, organic and frozen materials, loam, roots, topsoil, wood, trash, snow, ice, and other objectionable materials, or as identified by the Engineer. General.

C.

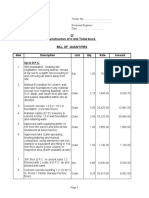

Screened Till Screened Till for use as the 6 inches of screened till fill and pipe bedding shall consist of inorganic mineral soil free of organic material, loam, trash, snow, ice, frozen soil, or other unsuitable materials have a permeability of 1x10-4cm/s or less as determined by ASTM D 5084, and shall conform to the following gradation: U. S. Standard % Finer Sieve Size By Weight 1 inch 100 No. 4 No. 40 #200 80-100 60-100 20 70

FILLING 861 - North Country Environmental Services Eastern Slope Closure 3/13 Revised 4/13

02223 - 2

D. 2.02

For other fill materials see Section 02234 Select Sand as applicable.

QUALITY CONTROL AND QUALITY ASSURANCE A. B. During earthwork operations, the Engineer will be present on the site to monitor and document the Contractor's activities relative to contract compliance. The Engineer shall complete laboratory analyses of a minimum of two (2) representative samples of common borrow and screened till. The Engineer shall conduct laboratory grain size analysis, moisture density testing, and permeability in accordance with ASTM C136/C117, ASTM D1557, and ASTM D5084 (at 95% MDD), respectively, to demonstrate conformance with Parts 2.01 and 3.02 of this Section. The Contractor shall provide a sample for Engineers laboratory analysis of at least one (1) representative sample of common borrow fill and screened till for each 5,000 cubic yards of material to be placed. The Engineer shall conduct laboratory grain size analysis and moisture density testing in accordance with ASTM C136/C117 and D1557, respectively, to demonstrate conformance with Parts 2.01 and 3.02 of this Section. The results of laboratory testing shall be reviewed by the Engineer prior to placement of fill materials. Costs for re-sampling and subsequent laboratory testing of all non-complying materials shall be borne by the Contractor. Field tests will be performed by the Engineer on in-place fill and backfill materials to confirm that specified densities are being achieved with the minimum required coverages and compaction equipment utilized by the Contractor. The Engineer will select locations and frequency for in-place density testing. At a minimum, the frequency of field tests shall be as follows: 1. 2. F. Common Borrow Fill: 1 test per 10,000 ft3 installed Screened Till: 1 test per 10,000 ft3 installed

C.

D.

E.

Acceptable materials placed and compacted to below the specified density shall alternatively be: 1. 2. Recompacted as required to achieve the specified density. Removed and replaced with properly placed and acceptably compacted material.

G.

Materials placed and compacted which do not conform to project specifications for the area placed shall be removed and replaced with suitable material by the Contractor.

FILLING 861 - North Country Environmental Services Eastern Slope Closure 3/13 Revised 4/13

02223 - 3

H. PART 3 3.01

The Contractor will bear all costs incurred in the recompaction, removal, and replacement of fill not meeting density requirements. EXECUTION

PREPARATION A. B. C. D. E. Fill to be used must be reviewed by the Engineer. The subgrade which is to receive the fill shall be fine-graded and compacted in accordance with Section 02222 "Excavation" and reviewed by the Engineer. All excavated surfaces shall be within 0.10'(+) and 0.20'(-) ft. of required line and grade. Surfaces to be filled against which are steeper than 4:1 shall be scarified or stepped and compacted to provide a bond with the new material. Fill materials will not be placed or compacted on frozen ground or during unfavorable weather conditions. Backfill operations will not be resumed until the moisture content and fill density are satisfactory to the Engineer. All fill material shall be placed "in-the-dry" on a prepared ground surface acceptable to the Engineer. The Contractor shall drain away ponded areas as required to perform the placement of fill in-the-dry.

F.

3.02

FILLING AND COMPACTION A. B. Approved suitable material shall be installed in lifts no greater than as specified. Lifts within utility trenches outside the landfill shall be compacted to at least the specified percentage of maximum dry density, within 3% of optimum moisture content. Field testing of these lifts will be performed in accordance with ASTM D6938-08a, and Paragraph 2.02 of this Section. Do not proceed with the next layer of fill until the preceding layer has been tested and approved by the Engineer. Areas at which tests indicate insufficient compaction shall be recompacted and retested until the areas conform to the requirements of this specification. For the materials specified herein, the following placement and compaction requirements are included:

C. D. E.

FILLING 861 - North Country Environmental Services Eastern Slope Closure 3/13 Revised 4/13

02223 - 4

Maximum Lift Before Compaction Common Borrow Fill Screened Till F. 12" 6"

Minimum % of Maximum Density per ASTM D1557 95 95

Compaction of screened till materials above the select sand layer as a moisture retention layer shall be accomplished by passage of the dozers and low ground pressure machinery only. Compaction of screened till to shape the intermediate drainage benches shall be completed by tamping with the excavator bucket or plate compactor to provide stable and firm subgrade for the construction of the bench.

3.03

BACKFILLING OF UTILITES AND PIPING A. After pipes and joints have been inspected and approved by the Engineer, screened till bedding or crushed stone (See Section 02232) shall be carefully placed and compacted and tamped in 6-inch layers under, around, and to the spring line of the pipe to firmly support the pipe, and prevent lateral movement. Care shall be taken to provide recesses in the bedding or trench bottom, as required, to relieve each bell of any load. Backfill from the top of the bedding to 12-inches above the pipe shall be completed in 12-inch layers with screened till sand, evenly on both sides of the pipe. The remainder of the backfill may be material removed from the trench excavation and shall be placed in approximately 12-inch layers and compacted to 95% of the maximum dry density, as demonstrated by in-place density testing completed by the Engineer.

B. C. D.

3.03

FINAL GRADING A. B. Perform all finish grading required to attain the elevations shown on the Plans, to within 0.1 feet, to eliminate all ponded water, or as otherwise indicated. Areas to be seeded shall be raked to remove all stones and other unsatisfactory material, and shall be suitably compacted.

3.04

TREATMENT AFTER COMPLETION OF GRADING A. After grading is complete and the Engineer has finished his reviews, the Contractor shall permit no further excavating, filling, grading, or vehicular access except to maintain erosion or sediment control. Use all means necessary to prevent erosion

FILLING 861 - North Country Environmental Services Eastern Slope Closure 3/13 Revised 4/13

02223 - 5

of freshly graded areas during construction and until such time as permanent drainage and erosion control measures have been installed. END OF SECTION

FILLING 861 - North Country Environmental Services Eastern Slope Closure 3/13 Revised 4/13

02223 - 6

You might also like

- Methodology of Earth WorksDocument8 pagesMethodology of Earth WorksMartinNo ratings yet

- Preambles and SpecificationsDocument17 pagesPreambles and SpecificationsJoseph WamuiNo ratings yet

- Method of Excavation For ReservoirDocument2 pagesMethod of Excavation For ReservoirLandon Mitchell100% (1)

- Method Statement: Waste Water Treatment ProjectDocument13 pagesMethod Statement: Waste Water Treatment ProjectRisdianto KahamNo ratings yet

- ZHJV W I Si 0167 0 A1 - Abutment Pile Cap FormworkDocument1 pageZHJV W I Si 0167 0 A1 - Abutment Pile Cap FormworkASAALE GLORIANo ratings yet

- MS005 Block WorkDocument5 pagesMS005 Block WorkMhando Ignas100% (1)

- West Bengal Schedule Rates of Building Works 2015Document399 pagesWest Bengal Schedule Rates of Building Works 2015Arunashish Mazumdar75% (8)

- Method Statement For CoringDocument4 pagesMethod Statement For CoringNasir Nagoor PitchaiNo ratings yet

- Method Statement For PilingDocument2 pagesMethod Statement For Pilinggilbert850507100% (1)

- Waterproofing Works For Intake Structure Method StatementDocument23 pagesWaterproofing Works For Intake Structure Method StatementMohammad Bader Al-DeinNo ratings yet

- Quotation Topo Jhosimath-TESDocument3 pagesQuotation Topo Jhosimath-TESAnkur Chauhan50% (2)

- 3-Month Rolling Programme (T2&T3)Document2 pages3-Month Rolling Programme (T2&T3)Salim AhmedNo ratings yet

- Civil SpecificationsDocument86 pagesCivil Specificationstiruyam@gmail.comNo ratings yet

- Standard Specifications For Road Works SERIES 6000-StructuresDocument65 pagesStandard Specifications For Road Works SERIES 6000-StructuresKisali SarakikyaNo ratings yet

- Sump Well-20 KL PDFDocument3 pagesSump Well-20 KL PDFvisali garikapatiNo ratings yet

- Methodology For PQC (00) Toll Plaza L&TDocument4 pagesMethodology For PQC (00) Toll Plaza L&TDeven PatleNo ratings yet

- Schedule of Rates For ROAD WORKS With New ItemsDocument161 pagesSchedule of Rates For ROAD WORKS With New ItemsShabbir1989No ratings yet

- Calc of Steel UNP 150.75.9.12,5 CanopyDocument11 pagesCalc of Steel UNP 150.75.9.12,5 CanopyOecoep IteemNo ratings yet

- AAC Block MasonaryDocument7 pagesAAC Block MasonaryDipak ThakerNo ratings yet

- Drainage System Specification FinalDocument3 pagesDrainage System Specification FinalRico EdureseNo ratings yet

- BbsDocument24 pagesBbsGanesh EshwarNo ratings yet

- RC Specification Structural Steel Rev 0Document56 pagesRC Specification Structural Steel Rev 0Waqas WaqasNo ratings yet

- Work Method Statement For Plain and Reinforced Cement Concrete PCCDocument2 pagesWork Method Statement For Plain and Reinforced Cement Concrete PCCBhargav BbvsNo ratings yet

- Vacuum de - Watered Flooring Method Statement: ActivitiesDocument1 pageVacuum de - Watered Flooring Method Statement: Activitiesவினோத் குமார்No ratings yet

- Method Statement For General Concrete Work and Cutting Bending of Steel ReinforcementDocument4 pagesMethod Statement For General Concrete Work and Cutting Bending of Steel ReinforcementSandip PaulNo ratings yet

- Lamp Flag Fence Post DesignDocument16 pagesLamp Flag Fence Post DesignJupiter AbianNo ratings yet

- Qcs 2010 Section 12 Part 3 Filling PDFDocument4 pagesQcs 2010 Section 12 Part 3 Filling PDFbryanpastor106100% (1)

- Water Proofing SpecificationDocument7 pagesWater Proofing SpecificationMohamedNo ratings yet

- Appendix K - Bill of Quantity For Roads, Drains, Dykes, Fencing and GDocument9 pagesAppendix K - Bill of Quantity For Roads, Drains, Dykes, Fencing and GPiyushNo ratings yet

- Grouted RiprapDocument2 pagesGrouted Riprapflmm09100% (1)

- MOS Change Road Kerb and SurfaceDocument6 pagesMOS Change Road Kerb and SurfacePrince Car-changNo ratings yet

- Requirements of Tower/AntennasDocument8 pagesRequirements of Tower/Antennasvaram1No ratings yet

- Lifting Hook DesignDocument7 pagesLifting Hook DesignAji V0% (1)

- Sub Section 7.1 Bill of Quantities (Road Works) : 00-034sabarmati River Front Development Corporation Ltd. 00-034page:7Document6 pagesSub Section 7.1 Bill of Quantities (Road Works) : 00-034sabarmati River Front Development Corporation Ltd. 00-034page:7alfaza3No ratings yet

- Tank Storage Association Tank Storage Association: Conference & Exhibition 22 September 2011Document35 pagesTank Storage Association Tank Storage Association: Conference & Exhibition 22 September 2011António FontesNo ratings yet

- Beme 4. N. Azaka Street With Drainage AbrakaDocument10 pagesBeme 4. N. Azaka Street With Drainage AbrakaOkoledo Onos Luke100% (1)

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Document6 pagesType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheNo ratings yet

- Treatment Plant HeaderDocument3 pagesTreatment Plant HeaderShamen AmarasekaraNo ratings yet

- Dampproofing (Revised)Document29 pagesDampproofing (Revised)masahinNo ratings yet

- Field Density FDT FormDocument3 pagesField Density FDT FormPedjaNo ratings yet

- Method Statement For Laying of ACWC 20Document3 pagesMethod Statement For Laying of ACWC 20Fa DylaNo ratings yet

- Gimpa Meeting Minutes For 4TH Technical MeetingDocument3 pagesGimpa Meeting Minutes For 4TH Technical MeetingNana BarimaNo ratings yet

- ManholeDocument11 pagesManholeNia ZainorinNo ratings yet

- Method StatementDocument8 pagesMethod StatementardsilvaNo ratings yet

- Methodolgy of Rigid Pavement: Friday, 13 July 2012Document19 pagesMethodolgy of Rigid Pavement: Friday, 13 July 2012Mac Lester MartinNo ratings yet

- Method Statement of Piling Concrete For Fire Water Tank MTDocument15 pagesMethod Statement of Piling Concrete For Fire Water Tank MTahmad100% (1)

- Cement Concrete PavementDocument8 pagesCement Concrete Pavementgtarun22guptaNo ratings yet

- Manhole Channel DesignDocument6 pagesManhole Channel DesignYoke ShuNo ratings yet

- Grade SlabDocument9 pagesGrade SlabDagur PavanNo ratings yet

- Methodology of The ProjectDocument91 pagesMethodology of The ProjectEr Ankur KamraNo ratings yet

- C. 7.4 - Construction MethodsDocument4 pagesC. 7.4 - Construction MethodsJhoycee MiclatNo ratings yet

- Project: Location: By: Date: Chk. By: Date: Clear Data Entry CellsDocument1 pageProject: Location: By: Date: Chk. By: Date: Clear Data Entry Cellsblackk7No ratings yet

- Method Statement For Bored Piling WorksDocument12 pagesMethod Statement For Bored Piling Workstinkerman02No ratings yet

- L9 - Construction Methodology - 1Document20 pagesL9 - Construction Methodology - 1J. Kumar Infraprojects LtdNo ratings yet

- Civil Specification Vol-IIIDocument266 pagesCivil Specification Vol-IIIIrshad KhanNo ratings yet

- False Form WKDocument12 pagesFalse Form WKRonald Cario SeguinNo ratings yet

- Housing For Jazan Infrastructure & Utility Buildings P09-67400 02222-1 EmbankmentsDocument5 pagesHousing For Jazan Infrastructure & Utility Buildings P09-67400 02222-1 Embankmentstamer5046882No ratings yet

- 31 32 13 Cement Stabilization PDFDocument7 pages31 32 13 Cement Stabilization PDFJUAN RULFONo ratings yet

- LAPRIL-C103 enDocument5 pagesLAPRIL-C103 enalpha NEPALNo ratings yet

- Water Agencies' Standards Standard SpecificationsDocument10 pagesWater Agencies' Standards Standard SpecificationsbolinagNo ratings yet

- Wavin PVC Pressure Pipe Systems Product and Technical Guide: Intelligent Solutions ForDocument1 pageWavin PVC Pressure Pipe Systems Product and Technical Guide: Intelligent Solutions ForGiora RozmarinNo ratings yet

- USCSDocument1 pageUSCSLamija AhmetspahićNo ratings yet

- KEMBLA CatalogueDocument13 pagesKEMBLA CatalogueGiora RozmarinNo ratings yet

- Approved Cross Sections 3Document1 pageApproved Cross Sections 3Giora RozmarinNo ratings yet

- Development of Critical Field Permeability and Pavement Density Values For Coarse-Graded Superpave PavementsDocument30 pagesDevelopment of Critical Field Permeability and Pavement Density Values For Coarse-Graded Superpave PavementsGiora RozmarinNo ratings yet

- Paper No. 01-2601: Leedoseu@pilot - Msu.eduDocument26 pagesPaper No. 01-2601: Leedoseu@pilot - Msu.eduGiora RozmarinNo ratings yet

- Niittymaki@hut - Fi: Development of Integrated Air Pollution Modelling Systems For Urban Planning-DIANA ProjectDocument18 pagesNiittymaki@hut - Fi: Development of Integrated Air Pollution Modelling Systems For Urban Planning-DIANA ProjectGiora RozmarinNo ratings yet

- 00149Document21 pages00149Giora RozmarinNo ratings yet

- Paper No. TRB #01-3486 Development of Testing Procedures To Determine The Water-Cement Ratio of Hardened Portland Cement Concrete Using Semi-Automated Image Analysis TechniquesDocument14 pagesPaper No. TRB #01-3486 Development of Testing Procedures To Determine The Water-Cement Ratio of Hardened Portland Cement Concrete Using Semi-Automated Image Analysis TechniquesGiora RozmarinNo ratings yet

- A Consultant's Perspective of Highway Network Asset Management Practice in EnglandDocument8 pagesA Consultant's Perspective of Highway Network Asset Management Practice in EnglandGiora RozmarinNo ratings yet

- Construction and Performance of Ultra-Thin Bonded Hma Wearing CourseDocument26 pagesConstruction and Performance of Ultra-Thin Bonded Hma Wearing CourseGiora Rozmarin100% (1)

- Constitutive Modeling of The Flexural Fatigue Performance of Fiber Reinforced and Lightweight ConcretesDocument18 pagesConstitutive Modeling of The Flexural Fatigue Performance of Fiber Reinforced and Lightweight ConcretesGiora RozmarinNo ratings yet

- Congestion Pricing and Roadspace Rationing: An Application To The San Francisco Bay Bridge CorridorDocument18 pagesCongestion Pricing and Roadspace Rationing: An Application To The San Francisco Bay Bridge CorridorGiora RozmarinNo ratings yet

- Concrete Slab Track State of The Practice: TRB Paper No. 01-0240Document32 pagesConcrete Slab Track State of The Practice: TRB Paper No. 01-0240Giora Rozmarin0% (1)

- A Comparison of Commuter Activity Scheduling and Sequencing Behavior Across Geographical ContextsDocument28 pagesA Comparison of Commuter Activity Scheduling and Sequencing Behavior Across Geographical ContextsGiora RozmarinNo ratings yet

- Comparative Evaluation of Field Performance of Pavement Marking Products On Alternative Test Deck DesignsDocument23 pagesComparative Evaluation of Field Performance of Pavement Marking Products On Alternative Test Deck DesignsGiora RozmarinNo ratings yet

- Paper No. 01-2558: Title: Commuter Rail Station Governance and Parking PracticesDocument20 pagesPaper No. 01-2558: Title: Commuter Rail Station Governance and Parking PracticesGiora RozmarinNo ratings yet

- TRB ID: 01-3271: Polydor@Document17 pagesTRB ID: 01-3271: Polydor@Giora RozmarinNo ratings yet

- AC A S T Gis D: Learinghouse Pproach To Haring Ransportation ATADocument16 pagesAC A S T Gis D: Learinghouse Pproach To Haring Ransportation ATAGiora RozmarinNo ratings yet

- LENOVO - Konfiguracije Mog PC-aDocument26 pagesLENOVO - Konfiguracije Mog PC-aAhuueha HehahuemeNo ratings yet

- CIVIL B Tech Projects - IIT KanpurDocument2 pagesCIVIL B Tech Projects - IIT Kanpurjayaram miryalaNo ratings yet

- RRC EstablishmentDocument4 pagesRRC Establishmentevil_dragonNo ratings yet

- Ceiling Finishes: Group MembersDocument32 pagesCeiling Finishes: Group MembersRoshan Maurya100% (1)

- Reducing Urban Heat Islands: Cool PavementsDocument39 pagesReducing Urban Heat Islands: Cool PavementsGreater Charlotte Harbor Sierra ClubNo ratings yet

- DSpace Manual PDFDocument805 pagesDSpace Manual PDFNestor Gabriel Navas GranadosNo ratings yet

- Application - Security - Research - Update - Report 2018 PDFDocument46 pagesApplication - Security - Research - Update - Report 2018 PDFGhilmer VHNo ratings yet

- IAG Contemporary Houses IIDocument11 pagesIAG Contemporary Houses IIAditya Niloy100% (2)

- Basic Structure of ComputersDocument26 pagesBasic Structure of ComputersLyn-Jo Chris SarmientoNo ratings yet

- Watts Radiant Full Line Catalog En-20100519Document112 pagesWatts Radiant Full Line Catalog En-20100519Pexheat.comNo ratings yet

- Catalogue - Floor Trims GuideDocument57 pagesCatalogue - Floor Trims GuideFloorkitNo ratings yet

- Refsheet My Thuan II Bridge ENDocument1 pageRefsheet My Thuan II Bridge ENIndra Nath MishraNo ratings yet

- Power Plant OperationDocument148 pagesPower Plant Operationkeerthi dayarathna100% (1)

- Architect Agreement Contract 2 PDFDocument5 pagesArchitect Agreement Contract 2 PDFS Lakhte Haider ZaidiNo ratings yet

- What Is Being Advertised in The TextDocument6 pagesWhat Is Being Advertised in The TextDian DianNo ratings yet

- Polycoat RbeDocument2 pagesPolycoat RbejovindhaNo ratings yet

- Avaya PD-PDS IntegrationDocument119 pagesAvaya PD-PDS IntegrationNaveenNo ratings yet

- Soil Mechanics Fomula SheetDocument7 pagesSoil Mechanics Fomula SheetKing EverestNo ratings yet

- Prestress Design of Cable Domes With New FormsDocument10 pagesPrestress Design of Cable Domes With New FormsChing-wen ChienNo ratings yet

- Negative Skin Friction in Piles and Design DecisionsDocument10 pagesNegative Skin Friction in Piles and Design DecisionsZaher J. YazejiNo ratings yet

- Wa0010Document180 pagesWa0010Zee ShinsukeNo ratings yet

- Art Appreciation Module #7Document1 pageArt Appreciation Module #7Angela ReyesNo ratings yet

- Oracle HackingDocument2 pagesOracle HackingadiNo ratings yet

- Everspring Sm103 ManualDocument4 pagesEverspring Sm103 ManualLokanatha ReddyNo ratings yet

- HW 076443Document64 pagesHW 076443حيدر قاسم احمدNo ratings yet

- Ds OpenbalanceDocument4 pagesDs OpenbalanceelorNo ratings yet

- Access Control GuideDocument69 pagesAccess Control GuideMuhammad AshiqNo ratings yet

- UntitledDocument305 pagesUntitledBilly ChristovelNo ratings yet

- GNS3 MikrotikDocument50 pagesGNS3 MikrotikGuido SullcaNo ratings yet

- Basement WallDocument0 pagesBasement WallSi Rerumpai Laut100% (1)